UMP 67x28 [M8+M10] GW F120 Lina / N38 - search holder

search holder

Catalog no 210381

GTIN/EAN: 5906301814009

Diameter Ø

67 mm [±1 mm]

Height

28 mm [±1 mm]

Weight

700 g

Load capacity

180.00 kg / 1765.20 N

Coating

[NiCuNi] Nickel

Magnetic Flux

~ 8 000 Gauss [±5%]

150.00 ZŁ with VAT / pcs + price for transport

121.95 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise contact us through

our online form

the contact form page.

Strength and appearance of a magnet can be calculated on our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

💡 Guide: How to choose a decent magnet and not get ripped off?

Instead of believing fairy tales on YouTube with tests on uncertified equipment, see what really determines your magnet's power:

- 📏 Magnet thickness in the casing (min. 10mm) – This is what matters most! Thin magnets are weak. Thanks to the 1cm thickness of N52 neodymium, your magnet "sees" metal even through thick rust and mud.

- 🛡️ Armored protection (Black Epoxy) – Forget about rust. This coating doesn't chip when hitting rocks and protects the magnet in water much better than regular nickel, which fails quickly.

- 🧲 Eyelets that don't steal power – Made of special non-magnetic steel, so they don't stick to the magnet and don't block the force. Important: mount only one eyelet at a time! Using 3 at once is a mistake that weakens the magnet.

- 🧶 Certified rope (min. 8mm) – You gain the certainty that your gear won't stay at the bottom. It's thick and comfortable, so it doesn't cut your fingers when pulling out heavy scrap metal.

- 🚀 Our advantage: We are the only ones combining the strongest N52 neodymium (10mm thick) with non-magnetic eyelets. This is real power and durability you won't find anywhere else.

Invest in solid equipment and enjoy the results!

Product card - UMP 67x28 [M8+M10] GW F120 Lina / N38 - search holder

Specification / characteristics - UMP 67x28 [M8+M10] GW F120 Lina / N38 - search holder

| properties | values |

|---|---|

| Cat. no. | 210381 |

| GTIN/EAN | 5906301814009 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 67 mm [±1 mm] |

