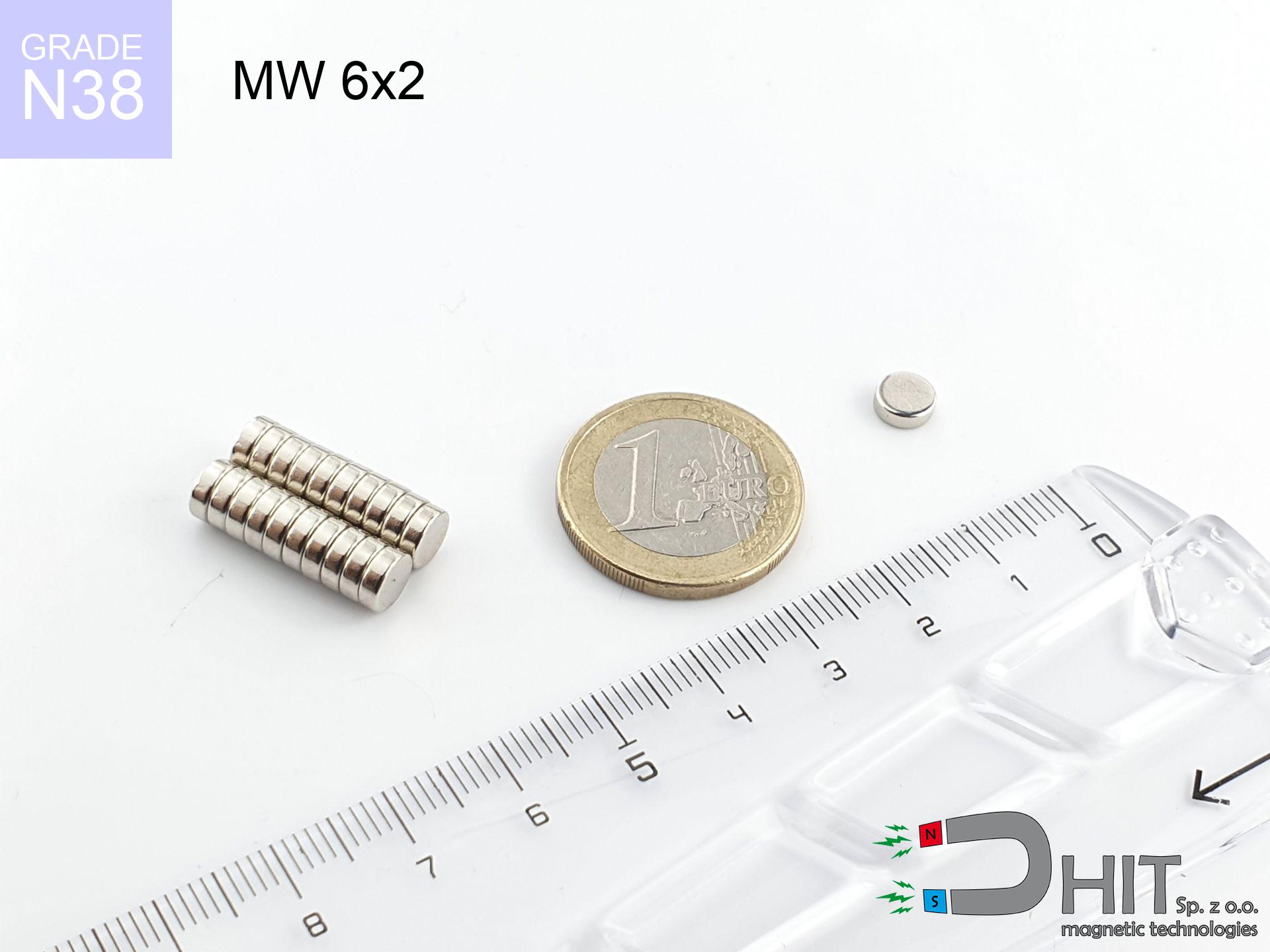

MW 6x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010092

GTIN/EAN: 5906301810919

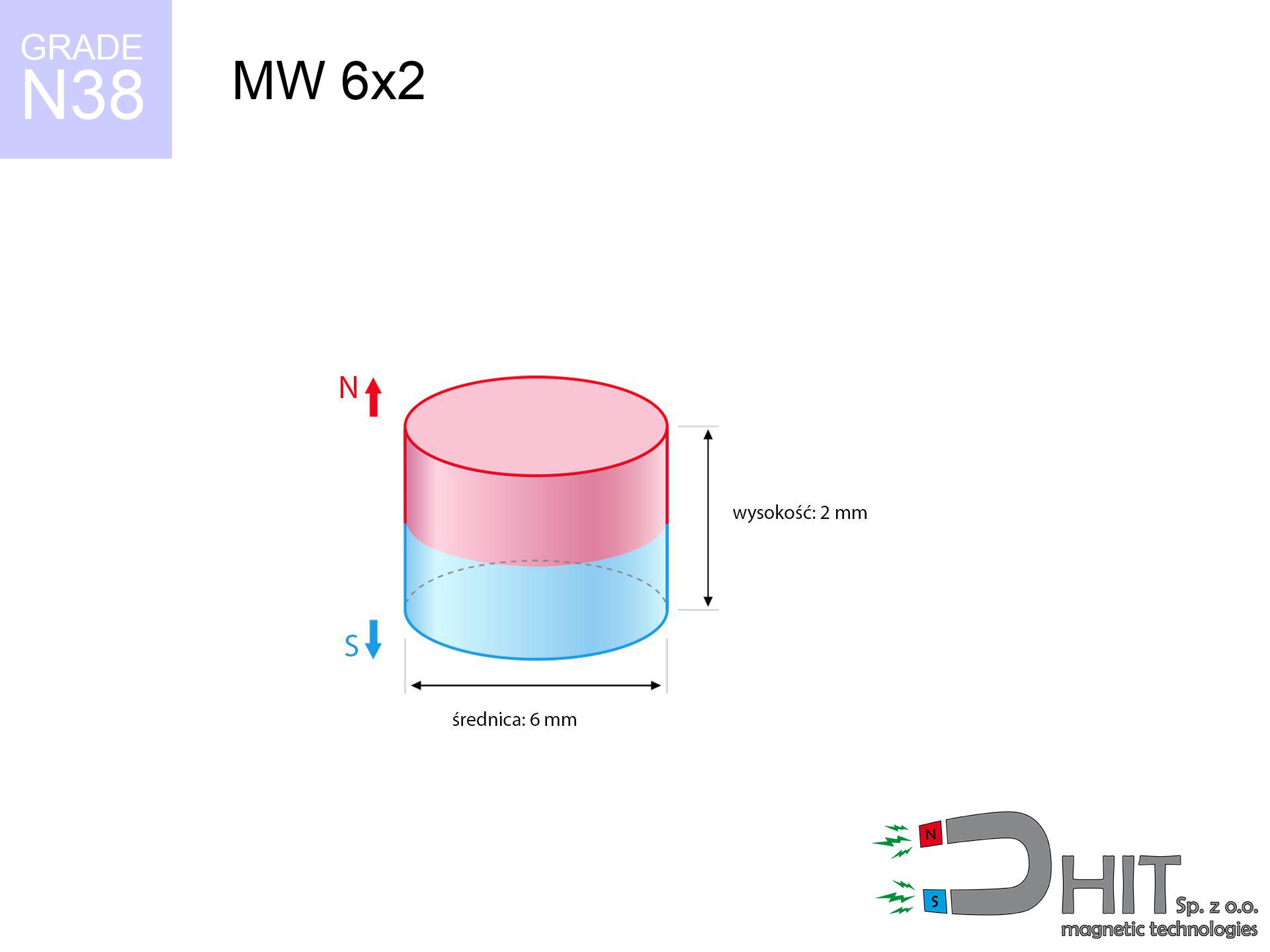

Diameter Ø

6 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

0.42 g

Magnetization Direction

↑ axial

Load capacity

0.86 kg / 8.43 N

Magnetic Induction

343.37 mT / 3434 Gs

Coating

[NiCuNi] Nickel

0.246 ZŁ with VAT / pcs + price for transport

0.200 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively send us a note through

our online form

the contact page.

