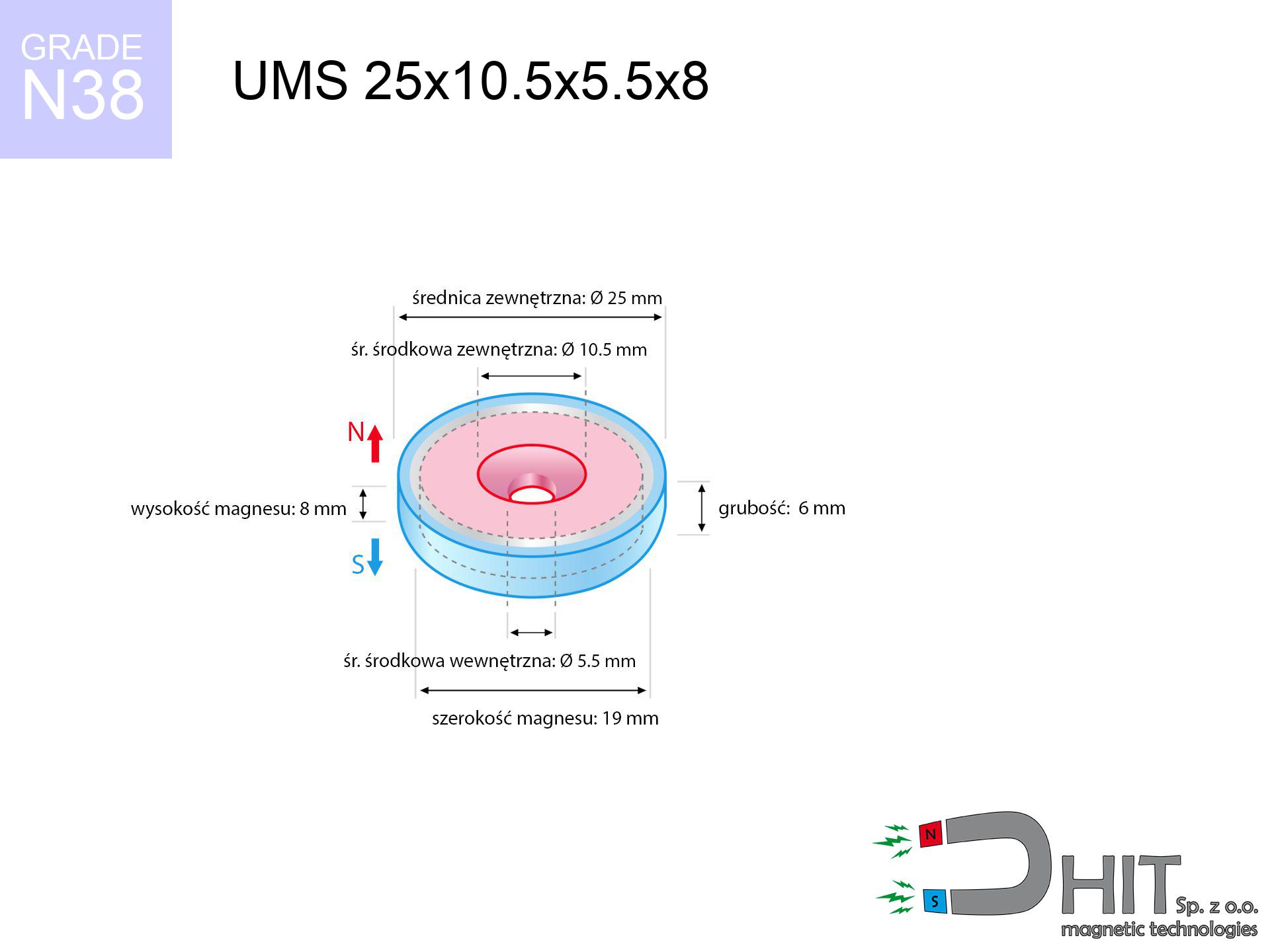

UMS 25x10.5x5.5x8 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220328

GTIN/EAN: 5906301814184

Diameter Ø

25 mm [±1 mm]

cone dimension Ø

10.5x5.5 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

21 g

Magnetization Direction

↑ axial

Load capacity

14.00 kg / 137.29 N

Coating

[NiCuNi] Nickel

9.72 ZŁ with VAT / pcs + price for transport

7.90 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer let us know using

our online form

through our site.

