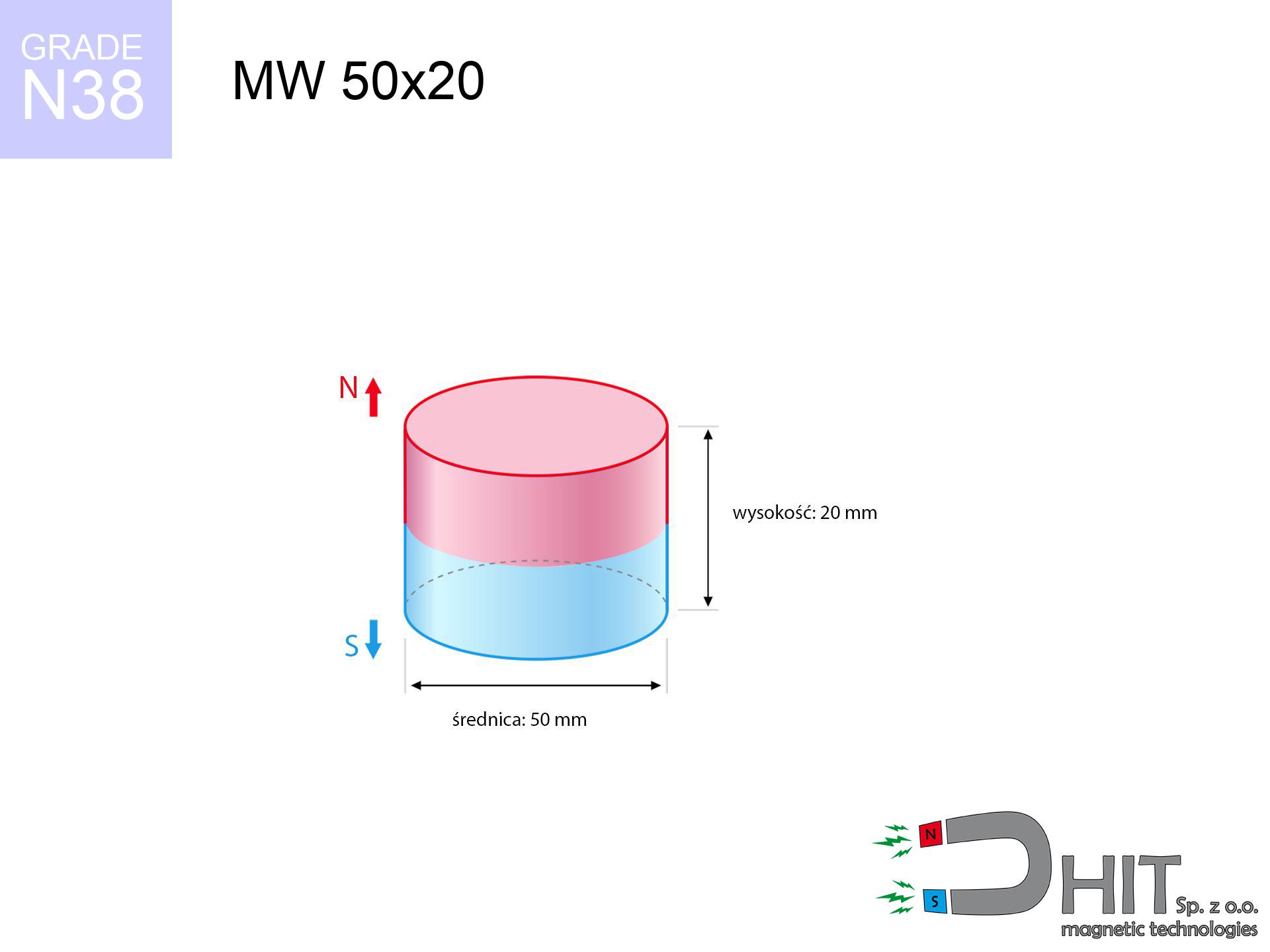

MW 50x20 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010080

GTIN/EAN: 5906301810797

Diameter Ø

50 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

294.52 g

Magnetization Direction

↑ axial

Load capacity

70.10 kg / 687.66 N

Magnetic Induction

387.23 mT / 3872 Gs

Coating

[NiCuNi] Nickel

106.96 ZŁ with VAT / pcs + price for transport

86.96 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

or send us a note using

inquiry form

the contact page.

