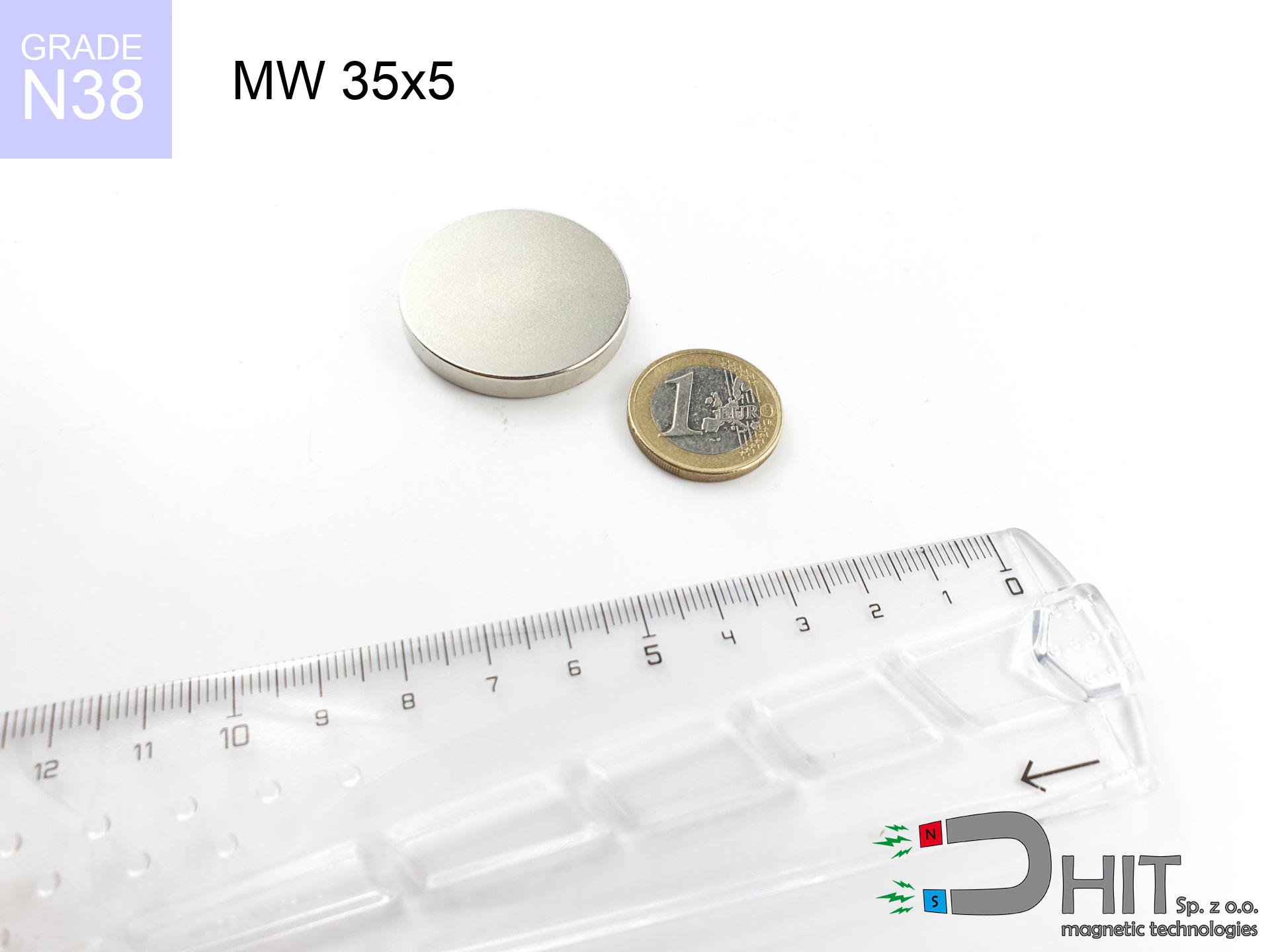

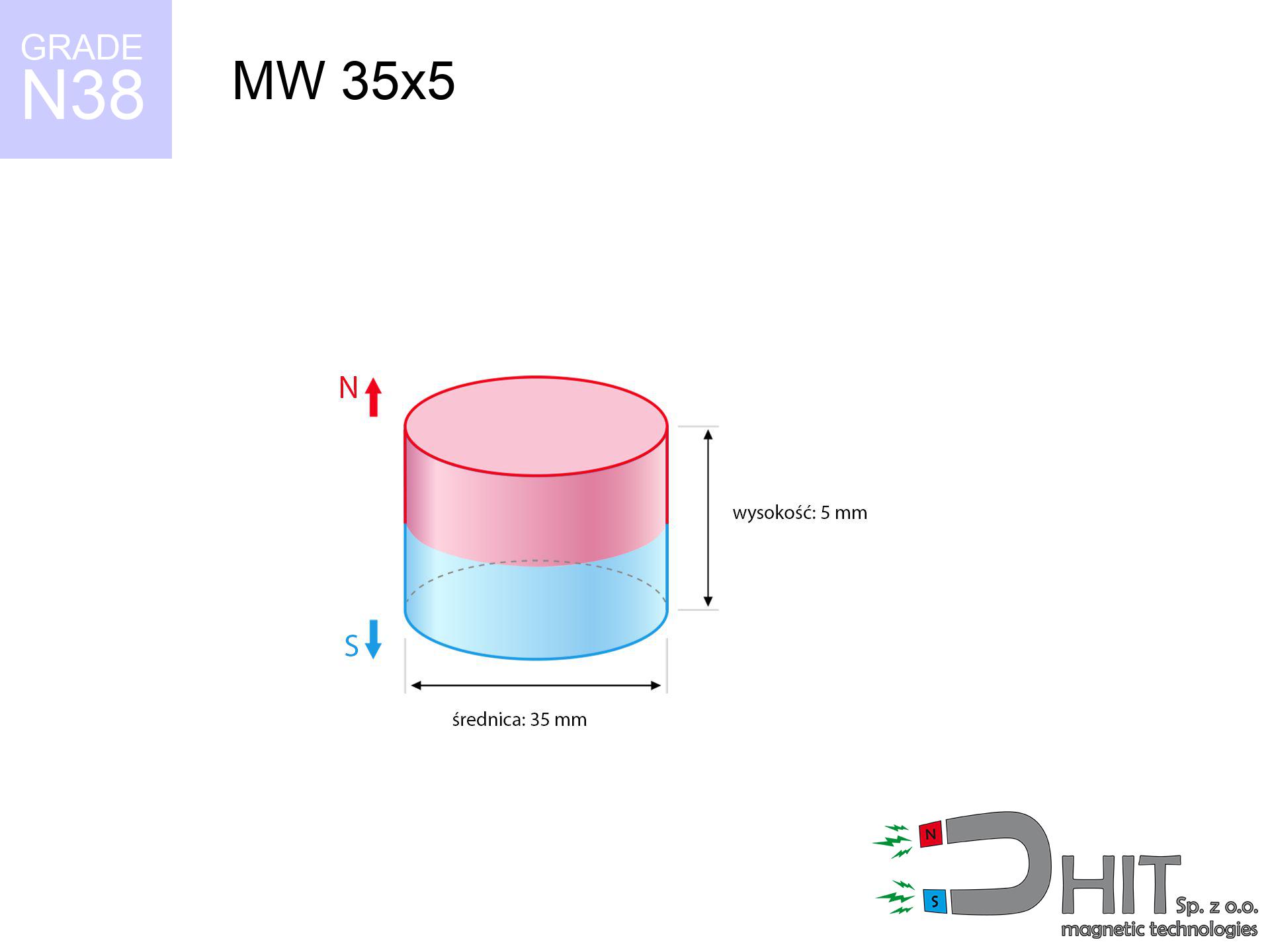

MW 35x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010059

GTIN/EAN: 5906301810582

Diameter Ø

35 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

36.08 g

Magnetization Direction

↑ axial

Load capacity

9.25 kg / 90.73 N

Magnetic Induction

170.30 mT / 1703 Gs

Coating

[NiCuNi] Nickel

13.81 ZŁ with VAT / pcs + price for transport

11.23 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise send us a note via

our online form

through our site.

