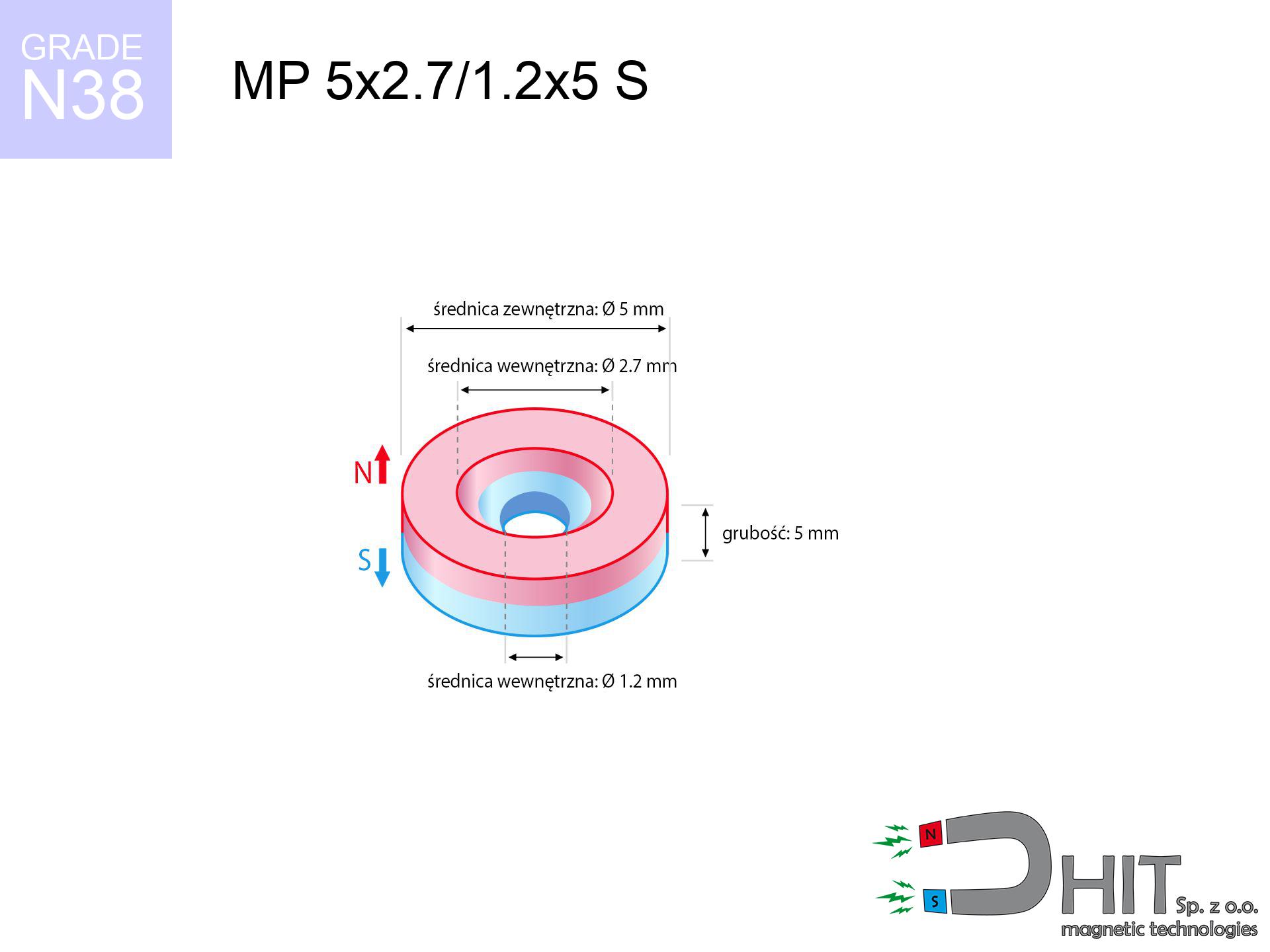

MP 5x2.7/1.2x5 S / N38 - ring magnet

ring magnet

Catalog no 030202

GTIN/EAN: 5906301812197

Diameter

5 mm [±0,1 mm]

internal diameter Ø

2.7/1.2 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

0.69 g

Magnetization Direction

↑ axial

Load capacity

0.75 kg / 7.31 N

Magnetic Induction

553.14 mT / 5531 Gs

Coating

[NiCuNi] Nickel

0.836 ZŁ with VAT / pcs + price for transport

0.680 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise get in touch by means of

contact form

the contact form page.

