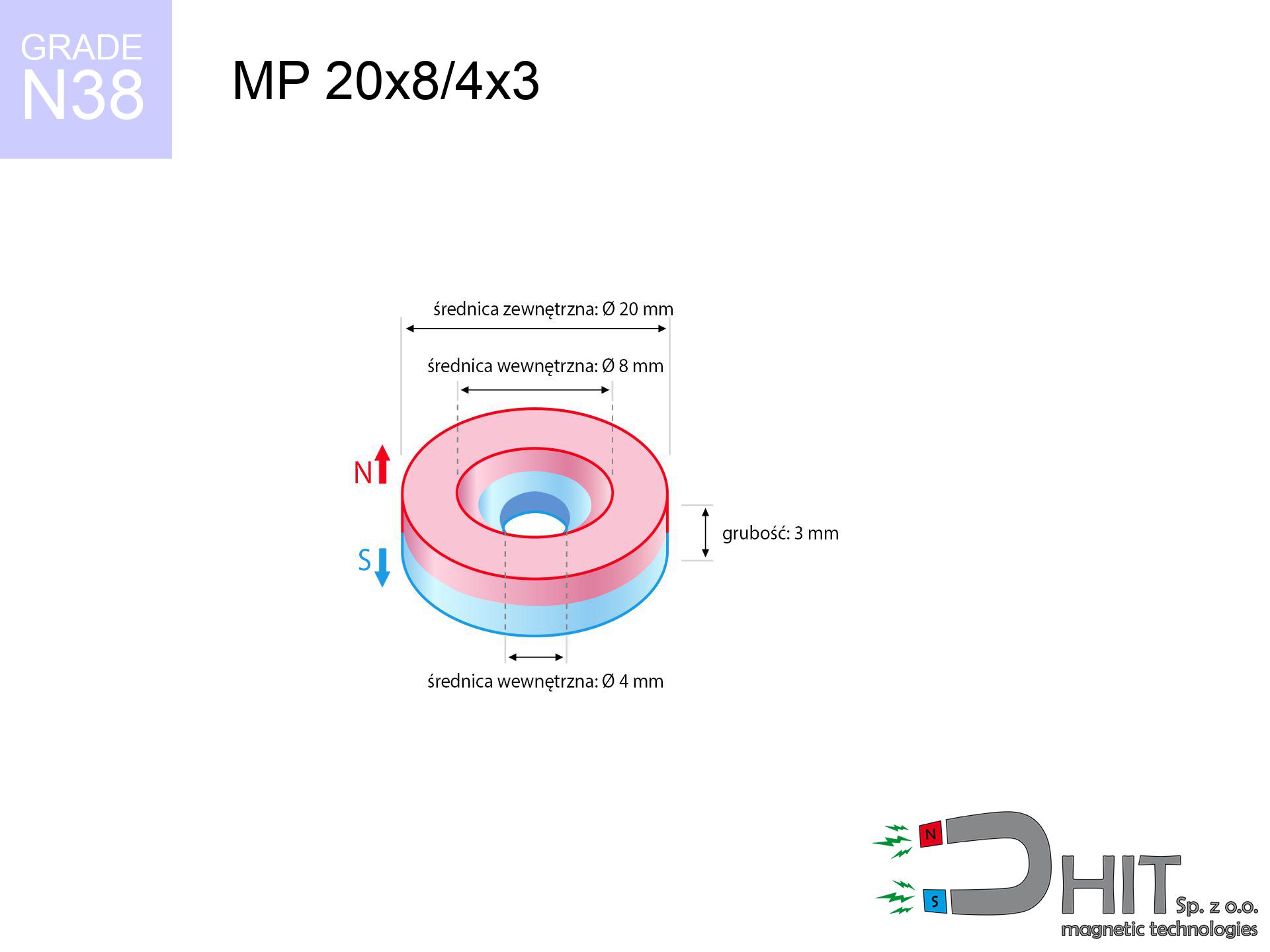

MP 20x8/4x3 / N38 - ring magnet

ring magnet

Catalog no 030187

GTIN/EAN: 5906301812043

Diameter

20 mm [±0,1 mm]

internal diameter Ø

8/4 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

6.79 g

Magnetization Direction

↑ axial

Load capacity

3.14 kg / 30.79 N

Magnetic Induction

178.11 mT / 1781 Gs

Coating

[NiCuNi] Nickel

3.59 ZŁ with VAT / pcs + price for transport

2.92 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise drop us a message using

inquiry form

our website.

Specifications and structure of magnets can be estimated with our

power calculator.

Same-day processing for orders placed before 14:00.

Technical specification of the product - MP 20x8/4x3 / N38 - ring magnet

Specification / characteristics - MP 20x8/4x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030187 |

| GTIN/EAN | 5906301812043 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±0,1 mm] |

| internal diameter Ø | 8/4 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 6.79 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.14 kg / 30.79 N |

| Magnetic Induction ~ ? | 178.11 mT / 1781 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

The following values constitute the result of a mathematical calculation. Values were calculated on algorithms for the material Nd2Fe14B. Actual conditions might slightly deviate from the simulation results. Treat these calculations as a reference point when designing systems.