Force along with appearance of magnets can be checked with our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - MW 50x20 / N38 - cylindrical magnet

Specification / characteristics - MW 50x20 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010080 |

| GTIN/EAN | 5906301810797 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 50 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 294.52 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 70.10 kg / 687.66 N |

| Magnetic Induction ~ ? | 387.23 mT / 3872 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - technical parameters

Presented information constitute the outcome of a physical calculation. Results were calculated on algorithms for the material Nd2Fe14B. Actual performance might slightly deviate from the simulation results. Use these data as a reference point during assembly planning.

Table 1: Static pull force (force vs gap) - power drop

MW 50x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3872 Gs

387.2 mT

|

70.10 kg / 154.54 LBS

70100.0 g / 687.7 N

|

critical level |

| 1 mm |

3740 Gs

374.0 mT

|

65.41 kg / 144.20 LBS

65408.0 g / 641.7 N

|

critical level |

| 2 mm |

3601 Gs

360.1 mT

|

60.65 kg / 133.72 LBS

60652.7 g / 595.0 N

|

critical level |

| 3 mm |

3459 Gs

345.9 mT

|

55.95 kg / 123.35 LBS

55950.5 g / 548.9 N

|

critical level |

| 5 mm |

3168 Gs

316.8 mT

|

46.94 kg / 103.47 LBS

46935.3 g / 460.4 N

|

critical level |

| 10 mm |

2460 Gs

246.0 mT

|

28.31 kg / 62.40 LBS

28306.3 g / 277.7 N

|

critical level |

| 15 mm |

1855 Gs

185.5 mT

|

16.10 kg / 35.48 LBS

16095.6 g / 157.9 N

|

critical level |

| 20 mm |

1384 Gs

138.4 mT

|

8.96 kg / 19.76 LBS

8963.2 g / 87.9 N

|

warning |

| 30 mm |

782 Gs

78.2 mT

|

2.86 kg / 6.31 LBS

2863.1 g / 28.1 N

|

warning |

| 50 mm |

293 Gs

29.3 mT

|

0.40 kg / 0.89 LBS

402.4 g / 3.9 N

|

safe |

Table 2: Vertical hold (wall)

MW 50x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

14.02 kg / 30.91 LBS

14020.0 g / 137.5 N

|

| 1 mm | Stal (~0.2) |

13.08 kg / 28.84 LBS

13082.0 g / 128.3 N

|

| 2 mm | Stal (~0.2) |

12.13 kg / 26.74 LBS

12130.0 g / 119.0 N

|

| 3 mm | Stal (~0.2) |

11.19 kg / 24.67 LBS

11190.0 g / 109.8 N

|

| 5 mm | Stal (~0.2) |

9.39 kg / 20.70 LBS

9388.0 g / 92.1 N

|

| 10 mm | Stal (~0.2) |

5.66 kg / 12.48 LBS

5662.0 g / 55.5 N

|

| 15 mm | Stal (~0.2) |

3.22 kg / 7.10 LBS

3220.0 g / 31.6 N

|

| 20 mm | Stal (~0.2) |

1.79 kg / 3.95 LBS

1792.0 g / 17.6 N

|

| 30 mm | Stal (~0.2) |

0.57 kg / 1.26 LBS

572.0 g / 5.6 N

|

| 50 mm | Stal (~0.2) |

0.08 kg / 0.18 LBS

80.0 g / 0.8 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 50x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

21.03 kg / 46.36 LBS

21030.0 g / 206.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

14.02 kg / 30.91 LBS

14020.0 g / 137.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

7.01 kg / 15.45 LBS

7010.0 g / 68.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

35.05 kg / 77.27 LBS

35050.0 g / 343.8 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 50x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.34 kg / 5.15 LBS