| Height | 28 mm [±1 mm] |

| Weight | 700 g |

| Load capacity ~ ? | 180.00 kg / 1765.20 N |

| Coating | [NiCuNi] Nickel |

| Holder Type | 2 sided |

| Material Type | Structural steel S235 (ferrous) |

| Magnetic Flux | ~ 8 000 Gauss [±5%] |

| Rope Length | 25 m |

| Rope Capacity | ~ 1595 kg |

| Rope Diameter | Ø 8 mm |

| Gloves | 1 pair |

| Size/Mount Quantity | 2xM8/1xM10 |

| Manufacturing Tolerance | ±1 mm |

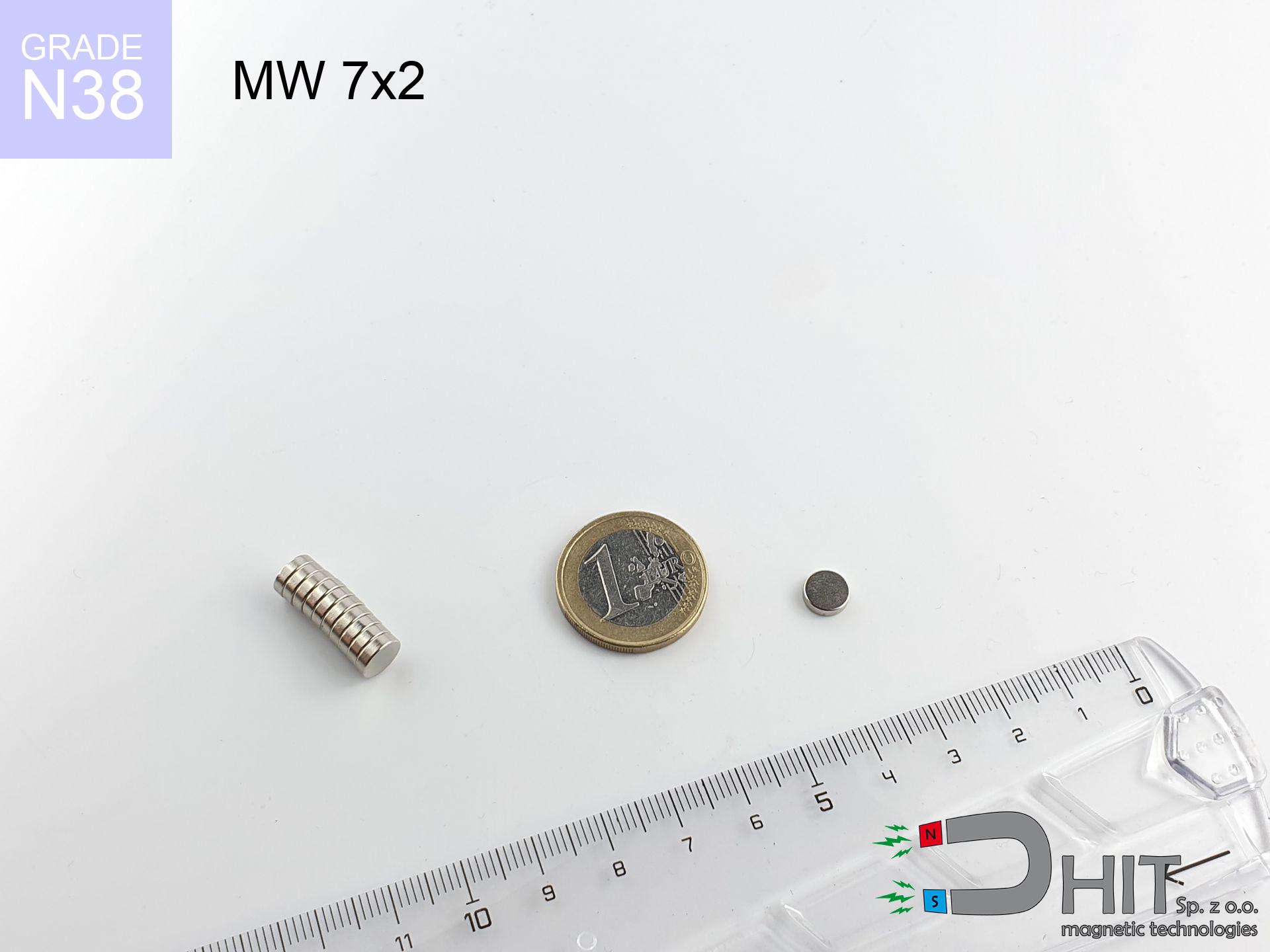

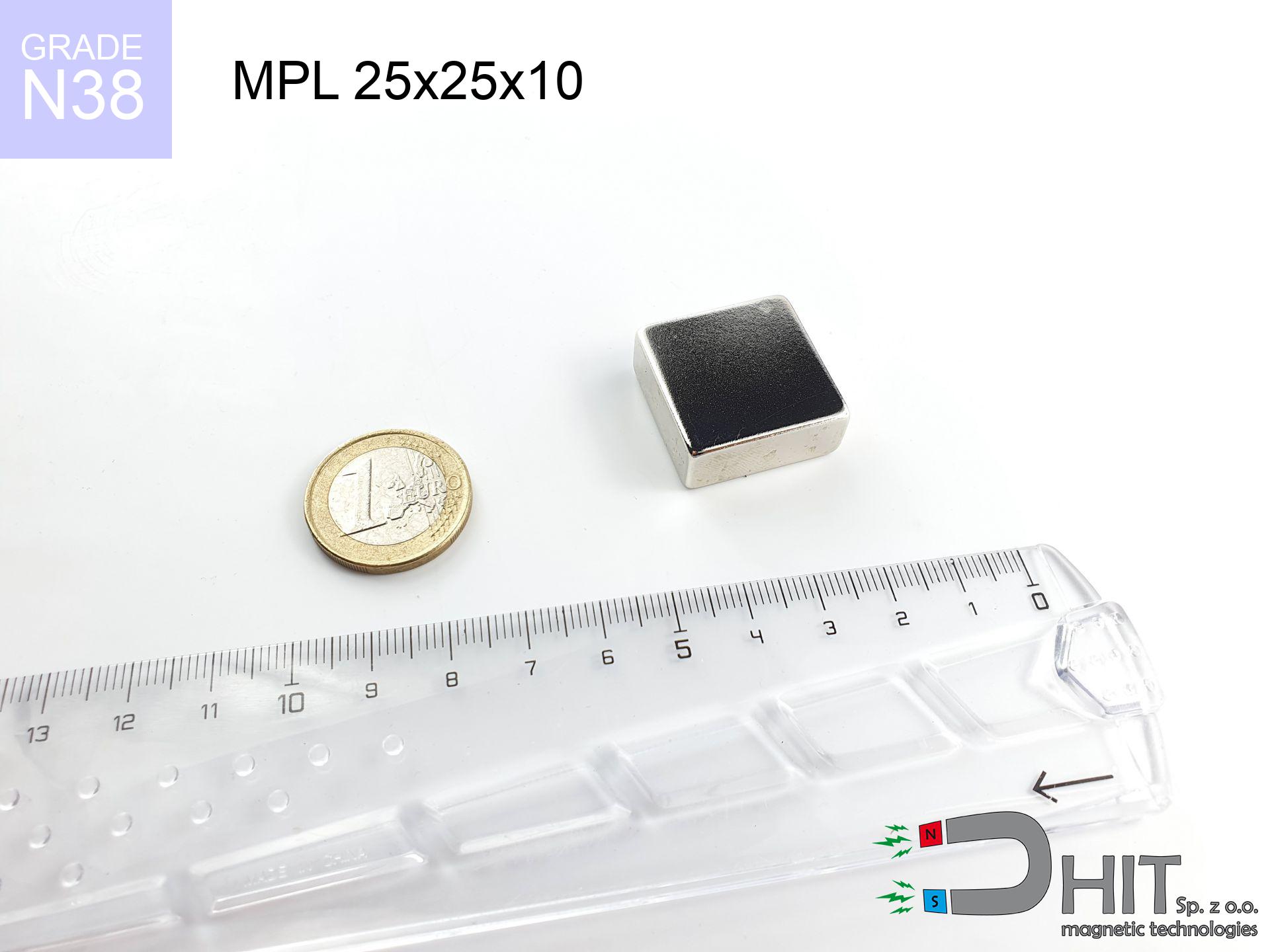

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Pros as well as cons of neodymium magnets.

Advantages

- They have constant strength, and over more than 10 years their attraction force decreases symbolically – ~1% (in testing),

- They are noted for resistance to demagnetization induced by external disturbances,

- In other words, due to the shiny layer of gold, the element looks attractive,

- Magnets have very high magnetic induction on the active area,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Considering the option of accurate shaping and adaptation to specialized projects, NdFeB magnets can be produced in a wide range of geometric configurations, which expands the range of possible applications,

- Versatile presence in future technologies – they find application in computer drives, brushless drives, medical equipment, as well as other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which enables their usage in miniature devices

Cons

- At very strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment - during use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic mount, due to difficulties in producing threads inside the magnet and complicated shapes.

- Potential hazard to health – tiny shards of magnets are risky, when accidentally swallowed, which gains importance in the context of child health protection. Furthermore, tiny parts of these devices can disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum magnetic pulling force – what affects it?

- with the use of a sheet made of low-carbon steel, guaranteeing full magnetic saturation

- with a thickness of at least 10 mm

- with an ideally smooth contact surface

- under conditions of gap-free contact (metal-to-metal)

- during detachment in a direction perpendicular to the mounting surface

- at ambient temperature room level

Determinants of lifting force in real conditions

- Gap (betwixt the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) leads to a reduction in force by up to 50% (this also applies to varnish, rust or debris).