Parameters as well as appearance of a neodymium magnet can be verified with our

modular calculator.

Same-day processing for orders placed before 14:00.

Technical - MW 35x5 / N38 - cylindrical magnet

Specification / characteristics - MW 35x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010059 |

| GTIN/EAN | 5906301810582 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 35 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 36.08 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 9.25 kg / 90.73 N |

| Magnetic Induction ~ ? | 170.30 mT / 1703 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - data

Presented values are the result of a mathematical analysis. Values rely on algorithms for the material Nd2Fe14B. Operational performance may differ from theoretical values. Please consider these data as a supplementary guide when designing systems.

Table 1: Static pull force (force vs distance) - interaction chart

MW 35x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1703 Gs

170.3 mT

|

9.25 kg / 20.39 LBS

9250.0 g / 90.7 N

|

strong |

| 1 mm |

1657 Gs

165.7 mT

|

8.76 kg / 19.31 LBS

8759.4 g / 85.9 N

|

strong |

| 2 mm |

1599 Gs

159.9 mT

|

8.15 kg / 17.97 LBS

8152.2 g / 80.0 N

|

strong |

| 3 mm |

1530 Gs

153.0 mT

|

7.47 kg / 16.47 LBS

7468.5 g / 73.3 N

|

strong |

| 5 mm |

1373 Gs

137.3 mT

|

6.01 kg / 13.25 LBS

6011.5 g / 59.0 N

|

strong |

| 10 mm |

959 Gs

95.9 mT

|

2.93 kg / 6.47 LBS

2932.7 g / 28.8 N

|

strong |

| 15 mm |

631 Gs

63.1 mT

|

1.27 kg / 2.80 LBS

1270.4 g / 12.5 N

|

weak grip |

| 20 mm |

413 Gs

41.3 mT

|

0.54 kg / 1.20 LBS

544.8 g / 5.3 N

|

weak grip |

| 30 mm |

190 Gs

19.0 mT

|

0.12 kg / 0.25 LBS

115.2 g / 1.1 N

|

weak grip |

| 50 mm |

56 Gs

5.6 mT

|

0.01 kg / 0.02 LBS

10.1 g / 0.1 N

|

weak grip |

Table 2: Sliding force (vertical surface)

MW 35x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.85 kg / 4.08 LBS

1850.0 g / 18.1 N

|

| 1 mm | Stal (~0.2) |

1.75 kg / 3.86 LBS

1752.0 g / 17.2 N

|

| 2 mm | Stal (~0.2) |

1.63 kg / 3.59 LBS

1630.0 g / 16.0 N

|

| 3 mm | Stal (~0.2) |

1.49 kg / 3.29 LBS

1494.0 g / 14.7 N

|

| 5 mm | Stal (~0.2) |

1.20 kg / 2.65 LBS

1202.0 g / 11.8 N

|

| 10 mm | Stal (~0.2) |

0.59 kg / 1.29 LBS

586.0 g / 5.7 N

|

| 15 mm | Stal (~0.2) |

0.25 kg / 0.56 LBS

254.0 g / 2.5 N

|

| 20 mm | Stal (~0.2) |

0.11 kg / 0.24 LBS

108.0 g / 1.1 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

24.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 35x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.78 kg / 6.12 LBS

2775.0 g / 27.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.85 kg / 4.08 LBS

1850.0 g / 18.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.93 kg / 2.04 LBS

925.0 g / 9.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.63 kg / 10.20 LBS

4625.0 g / 45.4 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 35x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.93 kg / 2.04 LBS

