Which Magnetic Separator?

is can separator for can segregation a good idea?

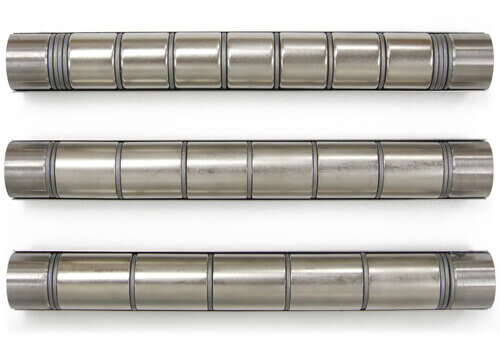

Magnetic rolls (also known as magnetic separator or cylindrical magnet) are widely used in metal separation, food production, and recycling. Our magnetic rolls consist of a neodymium magnet placed inside a stainless steel cylinder. They are used to remove iron dust during the process of separating metals from other waste for recycling, food production, and spinning. By placing the magnetic roll in the production line as a magnetic separator, it is possible to prevent metal contaminants (such as iron fragments or iron dust) from entering the food.

Both ends of the magnetic roll have M8 threaded holes (there is a possibility to make a one-sided roll for Heat Pump magnetic filter applications), which facilitates its installation in machines. Please choose the appropriate outer casing (stainless steel or acid-resistant steel), magnetic flux density on the surface, and temperature resistance specification (standard 80°C), which best suit your needs.

It is generally believed that the stronger the magnet, the better. However, this is not always true. The power of the magnet depends on the area where magnetic force lines can be applied and the total flux emitted from the entire surface. When choosing magnetic rolls, the type of material to be attracted by the magnet and the environment in which it will be installed are also important factors to consider.

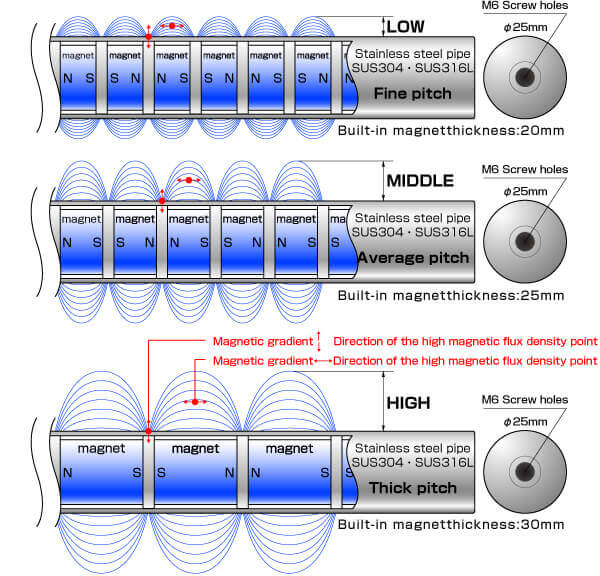

In terms of magnetic properties, they differ in terms of magnetic induction flux density, magnetic force lines, and magnetic field. The difference lies in whether the magnetic filter has a thick or thin filtering layer.

When it comes to choosing the magnetic force, pay attention to the objects to be attracted. For objects that are difficult to lift with your fingers, magnets with a power of 8000 gauss [φ25 mm] are suitable, while for larger objects, magnets with a power of 10000 gauss [φ32 mm] are recommended. However, the choice of magnet power is not mandatory according to the above recommendations, as both types are very strong and have excellent attraction capabilities.