Table 1: Static force (force vs distance) - power drop

MP 20x8/4x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1531 Gs

153.1 mT

|

3.14 kg / 6.92 lbs

3140.0 g / 30.8 N

|

warning |

| 1 mm |

1457 Gs

145.7 mT

|

2.84 kg / 6.27 lbs

2843.2 g / 27.9 N

|

warning |

| 2 mm |

1352 Gs

135.2 mT

|

2.45 kg / 5.39 lbs

2446.6 g / 24.0 N

|

warning |

| 3 mm |

1227 Gs

122.7 mT

|

2.02 kg / 4.44 lbs

2016.2 g / 19.8 N

|

warning |

| 5 mm |

963 Gs

96.3 mT

|

1.24 kg / 2.74 lbs

1241.9 g / 12.2 N

|

weak grip |

| 10 mm |

465 Gs

46.5 mT

|

0.29 kg / 0.64 lbs

289.3 g / 2.8 N

|

weak grip |

| 15 mm |

228 Gs

22.8 mT

|

0.07 kg / 0.15 lbs

69.7 g / 0.7 N

|

weak grip |

| 20 mm |

122 Gs

12.2 mT

|

0.02 kg / 0.04 lbs

20.0 g / 0.2 N

|

weak grip |

| 30 mm |

45 Gs

4.5 mT

|

0.00 kg / 0.01 lbs

2.7 g / 0.0 N

|

weak grip |

| 50 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

weak grip |

Table 2: Sliding force (wall)

MP 20x8/4x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.63 kg / 1.38 lbs

628.0 g / 6.2 N

|

| 1 mm | Stal (~0.2) |

0.57 kg / 1.25 lbs

568.0 g / 5.6 N

|

| 2 mm | Stal (~0.2) |

0.49 kg / 1.08 lbs

490.0 g / 4.8 N

|

| 3 mm | Stal (~0.2) |

0.40 kg / 0.89 lbs

404.0 g / 4.0 N

|

| 5 mm | Stal (~0.2) |

0.25 kg / 0.55 lbs

248.0 g / 2.4 N

|

| 10 mm | Stal (~0.2) |

0.06 kg / 0.13 lbs

58.0 g / 0.6 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MP 20x8/4x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.94 kg / 2.08 lbs

942.0 g / 9.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.63 kg / 1.38 lbs

628.0 g / 6.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.31 kg / 0.69 lbs

314.0 g / 3.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.57 kg / 3.46 lbs

1570.0 g / 15.4 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MP 20x8/4x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.31 kg / 0.69 lbs

314.0 g / 3.1 N

|

| 1 mm |

|

0.79 kg / 1.73 lbs

785.0 g / 7.7 N

|

| 2 mm |

|

1.57 kg / 3.46 lbs

1570.0 g / 15.4 N

|

| 3 mm |

|

2.36 kg / 5.19 lbs

2355.0 g / 23.1 N

|

| 5 mm |

|

3.14 kg / 6.92 lbs

3140.0 g / 30.8 N

|

| 10 mm |

|

3.14 kg / 6.92 lbs

3140.0 g / 30.8 N

|

| 11 mm |

|

3.14 kg / 6.92 lbs

3140.0 g / 30.8 N

|

| 12 mm |

|

3.14 kg / 6.92 lbs

3140.0 g / 30.8 N

|

Table 5: Working in heat (material behavior) - thermal limit

MP 20x8/4x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.14 kg / 6.92 lbs

3140.0 g / 30.8 N

|

OK |

| 40 °C | -2.2% |

3.07 kg / 6.77 lbs

3070.9 g / 30.1 N

|

OK |

| 60 °C | -4.4% |

3.00 kg / 6.62 lbs

3001.8 g / 29.4 N

|

|

| 80 °C | -6.6% |

2.93 kg / 6.47 lbs

2932.8 g / 28.8 N

|

|

| 100 °C | -28.8% |

2.24 kg / 4.93 lbs

2235.7 g / 21.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MP 20x8/4x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.71 kg / 8.17 lbs