Lifting power and form of a neodymium magnet can be tested using our

online calculation tool.

Order by 14:00 and we’ll ship today!

Detailed specification - MW 6x2 / N38 - cylindrical magnet

Specification / characteristics - MW 6x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010092 |

| GTIN/EAN | 5906301810919 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 6 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 0.42 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.86 kg / 8.43 N |

| Magnetic Induction ~ ? | 343.37 mT / 3434 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the assembly - technical parameters

Presented data constitute the outcome of a physical analysis. Results are based on algorithms for the material Nd2Fe14B. Operational performance might slightly differ. Use these calculations as a reference point when designing systems.

Table 1: Static force (force vs distance) - power drop

MW 6x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3430 Gs

343.0 mT

|

0.86 kg / 1.90 pounds

860.0 g / 8.4 N

|

low risk |

| 1 mm |

2423 Gs

242.3 mT

|

0.43 kg / 0.95 pounds

429.2 g / 4.2 N

|

low risk |

| 2 mm |

1521 Gs

152.1 mT

|

0.17 kg / 0.37 pounds

169.0 g / 1.7 N

|

low risk |

| 3 mm |

932 Gs

93.2 mT

|

0.06 kg / 0.14 pounds

63.5 g / 0.6 N

|

low risk |

| 5 mm |

382 Gs

38.2 mT

|

0.01 kg / 0.02 pounds

10.7 g / 0.1 N

|

low risk |

| 10 mm |

76 Gs

7.6 mT

|

0.00 kg / 0.00 pounds

0.4 g / 0.0 N

|

low risk |

| 15 mm |

26 Gs

2.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 20 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 30 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Shear force (wall)

MW 6x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.17 kg / 0.38 pounds

172.0 g / 1.7 N

|

| 1 mm | Stal (~0.2) |

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| 2 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

34.0 g / 0.3 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

12.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 6x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.26 kg / 0.57 pounds

258.0 g / 2.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.17 kg / 0.38 pounds

172.0 g / 1.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 6x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| 1 mm |

|

0.22 kg / 0.47 pounds

215.0 g / 2.1 N

|

| 2 mm |

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

| 3 mm |

|

0.65 kg / 1.42 pounds

645.0 g / 6.3 N

|

| 5 mm |

|

0.86 kg / 1.90 pounds

860.0 g / 8.4 N

|

| 10 mm |

|

0.86 kg / 1.90 pounds

860.0 g / 8.4 N

|

| 11 mm |

|

0.86 kg / 1.90 pounds

860.0 g / 8.4 N

|

| 12 mm |

|

0.86 kg / 1.90 pounds

860.0 g / 8.4 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MW 6x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.86 kg / 1.90 pounds

860.0 g / 8.4 N

|

OK |

| 40 °C | -2.2% |

0.84 kg / 1.85 pounds

841.1 g / 8.3 N

|

OK |

| 60 °C | -4.4% |

0.82 kg / 1.81 pounds

822.2 g / 8.1 N

|

|

| 80 °C | -6.6% |

0.80 kg / 1.77 pounds

803.2 g / 7.9 N

|

|

| 100 °C | -28.8% |

0.61 kg / 1.35 pounds

612.3 g / 6.0 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 6x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.05 kg / 4.52 pounds

4 944 Gs

|

0.31 kg / 0.68 pounds

308 g / 3.0 N

|

N/A |

| 1 mm |

1.52 kg / 3.34 pounds

5 900 Gs

|

0.23 kg / 0.50 pounds

228 g / 2.2 N

|

1.37 kg / 3.01 pounds

~0 Gs

|

| 2 mm |

1.02 kg / 2.26 pounds

4 847 Gs

|

0.15 kg / 0.34 pounds

154 g / 1.5 N

|

0.92 kg / 2.03 pounds

~0 Gs

|

| 3 mm |

0.65 kg / 1.44 pounds

3 869 Gs

|

0.10 kg / 0.22 pounds

98 g / 1.0 N

|

0.59 kg / 1.29 pounds

~0 Gs

|

| 5 mm |

0.25 kg / 0.54 pounds

2 379 Gs

|

0.04 kg / 0.08 pounds

37 g / 0.4 N

|

0.22 kg / 0.49 pounds

~0 Gs

|

| 10 mm |

0.03 kg / 0.06 pounds

764 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

153 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

12 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

7 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

3 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MW 6x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 6x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