- Load vector – highest force is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the power to be escaped into the air.

- Plate material – low-carbon steel attracts best. Alloy admixtures decrease magnetic properties and lifting capacity.

- Plate texture – ground elements guarantee perfect abutment, which improves force. Uneven metal reduce efficiency.

- Thermal factor – high temperature reduces magnetic field. Too high temperature can permanently demagnetize the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under perpendicular forces, in contrast under parallel forces the holding force is lower. Moreover, even a slight gap between the magnet’s surface and the plate reduces the lifting capacity.

Safety rules for work with neodymium magnets

Shattering risk

Beware of splinters. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. We recommend safety glasses.

Handling rules

Before starting, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

Fire warning

Drilling and cutting of neodymium magnets carries a risk of fire hazard. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Protect data

Very strong magnetic fields can destroy records on credit cards, hard drives, and storage devices. Stay away of at least 10 cm.

Avoid contact if allergic

Nickel alert: The Ni-Cu-Ni coating contains nickel. If redness appears, cease working with magnets and use protective gear.

Magnetic interference

A strong magnetic field negatively affects the operation of compasses in smartphones and navigation systems. Do not bring magnets near a smartphone to prevent damaging the sensors.

This is not a toy

Product intended for adults. Tiny parts can be swallowed, causing intestinal necrosis. Store out of reach of kids and pets.

Maximum temperature

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Medical interference

People with a heart stimulator should keep an absolute distance from magnets. The magnetic field can interfere with the functioning of the life-saving device.

Crushing force

Watch your fingers. Two powerful magnets will join immediately with a force of massive weight, destroying anything in their path. Be careful!

![Search magnet UMP 67x28 [M8+M10] GW F120 Lina / N38 - GOLD Series Search magnet UMP 67x28 [M8+M10] GW F120 Lina / N38 - GOLD Series](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMP 67x28 [M8+M10] GW F120 Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-67x28-m8+m10-gw-f-120+-lina-xiw.jpg)

![SM 25x125 [2xM8] / N42 - magnetic separator SM 25x125 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x125-2xm8-duj.jpg)