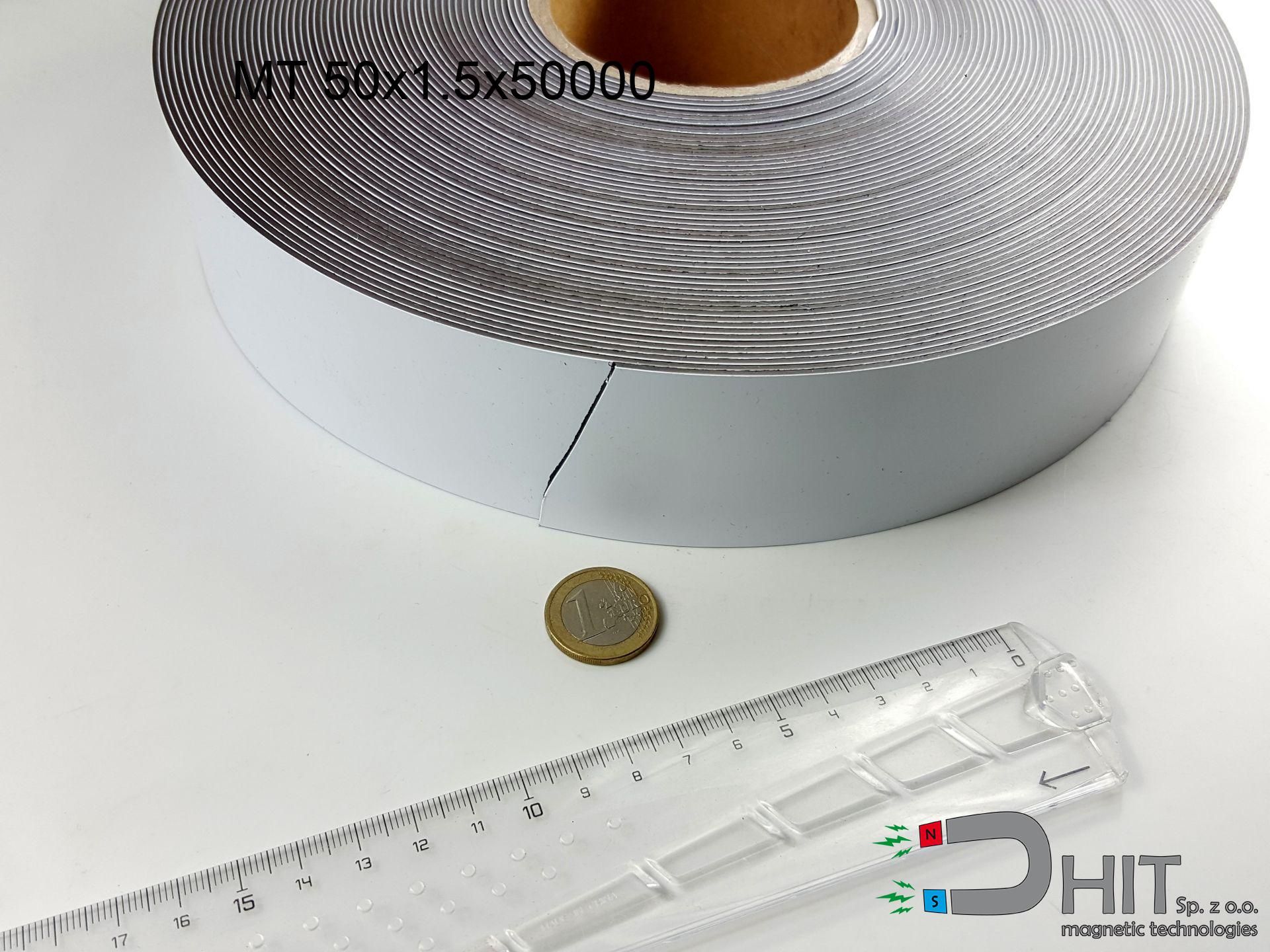

MT 50x1.5x50000 - magnetic tape

magnetic tape

Catalog no 380511

length

50 mm [±1 mm]

Width

1.5 mm [±1 mm]

Height

50000 mm [±1 mm]

430.50 ZŁ with VAT / pcs + price for transport

350.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

if you prefer let us know using

inquiry form

our website.