2 815 Gs

|

0.56 kg / 1.23 lbs

556 g / 5.5 N

|

N/A |

| 1 mm |

3.55 kg / 7.83 lbs

2 998 Gs

|

0.53 kg / 1.17 lbs

533 g / 5.2 N

|

3.20 kg / 7.05 lbs

~0 Gs

|

| 2 mm |

3.36 kg / 7.40 lbs

2 915 Gs

|

0.50 kg / 1.11 lbs

503 g / 4.9 N

|

3.02 kg / 6.66 lbs

~0 Gs

|

| 3 mm |

3.13 kg / 6.90 lbs

2 815 Gs

|

0.47 kg / 1.04 lbs

470 g / 4.6 N

|

2.82 kg / 6.21 lbs

~0 Gs

|

| 5 mm |

2.63 kg / 5.81 lbs

2 582 Gs

|

0.40 kg / 0.87 lbs

395 g / 3.9 N

|

2.37 kg / 5.23 lbs

~0 Gs

|

| 10 mm |

1.47 kg / 3.23 lbs

1 926 Gs

|

0.22 kg / 0.48 lbs

220 g / 2.2 N

|

1.32 kg / 2.91 lbs

~0 Gs

|

| 20 mm |

0.34 kg / 0.75 lbs

930 Gs

|

0.05 kg / 0.11 lbs

51 g / 0.5 N

|

0.31 kg / 0.68 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.02 lbs

143 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 lbs

90 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

59 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

41 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

30 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

22 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MP 20x8/4x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MP 20x8/4x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.90 km/h

(6.36 m/s)

|

0.14 J | |

| 30 mm |

37.58 km/h

(10.44 m/s)

|

0.37 J | |

| 50 mm |

48.50 km/h

(13.47 m/s)

|

0.62 J | |

| 100 mm |

68.58 km/h

(19.05 m/s)

|

1.23 J |

Table 9: Corrosion resistance

MP 20x8/4x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 20x8/4x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 044 Mx | 50.4 µWb |

| Pc Coefficient | 0.20 | Low (Flat) |

Table 11: Submerged application

MP 20x8/4x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.14 kg | Standard |

| Water (riverbed) |

3.60 kg

(+0.46 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds only approx. 20-30% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.20

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Advantages and disadvantages of neodymium magnets.

Pros

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (in laboratory conditions),

- Magnets effectively protect themselves against loss of magnetization caused by external fields,

- By using a decorative layer of nickel, the element gains an nice look,

- Magnetic induction on the working layer of the magnet is strong,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of exact machining as well as adjusting to atypical requirements,

- Significant place in advanced technology sectors – they are utilized in magnetic memories, electric motors, medical devices, also industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Disadvantages

- To avoid cracks under impact, we suggest using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in producing threads and complicated forms in magnets, we propose using cover - magnetic mechanism.

- Possible danger related to microscopic parts of magnets can be dangerous, if swallowed, which gains importance in the context of child safety. Additionally, tiny parts of these products can be problematic in diagnostics medical when they are in the body.

- Due to complex production process, their price is higher than average,

Holding force characteristics

Maximum lifting force for a neodymium magnet – what affects it?

- on a base made of mild steel, effectively closing the magnetic flux

- whose transverse dimension reaches at least 10 mm

- with an polished touching surface

- with zero gap (without impurities)

- under axial force vector (90-degree angle)

- at conditions approx. 20°C

Determinants of lifting force in real conditions

- Clearance – the presence of any layer (rust, dirt, air) interrupts the magnetic circuit, which lowers capacity rapidly (even by 50% at 0.5 mm).

- Force direction – catalog parameter refers to detachment vertically. When applying parallel force, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet limits the attraction force (the magnet "punches through" it).

- Material type – the best choice is pure iron steel. Hardened steels may attract less.

- Smoothness – ideal contact is possible only on polished steel. Rough texture reduce the real contact area, weakening the magnet.

- Temperature influence – high temperature reduces pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity testing was carried out on a smooth plate of optimal thickness, under a perpendicular pulling force, whereas under parallel forces the holding force is lower. Additionally, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Warnings

Thermal limits

Do not overheat. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).

Finger safety

Protect your hands. Two large magnets will snap together instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Handling rules

Be careful. Neodymium magnets attract from a long distance and connect with massive power, often quicker than you can move away.

Fragile material

Watch out for shards. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Allergy Warning

Some people have a contact allergy to Ni, which is the common plating for NdFeB magnets. Extended handling might lead to an allergic reaction. We recommend wear safety gloves.

Threat to electronics

Intense magnetic fields can corrupt files on payment cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

Danger to pacemakers

Warning for patients: Powerful magnets affect medical devices. Keep minimum 30 cm distance or ask another person to work with the magnets.

Do not give to children

Neodymium magnets are not intended for children. Swallowing multiple magnets can lead to them attracting across intestines, which constitutes a direct threat to life and necessitates immediate surgery.

Dust explosion hazard

Machining of NdFeB material carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Precision electronics

Navigation devices and smartphones are extremely sensitive to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the sensors in your phone.

![BM 650x180x70 [4x M8] - magnetic beam BM 650x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-650x180x70-4x-m8-laj.jpg)

![BM 550x180x70 [4x M8] - magnetic beam BM 550x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-550x180x70-4x-m8-nic.jpg)

![UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder UMP 135x40 [M10+M12] GW F 600 kg / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump135x40-m10+m12-gw-f-600-kg-luz.jpg)