UMP 135x40 [M10+M12] GW F600 Lina / N38 - search holder

search holder

Catalog no 210385

GTIN/EAN: 5906301814047

Diameter Ø

135 mm [±1 mm]

Height

40 mm [±1 mm]

Weight

4300 g

Load capacity

680.00 kg / 6668.52 N

Coating

[NiCuNi] Nickel

Magnetic Flux

~ 10 000 Gauss [±5%]

649.99 ZŁ with VAT / pcs + price for transport

528.45 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively contact us by means of

contact form

the contact section.

Specifications as well as form of a neodymium magnet can be analyzed with our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

💡 Guide: How to choose a decent magnet and not get ripped off?

Instead of believing fairy tales on YouTube with tests on uncertified equipment, see what really determines your magnet's power:

- 📏 Magnet thickness in the casing (min. 10mm) – This is what matters most! Thin magnets are weak. Thanks to the 1cm thickness of N52 neodymium, your magnet "sees" metal even through thick rust and mud.

- 🛡️ Armored protection (Black Epoxy) – Forget about rust. This coating doesn't chip when hitting rocks and protects the magnet in water much better than regular nickel, which fails quickly.

- 🧲 Eyelets that don't steal power – Made of special non-magnetic steel, so they don't stick to the magnet and don't block the force. Important: mount only one eyelet at a time! Using 3 at once is a mistake that weakens the magnet.

- 🧶 Certified rope (min. 8mm) – You gain the certainty that your gear won't stay at the bottom. It's thick and comfortable, so it doesn't cut your fingers when pulling out heavy scrap metal.

- 🚀 Our advantage: We are the only ones combining the strongest N52 neodymium (10mm thick) with non-magnetic eyelets. This is real power and durability you won't find anywhere else.

Invest in solid equipment and enjoy the results!

Technical details - UMP 135x40 [M10+M12] GW F600 Lina / N38 - search holder

Specification / characteristics - UMP 135x40 [M10+M12] GW F600 Lina / N38 - search holder

| properties | values |

|---|---|

| Cat. no. | 210385 |

| GTIN/EAN | 5906301814047 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 135 mm [±1 mm] |