2336.7 g / 22.9 N

|

| 1 mm |

|

5.84 kg / 12.88 LBS

5841.7 g / 57.3 N

|

| 2 mm |

|

11.68 kg / 25.76 LBS

11683.3 g / 114.6 N

|

| 3 mm |

|

17.53 kg / 38.64 LBS

17525.0 g / 171.9 N

|

| 5 mm |

|

29.21 kg / 64.39 LBS

29208.3 g / 286.5 N

|

| 10 mm |

|

58.42 kg / 128.79 LBS

58416.7 g / 573.1 N

|

| 11 mm |

|

64.26 kg / 141.67 LBS

64258.3 g / 630.4 N

|

| 12 mm |

|

70.10 kg / 154.54 LBS

70100.0 g / 687.7 N

|

Table 5: Thermal stability (stability) - power drop

MW 50x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

70.10 kg / 154.54 LBS

70100.0 g / 687.7 N

|

OK |

| 40 °C | -2.2% |

68.56 kg / 151.14 LBS

68557.8 g / 672.6 N

|

OK |

| 60 °C | -4.4% |

67.02 kg / 147.74 LBS

67015.6 g / 657.4 N

|

|

| 80 °C | -6.6% |

65.47 kg / 144.34 LBS

65473.4 g / 642.3 N

|

|

| 100 °C | -28.8% |

49.91 kg / 110.04 LBS

49911.2 g / 489.6 N

|

Table 6: Two magnets (attraction) - field range

MW 50x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

181.46 kg / 400.06 LBS

5 255 Gs

|

27.22 kg / 60.01 LBS

27220 g / 267.0 N

|

N/A |

| 1 mm |

175.47 kg / 386.84 LBS

7 615 Gs

|

26.32 kg / 58.03 LBS

26321 g / 258.2 N

|

157.92 kg / 348.16 LBS

~0 Gs

|

| 2 mm |

169.32 kg / 373.28 LBS

7 480 Gs

|

25.40 kg / 55.99 LBS

25398 g / 249.2 N

|

152.39 kg / 335.96 LBS

~0 Gs

|

| 3 mm |

163.16 kg / 359.70 LBS

7 343 Gs

|

24.47 kg / 53.96 LBS

24474 g / 240.1 N

|

146.84 kg / 323.73 LBS

~0 Gs

|

| 5 mm |

150.90 kg / 332.67 LBS

7 061 Gs

|

22.63 kg / 49.90 LBS

22634 g / 222.0 N

|

135.81 kg / 299.40 LBS

~0 Gs

|

| 10 mm |

121.50 kg / 267.86 LBS

6 336 Gs

|

18.22 kg / 40.18 LBS

18225 g / 178.8 N

|

109.35 kg / 241.07 LBS

~0 Gs

|

| 20 mm |

73.28 kg / 161.54 LBS

4 921 Gs

|

10.99 kg / 24.23 LBS

10991 g / 107.8 N

|

65.95 kg / 145.39 LBS

~0 Gs

|

| 50 mm |

12.99 kg / 28.63 LBS

2 071 Gs

|

1.95 kg / 4.29 LBS

1948 g / 19.1 N

|

11.69 kg / 25.76 LBS

~0 Gs

|

| 60 mm |

7.41 kg / 16.34 LBS

1 565 Gs

|

1.11 kg / 2.45 LBS

1112 g / 10.9 N

|

6.67 kg / 14.71 LBS

~0 Gs

|

| 70 mm |

4.35 kg / 9.58 LBS

1 198 Gs

|

0.65 kg / 1.44 LBS

652 g / 6.4 N

|

3.91 kg / 8.62 LBS

~0 Gs

|

| 80 mm |

2.62 kg / 5.78 LBS

931 Gs

|

0.39 kg / 0.87 LBS

393 g / 3.9 N

|

2.36 kg / 5.20 LBS

~0 Gs

|

| 90 mm |

1.63 kg / 3.59 LBS

734 Gs

|

0.24 kg / 0.54 LBS

245 g / 2.4 N

|

1.47 kg / 3.23 LBS

~0 Gs

|

| 100 mm |

1.04 kg / 2.30 LBS

587 Gs

|

0.16 kg / 0.34 LBS

156 g / 1.5 N

|

0.94 kg / 2.07 LBS

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 50x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 24.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 19.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 15.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 11.5 cm |

| Car key | 50 Gs (5.0 mT) | 10.5 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 50x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.09 km/h

