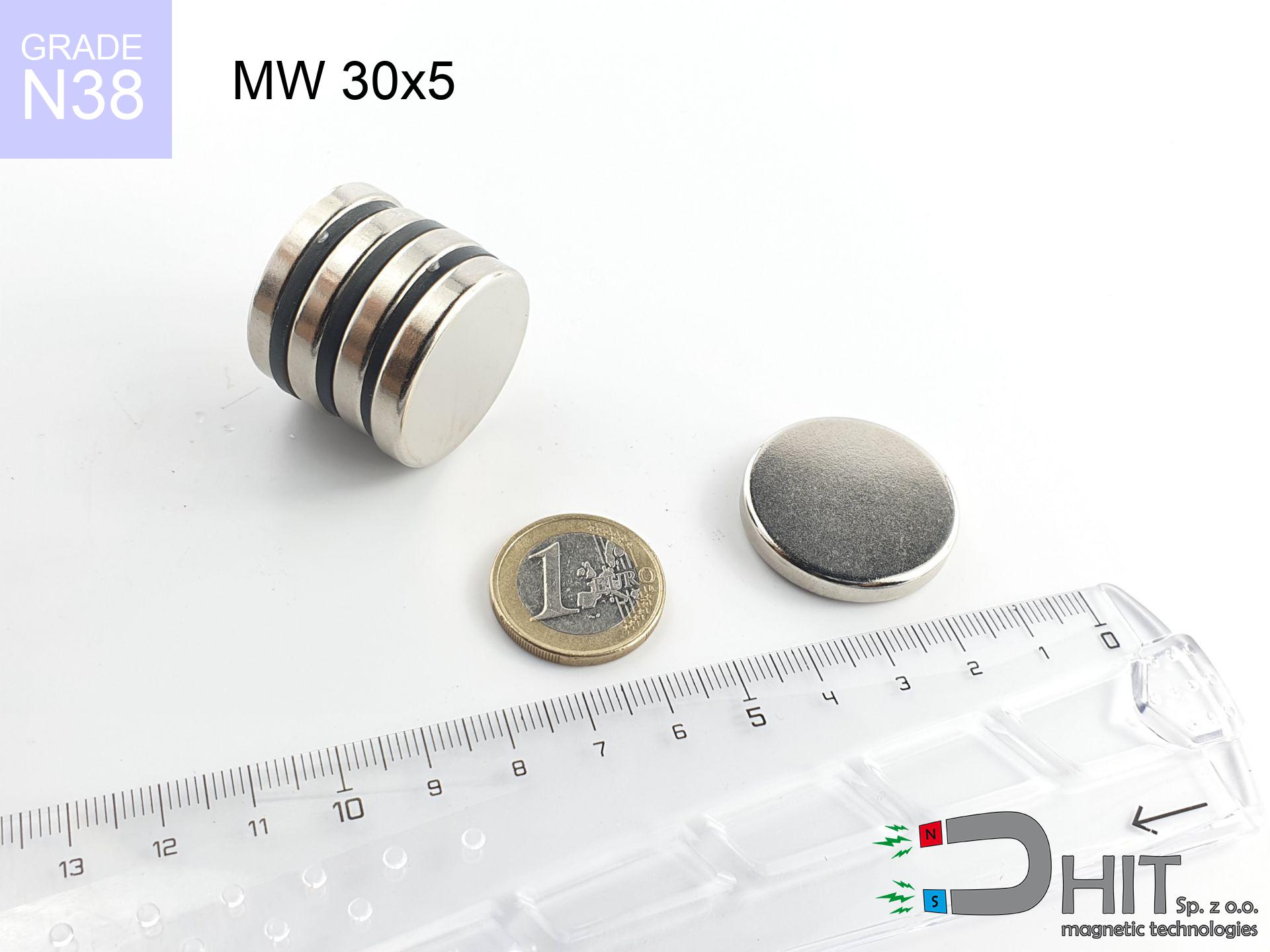

MW 30x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010056

GTIN/EAN: 5906301810551

Diameter Ø

30 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

26.51 g

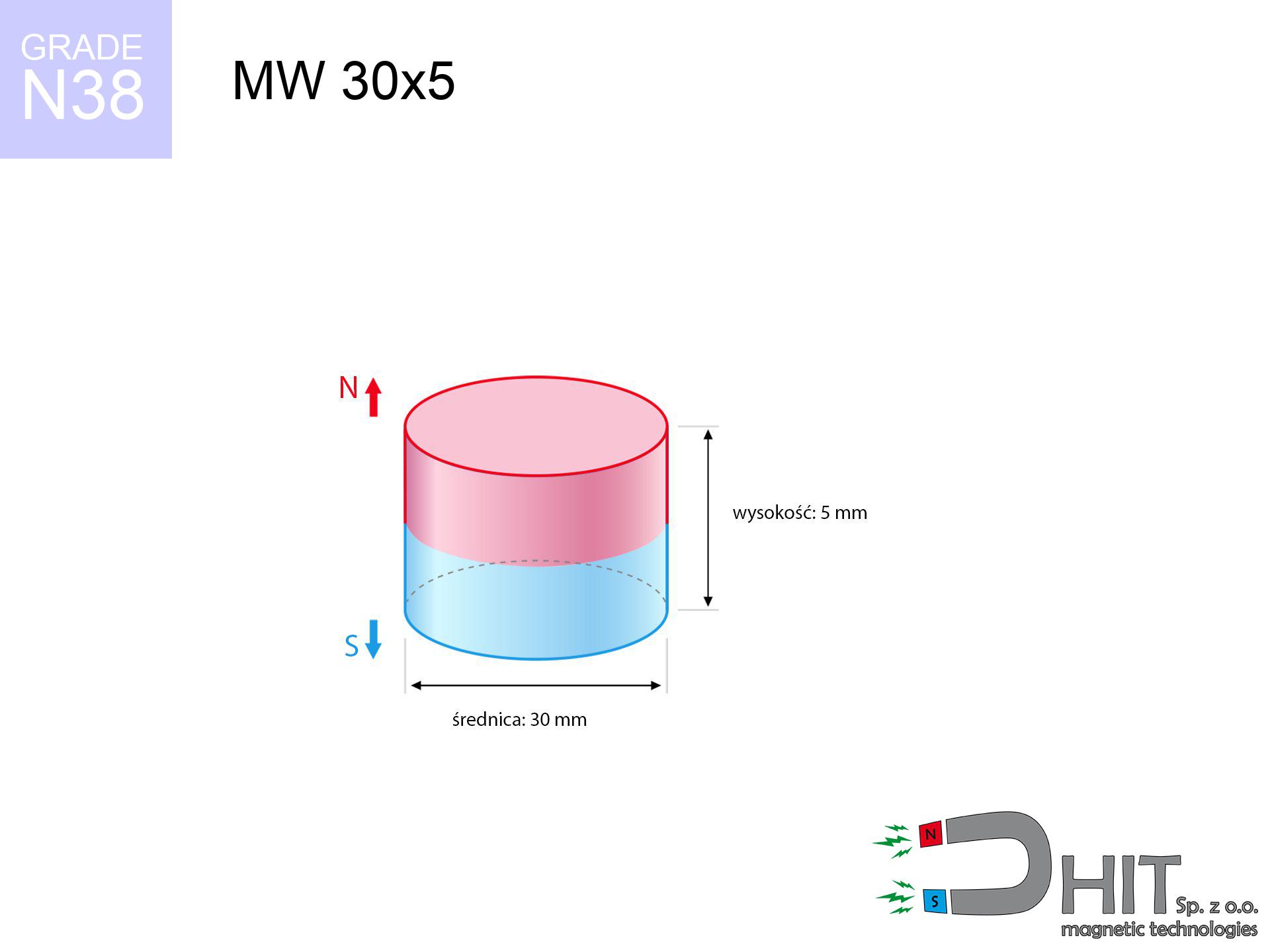

Magnetization Direction

↑ axial

Load capacity

8.71 kg / 85.42 N

Magnetic Induction

196.02 mT / 1960 Gs

Coating

[NiCuNi] Nickel

8.35 ZŁ with VAT / pcs + price for transport

6.79 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

if you prefer drop us a message through

contact form

the contact section.

Specifications along with shape of a neodymium magnet can be tested with our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MW 30x5 / N38 - cylindrical magnet

Specification / characteristics - MW 30x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010056 |

| GTIN/EAN | 5906301810551 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 30 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 26.51 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 8.71 kg / 85.42 N |

| Magnetic Induction ~ ? | 196.02 mT / 1960 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

Presented information represent the result of a engineering simulation. Results rely on algorithms for the class Nd2Fe14B. Operational conditions may differ from theoretical values. Use these data as a reference point when designing systems.

Table 1: Static force (force vs gap) - power drop

MW 30x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1960 Gs

196.0 mT

|

8.71 kg / 19.20 LBS

8710.0 g / 85.4 N

|

medium risk |

| 1 mm |

1890 Gs

189.0 mT

|

8.10 kg / 17.86 LBS

8100.7 g / 79.5 N

|

medium risk |

| 2 mm |

1802 Gs

180.2 mT

|

7.37 kg / 16.24 LBS

7366.2 g / 72.3 N

|

medium risk |

| 3 mm |

1702 Gs

170.2 mT

|

6.57 kg / 14.47 LBS

6565.7 g / 64.4 N

|

medium risk |

| 5 mm |

1479 Gs

147.9 mT

|

4.96 kg / 10.93 LBS

4956.4 g / 48.6 N

|

medium risk |

| 10 mm |

945 Gs

94.5 mT

|

2.02 kg / 4.46 LBS

2024.4 g / 19.9 N

|

medium risk |

| 15 mm |

576 Gs

57.6 mT

|

0.75 kg / 1.66 LBS

752.1 g / 7.4 N

|

safe |

| 20 mm |

356 Gs

35.6 mT

|

0.29 kg / 0.64 LBS

288.1 g / 2.8 N

|

safe |

| 30 mm |

153 Gs

15.3 mT

|

0.05 kg / 0.12 LBS

53.2 g / 0.5 N

|

safe |

| 50 mm |

43 Gs

4.3 mT

|

0.00 kg / 0.01 LBS

4.2 g / 0.0 N

|

safe |

Table 2: Slippage load (wall)

MW 30x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.74 kg / 3.84 LBS

1742.0 g / 17.1 N

|

| 1 mm | Stal (~0.2) |

1.62 kg / 3.57 LBS

1620.0 g / 15.9 N

|

| 2 mm | Stal (~0.2) |

1.47 kg / 3.25 LBS

1474.0 g / 14.5 N

|

| 3 mm | Stal (~0.2) |

1.31 kg / 2.90 LBS

1314.0 g / 12.9 N

|

| 5 mm | Stal (~0.2) |

0.99 kg / 2.19 LBS

992.0 g / 9.7 N

|

| 10 mm | Stal (~0.2) |

0.40 kg / 0.89 LBS

404.0 g / 4.0 N

|

| 15 mm | Stal (~0.2) |

0.15 kg / 0.33 LBS

150.0 g / 1.5 N

|

| 20 mm | Stal (~0.2) |

0.06 kg / 0.13 LBS

58.0 g / 0.6 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 30x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.61 kg / 5.76 LBS

2613.0 g / 25.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.74 kg / 3.84 LBS

1742.0 g / 17.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.87 kg / 1.92 LBS

871.0 g / 8.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.36 kg / 9.60 LBS

4355.0 g / 42.7 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 30x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.87 kg / 1.92 LBS

871.0 g / 8.5 N

|

| 1 mm |

|

2.18 kg / 4.80 LBS

2177.5 g / 21.4 N

|

| 2 mm |

|

4.36 kg / 9.60 LBS

4355.0 g / 42.7 N

|

| 3 mm |

|

6.53 kg / 14.40 LBS

6532.5 g / 64.1 N

|

| 5 mm |

|

8.71 kg / 19.20 LBS

8710.0 g / 85.4 N

|

| 10 mm |

|

8.71 kg / 19.20 LBS

8710.0 g / 85.4 N

|

| 11 mm |

|

8.71 kg / 19.20 LBS

8710.0 g / 85.4 N

|

| 12 mm |

|

8.71 kg / 19.20 LBS

8710.0 g / 85.4 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MW 30x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

8.71 kg / 19.20 LBS

8710.0 g / 85.4 N

|

OK |

| 40 °C | -2.2% |

8.52 kg / 18.78 LBS

8518.4 g / 83.6 N

|

OK |

| 60 °C | -4.4% |

8.33 kg / 18.36 LBS

8326.8 g / 81.7 N

|

|

| 80 °C | -6.6% |

8.14 kg / 17.93 LBS

8135.1 g / 79.8 N

|

|

| 100 °C | -28.8% |

6.20 kg / 13.67 LBS

6201.5 g / 60.8 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 30x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

16.74 kg / 36.91 LBS

3 437 Gs

|

2.51 kg / 5.54 LBS

2511 g / 24.6 N

|

N/A |

| 1 mm |

16.20 kg / 35.71 LBS

3 856 Gs

|

2.43 kg / 5.36 LBS

2429 g / 23.8 N

|

14.58 kg / 32.14 LBS

~0 Gs

|

| 2 mm |

15.57 kg / 34.33 LBS

3 780 Gs

|

2.34 kg / 5.15 LBS

2335 g / 22.9 N

|

14.01 kg / 30.89 LBS

~0 Gs

|

| 3 mm |

14.89 kg / 32.82 LBS

3 696 Gs

|

2.23 kg / 4.92 LBS

2233 g / 21.9 N

|

13.40 kg / 29.54 LBS

~0 Gs

|

| 5 mm |

13.40 kg / 29.54 LBS

3 507 Gs

|

2.01 kg / 4.43 LBS

2010 g / 19.7 N

|

12.06 kg / 26.58 LBS

~0 Gs

|

| 10 mm |

9.53 kg / 21.00 LBS

2 957 Gs

|

1.43 kg / 3.15 LBS

1429 g / 14.0 N

|

8.57 kg / 18.90 LBS

~0 Gs

|

| 20 mm |

3.89 kg / 8.58 LBS

1 890 Gs

|

0.58 kg / 1.29 LBS

584 g / 5.7 N

|

3.50 kg / 7.72 LBS

~0 Gs

|

| 50 mm |

0.23 kg / 0.50 LBS

458 Gs

|

0.03 kg / 0.08 LBS

34 g / 0.3 N

|

0.21 kg / 0.45 LBS

~0 Gs

|

| 60 mm |

0.10 kg / 0.23 LBS

307 Gs

|

0.02 kg / 0.03 LBS

15 g / 0.2 N

|

0.09 kg / 0.20 LBS

~0 Gs

|

| 70 mm |

0.05 kg / 0.11 LBS

213 Gs

|

0.01 kg / 0.02 LBS

7 g / 0.1 N

|

0.04 kg / 0.10 LBS

~0 Gs

|

| 80 mm |

0.03 kg / 0.06 LBS

153 Gs

|

0.00 kg / 0.01 LBS

4 g / 0.0 N

|

0.02 kg / 0.05 LBS

~0 Gs

|

| 90 mm |

0.01 kg / 0.03 LBS

113 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.03 LBS

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 LBS

86 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 30x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 7.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 5.5 cm |

| Remote | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 30x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.77 km/h

(5.77 m/s)

|

0.44 J | |

| 30 mm |

31.78 km/h

(8.83 m/s)

|

1.03 J | |

| 50 mm |

40.89 km/h

(11.36 m/s)

|

1.71 J | |

| 100 mm |

57.81 km/h

(16.06 m/s)

|

3.42 J |

Table 9: Anti-corrosion coating durability

MW 30x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 30x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 658 Mx | 166.6 µWb |

| Pc Coefficient | 0.25 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 30x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 8.71 kg | Standard |

| Water (riverbed) |

9.97 kg

(+1.26 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet retains only ~20% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.25

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Benefits

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- They possess excellent resistance to magnetism drop due to opposing magnetic fields,

- The use of an shiny layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a distinguishing feature,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to versatility in designing and the capacity to customize to complex applications,

- Key role in high-tech industry – they are utilized in hard drives, electric motors, medical equipment, as well as modern systems.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Weaknesses

- Brittleness is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a strong case, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They oxidize in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We recommend cover - magnetic holder, due to difficulties in realizing threads inside the magnet and complicated forms.

- Possible danger to health – tiny shards of magnets are risky, in case of ingestion, which is particularly important in the context of child safety. It is also worth noting that tiny parts of these products can complicate diagnosis medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Magnetic strength at its maximum – what contributes to it?

- on a block made of mild steel, optimally conducting the magnetic field

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an ideally smooth contact surface

- without the slightest insulating layer between the magnet and steel

- during detachment in a direction vertical to the plane

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Distance (between the magnet and the plate), since even a microscopic distance (e.g. 0.5 mm) results in a decrease in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet exhibits much less (typically approx. 20-30% of nominal force).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal limits the lifting capacity (the magnet "punches through" it).

- Metal type – not every steel reacts the same. High carbon content worsen the interaction with the magnet.

- Smoothness – ideal contact is possible only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Thermal environment – heating the magnet results in weakening of induction. Check the thermal limit for a given model.

Lifting capacity was determined with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. In addition, even a small distance between the magnet and the plate lowers the lifting capacity.

H&S for magnets

Crushing risk

Large magnets can smash fingers instantly. Under no circumstances place your hand between two attracting surfaces.

Impact on smartphones

GPS units and mobile phones are highly sensitive to magnetic fields. Direct contact with a strong magnet can permanently damage the internal compass in your phone.

Choking Hazard

Product intended for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Store away from children and animals.

Fire warning

Powder generated during cutting of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Do not overheat magnets

Watch the temperature. Heating the magnet above 80 degrees Celsius will permanently weaken its properties and strength.

Metal Allergy

It is widely known that the nickel plating (standard magnet coating) is a potent allergen. For allergy sufferers, avoid touching magnets with bare hands and choose coated magnets.

Eye protection

Despite the nickel coating, neodymium is brittle and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

Data carriers

Avoid bringing magnets close to a wallet, computer, or screen. The magnetism can permanently damage these devices and wipe information from cards.

Medical interference

Individuals with a heart stimulator must keep an safe separation from magnets. The magnetism can disrupt the operation of the life-saving device.

Do not underestimate power

Handle magnets with awareness. Their huge power can shock even professionals. Stay alert and respect their force.