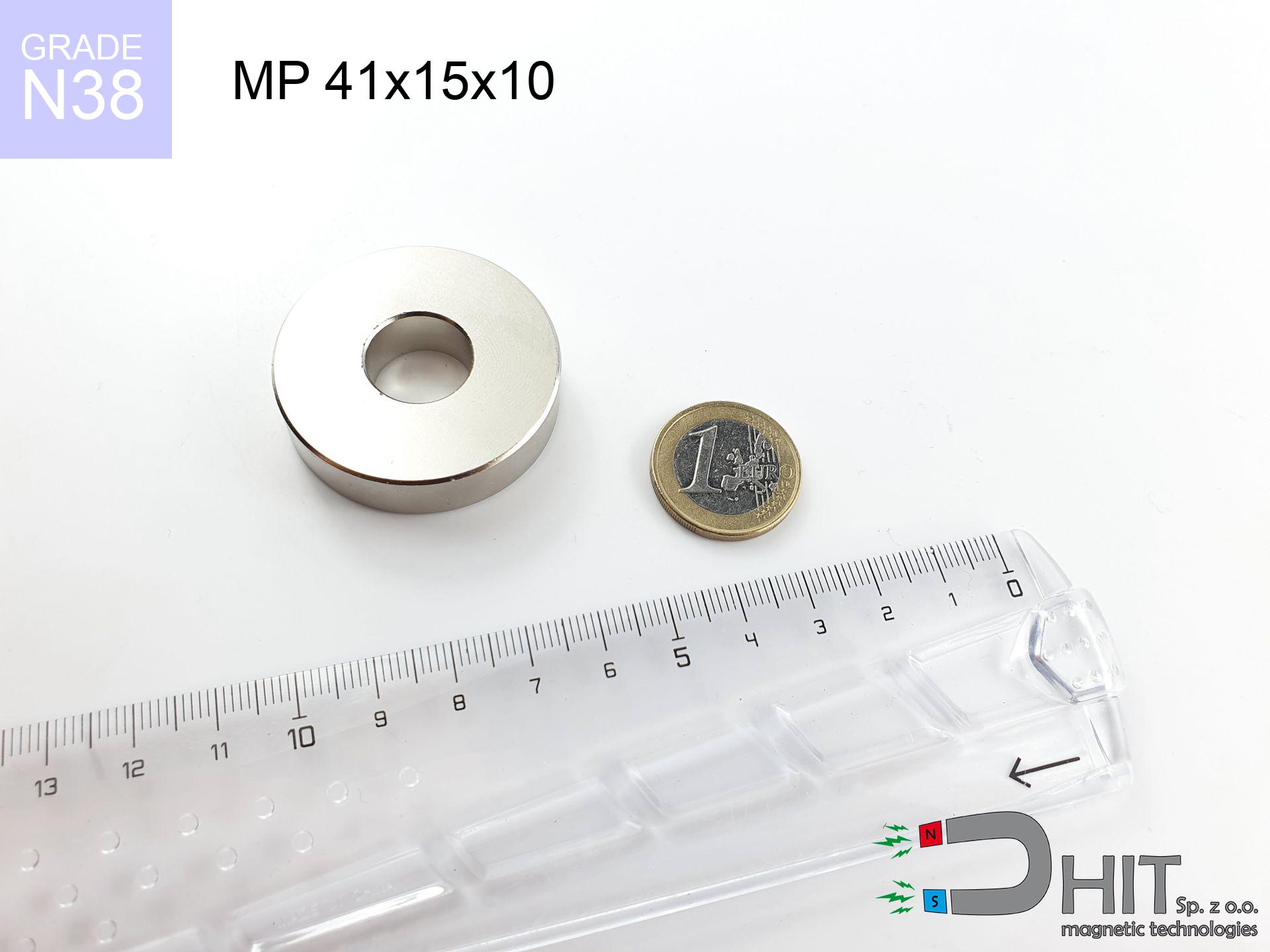

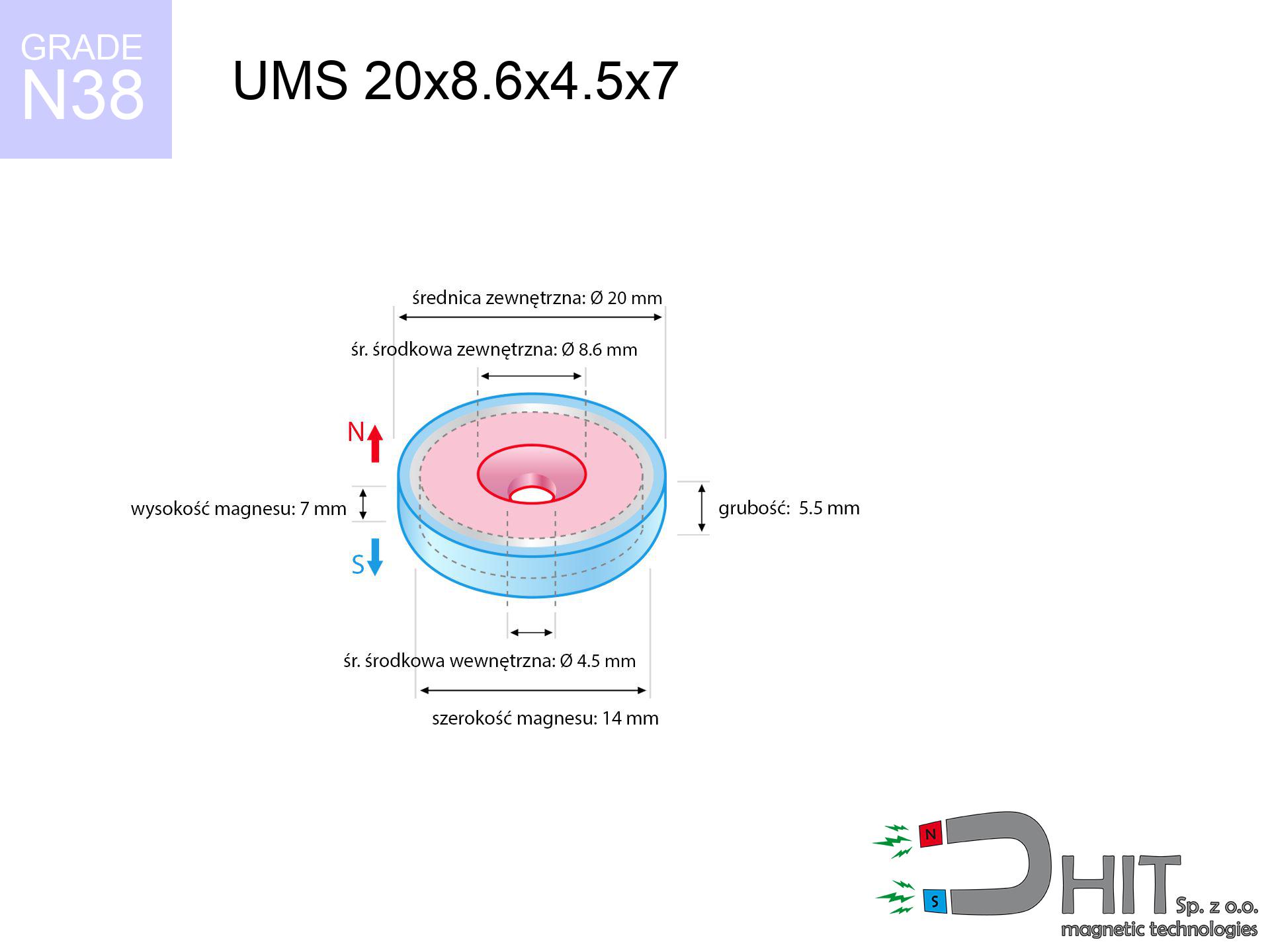

UMS 20x8.6x4.5x7 / N38 - conical magnetic holder

conical magnetic holder

Catalog no 220327

GTIN/EAN: 5906301814177

Diameter Ø

20 mm [±1 mm]

cone dimension Ø

8.6x4.5 mm [±1 mm]

Height

7 mm [±1 mm]

Weight

12 g

Magnetization Direction

↑ axial

Load capacity

6.00 kg / 58.84 N

Coating

[NiCuNi] Nickel

6.46 ZŁ with VAT / pcs + price for transport

5.25 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise let us know by means of

contact form

through our site.

