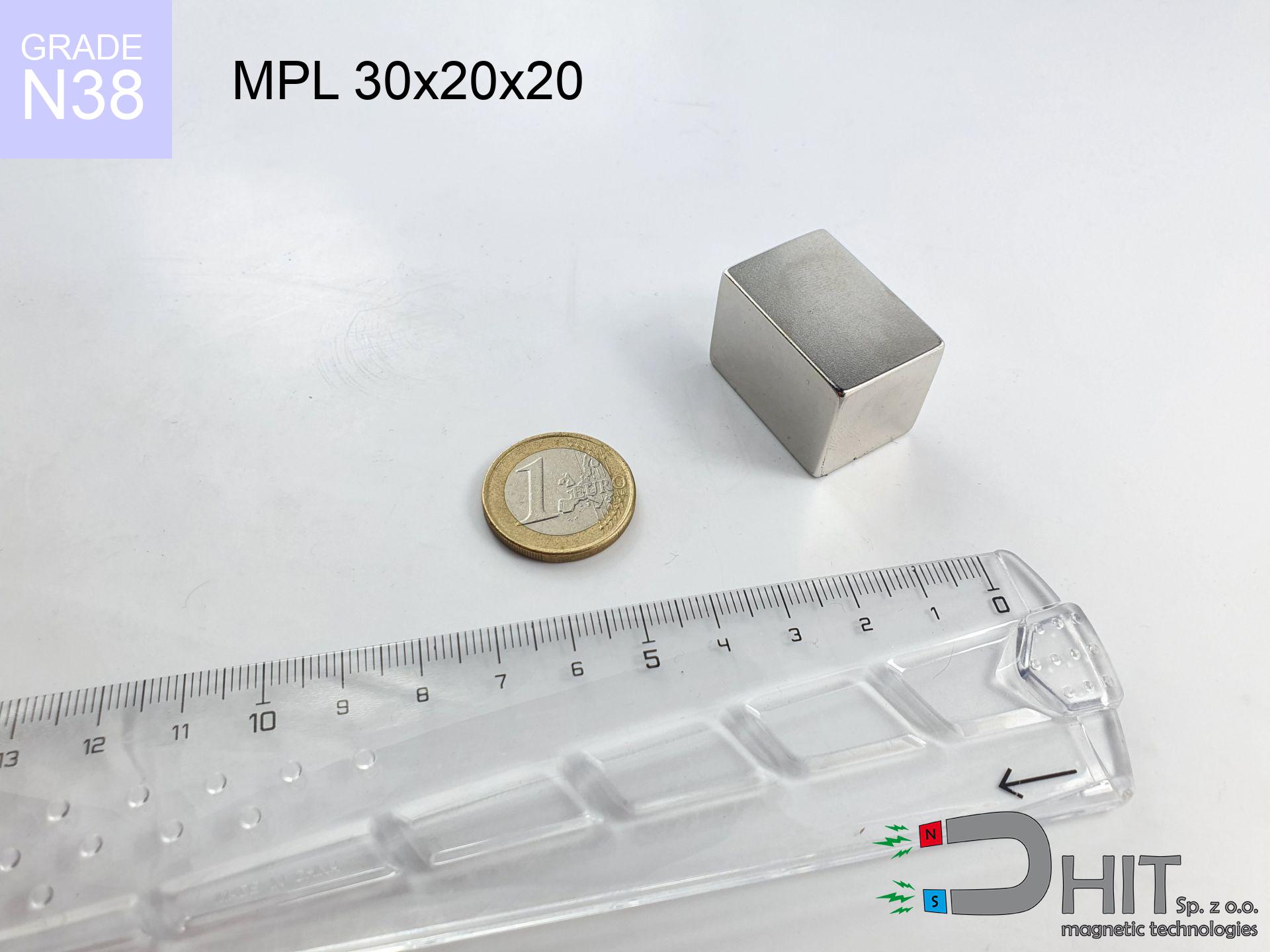

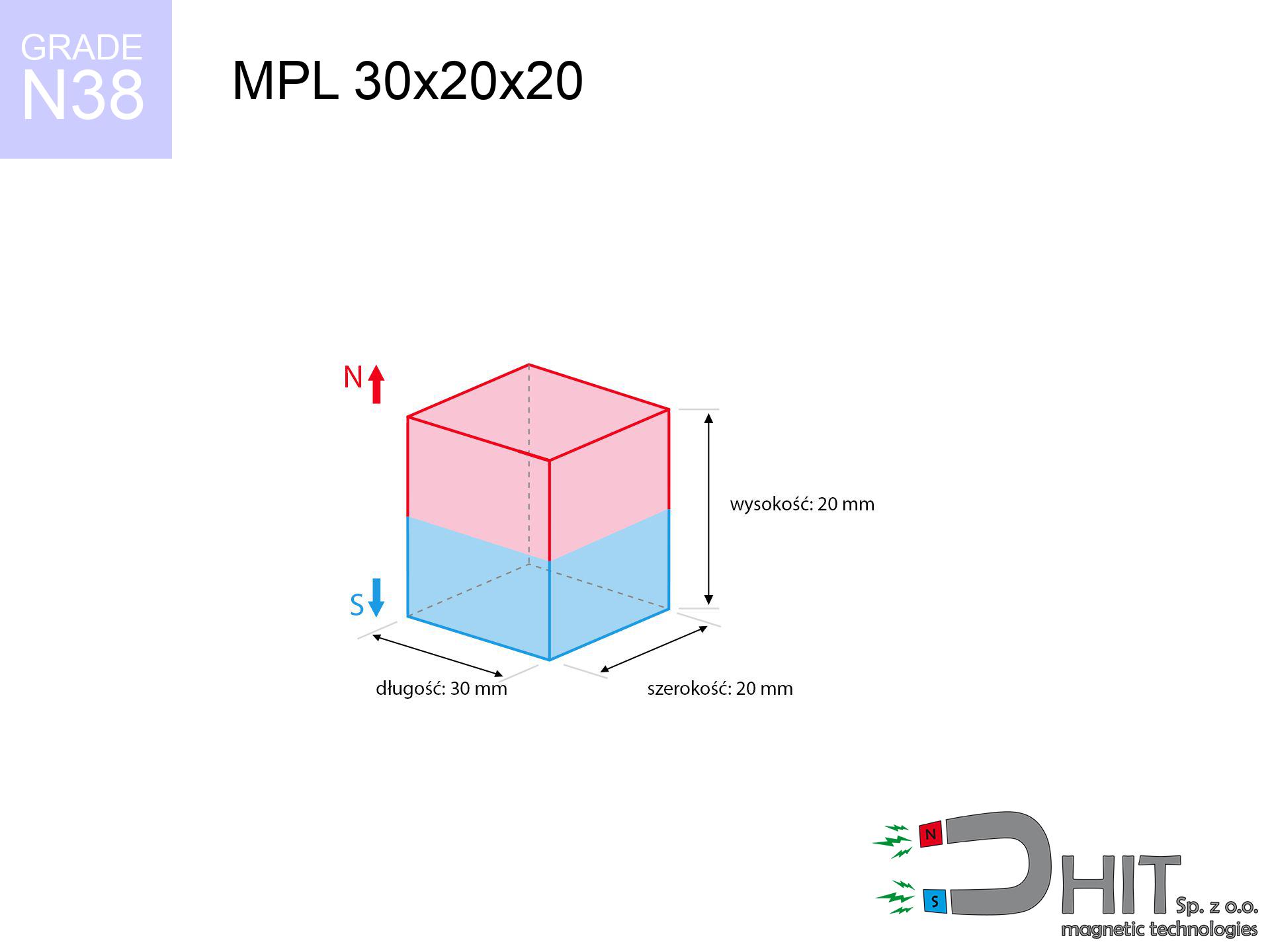

MPL 30x20x20 / N38 - lamellar magnet

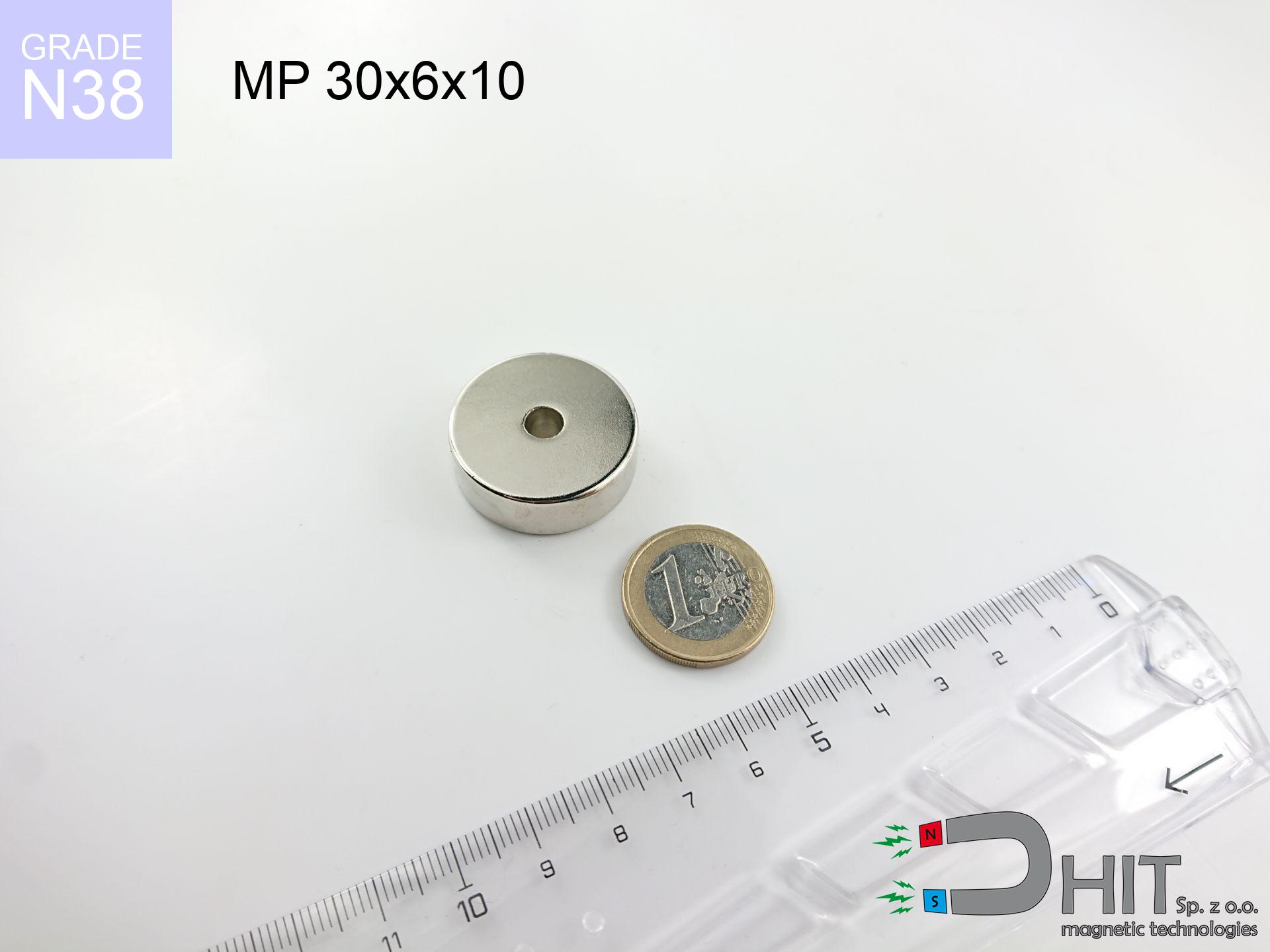

lamellar magnet

Catalog no 020142

GTIN/EAN: 5906301811480

length

30 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

90 g

Magnetization Direction

↑ axial

Load capacity

24.27 kg / 238.07 N

Magnetic Induction

512.53 mT / 5125 Gs

Coating

[NiCuNi] Nickel

43.22 ZŁ with VAT / pcs + price for transport

35.14 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

alternatively send us a note through

form

through our site.

Lifting power along with form of a magnet can be reviewed using our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Technical - MPL 30x20x20 / N38 - lamellar magnet

Specification / characteristics - MPL 30x20x20 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020142 |

| GTIN/EAN | 5906301811480 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 90 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 24.27 kg / 238.07 N |

| Magnetic Induction ~ ? | 512.53 mT / 5125 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - technical parameters

The following values constitute the result of a mathematical analysis. Results are based on algorithms for the material Nd2Fe14B. Operational conditions might slightly differ. Use these data as a reference point during assembly planning.

Table 1: Static pull force (pull vs gap) - characteristics

MPL 30x20x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5124 Gs

512.4 mT

|

24.27 kg / 53.51 lbs

24270.0 g / 238.1 N

|

crushing |

| 1 mm |

4730 Gs

473.0 mT

|

20.68 kg / 45.60 lbs

20685.0 g / 202.9 N

|

crushing |

| 2 mm |

4335 Gs

433.5 mT

|

17.37 kg / 38.30 lbs

17370.7 g / 170.4 N

|

crushing |

| 3 mm |

3950 Gs

395.0 mT

|

14.43 kg / 31.80 lbs

14425.2 g / 141.5 N

|

crushing |

| 5 mm |

3240 Gs

324.0 mT

|

9.71 kg / 21.40 lbs

9706.2 g / 95.2 N

|

medium risk |

| 10 mm |

1923 Gs

192.3 mT

|

3.42 kg / 7.53 lbs

3417.4 g / 33.5 N

|

medium risk |

| 15 mm |

1163 Gs

116.3 mT

|

1.25 kg / 2.76 lbs

1250.2 g / 12.3 N

|

low risk |

| 20 mm |

736 Gs

73.6 mT

|

0.50 kg / 1.10 lbs

500.4 g / 4.9 N

|

low risk |

| 30 mm |

338 Gs

33.8 mT

|

0.11 kg / 0.23 lbs

105.3 g / 1.0 N

|

low risk |

| 50 mm |

106 Gs

10.6 mT

|

0.01 kg / 0.02 lbs

10.3 g / 0.1 N

|

low risk |

Table 2: Sliding hold (wall)

MPL 30x20x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.85 kg / 10.70 lbs

4854.0 g / 47.6 N

|

| 1 mm | Stal (~0.2) |

4.14 kg / 9.12 lbs

4136.0 g / 40.6 N

|

| 2 mm | Stal (~0.2) |

3.47 kg / 7.66 lbs

3474.0 g / 34.1 N

|

| 3 mm | Stal (~0.2) |

2.89 kg / 6.36 lbs

2886.0 g / 28.3 N

|

| 5 mm | Stal (~0.2) |

1.94 kg / 4.28 lbs

1942.0 g / 19.1 N

|

| 10 mm | Stal (~0.2) |

0.68 kg / 1.51 lbs

684.0 g / 6.7 N

|

| 15 mm | Stal (~0.2) |

0.25 kg / 0.55 lbs

250.0 g / 2.5 N

|

| 20 mm | Stal (~0.2) |

0.10 kg / 0.22 lbs

100.0 g / 1.0 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

22.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 30x20x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

7.28 kg / 16.05 lbs

7281.0 g / 71.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.85 kg / 10.70 lbs

4854.0 g / 47.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.43 kg / 5.35 lbs

2427.0 g / 23.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

12.14 kg / 26.75 lbs

12135.0 g / 119.0 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 30x20x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.21 kg / 2.68 lbs

1213.5 g / 11.9 N

|

| 1 mm |

|

3.03 kg / 6.69 lbs

3033.8 g / 29.8 N

|

| 2 mm |

|

6.07 kg / 13.38 lbs

6067.5 g / 59.5 N

|

| 3 mm |

|

9.10 kg / 20.06 lbs

9101.3 g / 89.3 N

|

| 5 mm |

|

15.17 kg / 33.44 lbs

15168.8 g / 148.8 N

|

| 10 mm |

|

24.27 kg / 53.51 lbs

24270.0 g / 238.1 N

|

| 11 mm |

|

24.27 kg / 53.51 lbs

24270.0 g / 238.1 N

|

| 12 mm |

|

24.27 kg / 53.51 lbs

24270.0 g / 238.1 N

|

Table 5: Thermal resistance (material behavior) - power drop

MPL 30x20x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

24.27 kg / 53.51 lbs

24270.0 g / 238.1 N

|

OK |

| 40 °C | -2.2% |

23.74 kg / 52.33 lbs

23736.1 g / 232.9 N

|

OK |

| 60 °C | -4.4% |

23.20 kg / 51.15 lbs

23202.1 g / 227.6 N

|

OK |

| 80 °C | -6.6% |

22.67 kg / 49.97 lbs

22668.2 g / 222.4 N

|

|

| 100 °C | -28.8% |

17.28 kg / 38.10 lbs

17280.2 g / 169.5 N

|

Table 6: Two magnets (attraction) - field range

MPL 30x20x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

97.11 kg / 214.09 lbs

5 859 Gs

|

14.57 kg / 32.11 lbs

14567 g / 142.9 N

|

N/A |

| 1 mm |

89.88 kg / 198.15 lbs

9 859 Gs

|

13.48 kg / 29.72 lbs

13482 g / 132.3 N

|

80.89 kg / 178.34 lbs

~0 Gs

|

| 2 mm |

82.77 kg / 182.47 lbs

9 461 Gs

|

12.42 kg / 27.37 lbs

12415 g / 121.8 N

|

74.49 kg / 164.22 lbs

~0 Gs

|

| 3 mm |

75.96 kg / 167.47 lbs

9 063 Gs

|

11.39 kg / 25.12 lbs

11394 g / 111.8 N

|

68.37 kg / 150.72 lbs

~0 Gs

|

| 5 mm |

63.42 kg / 139.81 lbs

8 281 Gs

|

9.51 kg / 20.97 lbs

9513 g / 93.3 N

|

57.08 kg / 125.83 lbs

~0 Gs

|

| 10 mm |

38.84 kg / 85.62 lbs

6 481 Gs

|

5.83 kg / 12.84 lbs

5826 g / 57.1 N

|

34.95 kg / 77.06 lbs

~0 Gs

|

| 20 mm |

13.67 kg / 30.15 lbs

3 845 Gs

|

2.05 kg / 4.52 lbs

2051 g / 20.1 N

|

12.31 kg / 27.13 lbs

~0 Gs

|

| 50 mm |

0.88 kg / 1.94 lbs

976 Gs

|

0.13 kg / 0.29 lbs

132 g / 1.3 N

|

0.79 kg / 1.75 lbs

~0 Gs

|

| 60 mm |

0.42 kg / 0.93 lbs

675 Gs

|

0.06 kg / 0.14 lbs

63 g / 0.6 N

|

0.38 kg / 0.84 lbs

~0 Gs

|

| 70 mm |

0.22 kg / 0.48 lbs

484 Gs

|

0.03 kg / 0.07 lbs

33 g / 0.3 N

|

0.20 kg / 0.43 lbs

~0 Gs

|

| 80 mm |

0.12 kg / 0.26 lbs

358 Gs

|

0.02 kg / 0.04 lbs

18 g / 0.2 N

|

0.11 kg / 0.24 lbs

~0 Gs

|

| 90 mm |

0.07 kg / 0.15 lbs

272 Gs

|

0.01 kg / 0.02 lbs

10 g / 0.1 N

|

0.06 kg / 0.14 lbs

~0 Gs

|

| 100 mm |

0.04 kg / 0.09 lbs

211 Gs

|

0.01 kg / 0.01 lbs

6 g / 0.1 N

|

0.04 kg / 0.08 lbs

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 30x20x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 16.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 12.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 10.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 7.5 cm |

| Remote | 50 Gs (5.0 mT) | 7.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 30x20x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.96 km/h

(4.99 m/s)

|

1.12 J | |

| 30 mm |

28.76 km/h

(7.99 m/s)

|

2.87 J | |

| 50 mm |

37.04 km/h

(10.29 m/s)

|

4.76 J | |

| 100 mm |

52.37 km/h

(14.55 m/s)

|

9.52 J |

Table 9: Corrosion resistance

MPL 30x20x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 30x20x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 30 878 Mx | 308.8 µWb |

| Pc Coefficient | 0.74 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MPL 30x20x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 24.27 kg | Standard |

| Water (riverbed) |

27.79 kg

(+3.52 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains merely ~20% of its perpendicular strength.

2. Steel saturation

*Thin steel (e.g. 0.5mm PC case) severely limits the holding force.

3. Power loss vs temp

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.74

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more deals

Advantages as well as disadvantages of rare earth magnets.

Strengths

- They retain full power for almost ten years – the drop is just ~1% (in theory),

- They maintain their magnetic properties even under close interference source,

- By using a reflective coating of silver, the element acquires an elegant look,

- Neodymium magnets achieve maximum magnetic induction on a small surface, which increases force concentration,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to modularity in forming and the ability to modify to complex applications,

- Universal use in innovative solutions – they are used in mass storage devices, electromotive mechanisms, medical equipment, as well as other advanced devices.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Cons

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a strong case, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- Due to limitations in realizing nuts and complicated forms in magnets, we recommend using a housing - magnetic mount.

- Potential hazard to health – tiny shards of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. It is also worth noting that tiny parts of these products can be problematic in diagnostics medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Best holding force of the magnet in ideal parameters – what affects it?

- with the contact of a yoke made of special test steel, guaranteeing maximum field concentration

- with a cross-section of at least 10 mm

- with a plane free of scratches

- under conditions of ideal adhesion (surface-to-surface)

- during pulling in a direction perpendicular to the mounting surface

- at ambient temperature approx. 20 degrees Celsius

Practical lifting capacity: influencing factors

- Distance – the presence of foreign body (paint, dirt, air) interrupts the magnetic circuit, which reduces power steeply (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Chemical composition of the base – mild steel gives the best results. Alloy admixtures reduce magnetic properties and lifting capacity.

- Surface condition – ground elements guarantee perfect abutment, which increases force. Rough surfaces reduce efficiency.

- Heat – neodymium magnets have a sensitivity to temperature. When it is hot they lose power, and in frost they can be stronger (up to a certain limit).

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under parallel forces the load capacity is reduced by as much as 5 times. Moreover, even a small distance between the magnet and the plate lowers the load capacity.

Precautions when working with neodymium magnets

Magnet fragility

Despite the nickel coating, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Electronic hazard

Powerful magnetic fields can corrupt files on payment cards, hard drives, and other magnetic media. Keep a distance of min. 10 cm.

Serious injuries

Danger of trauma: The pulling power is so great that it can cause blood blisters, pinching, and even bone fractures. Use thick gloves.

Pacemakers

Individuals with a ICD have to keep an large gap from magnets. The magnetic field can interfere with the functioning of the implant.

Do not give to children

Neodymium magnets are not suitable for play. Eating a few magnets may result in them connecting inside the digestive tract, which poses a direct threat to life and requires urgent medical intervention.

Sensitization to coating

Studies show that nickel (standard magnet coating) is a common allergen. For allergy sufferers, prevent touching magnets with bare hands or opt for encased magnets.

Flammability

Dust created during cutting of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Maximum temperature

Control the heat. Exposing the magnet above 80 degrees Celsius will destroy its properties and strength.

Safe operation

Handle with care. Rare earth magnets act from a long distance and connect with massive power, often quicker than you can react.

Threat to navigation

A powerful magnetic field interferes with the functioning of magnetometers in smartphones and navigation systems. Do not bring magnets near a device to avoid breaking the sensors.

![SM 25x350 [2xM8] / N52 - magnetic separator SM 25x350 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-geb.jpg)