AM ucho [M10] - magnetic accessories

magnetic accessories

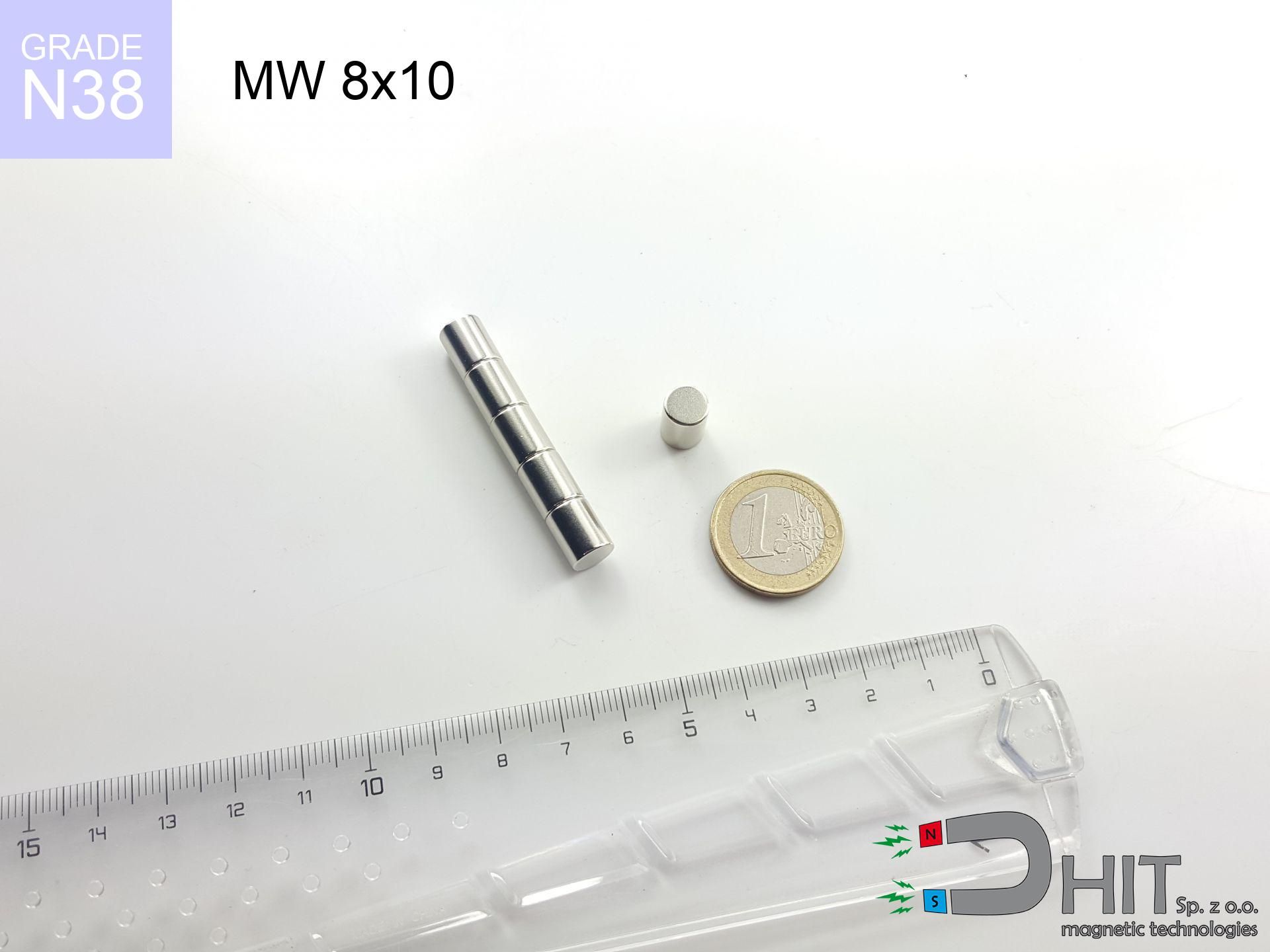

Catalog no 080346

GTIN/EAN: 5906301812494

Weight

71.5 g

Load capacity

320.00 kg / 3138.13 N

7.38 ZŁ with VAT / pcs + price for transport

6.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively contact us via

our online form

our website.

Parameters and form of magnets can be checked with our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Product card - AM ucho [M10] - magnetic accessories

Specification / characteristics - AM ucho [M10] - magnetic accessories

| properties | values |

|---|---|

| Cat. no. | 080346 |

| GTIN/EAN | 5906301812494 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 71.5 g |

| Load capacity ~ ? | 320.00 kg / 3138.13 N |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Advantages as well as disadvantages of neodymium magnets.

Pros

- They have unchanged lifting capacity, and over nearly ten years their attraction force decreases symbolically – ~1% (according to theory),

- They do not lose their magnetic properties even under close interference source,

- The use of an elegant layer of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- They show high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of precise modeling and adjusting to defined needs,

- Versatile presence in innovative solutions – they find application in HDD drives, motor assemblies, diagnostic systems, and complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which makes them useful in miniature devices

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can rust. Therefore while using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in realizing threads and complex shapes in magnets, we recommend using casing - magnetic holder.

- Health risk to health – tiny shards of magnets are risky, if swallowed, which becomes key in the context of child safety. It is also worth noting that small elements of these magnets can be problematic in diagnostics medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Lifting parameters

Breakaway strength of the magnet in ideal conditions – what affects it?

- using a sheet made of high-permeability steel, functioning as a ideal flux conductor

- possessing a massiveness of min. 10 mm to ensure full flux closure

- with an ground contact surface

- under conditions of ideal adhesion (surface-to-surface)

- under perpendicular application of breakaway force (90-degree angle)

- at ambient temperature room level

Determinants of practical lifting force of a magnet

- Space between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – maximum parameter is available only during pulling at a 90° angle. The shear force of the magnet along the surface is typically many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Cast iron may generate lower lifting capacity.

- Base smoothness – the more even the surface, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was determined with the use of a polished steel plate of suitable thickness (min. 20 mm), under vertically applied force, whereas under shearing force the load capacity is reduced by as much as 75%. Moreover, even a slight gap between the magnet and the plate reduces the lifting capacity.

Safety rules for work with neodymium magnets

This is not a toy

Only for adults. Tiny parts pose a choking risk, leading to severe trauma. Keep away from children and animals.

Allergic reactions

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If skin irritation occurs, immediately stop working with magnets and wear gloves.

Bone fractures

Large magnets can crush fingers instantly. Do not put your hand betwixt two attracting surfaces.

Safe distance

Intense magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Stay away of min. 10 cm.

Magnets are brittle

Neodymium magnets are sintered ceramics, meaning they are very brittle. Clashing of two magnets will cause them cracking into shards.

Handling rules

Handle with care. Rare earth magnets act from a distance and snap with huge force, often faster than you can move away.

Dust explosion hazard

Drilling and cutting of neodymium magnets carries a risk of fire hazard. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Medical interference

Individuals with a ICD should maintain an safe separation from magnets. The magnetism can disrupt the functioning of the life-saving device.

Threat to navigation

Note: rare earth magnets generate a field that interferes with sensitive sensors. Keep a separation from your phone, tablet, and GPS.

Demagnetization risk

Standard neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

![Magnetic accessories AM ucho [M10] Magnetic accessories AM ucho [M10]](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![AM ucho [M10] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m10-tij.jpg)

![SM 32x200 [2xM8] / N42 - magnetic separator SM 32x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-fub.jpg)

![SM 25x375 [2xM8] / N42 - magnetic separator SM 25x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-feg.jpg)