Lifting power and shape of neodymium magnets can be verified on our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical of the product - UMS 20x8.6x4.5x7 / N38 - conical magnetic holder

Specification / characteristics - UMS 20x8.6x4.5x7 / N38 - conical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 220327 |

| GTIN/EAN | 5906301814177 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±1 mm] |

| cone dimension Ø | 8.6x4.5 mm [±1 mm] |

| Height | 7 mm [±1 mm] |

| Weight | 12 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.00 kg / 58.84 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Strengths

- They have constant strength, and over more than ten years their attraction force decreases symbolically – ~1% (in testing),

- They are noted for resistance to demagnetization induced by external magnetic fields,

- Thanks to the reflective finish, the layer of Ni-Cu-Ni, gold-plated, or silver-plated gives an aesthetic appearance,

- Neodymium magnets ensure maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, enabling functioning at temperatures approaching 230°C and above...

- Thanks to freedom in designing and the ability to modify to specific needs,

- Key role in modern technologies – they are commonly used in computer drives, electric drive systems, medical equipment, as well as industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which enables their usage in miniature devices

Weaknesses

- At strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in producing threads and complex shapes in magnets, we recommend using casing - magnetic mount.

- Health risk resulting from small fragments of magnets can be dangerous, if swallowed, which is particularly important in the context of child safety. Additionally, small components of these magnets are able to complicate diagnosis medical after entering the body.

- Due to complex production process, their price is higher than average,

Lifting parameters

Maximum lifting force for a neodymium magnet – what affects it?

- with the application of a yoke made of low-carbon steel, guaranteeing maximum field concentration

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an ground touching surface

- with direct contact (without impurities)

- during pulling in a direction vertical to the mounting surface

- in neutral thermal conditions

Determinants of lifting force in real conditions

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Chemical composition of the base – low-carbon steel gives the best results. Higher carbon content reduce magnetic permeability and lifting capacity.

- Surface finish – full contact is obtained only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – temperature increase causes a temporary drop of force. Check the maximum operating temperature for a given model.

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under shearing force the load capacity is reduced by as much as 5 times. In addition, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Data carriers

Very strong magnetic fields can destroy records on credit cards, HDDs, and other magnetic media. Keep a distance of at least 10 cm.

Fire warning

Mechanical processing of neodymium magnets poses a fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Keep away from children

Strictly keep magnets away from children. Ingestion danger is high, and the effects of magnets clamping inside the body are tragic.

Medical implants

For implant holders: Strong magnetic fields disrupt electronics. Keep at least 30 cm distance or request help to work with the magnets.

Beware of splinters

NdFeB magnets are sintered ceramics, which means they are very brittle. Impact of two magnets leads to them cracking into small pieces.

Do not underestimate power

Be careful. Neodymium magnets attract from a distance and connect with massive power, often faster than you can move away.

Allergic reactions

It is widely known that nickel (the usual finish) is a potent allergen. If your skin reacts to metals, refrain from direct skin contact and choose versions in plastic housing.

Power loss in heat

Do not overheat. NdFeB magnets are susceptible to temperature. If you require operation above 80°C, look for HT versions (H, SH, UH).

Impact on smartphones

Remember: neodymium magnets generate a field that confuses sensitive sensors. Keep a separation from your mobile, device, and GPS.

Bodily injuries

Pinching hazard: The pulling power is so great that it can cause hematomas, pinching, and even bone fractures. Protective gloves are recommended.

![SM 25x375 [2xM8] / N52 - magnetic separator SM 25x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x375-2xm8-soh.jpg)