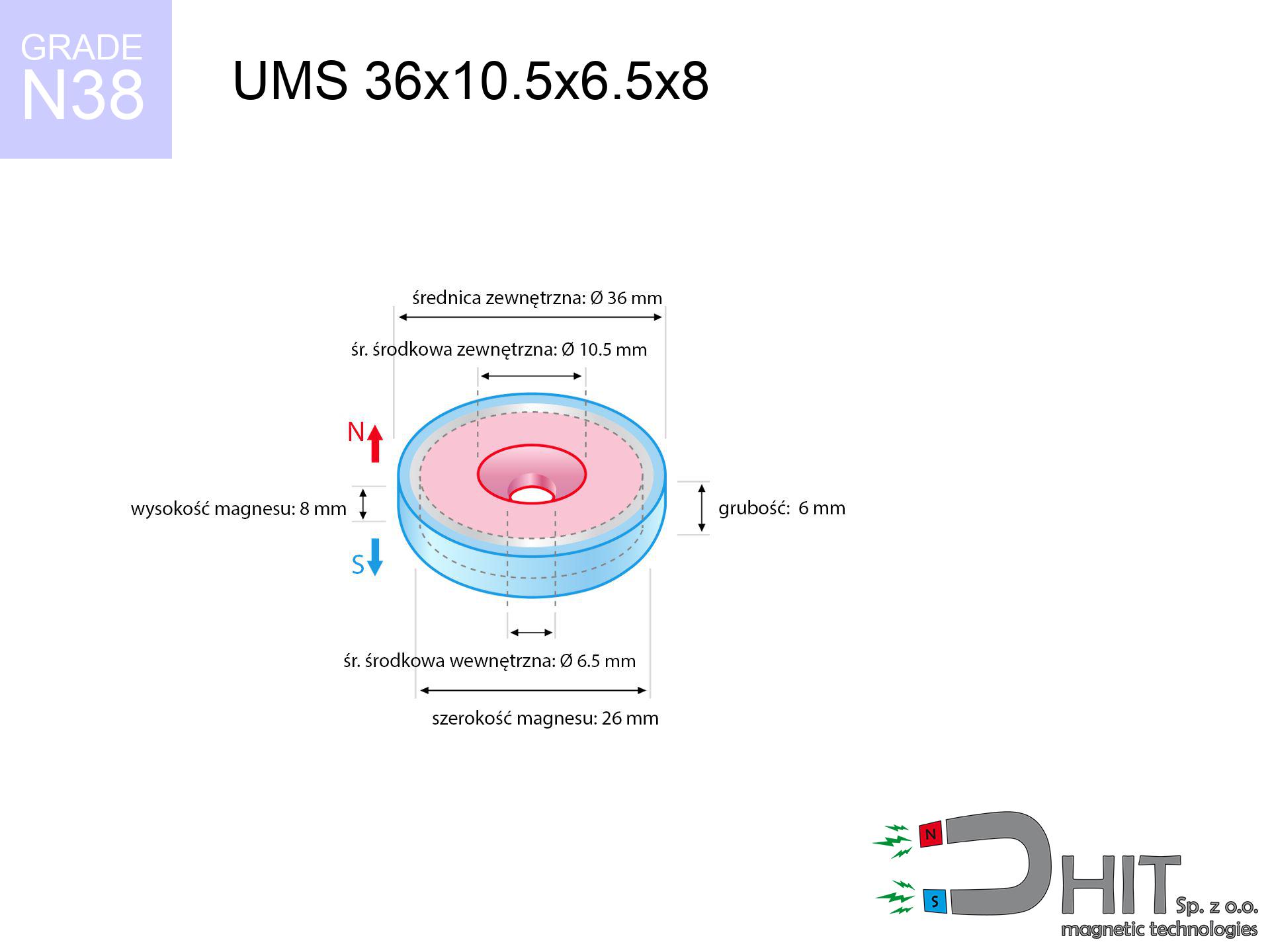

UMS 36x10.5x6.5x8 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220330

GTIN/EAN: 5906301814207

Diameter Ø

36 mm [±1 mm]

cone dimension Ø

10.5x6.5 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

45 g

Magnetization Direction

↑ axial

Load capacity

29.00 kg / 284.39 N

Coating

[NiCuNi] Nickel

22.94 ZŁ with VAT / pcs + price for transport

18.65 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

alternatively contact us via

request form

our website.

Specifications and appearance of a neodymium magnet can be analyzed on our

magnetic mass calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - UMS 36x10.5x6.5x8 / N38 - conical magnetic holder

Specification / characteristics - UMS 36x10.5x6.5x8 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220330 |

| GTIN/EAN | 5906301814207 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 36 mm [±1 mm] |

| cone dimension Ø | 10.5x6.5 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 45 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 29.00 kg / 284.39 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros and cons of Nd2Fe14B magnets.

Benefits

- They virtually do not lose power, because even after ten years the decline in efficiency is only ~1% (according to literature),

- They maintain their magnetic properties even under external field action,

- A magnet with a metallic gold surface has an effective appearance,

- Neodymium magnets deliver maximum magnetic induction on a their surface, which allows for strong attraction,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to versatility in shaping and the capacity to customize to client solutions,

- Key role in modern industrial fields – they find application in magnetic memories, electric motors, diagnostic systems, as well as other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in compact constructions

Cons

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of producing threads in the magnet and complex forms - recommended is casing - mounting mechanism.

- Potential hazard related to microscopic parts of magnets pose a threat, if swallowed, which becomes key in the aspect of protecting the youngest. It is also worth noting that small components of these products can complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Highest magnetic holding force – what it depends on?

- using a plate made of low-carbon steel, serving as a magnetic yoke

- whose thickness reaches at least 10 mm

- characterized by even structure

- with direct contact (no paint)

- during detachment in a direction perpendicular to the mounting surface

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Gap (betwixt the magnet and the plate), because even a tiny clearance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Force direction – catalog parameter refers to pulling vertically. When slipping, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Plate material – low-carbon steel attracts best. Alloy admixtures lower magnetic permeability and holding force.

- Surface structure – the smoother and more polished the surface, the larger the contact zone and higher the lifting capacity. Unevenness creates an air distance.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under attempts to slide the magnet the holding force is lower. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Warnings

Product not for children

Always keep magnets away from children. Risk of swallowing is high, and the effects of magnets clamping inside the body are life-threatening.

Pinching danger

Mind your fingers. Two powerful magnets will join instantly with a force of several hundred kilograms, destroying anything in their path. Exercise extreme caution!

Respect the power

Before starting, check safety instructions. Sudden snapping can break the magnet or hurt your hand. Think ahead.

ICD Warning

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have electronic implants.

Allergy Warning

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If redness occurs, immediately stop handling magnets and use protective gear.

Beware of splinters

Despite metallic appearance, the material is delicate and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

GPS Danger

Navigation devices and smartphones are highly susceptible to magnetism. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Fire warning

Drilling and cutting of NdFeB material poses a fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Keep away from computers

Do not bring magnets near a wallet, computer, or TV. The magnetism can permanently damage these devices and erase data from cards.

Do not overheat magnets

Keep cool. NdFeB magnets are susceptible to heat. If you require operation above 80°C, look for special high-temperature series (H, SH, UH).

![UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-60x30x15-m10-gz-bas.jpg)