925.0 g / 9.1 N

|

| 1 mm |

|

2.31 kg / 5.10 LBS

2312.5 g / 22.7 N

|

| 2 mm |

|

4.63 kg / 10.20 LBS

4625.0 g / 45.4 N

|

| 3 mm |

|

6.94 kg / 15.29 LBS

6937.5 g / 68.1 N

|

| 5 mm |

|

9.25 kg / 20.39 LBS

9250.0 g / 90.7 N

|

| 10 mm |

|

9.25 kg / 20.39 LBS

9250.0 g / 90.7 N

|

| 11 mm |

|

9.25 kg / 20.39 LBS

9250.0 g / 90.7 N

|

| 12 mm |

|

9.25 kg / 20.39 LBS

9250.0 g / 90.7 N

|

Table 5: Working in heat (material behavior) - power drop

MW 35x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

9.25 kg / 20.39 LBS

9250.0 g / 90.7 N

|

OK |

| 40 °C | -2.2% |

9.05 kg / 19.94 LBS

9046.5 g / 88.7 N

|

OK |

| 60 °C | -4.4% |

8.84 kg / 19.50 LBS

8843.0 g / 86.7 N

|

|

| 80 °C | -6.6% |

8.64 kg / 19.05 LBS

8639.5 g / 84.8 N

|

|

| 100 °C | -28.8% |

6.59 kg / 14.52 LBS

6586.0 g / 64.6 N

|

Table 6: Two magnets (attraction) - field collision

MW 35x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.20 kg / 37.92 LBS

3 075 Gs

|

2.58 kg / 5.69 LBS

2580 g / 25.3 N

|

N/A |

| 1 mm |

16.78 kg / 36.99 LBS

3 364 Gs

|

2.52 kg / 5.55 LBS

2517 g / 24.7 N

|

15.10 kg / 33.29 LBS

~0 Gs

|

| 2 mm |

16.29 kg / 35.91 LBS

3 314 Gs

|

2.44 kg / 5.39 LBS

2443 g / 24.0 N

|

14.66 kg / 32.32 LBS

~0 Gs

|

| 3 mm |

15.75 kg / 34.71 LBS

3 259 Gs

|

2.36 kg / 5.21 LBS

2362 g / 23.2 N

|

14.17 kg / 31.24 LBS

~0 Gs

|

| 5 mm |

14.54 kg / 32.05 LBS

3 131 Gs

|

2.18 kg / 4.81 LBS

2180 g / 21.4 N

|

13.08 kg / 28.84 LBS

~0 Gs

|

| 10 mm |

11.18 kg / 24.64 LBS

2 746 Gs

|

1.68 kg / 3.70 LBS

1677 g / 16.4 N

|

10.06 kg / 22.18 LBS

~0 Gs

|

| 20 mm |

5.45 kg / 12.02 LBS

1 918 Gs

|

0.82 kg / 1.80 LBS

818 g / 8.0 N

|

4.91 kg / 10.82 LBS

~0 Gs

|

| 50 mm |

0.45 kg / 1.00 LBS

552 Gs

|

0.07 kg / 0.15 LBS

68 g / 0.7 N

|

0.41 kg / 0.90 LBS

~0 Gs

|

| 60 mm |

0.21 kg / 0.47 LBS

380 Gs

|

0.03 kg / 0.07 LBS

32 g / 0.3 N

|

0.19 kg / 0.42 LBS

~0 Gs

|

| 70 mm |

0.11 kg / 0.24 LBS

269 Gs

|

0.02 kg / 0.04 LBS

16 g / 0.2 N

|

0.10 kg / 0.21 LBS

~0 Gs

|

| 80 mm |

0.06 kg / 0.13 LBS

197 Gs

|

0.01 kg / 0.02 LBS

9 g / 0.1 N

|

0.05 kg / 0.11 LBS

~0 Gs

|

| 90 mm |

0.03 kg / 0.07 LBS

147 Gs

|

0.00 kg / 0.01 LBS

5 g / 0.0 N

|

0.03 kg / 0.06 LBS

~0 Gs

|

| 100 mm |

0.02 kg / 0.04 LBS

112 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MW 35x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 12.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 7.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.0 cm |

| Car key | 50 Gs (5.0 mT) | 5.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MW 35x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.08 km/h