45.65 km/h

(12.68 m/s)

|

0.03 J | |

| 30 mm |

79.04 km/h

(21.96 m/s)

|

0.10 J | |

| 50 mm |

102.04 km/h

(28.35 m/s)

|

0.17 J | |

| 100 mm |

144.31 km/h

(40.09 m/s)

|

0.34 J |

Table 9: Anti-corrosion coating durability

MW 6x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 6x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 029 Mx | 10.3 µWb |

| Pc Coefficient | 0.44 | Low (Flat) |

Table 11: Physics of underwater searching

MW 6x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.86 kg | Standard |

| Water (riverbed) |

0.98 kg

(+0.12 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet retains just approx. 20-30% of its max power.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) significantly limits the holding force.

3. Heat tolerance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.44

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

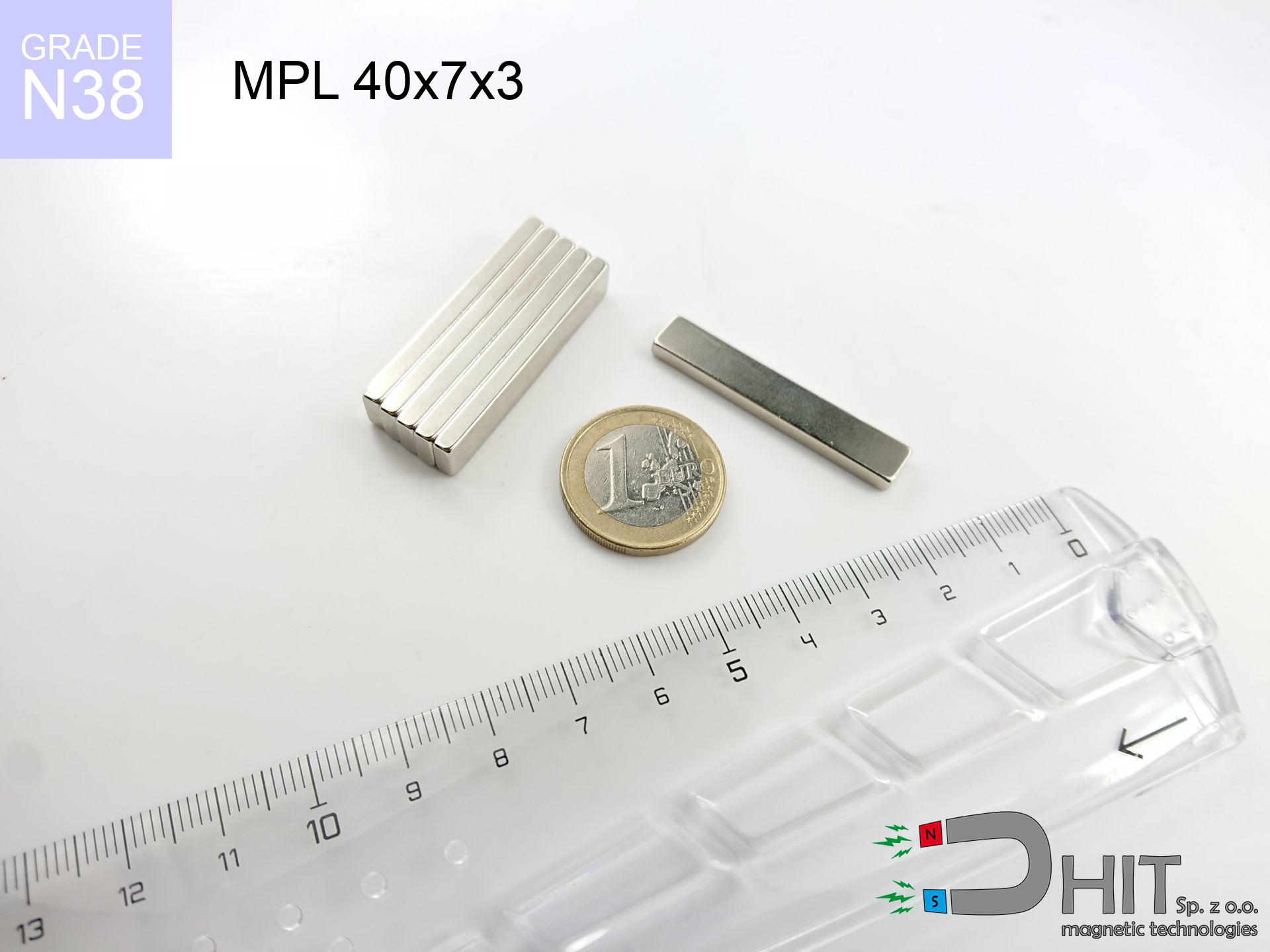

Check out also deals

Strengths and weaknesses of rare earth magnets.

Pros

- They virtually do not lose strength, because even after ten years the performance loss is only ~1% (in laboratory conditions),

- They do not lose their magnetic properties even under strong external field,

- The use of an metallic layer of noble metals (nickel, gold, silver) causes the element to look better,

- They show high magnetic induction at the operating surface, which increases their power,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- In view of the possibility of precise molding and adaptation to custom projects, NdFeB magnets can be modeled in a variety of forms and dimensions, which expands the range of possible applications,

- Key role in innovative solutions – they find application in mass storage devices, drive modules, diagnostic systems, and industrial machines.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Weaknesses

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- Limited possibility of producing threads in the magnet and complex shapes - preferred is casing - magnetic holder.

- Potential hazard related to microscopic parts of magnets are risky, when accidentally swallowed, which is particularly important in the context of child health protection. Furthermore, small elements of these magnets are able to be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Highest magnetic holding force – what affects it?

- using a base made of mild steel, acting as a circuit closing element

- with a thickness minimum 10 mm

- characterized by even structure

- without the slightest insulating layer between the magnet and steel

- during detachment in a direction vertical to the plane