Strength and structure of a magnet can be analyzed on our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical data - MT 50x1.5x50000 - magnetic tape

Specification / characteristics - MT 50x1.5x50000 - magnetic tape

| properties | values |

|---|---|

| Cat. no. | 380511 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±1 mm] |

| Width | 1.5 mm [±1 mm] |

| Height | 50000 mm [±1 mm] |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths and weaknesses of Nd2Fe14B magnets.

Benefits

- They have stable power, and over more than ten years their performance decreases symbolically – ~1% (according to theory),

- They feature excellent resistance to magnetic field loss when exposed to external fields,

- A magnet with a shiny gold surface looks better,

- Magnetic induction on the working layer of the magnet turns out to be maximum,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Thanks to versatility in designing and the ability to adapt to specific needs,

- Universal use in innovative solutions – they are utilized in mass storage devices, brushless drives, precision medical tools, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in small dimensions, which makes them useful in small systems

Limitations

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of creating nuts in the magnet and complex shapes - recommended is casing - mounting mechanism.

- Health risk resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the context of child safety. Additionally, tiny parts of these magnets can be problematic in diagnostics medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum lifting capacity of the magnet – what affects it?

- on a block made of structural steel, effectively closing the magnetic flux

- possessing a thickness of at least 10 mm to ensure full flux closure

- with an ground contact surface

- without the slightest clearance between the magnet and steel

- under vertical force vector (90-degree angle)

- at temperature room level

Practical lifting capacity: influencing factors

- Distance – existence of any layer (rust, dirt, gap) acts as an insulator, which reduces power steeply (even by 50% at 0.5 mm).

- Angle of force application – maximum parameter is available only during perpendicular pulling. The shear force of the magnet along the plate is typically many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Metal type – not every steel attracts identically. High carbon content worsen the interaction with the magnet.

- Surface structure – the more even the plate, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Temperature – heating the magnet results in weakening of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was measured with the use of a smooth steel plate of optimal thickness (min. 20 mm), under vertically applied force, whereas under parallel forces the holding force is lower. In addition, even a small distance between the magnet and the plate lowers the lifting capacity.

H&S for magnets

Fragile material

NdFeB magnets are ceramic materials, which means they are very brittle. Clashing of two magnets will cause them shattering into small pieces.

Permanent damage

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will ruin its magnetic structure and pulling force.

Crushing force

Pinching hazard: The pulling power is so great that it can cause hematomas, pinching, and broken bones. Use thick gloves.

Danger to pacemakers

Health Alert: Strong magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Allergic reactions

Certain individuals experience a hypersensitivity to Ni, which is the common plating for NdFeB magnets. Frequent touching might lead to skin redness. We suggest wear safety gloves.

Keep away from children

These products are not intended for children. Swallowing multiple magnets can lead to them attracting across intestines, which constitutes a critical condition and necessitates immediate surgery.

GPS Danger

Remember: neodymium magnets produce a field that disrupts precision electronics. Keep a safe distance from your phone, tablet, and navigation systems.

Dust is flammable

Combustion risk: Rare earth powder is explosive. Do not process magnets in home conditions as this may cause fire.

Safe distance

Powerful magnetic fields can destroy records on payment cards, HDDs, and other magnetic media. Stay away of min. 10 cm.

Handling rules

Handle magnets with awareness. Their immense force can surprise even professionals. Stay alert and respect their power.

![AM ucho małe [M8] - magnetic accessories AM ucho małe [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-małe-m8-zud.jpg)