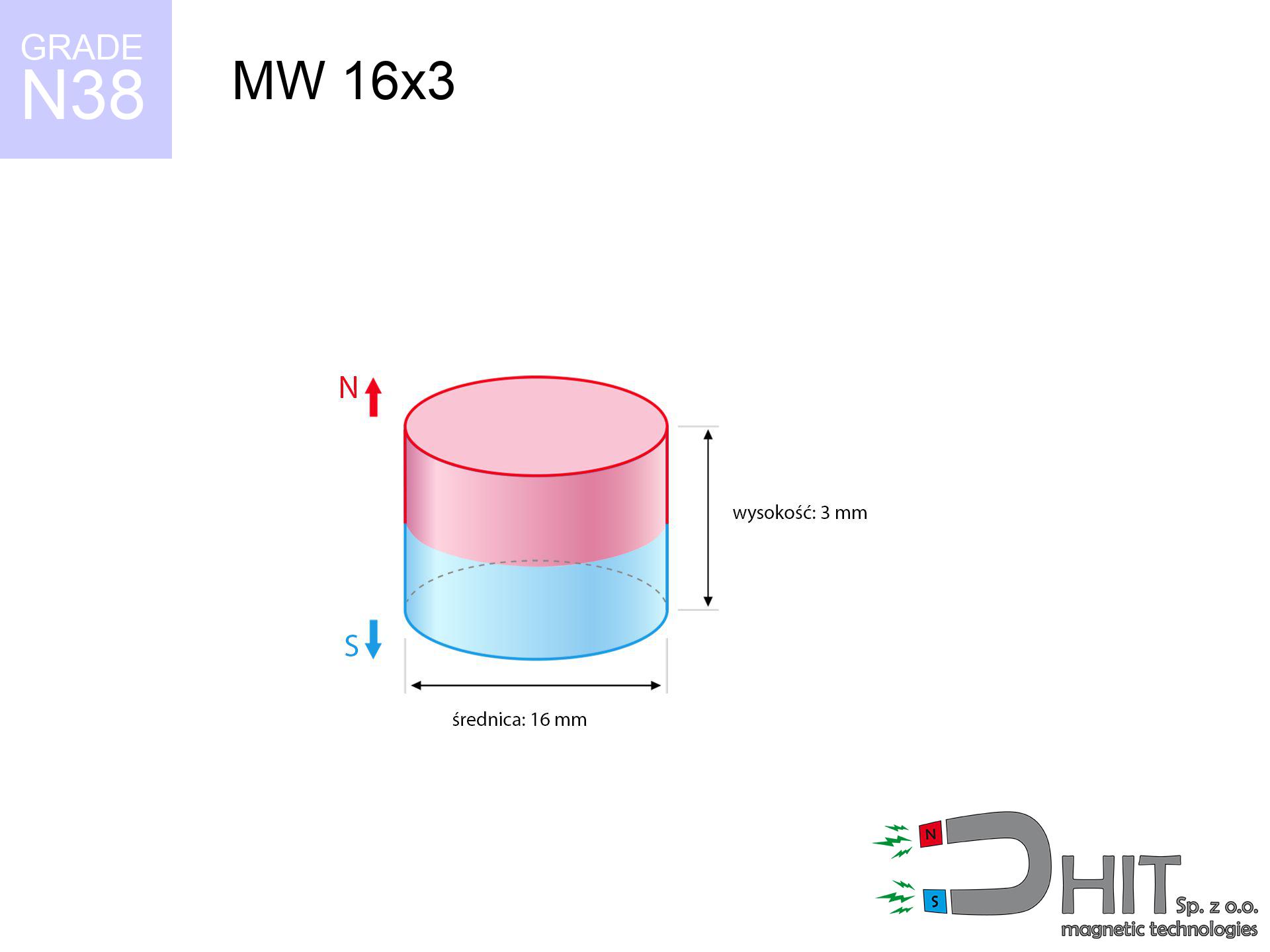

MW 16x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010033

GTIN/EAN: 5906301810322

Diameter Ø

16 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

4.52 g

Magnetization Direction

↑ axial

Load capacity

2.97 kg / 29.11 N

Magnetic Induction

217.61 mT / 2176 Gs

Coating

[NiCuNi] Nickel

1.734 ZŁ with VAT / pcs + price for transport

1.410 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

if you prefer get in touch through

contact form

the contact page.

Parameters along with form of magnets can be tested on our

power calculator.

Same-day processing for orders placed before 14:00.

Technical specification - MW 16x3 / N38 - cylindrical magnet

Specification / characteristics - MW 16x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010033 |

| GTIN/EAN | 5906301810322 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 16 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 4.52 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.97 kg / 29.11 N |

| Magnetic Induction ~ ? | 217.61 mT / 2176 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - report

These values are the outcome of a mathematical simulation. Results were calculated on models for the class Nd2Fe14B. Real-world conditions might slightly differ from theoretical values. Treat these calculations as a reference point when designing systems.