| Height | 40 mm [±1 mm] |

| Weight | 4300 g |

| Load capacity ~ ? | 680.00 kg / 6668.52 N |

| Coating | [NiCuNi] Nickel |

| Holder Type | 2 sided |

| Material Type | Structural steel S235 (ferrous) |

| Magnetic Flux | ~ 10 000 Gauss [±5%] |

| Rope Length | 25 m |

| Rope Capacity | ~ 1595 kg |

| Rope Diameter | Ø 8 mm |

| Gloves | 1 pair |

| Size/Mount Quantity | 3xM10 |

| Manufacturing Tolerance | ±1 mm |

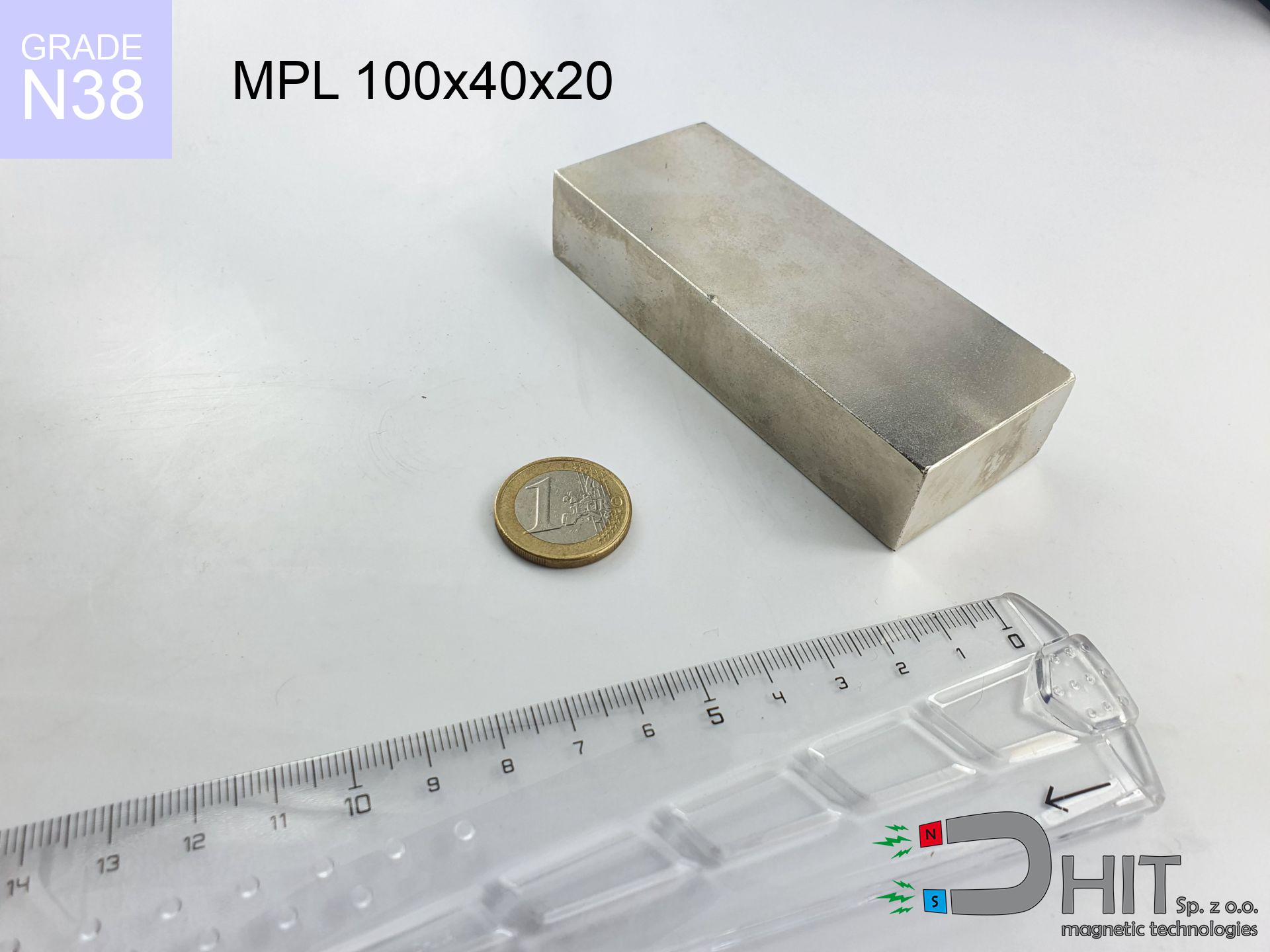

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros as well as cons of neodymium magnets.

Strengths

- They do not lose magnetism, even over approximately ten years – the reduction in power is only ~1% (according to tests),

- Magnets very well resist against demagnetization caused by foreign field sources,

- A magnet with a smooth silver surface has an effective appearance,

- Magnets are distinguished by huge magnetic induction on the outer side,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the shape) even at a temperature of 230°C or more...

- Possibility of precise modeling as well as adjusting to atypical conditions,

- Significant place in future technologies – they are used in HDD drives, electric motors, medical devices, and other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a strong case, which not only secures them against impacts but also increases their durability

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in creating threads and complex forms in magnets, we propose using cover - magnetic mechanism.

- Possible danger to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which gains importance in the context of child safety. It is also worth noting that small elements of these devices are able to disrupt the diagnostic process medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- using a base made of mild steel, serving as a ideal flux conductor

- whose transverse dimension reaches at least 10 mm

- with a plane perfectly flat

- under conditions of gap-free contact (surface-to-surface)

- during detachment in a direction perpendicular to the plane

- in neutral thermal conditions

Determinants of practical lifting force of a magnet

- Space between surfaces – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to pulling vertically. When slipping, the magnet exhibits significantly lower power (often approx. 20-30% of nominal force).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux penetrates through instead of converting into lifting capacity.

- Plate material – mild steel gives the best results. Alloy steels decrease magnetic permeability and holding force.

- Surface finish – ideal contact is possible only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Thermal factor – high temperature weakens pulling force. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was performed on a smooth plate of suitable thickness, under perpendicular forces, whereas under shearing force the lifting capacity is smaller. Additionally, even a small distance between the magnet and the plate decreases the holding force.

Warnings

GPS and phone interference

GPS units and smartphones are extremely susceptible to magnetism. Direct contact with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Thermal limits

Do not overheat. NdFeB magnets are susceptible to heat. If you need operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Machining danger

Combustion risk: Rare earth powder is explosive. Avoid machining magnets without safety gear as this may cause fire.

Product not for children

These products are not toys. Accidental ingestion of a few magnets may result in them connecting inside the digestive tract, which poses a critical condition and requires urgent medical intervention.

Life threat

Medical warning: Strong magnets can turn off pacemakers and defibrillators. Stay away if you have medical devices.

Do not underestimate power

Use magnets consciously. Their powerful strength can shock even experienced users. Plan your moves and respect their power.

Allergy Warning

Some people experience a sensitization to Ni, which is the common plating for NdFeB magnets. Frequent touching can result in a rash. We suggest use protective gloves.

Magnet fragility

NdFeB magnets are sintered ceramics, which means they are very brittle. Collision of two magnets will cause them cracking into shards.

Data carriers

Device Safety: Strong magnets can ruin payment cards and delicate electronics (pacemakers, hearing aids, mechanical watches).

Crushing force

Pinching hazard: The attraction force is so immense that it can result in hematomas, crushing, and broken bones. Protective gloves are recommended.

![Search magnet UMP 135x40 [M10+M12] GW F600 Lina / N38 - GOLD Series Search magnet UMP 135x40 [M10+M12] GW F600 Lina / N38 - GOLD Series](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMP 135x40 [M10+M12] GW F600 Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-135x40-m10+m12-gw-f600-+lina-sej.jpg)