Specifications as well as form of magnetic components can be reviewed on our

magnetic mass calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - UMS 25x10.5x5.5x8 / N38 - conical magnetic holder

Specification / characteristics - UMS 25x10.5x5.5x8 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220328 |

| GTIN/EAN | 5906301814184 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 25 mm [±1 mm] |

| cone dimension Ø | 10.5x5.5 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 21 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 14.00 kg / 137.29 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Strengths and weaknesses of neodymium magnets.

Benefits

- Their power remains stable, and after around 10 years it decreases only by ~1% (according to research),

- They show high resistance to demagnetization induced by external field influence,

- In other words, due to the reflective layer of gold, the element is aesthetically pleasing,

- The surface of neodymium magnets generates a powerful magnetic field – this is a distinguishing feature,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Thanks to freedom in forming and the capacity to modify to unusual requirements,

- Universal use in electronics industry – they serve a role in data components, electric drive systems, medical equipment, as well as technologically advanced constructions.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Disadvantages

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation and corrosion.

- Due to limitations in realizing threads and complex forms in magnets, we recommend using casing - magnetic holder.

- Potential hazard resulting from small fragments of magnets are risky, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, small elements of these products are able to complicate diagnosis medical when they are in the body.

- With large orders the cost of neodymium magnets is a challenge,

Pull force analysis

Magnetic strength at its maximum – what contributes to it?

- using a plate made of high-permeability steel, serving as a ideal flux conductor

- whose thickness is min. 10 mm

- with an ground contact surface

- without the slightest clearance between the magnet and steel

- for force acting at a right angle (in the magnet axis)

- in temp. approx. 20°C

Determinants of practical lifting force of a magnet

- Gap (betwixt the magnet and the plate), since even a very small distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to paint, rust or dirt).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Metal type – not every steel attracts identically. Alloy additives weaken the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which improves force. Uneven metal reduce efficiency.

- Operating temperature – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity testing was performed on a smooth plate of optimal thickness, under a perpendicular pulling force, however under attempts to slide the magnet the holding force is lower. Additionally, even a slight gap between the magnet and the plate reduces the holding force.

Warnings

Choking Hazard

These products are not suitable for play. Swallowing multiple magnets may result in them attracting across intestines, which poses a severe health hazard and necessitates urgent medical intervention.

Fire warning

Powder created during machining of magnets is flammable. Avoid drilling into magnets unless you are an expert.

Allergic reactions

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If an allergic reaction appears, cease working with magnets and wear gloves.

Operating temperature

Monitor thermal conditions. Heating the magnet to high heat will destroy its properties and strength.

Precision electronics

Navigation devices and smartphones are highly susceptible to magnetism. Direct contact with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Protect data

Equipment safety: Strong magnets can damage payment cards and delicate electronics (heart implants, hearing aids, timepieces).

Bodily injuries

Big blocks can break fingers instantly. Do not place your hand between two strong magnets.

Do not underestimate power

Before starting, read the rules. Sudden snapping can destroy the magnet or hurt your hand. Be predictive.

Material brittleness

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Clashing of two magnets leads to them breaking into shards.

Medical interference

Life threat: Strong magnets can turn off pacemakers and defibrillators. Do not approach if you have electronic implants.

![AM ucho [M12] - magnetic accessories AM ucho [M12] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m12-maz.jpg)

![SM 25x375 [2xM8] / N42 - magnetic separator SM 25x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-feg.jpg)