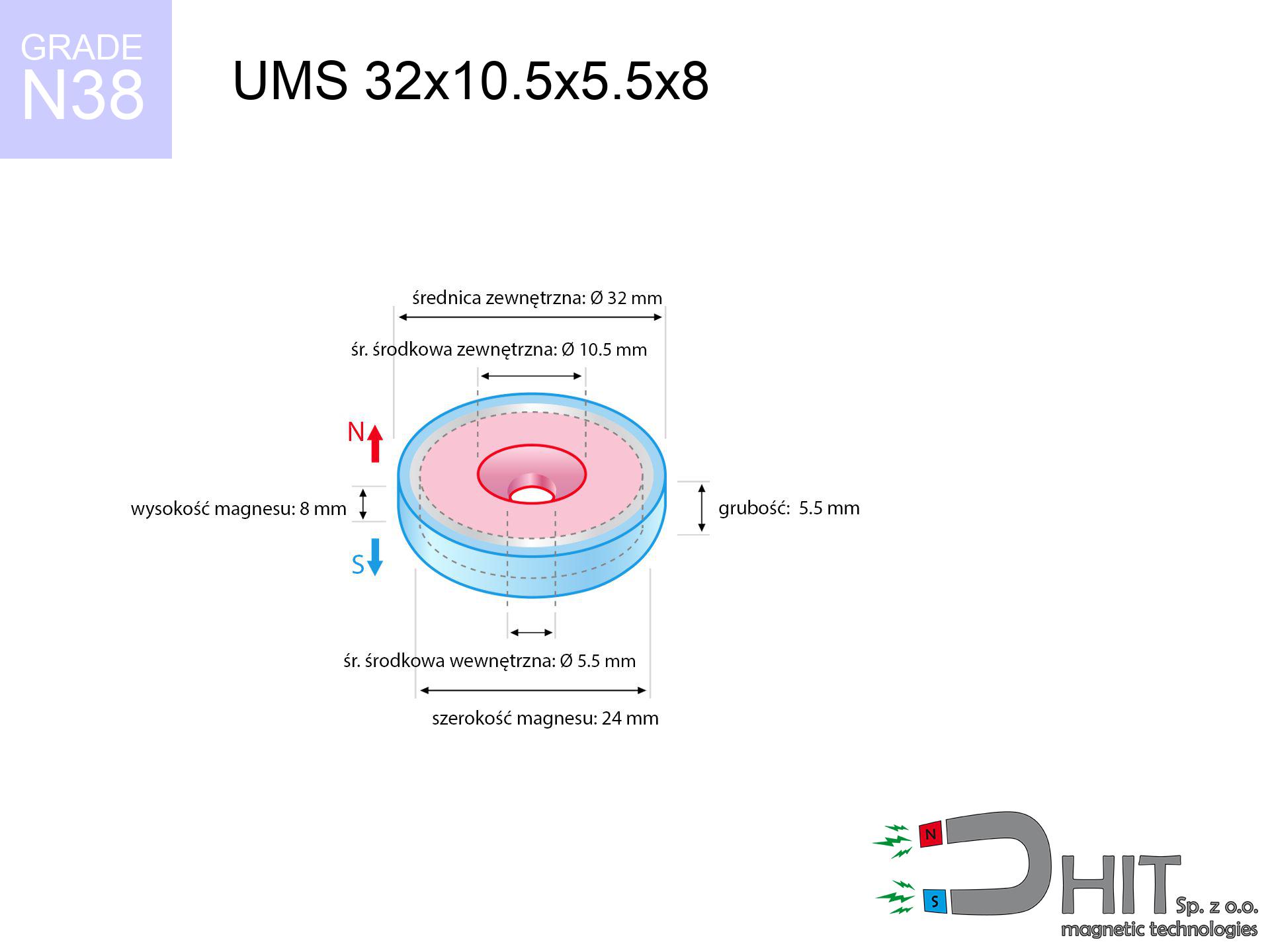

UMS 32x10.5x5.5x8 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220329

GTIN/EAN: 5906301814191

Diameter Ø

32 mm [±1 mm]

cone dimension Ø

10.5x5.5 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

37 g

Magnetization Direction

↑ axial

Load capacity

25.00 kg / 245.17 N

Coating

[NiCuNi] Nickel

12.09 ZŁ with VAT / pcs + price for transport

9.83 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

otherwise get in touch via

request form

the contact form page.

Force as well as structure of a neodymium magnet can be verified with our

power calculator.

Same-day processing for orders placed before 14:00.

Technical specification - UMS 32x10.5x5.5x8 / N38 - conical magnetic holder

Specification / characteristics - UMS 32x10.5x5.5x8 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220329 |

| GTIN/EAN | 5906301814191 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 32 mm [±1 mm] |

| cone dimension Ø | 10.5x5.5 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 37 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 25.00 kg / 245.17 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more proposals

Pros and cons of rare earth magnets.

Advantages

- They do not lose power, even over nearly ten years – the drop in strength is only ~1% (theoretically),

- Neodymium magnets are characterized by exceptionally resistant to demagnetization caused by external magnetic fields,

- In other words, due to the metallic layer of gold, the element looks attractive,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a key feature,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in constructing and the capacity to modify to individual projects,

- Universal use in electronics industry – they are used in hard drives, electric motors, advanced medical instruments, also multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which makes them useful in small systems

Limitations

- At very strong impacts they can break, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation as well as corrosion.

- Due to limitations in creating nuts and complicated forms in magnets, we recommend using casing - magnetic mechanism.

- Potential hazard related to microscopic parts of magnets can be dangerous, if swallowed, which gains importance in the context of child safety. Furthermore, small elements of these products are able to be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Maximum magnetic pulling force – what contributes to it?

- on a plate made of mild steel, effectively closing the magnetic field

- whose thickness reaches at least 10 mm

- with a plane perfectly flat

- under conditions of gap-free contact (metal-to-metal)

- under vertical application of breakaway force (90-degree angle)

- at room temperature

Key elements affecting lifting force

- Distance (betwixt the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to varnish, rust or debris).

- Direction of force – highest force is obtained only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is standardly several times smaller (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the flux to be escaped to the other side.

- Material type – the best choice is high-permeability steel. Cast iron may have worse magnetic properties.

- Surface quality – the smoother and more polished the surface, the better the adhesion and higher the lifting capacity. Roughness acts like micro-gaps.

- Operating temperature – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity was determined with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, however under shearing force the load capacity is reduced by as much as 75%. Moreover, even a minimal clearance between the magnet and the plate lowers the lifting capacity.

Safe handling of neodymium magnets

Fire warning

Mechanical processing of NdFeB material carries a risk of fire risk. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Skin irritation risks

It is widely known that the nickel plating (standard magnet coating) is a common allergen. For allergy sufferers, prevent direct skin contact or choose encased magnets.

Danger to pacemakers

Patients with a pacemaker should maintain an safe separation from magnets. The magnetic field can disrupt the functioning of the life-saving device.

Immense force

Before use, read the rules. Sudden snapping can break the magnet or injure your hand. Be predictive.

Protect data

Powerful magnetic fields can destroy records on credit cards, hard drives, and other magnetic media. Stay away of min. 10 cm.

Bodily injuries

Large magnets can break fingers in a fraction of a second. Never put your hand between two strong magnets.

Impact on smartphones

A powerful magnetic field interferes with the operation of magnetometers in phones and navigation systems. Maintain magnets near a device to avoid breaking the sensors.

Danger to the youngest

These products are not suitable for play. Swallowing a few magnets may result in them pinching intestinal walls, which constitutes a direct threat to life and necessitates urgent medical intervention.

Power loss in heat

Control the heat. Heating the magnet above 80 degrees Celsius will destroy its properties and strength.

Magnet fragility

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. We recommend safety glasses.

![HH 25x7.7 [M5] / N38 - through hole magnetic holder HH 25x7.7 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-25x7.7-m5-pov.jpg)