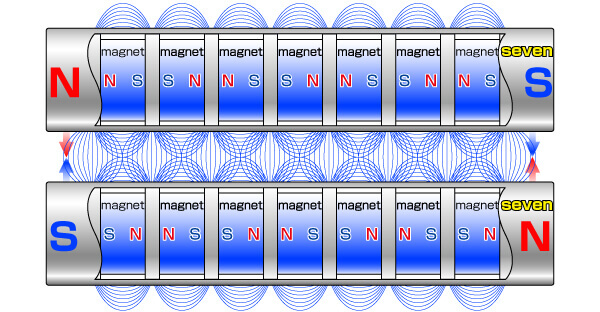

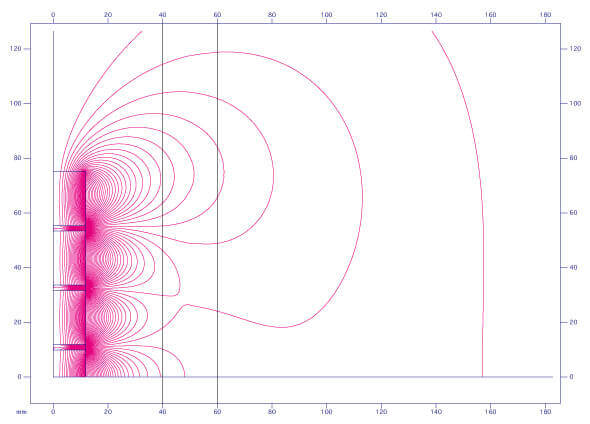

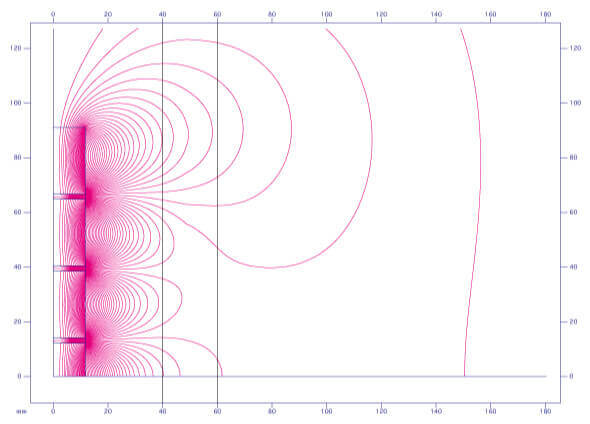

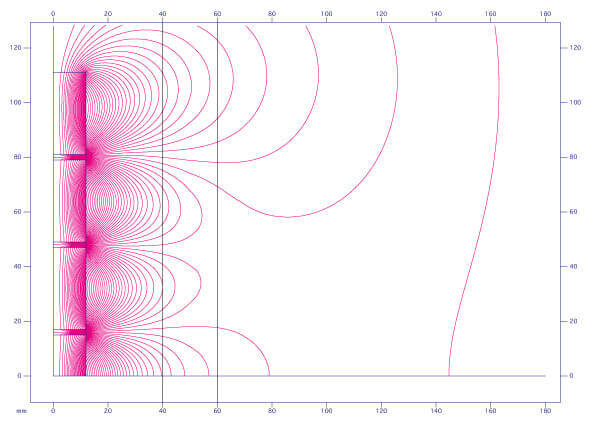

Magnetic rolls are placed in such a way that they repel the N and S poles of neodymium magnets embedded in a stainless steel housing. The area where magnetic substances can be attracted will differ depending on the thickness of the embedded magnet. If the embedded magnet is thin with a narrow step, the magnetic force lines will be low and short. In comparison, the magnetic force lines will be long and extend far when the magnet is thick with a wide step. Generally, the area where magnetic substances can be attracted is larger when the magnetic force lines are longer.

A narrow step has many adsorption points, while a wide step has fewer. It is generally believed that the more adsorption points, the better, but the range is shorter and the power of the separator will be shorter.

In magnetic separators, we use jumps for [φ25 mm] 20mm and [φ32 mm] 30 mm.

Technical designations: magnetic roll, cylindrical magnet, neodymium magnetic separator.

In our magnetic separators, we use 1mm thick AISI 304 / EN 1.4301 stainless steel tubes and magnets with a strength of 6500, 8000, or 10,000 Gauss because these parameters provide optimal performance and durability of the device. Choosing the appropriate thickness of the tube wall is crucial to avoid wear and premature wear of the separator. A too thin wall could be easily damaged, while a too thick wall would weaken the magnetic force of the separator.

For magnets, we offer various options for magnetic strength (6500, 8000, or 10,000 Gauss) to customize the separator to the customer's individual needs. We use magnets with high energy coefficients (N42 or N52), which ensure high magnetic strength and long-term stability.