Table 1: Static pull force (pull vs distance) - interaction chart

MW 16x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2176 Gs

217.6 mT

|

2.97 kg / 6.55 LBS

2970.0 g / 29.1 N

|

warning |

| 1 mm |

2004 Gs

200.4 mT

|

2.52 kg / 5.55 LBS

2519.3 g / 24.7 N

|

warning |

| 2 mm |

1782 Gs

178.2 mT

|

1.99 kg / 4.39 LBS

1993.2 g / 19.6 N

|

weak grip |

| 3 mm |

1543 Gs

154.3 mT

|

1.49 kg / 3.29 LBS

1494.0 g / 14.7 N

|

weak grip |

| 5 mm |

1098 Gs

109.8 mT

|

0.76 kg / 1.67 LBS

756.6 g / 7.4 N

|

weak grip |

| 10 mm |

439 Gs

43.9 mT

|

0.12 kg / 0.27 LBS

120.9 g / 1.2 N

|

weak grip |

| 15 mm |

195 Gs

19.5 mT

|

0.02 kg / 0.05 LBS

23.9 g / 0.2 N

|

weak grip |

| 20 mm |

99 Gs

9.9 mT

|

0.01 kg / 0.01 LBS

6.2 g / 0.1 N

|

weak grip |

| 30 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 LBS

0.8 g / 0.0 N

|

weak grip |

| 50 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Shear load (wall)

MW 16x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.59 kg / 1.31 LBS

594.0 g / 5.8 N

|

| 1 mm | Stal (~0.2) |

0.50 kg / 1.11 LBS

504.0 g / 4.9 N

|

| 2 mm | Stal (~0.2) |

0.40 kg / 0.88 LBS

398.0 g / 3.9 N

|

| 3 mm | Stal (~0.2) |

0.30 kg / 0.66 LBS

298.0 g / 2.9 N

|

| 5 mm | Stal (~0.2) |

0.15 kg / 0.34 LBS

152.0 g / 1.5 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

24.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 16x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.89 kg / 1.96 LBS

891.0 g / 8.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.59 kg / 1.31 LBS

594.0 g / 5.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.30 kg / 0.65 LBS

297.0 g / 2.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.49 kg / 3.27 LBS

1485.0 g / 14.6 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 16x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.30 kg / 0.65 LBS

297.0 g / 2.9 N

|

| 1 mm |

|

0.74 kg / 1.64 LBS

742.5 g / 7.3 N

|

| 2 mm |

|

1.49 kg / 3.27 LBS

1485.0 g / 14.6 N

|

| 3 mm |

|

2.23 kg / 4.91 LBS

2227.5 g / 21.9 N

|

| 5 mm |

|

2.97 kg / 6.55 LBS

2970.0 g / 29.1 N

|

| 10 mm |

|

2.97 kg / 6.55 LBS

2970.0 g / 29.1 N

|

| 11 mm |

|

2.97 kg / 6.55 LBS

2970.0 g / 29.1 N

|

| 12 mm |

|

2.97 kg / 6.55 LBS

2970.0 g / 29.1 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 16x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.97 kg / 6.55 LBS