(5.30 m/s)

|

4.14 J | |

| 30 mm |

27.63 km/h

(7.67 m/s)

|

8.67 J | |

| 50 mm |

34.92 km/h

(9.70 m/s)

|

13.85 J | |

| 100 mm |

49.21 km/h

(13.67 m/s)

|

27.51 J |

Table 9: Corrosion resistance

MW 50x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 50x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 78 540 Mx | 785.4 µWb |

| Pc Coefficient | 0.50 | Low (Flat) |

Table 11: Submerged application

MW 50x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 70.10 kg | Standard |

| Water (riverbed) |

80.26 kg

(+10.16 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical wall, the magnet retains just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.50

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages and disadvantages of Nd2Fe14B magnets.

Pros

- They do not lose power, even during around 10 years – the reduction in strength is only ~1% (according to tests),

- Magnets perfectly protect themselves against demagnetization caused by external fields,

- A magnet with a shiny silver surface has an effective appearance,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a key feature,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures approaching 230°C and above...

- Possibility of precise machining and adjusting to atypical requirements,

- Universal use in high-tech industry – they are used in hard drives, drive modules, advanced medical instruments, as well as other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which makes them useful in miniature devices

Cons

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only shields the magnet but also increases its resistance to damage

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Limited possibility of making threads in the magnet and complicated shapes - recommended is casing - mounting mechanism.

- Health risk resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the context of child health protection. Additionally, small components of these products can disrupt the diagnostic process medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- with the application of a yoke made of low-carbon steel, guaranteeing full magnetic saturation

- with a cross-section minimum 10 mm

- characterized by lack of roughness

- with direct contact (without impurities)

- during detachment in a direction vertical to the mounting surface

- at standard ambient temperature

Practical aspects of lifting capacity – factors

- Distance – existence of any layer (paint, dirt, gap) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Angle of force application – highest force is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is usually several times lower (approx. 1/5 of the lifting capacity).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Plate material – low-carbon steel gives the best results. Alloy steels lower magnetic permeability and lifting capacity.

- Surface structure – the smoother and more polished the surface, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was measured by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under vertically applied force, however under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet and the plate decreases the load capacity.

Safety rules for work with NdFeB magnets

Combustion hazard

Combustion risk: Rare earth powder is highly flammable. Avoid machining magnets without safety gear as this risks ignition.

Implant safety

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or request help to handle the magnets.

Safe distance

Powerful magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Stay away of min. 10 cm.

Heat sensitivity

Do not overheat. NdFeB magnets are susceptible to heat. If you require operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Shattering risk

Protect your eyes. Magnets can explode upon violent connection, ejecting shards into the air. Wear goggles.

Hand protection

Protect your hands. Two large magnets will snap together instantly with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Skin irritation risks

Certain individuals suffer from a contact allergy to nickel, which is the common plating for NdFeB magnets. Frequent touching may cause a rash. We strongly advise wear safety gloves.

Safe operation

Use magnets with awareness. Their huge power can shock even experienced users. Plan your moves and respect their power.

Choking Hazard

These products are not toys. Accidental ingestion of several magnets may result in them attracting across intestines, which poses a severe health hazard and necessitates urgent medical intervention.

Keep away from electronics

An intense magnetic field disrupts the functioning of magnetometers in smartphones and GPS navigation. Do not bring magnets close to a device to avoid breaking the sensors.

![AM szekla [M10] - magnetic accessories AM szekla [M10] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-szekla-m10-zeh.jpg)

![UMH 20x7x35 [M4] / N38 - magnetic holder with hook UMH 20x7x35 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-20x7x35-m4-hiz.jpg)