This configuration of our magnetic separators allows us to avoid problems related to low quality and short-term operation of competitive devices, such as competitive products that often have poor workmanship and quick wear but have high magnetic power. However, in practice, long-lasting and reliable operation of the separator is equally if not more important than maximum magnetic strength. Therefore, in our separators, we focus on the optimal combination of performance and durability, which allows for effective separation of metallic particles while protecting the customer's investment in the long run.

In summary, using a 0.5mm thick wall can indeed increase the magnetic force of the separator, reaching up to ~ 14,000 Gauss, but it shortens the lifespan of the device due to a higher risk of damage. In our opinion, a magnetic force of around ~ 10,000 Gauss or more is sufficient to capture all metal particles while providing a longer lifespan of the separator by using a 1mm thick wall. This makes our magnetic separators efficient, reliable, and long-lasting, translating into customer satisfaction and better work results.

It is generally believed that the stronger the magnet, the better. However, this is not necessarily true. It will depend on the affected area, including the distance that the magnetic force lines can reach and the total flux emitted from the entire surface. In the case of magnetic rolls, it also depends on the magnetic substance attracted to the magnet and the installation environment. To determine whether 8000 Gauss or 10000 Gauss would be better, please refer to the following comparison table.

| Indukcja magnetyczna na powierzchni | Punkt absorpcji | Drobny proszek i sproszkowane żelazo | Zdolność przyciągania na krótkich dystansach | Zdolność przyciągania na długich dystansach | Zdolność przyciągania na duże odległości | Zasięg działania |

|---|---|---|---|---|---|---|

| [φ25 mm] ~ 8000 Gs | ○ | ○ | ○ | |||

| [φ32 mm] ~ 10000 Gs | ○ | ○ | ○ |

In terms of magnetic properties, the surface induction flux density, magnetic force lines, and magnetic field are different. In simple terms, the difference lies in whether the magnetic filter has coarse or fine filtration.

| Indukcja magnetyczna na powierzchni | Filtrowanie |

|---|---|

| [φ25 mm] ~ 8000 Gs | Dobre, cienkie |

| [φ32 mm] ~ 10000 Gs | Szorstkie, grube |

Magnetic separators are arranged to repel the N and S poles of neodymium magnets embedded in a stainless steel housing. The affected area where magnetic substances can be attracted will differ depending on the thickness of the embedded magnets. If the embedded magnet is thin with a thin step, the magnetic force lines will be small and short. In comparison, the magnetic force lines will be long and extend far when the magnet is thick with a wide step. Generally, the affected area is larger when the magnetic force lines are longer.

For items that are difficult to lift with your fingers, 8000 Gauss is suitable, and for items large enough to be lifted with your fingers, 10000 Gauss is recommended. However, the choice according to the above is not mandatory, as both types are very strong and have excellent attraction capabilities.

There are many adsorption points with a thin pack and fewer with a thick pack. It is generally believed that the more adsorption points, the better.

View through the magnetic field indicator - magnetic foil.

Iron powder scattered on the magnetic separator.

View inside the magnetic separator.

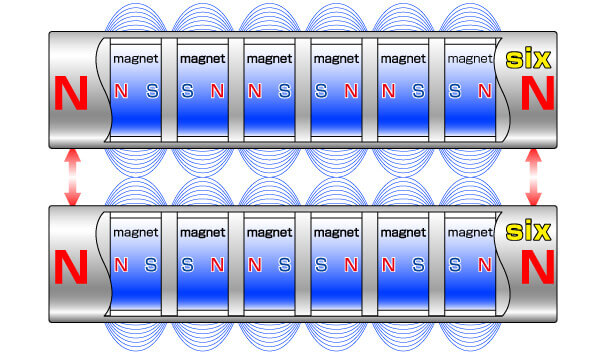

When arranging and assembling multiple magnetic separators, it is important which end is the N pole and which end is the S pole. A strong magnetic filter can be created by installing them in a magnetically compatible manner. In general, the magnetic filter will be stronger if the number of embedded magnets is an odd number rather than an even number. It is also easier to assemble an odd number of magnets.