Lifting power along with appearance of neodymium magnets can be verified using our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical specification of the product - MP 5x2.7/1.2x5 S / N38 - ring magnet

Specification / characteristics - MP 5x2.7/1.2x5 S / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030202 |

| GTIN/EAN | 5906301812197 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 5 mm [±0,1 mm] |

| internal diameter Ø | 2.7/1.2 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 0.69 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.75 kg / 7.31 N |

| Magnetic Induction ~ ? | 553.14 mT / 5531 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the magnet - technical parameters

The following data are the outcome of a engineering simulation. Results are based on algorithms for the material Nd2Fe14B. Actual conditions may differ. Please consider these data as a reference point when designing systems.

Table 1: Static pull force (pull vs distance) - power drop

MP 5x2.7/1.2x5 S / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5322 Gs

532.2 mT

|

0.75 kg / 1.65 LBS

750.0 g / 7.4 N

|

safe |

| 1 mm |

3295 Gs

329.5 mT

|

0.29 kg / 0.63 LBS

287.5 g / 2.8 N

|

safe |

| 2 mm |

1883 Gs

188.3 mT

|

0.09 kg / 0.21 LBS

93.9 g / 0.9 N

|

safe |

| 3 mm |

1098 Gs

109.8 mT

|

0.03 kg / 0.07 LBS

31.9 g / 0.3 N

|

safe |

| 5 mm |

440 Gs

44.0 mT

|

0.01 kg / 0.01 LBS

5.1 g / 0.1 N

|

safe |

| 10 mm |

92 Gs

9.2 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

safe |

| 15 mm |

33 Gs

3.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 20 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Shear hold (wall)

MP 5x2.7/1.2x5 S / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.15 kg / 0.33 LBS

150.0 g / 1.5 N

|

| 1 mm | Stal (~0.2) |

0.06 kg / 0.13 LBS

58.0 g / 0.6 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

18.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MP 5x2.7/1.2x5 S / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.22 kg / 0.50 LBS

225.0 g / 2.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.15 kg / 0.33 LBS

150.0 g / 1.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.17 LBS

75.0 g / 0.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.38 kg / 0.83 LBS

375.0 g / 3.7 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 5x2.7/1.2x5 S / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.17 LBS

75.0 g / 0.7 N

|

| 1 mm |

|

0.19 kg / 0.41 LBS

187.5 g / 1.8 N

|

| 2 mm |

|

0.38 kg / 0.83 LBS

375.0 g / 3.7 N

|

| 3 mm |

|

0.56 kg / 1.24 LBS

562.5 g / 5.5 N

|

| 5 mm |

|

0.75 kg / 1.65 LBS

750.0 g / 7.4 N

|

| 10 mm |

|

0.75 kg / 1.65 LBS

750.0 g / 7.4 N

|

| 11 mm |

|

0.75 kg / 1.65 LBS

750.0 g / 7.4 N

|

| 12 mm |

|

0.75 kg / 1.65 LBS

750.0 g / 7.4 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MP 5x2.7/1.2x5 S / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.75 kg / 1.65 LBS

750.0 g / 7.4 N

|

OK |

| 40 °C | -2.2% |

0.73 kg / 1.62 LBS

733.5 g / 7.2 N

|

OK |

| 60 °C | -4.4% |

0.72 kg / 1.58 LBS

717.0 g / 7.0 N

|

OK |

| 80 °C | -6.6% |

0.70 kg / 1.54 LBS

700.5 g / 6.9 N

|

|

| 100 °C | -28.8% |

0.53 kg / 1.18 LBS

534.0 g / 5.2 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MP 5x2.7/1.2x5 S / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.75 kg / 6.06 LBS