(5.30 m/s)

|

0.51 J | |

| 30 mm |

28.19 km/h

(7.83 m/s)

|

1.11 J | |

| 50 mm |

36.13 km/h

(10.04 m/s)

|

1.82 J | |

| 100 mm |

51.07 km/h

(14.18 m/s)

|

3.63 J |

Table 9: Anti-corrosion coating durability

MW 35x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 35x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 20 291 Mx | 202.9 µWb |

| Pc Coefficient | 0.22 | Low (Flat) |

Table 11: Physics of underwater searching

MW 35x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 9.25 kg | Standard |

| Water (riverbed) |

10.59 kg

(+1.34 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds just ~20% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) significantly reduces the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.22

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Strengths

- Their strength is durable, and after around ten years it drops only by ~1% (theoretically),

- They are noted for resistance to demagnetization induced by presence of other magnetic fields,

- Thanks to the glossy finish, the coating of Ni-Cu-Ni, gold-plated, or silver-plated gives an elegant appearance,

- They are known for high magnetic induction at the operating surface, which improves attraction properties,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Possibility of exact creating and adjusting to individual applications,

- Wide application in modern industrial fields – they are commonly used in hard drives, electric drive systems, advanced medical instruments, as well as complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which allows their use in small systems

Cons

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also raises their durability

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- Limited possibility of creating threads in the magnet and complex forms - preferred is cover - magnet mounting.

- Health risk related to microscopic parts of magnets can be dangerous, if swallowed, which becomes key in the context of child health protection. Additionally, small elements of these magnets are able to be problematic in diagnostics medical after entering the body.

- With budget limitations the cost of neodymium magnets is economically unviable,

Pull force analysis

Detachment force of the magnet in optimal conditions – what it depends on?

- using a sheet made of low-carbon steel, acting as a magnetic yoke

- whose thickness reaches at least 10 mm

- with a surface free of scratches

- without the slightest clearance between the magnet and steel

- under vertical application of breakaway force (90-degree angle)

- in stable room temperature

Magnet lifting force in use – key factors

- Gap (between the magnet and the metal), since even a tiny clearance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to paint, corrosion or dirt).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Plate thickness – too thin sheet does not close the flux, causing part of the power to be lost into the air.

- Metal type – different alloys reacts the same. High carbon content weaken the attraction effect.

- Base smoothness – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Unevenness creates an air distance.

- Temperature – heating the magnet causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was assessed using a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. Additionally, even a slight gap between the magnet and the plate lowers the load capacity.

Safe handling of NdFeB magnets

Skin irritation risks

Warning for allergy sufferers: The Ni-Cu-Ni coating consists of nickel. If redness happens, cease handling magnets and wear gloves.

Fire risk

Drilling and cutting of neodymium magnets poses a fire risk. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Life threat

Individuals with a heart stimulator should keep an safe separation from magnets. The magnetism can stop the functioning of the implant.

Phone sensors

Remember: neodymium magnets produce a field that confuses sensitive sensors. Maintain a separation from your mobile, tablet, and navigation systems.

Magnetic media

Avoid bringing magnets close to a purse, laptop, or screen. The magnetism can destroy these devices and wipe information from cards.

Fragile material

Watch out for shards. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

Power loss in heat

Keep cool. Neodymium magnets are sensitive to temperature. If you need resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Bone fractures

Large magnets can smash fingers instantly. Do not put your hand between two attracting surfaces.

Do not underestimate power

Exercise caution. Neodymium magnets act from a distance and connect with massive power, often faster than you can move away.

Product not for children

Neodymium magnets are not suitable for play. Eating a few magnets can lead to them attracting across intestines, which poses a critical condition and necessitates urgent medical intervention.

![UMGW 32x18x8 [M6] GW / N38 - magnetic holder internal thread UMGW 32x18x8 [M6] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um32x18x8-m6-gw--hec.jpg)

![UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump135x40-m10+m12-gw-f-600-kg-luz.jpg)

![SM 18x100 [2xM5] / N42 - magnetic separator SM 18x100 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x100-2xm5-pem.jpg)