If there is an odd number of embedded magnets

The N and S poles of the arranged magnets are magnetically compatible, creating a strong magnetic filter. It is possible to easily assemble multiple magnetic separators to be magnetically compatible.

If there is an even number of embedded magnets

The N and S poles of the arranged magnets repel each other, creating a magnetic filter that is weaker than in the case of an odd number of embedded magnets. If there are multiple magnets, they will repel each other, making assembly very difficult.

* We can solve the above by creating two rows, one with an N pole at each end and the other with an S pole at each end. In this way, even with an even number of magnets, the arrangement will be magnetically compatible.

Parallel reflection

Numbers of

embedded magnets

Even

2/4/6/8/10/12/14/16

Parallel adsorption

Numbers of

embedded magnets

Odd

3/5/7/9/11/13/15/17

| Wbudowane magnesy | Czynniki | Zgodność | Odpychające bieguny | Siła magnetyczna | Pojemność magnetyczna | Łatwość montażu |

|---|---|---|---|---|---|---|

| Parzyste | 2,4,6,8,12,16 | |||||

| Nieparzyste | 3,5,7,9,11,13 | ○ | ○ | ○ | ○ | ○ |

It can be seen that the magnetic force lines extend further with a thick tone rather than a thin tone. On the other hand, a thin pack has many adsorption points, and the total induction flux is higher.

Embedded magnets of type 20 mm (fine step)

Distance of magnetic substance attraction is about 20 mm from the surface

Embedded magnets of type 25 mm (regular step)

Distance of magnetic substance attraction is about 25 mm from the surface

Embedded magnets of type 30 mm (thick step)

Distance of magnetic substance attraction is about 30 mm from the surface

The casings of the magnetic separator are made of stainless steel using AISI 304, AISI 316, or AISI 316L, all of which have excellent corrosion resistance properties. AISI 304 is sufficient for use in fresh water. AISI 316 is recommended if you are using the magnetic separator in an environment where it would come into contact with saltwater or chemicals. Even with AISI 316 steel, the magnetic separator can rust if it comes into contact with rock salt or highly concentrated salt.

| Obudowa zewnętrzna | Odporność na korozję | Rodzaj separatora | Charakterystyka |

|---|---|---|---|

| SUS304 | ○ | Świeża woda i bez soli | Są zwykle szeroko stosowane w fabrykach spożywczych. |

| SUS316L | Słona woda i środki chemiczne | Mają odporność na korozję i korozję wżerową, które mogą wytrzymać słoną wodę. |

Possible sizes and diameters of threaded holes in the external casing of the stainless steel separator - they vary depending on the outer diameter. We typically use M8 screw threads in separators due to their versatility and consistent manufacturing.

Reference images φ25 mm, φ32 mm

| Średnica | Gwint wewnętrzny | Maks. długość mm | Maks. indukcja Tesla | Min. indukcja Gauss |

|---|---|---|---|---|

| φ18 mm | M8 | 1000 | ~ 1.2 | ~ 8000 |

| φ19 mm | M8 | 1000 | ~ 1.2 | ~ 8000 |

| φ22 mm | M8 | 1000 | ~ 1.2 | ~ 8000 |

| φ25 mm | M8 | 1000 | ~ 1.2 | ~ 10000 |

| φ32 mm | M8 | 1000 | ~ 1.2 | ~ 10000 |

* We can make these products. *We do not have an AISI 304 steel casing.

| Tolerancja | Średnica | 100 mm | 200 mm | 300 mm | 400 mm | 500 mm | 600 mm | 700 mm | 800 mm | 900 mm | 1,000 mm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| φ25 mm | 0.7 mm | 0.7 mm | 0.7 mm | 0.7 mm | 0.7 mm | 0.85 mm | 1.0 mm | 1.0 mm | 1.1 mm | 1.1 mm | |

| φ32 mm | 0.7 mm | 0.7 mm | 0.7 mm | 0.7 mm | 0.7 mm | 0.85 mm | 1.0 mm | 1.0 mm | 1.1 mm | 1.1 mm |

* To determine dimensional tolerance, the product must be custom-made. Our standard stock products do not meet the above tolerance.