5 924 Gs

|

0.41 kg / 0.91 LBS

412 g / 4.0 N

|

N/A |

| 1 mm |

1.77 kg / 3.90 LBS

8 541 Gs

|

0.27 kg / 0.58 LBS

265 g / 2.6 N

|

1.59 kg / 3.51 LBS

~0 Gs

|

| 2 mm |

1.05 kg / 2.32 LBS

6 590 Gs

|

0.16 kg / 0.35 LBS

158 g / 1.5 N

|

0.95 kg / 2.09 LBS

~0 Gs

|

| 3 mm |

0.60 kg / 1.33 LBS

4 992 Gs

|

0.09 kg / 0.20 LBS

91 g / 0.9 N

|

0.54 kg / 1.20 LBS

~0 Gs

|

| 5 mm |

0.20 kg / 0.44 LBS

2 860 Gs

|

0.03 kg / 0.07 LBS

30 g / 0.3 N

|

0.18 kg / 0.39 LBS

~0 Gs

|

| 10 mm |

0.02 kg / 0.04 LBS

880 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

184 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

10 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

2 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MP 5x2.7/1.2x5 S / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MP 5x2.7/1.2x5 S / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

33.26 km/h

(9.24 m/s)

|

0.03 J | |

| 30 mm |

57.59 km/h

(16.00 m/s)

|

0.09 J | |

| 50 mm |

74.35 km/h

(20.65 m/s)

|

0.15 J | |

| 100 mm |

105.14 km/h

(29.21 m/s)

|

0.29 J |

Table 9: Coating parameters (durability)

MP 5x2.7/1.2x5 S / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 5x2.7/1.2x5 S / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 862 Mx | 8.6 µWb |

| Pc Coefficient | 0.83 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 5x2.7/1.2x5 S / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.75 kg | Standard |

| Water (riverbed) |

0.86 kg

(+0.11 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds merely approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) significantly reduces the holding force.

3. Thermal stability

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.83

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths and weaknesses of neodymium magnets.

Advantages

- They have unchanged lifting capacity, and over more than ten years their performance decreases symbolically – ~1% (according to theory),

- They possess excellent resistance to weakening of magnetic properties due to external magnetic sources,

- By using a decorative layer of gold, the element has an professional look,

- Neodymium magnets ensure maximum magnetic induction on a their surface, which increases force concentration,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to the possibility of accurate molding and customization to unique solutions, neodymium magnets can be manufactured in a wide range of shapes and sizes, which makes them more universal,

- Key role in modern technologies – they find application in magnetic memories, brushless drives, precision medical tools, and industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Limitations

- They are fragile upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- We suggest cover - magnetic holder, due to difficulties in creating nuts inside the magnet and complicated forms.

- Possible danger related to microscopic parts of magnets can be dangerous, if swallowed, which gains importance in the context of child safety. It is also worth noting that tiny parts of these devices can complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Lifting parameters

Maximum holding power of the magnet – what affects it?

- with the application of a yoke made of special test steel, ensuring maximum field concentration

- with a cross-section no less than 10 mm

- with a surface free of scratches

- with total lack of distance (without impurities)

- during pulling in a direction vertical to the mounting surface

- at temperature room level

Determinants of practical lifting force of a magnet

- Space between magnet and steel – every millimeter of separation (caused e.g. by varnish or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When slipping, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Material type – the best choice is pure iron steel. Hardened steels may generate lower lifting capacity.

- Smoothness – ideal contact is possible only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal factor – high temperature weakens magnetic field. Too high temperature can permanently demagnetize the magnet.

Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under attempts to slide the magnet the lifting capacity is smaller. Moreover, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Safety rules for work with NdFeB magnets

This is not a toy

Absolutely store magnets out of reach of children. Choking hazard is significant, and the effects of magnets connecting inside the body are life-threatening.

Risk of cracking

Neodymium magnets are ceramic materials, meaning they are very brittle. Impact of two magnets leads to them shattering into small pieces.

Power loss in heat

Control the heat. Exposing the magnet above 80 degrees Celsius will destroy its magnetic structure and strength.

Pacemakers

Health Alert: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Safe operation

Before use, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Protect data

Intense magnetic fields can erase data on payment cards, hard drives, and other magnetic media. Maintain a gap of at least 10 cm.

GPS Danger

GPS units and mobile phones are extremely susceptible to magnetism. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Skin irritation risks

Certain individuals suffer from a contact allergy to Ni, which is the common plating for NdFeB magnets. Frequent touching can result in dermatitis. We suggest use protective gloves.

Combustion hazard

Powder created during cutting of magnets is flammable. Do not drill into magnets unless you are an expert.

Bodily injuries

Big blocks can break fingers in a fraction of a second. Under no circumstances put your hand betwixt two attracting surfaces.

![UMH 16x5x32 [M4] / N38 - magnetic holder with hook UMH 16x5x32 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-16x5x32-m4-lak.jpg)