2970.0 g / 29.1 N

|

OK |

| 40 °C | -2.2% |

2.90 kg / 6.40 LBS

2904.7 g / 28.5 N

|

OK |

| 60 °C | -4.4% |

2.84 kg / 6.26 LBS

2839.3 g / 27.9 N

|

|

| 80 °C | -6.6% |

2.77 kg / 6.12 LBS

2774.0 g / 27.2 N

|

|

| 100 °C | -28.8% |

2.11 kg / 4.66 LBS

2114.6 g / 20.7 N

|

Table 6: Two magnets (attraction) - field collision

MW 16x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.87 kg / 12.93 LBS

3 716 Gs

|

0.88 kg / 1.94 LBS

880 g / 8.6 N

|

N/A |

| 1 mm |

5.46 kg / 12.03 LBS

4 197 Gs

|

0.82 kg / 1.80 LBS

819 g / 8.0 N

|

4.91 kg / 10.83 LBS

~0 Gs

|

| 2 mm |

4.98 kg / 10.97 LBS

4 007 Gs

|

0.75 kg / 1.65 LBS

746 g / 7.3 N

|

4.48 kg / 9.87 LBS

~0 Gs

|

| 3 mm |

4.46 kg / 9.83 LBS

3 794 Gs

|

0.67 kg / 1.48 LBS

669 g / 6.6 N

|

4.01 kg / 8.85 LBS

~0 Gs

|

| 5 mm |

3.43 kg / 7.56 LBS

3 326 Gs

|

0.51 kg / 1.13 LBS

514 g / 5.0 N

|

3.09 kg / 6.80 LBS

~0 Gs

|

| 10 mm |

1.49 kg / 3.30 LBS

2 196 Gs

|

0.22 kg / 0.49 LBS

224 g / 2.2 N

|

1.35 kg / 2.97 LBS

~0 Gs

|

| 20 mm |

0.24 kg / 0.53 LBS

878 Gs

|

0.04 kg / 0.08 LBS

36 g / 0.4 N

|

0.21 kg / 0.47 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

113 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

70 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

46 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

32 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

23 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

17 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 16x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 16x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.50 km/h

(7.36 m/s)

|

0.12 J | |

| 30 mm |

44.78 km/h

(12.44 m/s)

|

0.35 J | |

| 50 mm |

57.81 km/h

(16.06 m/s)

|

0.58 J | |

| 100 mm |

81.75 km/h

(22.71 m/s)

|

1.17 J |

Table 9: Coating parameters (durability)

MW 16x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 16x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 141 Mx | 51.4 µWb |

| Pc Coefficient | 0.27 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 16x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.97 kg | Standard |

| Water (riverbed) |

3.40 kg

(+0.43 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds just ~20% of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.27

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more products

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (in laboratory conditions),

- Neodymium magnets remain exceptionally resistant to demagnetization caused by external field sources,

- By covering with a reflective layer of gold, the element has an aesthetic look,

- Neodymium magnets achieve maximum magnetic induction on a their surface, which ensures high operational effectiveness,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to freedom in forming and the capacity to customize to unusual requirements,

- Significant place in future technologies – they are used in hard drives, motor assemblies, diagnostic systems, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which enables their usage in compact constructions

Disadvantages

- To avoid cracks upon strong impacts, we recommend using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in producing nuts and complicated shapes in magnets, we propose using casing - magnetic holder.

- Potential hazard to health – tiny shards of magnets pose a threat, if swallowed, which is particularly important in the context of child health protection. Furthermore, small components of these products can disrupt the diagnostic process medical when they are in the body.

- With budget limitations the cost of neodymium magnets is economically unviable,

Holding force characteristics

Best holding force of the magnet in ideal parameters – what affects it?

- using a plate made of low-carbon steel, functioning as a circuit closing element

- whose transverse dimension is min. 10 mm

- with a surface cleaned and smooth

- without the slightest air gap between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- in stable room temperature

Practical lifting capacity: influencing factors

- Clearance – the presence of any layer (paint, dirt, air) interrupts the magnetic circuit, which reduces power rapidly (even by 50% at 0.5 mm).

- Direction of force – highest force is available only during pulling at a 90° angle. The shear force of the magnet along the surface is usually several times smaller (approx. 1/5 of the lifting capacity).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet limits the attraction force (the magnet "punches through" it).

- Steel grade – ideal substrate is high-permeability steel. Stainless steels may have worse magnetic properties.

- Surface condition – ground elements guarantee perfect abutment, which increases field saturation. Uneven metal weaken the grip.

- Temperature influence – hot environment weakens magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity testing was performed on a smooth plate of optimal thickness, under a perpendicular pulling force, in contrast under shearing force the holding force is lower. Additionally, even a small distance between the magnet’s surface and the plate reduces the lifting capacity.

Safe handling of NdFeB magnets

Demagnetization risk

Regular neodymium magnets (grade N) undergo demagnetization when the temperature exceeds 80°C. Damage is permanent.

Danger to pacemakers

People with a pacemaker must maintain an large gap from magnets. The magnetic field can disrupt the functioning of the life-saving device.

Magnet fragility

Neodymium magnets are ceramic materials, which means they are fragile like glass. Impact of two magnets leads to them breaking into shards.

Respect the power

Handle with care. Neodymium magnets act from a long distance and connect with huge force, often faster than you can move away.

Swallowing risk

Strictly keep magnets away from children. Risk of swallowing is significant, and the consequences of magnets clamping inside the body are fatal.

Finger safety

Mind your fingers. Two powerful magnets will snap together instantly with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Cards and drives

Avoid bringing magnets close to a purse, laptop, or TV. The magnetic field can irreversibly ruin these devices and erase data from cards.

Nickel coating and allergies

Certain individuals have a sensitization to Ni, which is the common plating for NdFeB magnets. Prolonged contact can result in a rash. We suggest wear protective gloves.

Mechanical processing

Drilling and cutting of neodymium magnets carries a risk of fire risk. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Precision electronics

A powerful magnetic field interferes with the operation of magnetometers in smartphones and GPS navigation. Maintain magnets near a device to prevent breaking the sensors.