- at temperature room level

What influences lifting capacity in practice

- Air gap (betwixt the magnet and the plate), since even a very small clearance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to paint, rust or dirt).

- Angle of force application – maximum parameter is obtained only during perpendicular pulling. The force required to slide of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Steel type – low-carbon steel attracts best. Alloy steels reduce magnetic properties and lifting capacity.

- Smoothness – full contact is possible only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures gain strength (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under shearing force the load capacity is reduced by as much as 75%. Moreover, even a small distance between the magnet and the plate decreases the holding force.

Precautions when working with NdFeB magnets

Machining danger

Combustion risk: Neodymium dust is explosive. Do not process magnets without safety gear as this may cause fire.

Threat to navigation

Be aware: rare earth magnets produce a field that confuses sensitive sensors. Maintain a safe distance from your phone, device, and GPS.

Heat warning

Control the heat. Exposing the magnet to high heat will ruin its magnetic structure and pulling force.

Protective goggles

Despite metallic appearance, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Product not for children

Absolutely store magnets away from children. Choking hazard is significant, and the consequences of magnets connecting inside the body are life-threatening.

Health Danger

Individuals with a pacemaker have to keep an absolute distance from magnets. The magnetic field can interfere with the operation of the life-saving device.

Allergic reactions

It is widely known that nickel (standard magnet coating) is a common allergen. If your skin reacts to metals, prevent direct skin contact and choose coated magnets.

Threat to electronics

Avoid bringing magnets close to a purse, computer, or screen. The magnetic field can permanently damage these devices and erase data from cards.

Safe operation

Be careful. Rare earth magnets act from a distance and snap with massive power, often quicker than you can move away.

Bodily injuries

Risk of injury: The attraction force is so great that it can cause hematomas, pinching, and broken bones. Protective gloves are recommended.

![SM 32x450 [2xM8] / N42 - magnetic separator SM 32x450 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x450-2xm8-bex.jpg)

![SM 32x150 [2xM8] / N42 - magnetic separator SM 32x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xus.jpg)