Neodymium magnets – magnetic force for various applications

Neodymium magnets are unique products with an immense magnetic force, used in many areas of life. They began to be produced by sintering mechanically in the 1980s, and their composition includes neodymium, iron - metal, and a trace of boron, all encapsulated in nickel. Thanks to high-quality materials such as neodymium powders and rare earth elements, these magnets offer durability, power, and precision that traditional ferrite magnets cannot provide. In our online store, you will find neodymium magnets tailored to various applications and needs.

Types of neodymium magnets in our offer

- Disc Magnets – Ideal for industrial devices and tools where a strong magnet is required.

- Cylindrical Magnets – Used in mechanisms requiring strong magnetic attraction, offering a powerful neodymium magnet in a compact form.

- Ring Magnets – With a hole for screws, perfect for constructions requiring installation with a threaded sleeve. Neodymium magnets with a hole are easy to install in various applications.

- Magnets with a hole for a tapered screw – Used in assembly with flat surfaces, offering durability and strong attraction.

- Magnetic Balls – Used in modeling and precision devices, as well as strong decorative magnets.

- Magnesy neodymowe do poszukiwań podwodnych – W ofercie znajdują się magnesy f200x2, f300x2 idealne do poszukiwań w wodzie.

Advantages of neodymium magnets

- Enormous magnetic force – Neodymium magnets are up to 10 times stronger than ferrite ring magnets, making them indispensable in many industries.

- Durability and reliability – Thanks to the use of neodymium powders, magnets have long life and resistance to demagnetization.

- Variety of shapes and sizes – We offer neodymium magnets tailored to the most demanding applications, such as magnets with holes or ring magnets.

- Mounting capability – With holes for screws, threaded sleeves, and the use of adhesives, neodymium magnets can be easily mounted in hard-to-reach places.

Applications of neodymium magnets

- Industry – In magnetic devices, sensors, and precision tools, where strong magnets are required.

- Automotive – For producing electric motors and mounting systems, where strong neodymium magnets are used.

- Home applications – For hanging tools, mounting structures, or as decorative magnets, such as neodymium magnets with holes.

- Technology and electronics – Used in audio equipment, hard drives, and generators, where high-quality neodymium magnets are essential.

Neodymium magnets for searching are perfect for applications requiring a strong magnetic field. Thanks to the large magnets, the production of ferromagnetic magnets is much more efficient, and the use of iron and boron as key components in the production process ensures high quality. The high magnetic properties of sintered neodymium magnets allow them to be used in various industries, including electronics, where corrosion resistance and the ability to operate at elevated temperatures (above 80°C) are crucial. Samarium-cobalt magnets have even higher resistance to demagnetization and deformation. Meanwhile, magnets made from powdered components such as dysprosium and praseodymium have properties that allow them to bear heavy loads in challenging conditions. In powder metallurgy and electrotechnics, high-lift magnets can be used in the production of accessories, such as in gluing components in plastics and ceramics. Thanks to their high temperature tolerance, we do not have to worry about damage during high working temperatures. If you have any questions about our products or would like to contact our warehouse, feel free to get in touch with us – we will be happy to prepare an appropriate offer for you.

Our website offers a wide selection of neodymium magnets that are suitable for various applications. You can easily browse product categories and choose those that best meet your needs. With our shopping cart, you can add the magnets you are interested in and proceed to the ordering process. We also offer the option to sign up for an account, which enables quicker order placement in the future. Remember, all our products are available at attractive prices, so it’s worth checking out our full offer. Right now, you can take advantage of exceptional discounts!

Catalog no 010500

diameter Ø

12 mm [±0,1 mm]

height

4 mm [±0,1 mm]

Weight

3.39 g

Magnetization direction

↑ axial

Lifting Capacity

3.6 kg / 35.3 N

Magnetic Induction

400.45 mT

Coating

[NiCuNi] nickel

1.72 ZŁ z VAT brutto / pcs + price for transport

1.40 ZŁ net price + 23% VAT / pcs

1.32 ZŁ net was the lowest price in the last 30 days

quantity discounts:

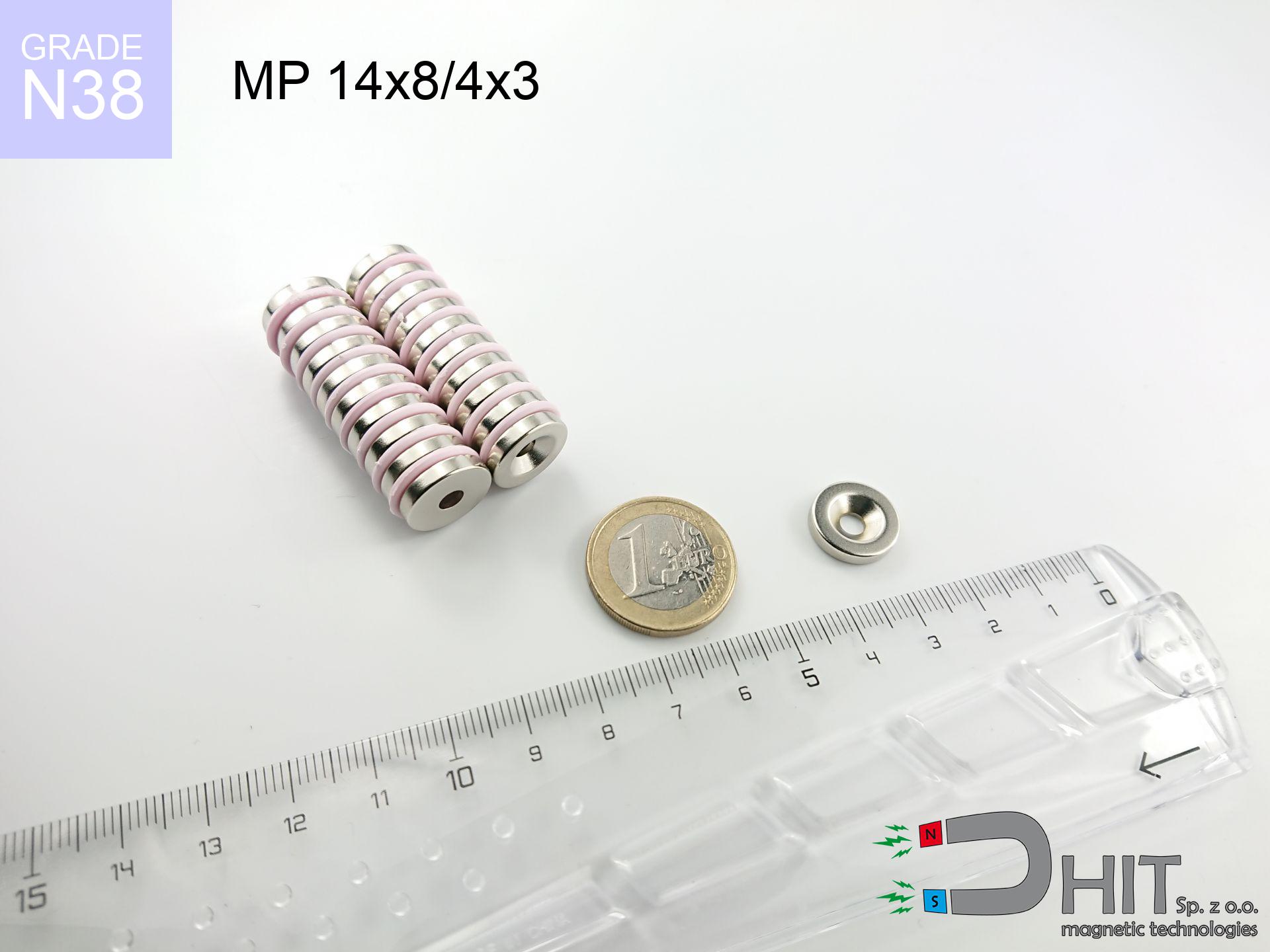

Catalog no 030181

GTIN: 5906301811985

external diameter Ø

14 mm [±0,1 mm]

internal diameter Ø

8/4 mm [±0,1 mm]

height

3 mm [±0,1 mm]

Weight

5.65 g

Magnetization direction

↑ axial

Lifting Capacity

1.03 kg / 10.1 N

Magnetic Induction

270.17 mT

Coating

[NiCuNi] nickel

1.50 ZŁ z VAT brutto / pcs + price for transport

1.22 ZŁ net price + 23% VAT / pcs

quantity discounts:

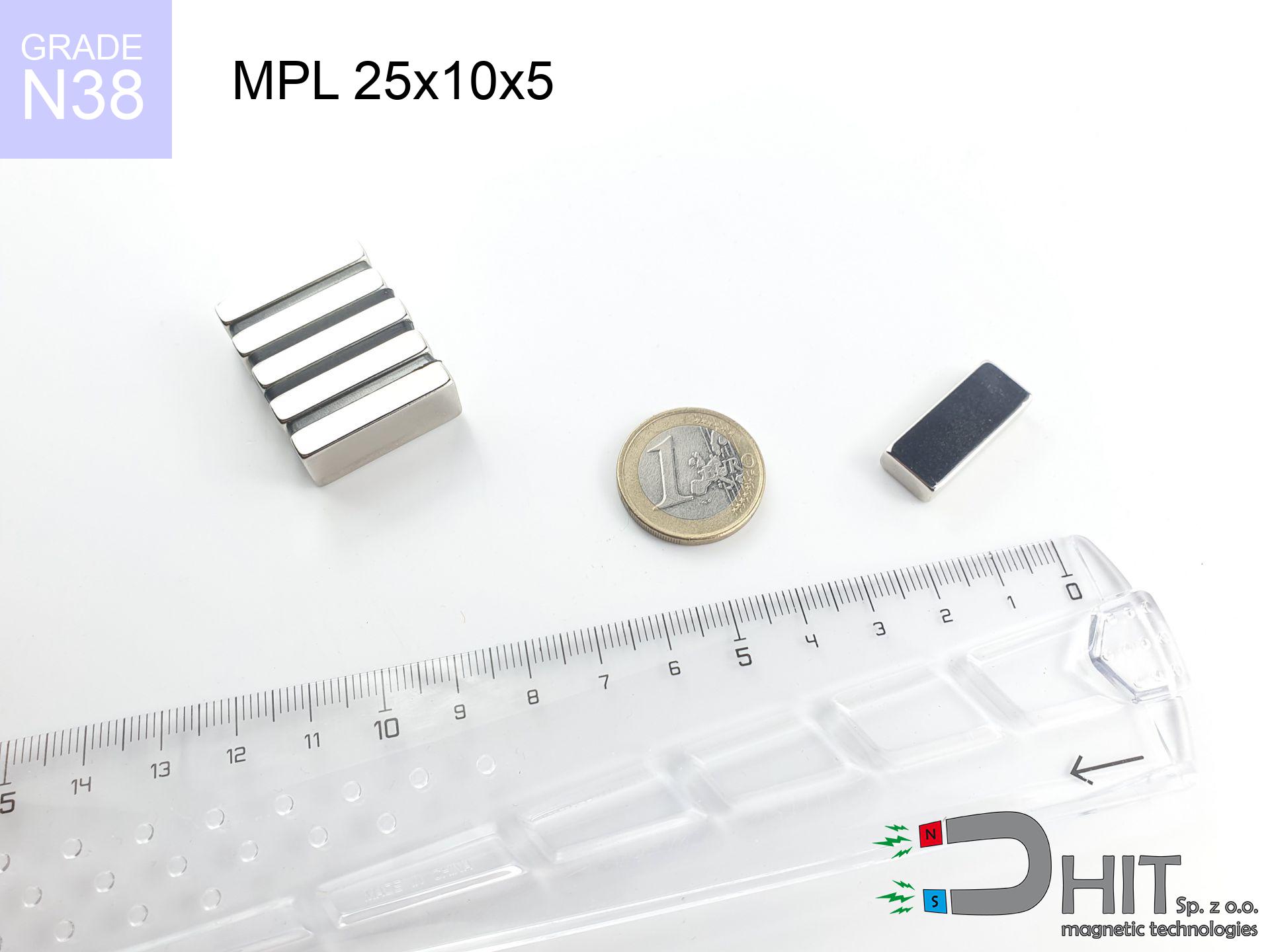

Catalog no 020135

GTIN: 5906301811411

length

25 mm [±0,1 mm]

width

10 mm [±0,1 mm]

height

5 mm [±0,1 mm]

Weight

9.38 g

Magnetization direction

↑ axial

Lifting Capacity

6.24 kg / 61.19 N

Magnetic Induction

337.05 mT

Coating

[NiCuNi] nickel

4.30 ZŁ z VAT brutto / pcs + price for transport

3.50 ZŁ net price + 23% VAT / pcs

quantity discounts: