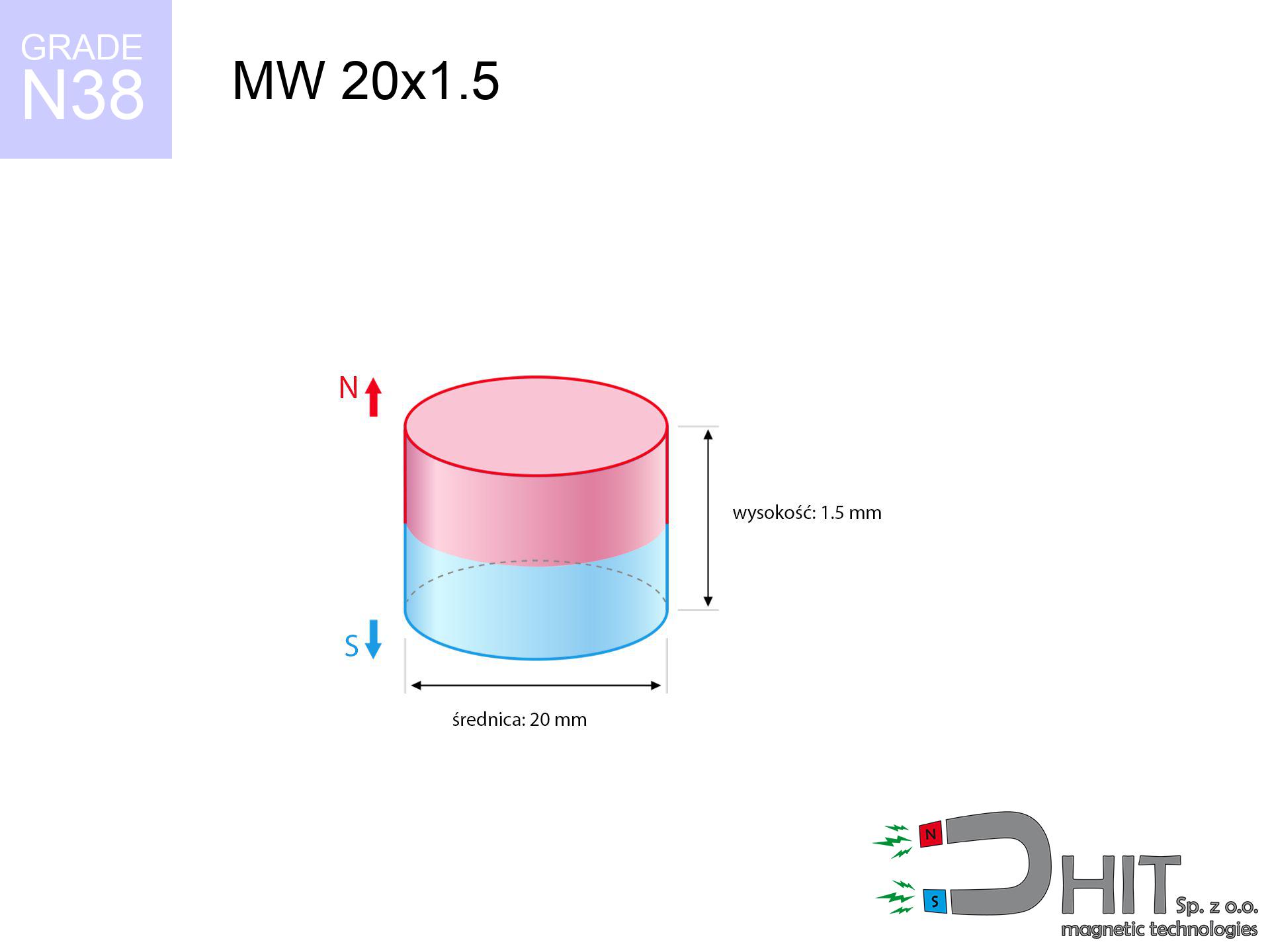

MW 20x1.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010039

GTIN/EAN: 5906301810384

Diameter Ø

20 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

3.53 g

Magnetization Direction

↑ axial

Load capacity

0.97 kg / 9.50 N

Magnetic Induction

91.96 mT / 920 Gs

Coating

[NiCuNi] Nickel

1.574 ZŁ with VAT / pcs + price for transport

1.280 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise contact us by means of

request form

the contact form page.

Parameters and appearance of magnetic components can be reviewed on our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Physical properties - MW 20x1.5 / N38 - cylindrical magnet

Specification / characteristics - MW 20x1.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010039 |

| GTIN/EAN | 5906301810384 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 3.53 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.97 kg / 9.50 N |

| Magnetic Induction ~ ? | 91.96 mT / 920 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - data

Presented information represent the outcome of a engineering simulation. Results rely on algorithms for the class Nd2Fe14B. Operational conditions may deviate from the simulation results. Please consider these calculations as a reference point when designing systems.

Table 1: Static pull force (force vs gap) - power drop

MW 20x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

920 Gs

92.0 mT

|

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

weak grip |

| 1 mm |

887 Gs

88.7 mT

|

0.90 kg / 1.99 LBS

902.2 g / 8.9 N

|

weak grip |

| 2 mm |

832 Gs

83.2 mT

|

0.79 kg / 1.75 LBS

794.6 g / 7.8 N

|

weak grip |

| 3 mm |

763 Gs

76.3 mT

|

0.67 kg / 1.47 LBS

667.4 g / 6.5 N

|

weak grip |

| 5 mm |

606 Gs

60.6 mT

|

0.42 kg / 0.93 LBS

421.6 g / 4.1 N

|

weak grip |

| 10 mm |

294 Gs

29.4 mT

|

0.10 kg / 0.22 LBS

99.5 g / 1.0 N

|

weak grip |

| 15 mm |

144 Gs

14.4 mT

|

0.02 kg / 0.05 LBS

23.6 g / 0.2 N

|

weak grip |

| 20 mm |

76 Gs

7.6 mT

|

0.01 kg / 0.01 LBS

6.7 g / 0.1 N

|

weak grip |

| 30 mm |

28 Gs

2.8 mT

|

0.00 kg / 0.00 LBS

0.9 g / 0.0 N

|

weak grip |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

Table 2: Sliding load (vertical surface)

MW 20x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.19 kg / 0.43 LBS

194.0 g / 1.9 N

|

| 1 mm | Stal (~0.2) |

0.18 kg / 0.40 LBS

180.0 g / 1.8 N

|

| 2 mm | Stal (~0.2) |

0.16 kg / 0.35 LBS

158.0 g / 1.5 N

|

| 3 mm | Stal (~0.2) |

0.13 kg / 0.30 LBS

134.0 g / 1.3 N

|

| 5 mm | Stal (~0.2) |

0.08 kg / 0.19 LBS

84.0 g / 0.8 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

20.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 20x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.29 kg / 0.64 LBS

291.0 g / 2.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.19 kg / 0.43 LBS

194.0 g / 1.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.10 kg / 0.21 LBS

97.0 g / 1.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.49 kg / 1.07 LBS

485.0 g / 4.8 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 20x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.10 kg / 0.21 LBS

97.0 g / 1.0 N

|

| 1 mm |

|

0.24 kg / 0.53 LBS

242.5 g / 2.4 N

|

| 2 mm |

|

0.49 kg / 1.07 LBS

485.0 g / 4.8 N

|

| 3 mm |

|

0.73 kg / 1.60 LBS

727.5 g / 7.1 N

|

| 5 mm |

|

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

| 10 mm |

|

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

| 11 mm |

|

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

| 12 mm |

|

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

Table 5: Thermal resistance (stability) - thermal limit

MW 20x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

OK |

| 40 °C | -2.2% |

0.95 kg / 2.09 LBS

948.7 g / 9.3 N

|

OK |

| 60 °C | -4.4% |

0.93 kg / 2.04 LBS

927.3 g / 9.1 N

|

|

| 80 °C | -6.6% |

0.91 kg / 2.00 LBS

906.0 g / 8.9 N

|

|

| 100 °C | -28.8% |

0.69 kg / 1.52 LBS

690.6 g / 6.8 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MW 20x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.64 kg / 3.61 LBS

1 781 Gs

|

0.25 kg / 0.54 LBS

246 g / 2.4 N

|

N/A |

| 1 mm |

1.59 kg / 3.51 LBS

1 813 Gs

|

0.24 kg / 0.53 LBS

239 g / 2.3 N

|

1.43 kg / 3.16 LBS

~0 Gs

|

| 2 mm |

1.52 kg / 3.36 LBS

1 774 Gs

|

0.23 kg / 0.50 LBS

228 g / 2.2 N

|

1.37 kg / 3.02 LBS

~0 Gs

|

| 3 mm |

1.44 kg / 3.17 LBS

1 724 Gs

|

0.22 kg / 0.48 LBS

216 g / 2.1 N

|

1.29 kg / 2.85 LBS

~0 Gs

|

| 5 mm |

1.24 kg / 2.73 LBS

1 598 Gs

|

0.19 kg / 0.41 LBS

185 g / 1.8 N

|

1.11 kg / 2.45 LBS

~0 Gs

|

| 10 mm |

0.71 kg / 1.57 LBS

1 212 Gs

|

0.11 kg / 0.24 LBS

107 g / 1.0 N

|

0.64 kg / 1.41 LBS

~0 Gs

|

| 20 mm |

0.17 kg / 0.37 LBS

589 Gs

|

0.03 kg / 0.06 LBS

25 g / 0.2 N

|

0.15 kg / 0.33 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

88 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

55 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

36 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

25 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

18 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

13 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 20x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 20x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.76 km/h

(4.93 m/s)

|

0.04 J | |

| 30 mm |

28.97 km/h

(8.05 m/s)

|

0.11 J | |

| 50 mm |

37.38 km/h

(10.38 m/s)

|

0.19 J | |

| 100 mm |

52.87 km/h

(14.69 m/s)

|

0.38 J |

Table 9: Corrosion resistance

MW 20x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 20x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 979 Mx | 39.8 µWb |

| Pc Coefficient | 0.12 | Low (Flat) |

Table 11: Submerged application

MW 20x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.97 kg | Standard |

| Water (riverbed) |

1.11 kg

(+0.14 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds merely approx. 20-30% of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) severely limits the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.12

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of rare earth magnets.

Advantages

- They retain attractive force for around 10 years – the drop is just ~1% (in theory),

- They are resistant to demagnetization induced by presence of other magnetic fields,

- The use of an shiny coating of noble metals (nickel, gold, silver) causes the element to look better,

- Neodymium magnets achieve maximum magnetic induction on a contact point, which allows for strong attraction,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- In view of the possibility of free forming and adaptation to unique projects, NdFeB magnets can be created in a variety of geometric configurations, which expands the range of possible applications,

- Huge importance in future technologies – they are utilized in data components, electric drive systems, medical devices, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which makes them useful in small systems

Limitations

- At very strong impacts they can break, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets lose power when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They oxidize in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing threads and complex shapes in magnets, we recommend using cover - magnetic holder.

- Potential hazard to health – tiny shards of magnets pose a threat, in case of ingestion, which is particularly important in the context of child health protection. Furthermore, small components of these devices can disrupt the diagnostic process medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- on a plate made of structural steel, optimally conducting the magnetic flux

- possessing a thickness of min. 10 mm to ensure full flux closure

- characterized by lack of roughness

- without the slightest insulating layer between the magnet and steel

- under axial force vector (90-degree angle)

- at temperature room level

Key elements affecting lifting force

- Distance (between the magnet and the metal), because even a very small clearance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Loading method – catalog parameter refers to detachment vertically. When attempting to slide, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Material type – the best choice is high-permeability steel. Hardened steels may attract less.

- Surface finish – full contact is possible only on smooth steel. Rough texture reduce the real contact area, weakening the magnet.

- Temperature – temperature increase causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under vertically applied force, however under parallel forces the holding force is lower. Moreover, even a small distance between the magnet and the plate lowers the holding force.

Precautions when working with NdFeB magnets

Magnetic interference

A powerful magnetic field negatively affects the operation of magnetometers in smartphones and GPS navigation. Keep magnets close to a device to avoid breaking the sensors.

Safe distance

Do not bring magnets near a purse, computer, or TV. The magnetism can permanently damage these devices and erase data from cards.

Do not give to children

Always store magnets away from children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are tragic.

Heat warning

Avoid heat. Neodymium magnets are sensitive to heat. If you require operation above 80°C, inquire about HT versions (H, SH, UH).

Combustion hazard

Combustion risk: Rare earth powder is explosive. Do not process magnets in home conditions as this risks ignition.

Metal Allergy

A percentage of the population experience a hypersensitivity to nickel, which is the standard coating for NdFeB magnets. Prolonged contact can result in dermatitis. We recommend use protective gloves.

Eye protection

NdFeB magnets are ceramic materials, meaning they are prone to chipping. Impact of two magnets will cause them shattering into small pieces.

Respect the power

Be careful. Rare earth magnets attract from a long distance and connect with huge force, often quicker than you can move away.

Pinching danger

Big blocks can smash fingers in a fraction of a second. Never put your hand between two strong magnets.

Danger to pacemakers

Medical warning: Neodymium magnets can turn off pacemakers and defibrillators. Stay away if you have medical devices.