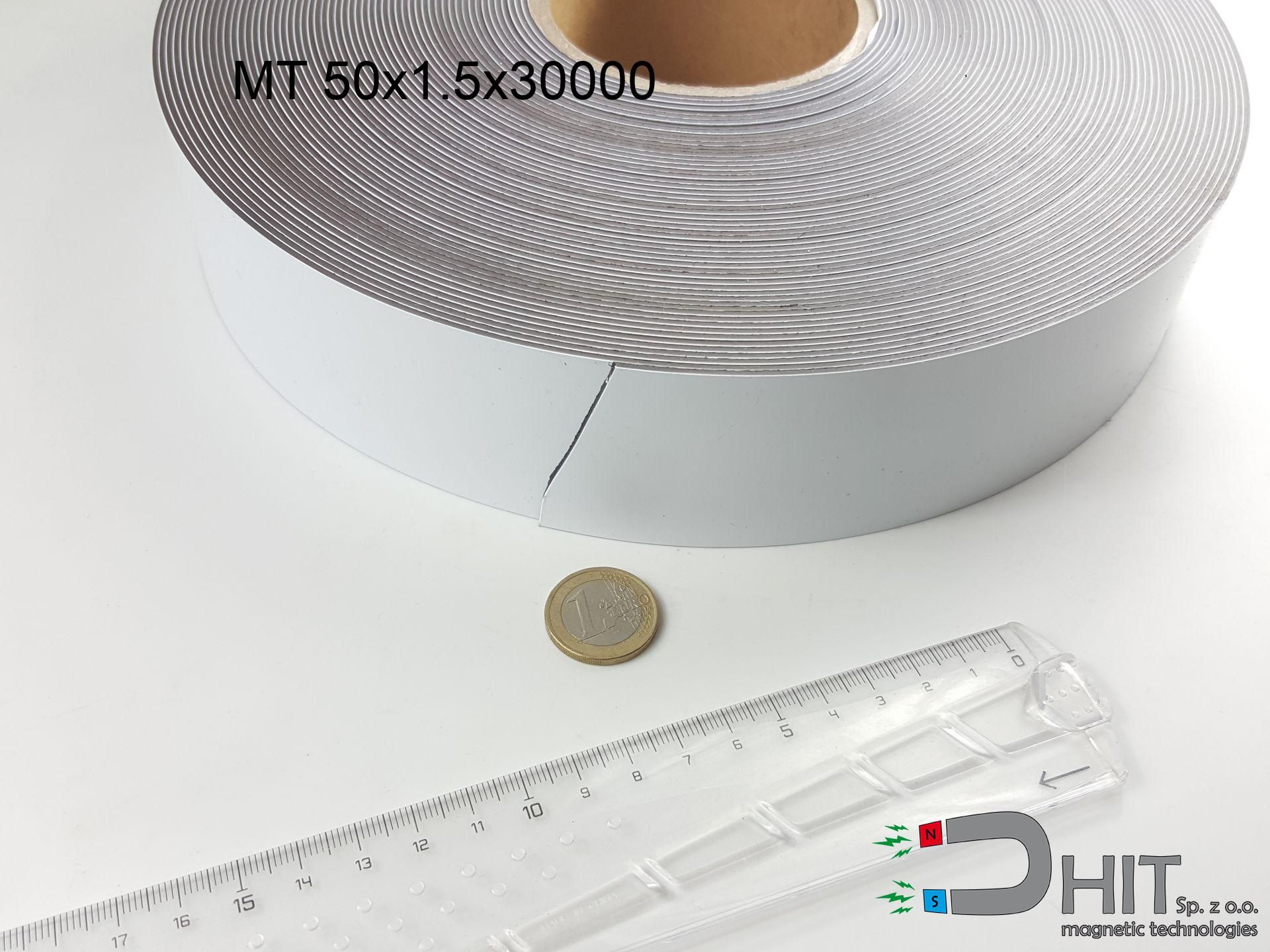

MT 50x1.5x30000 - magnetic tape

magnetic tape

Catalog no 380510

length

50 mm [±1 mm]

Width

1.5 mm [±1 mm]

Height

30000 mm [±1 mm]

258.30 ZŁ with VAT / pcs + price for transport

210.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

alternatively drop us a message by means of

request form

the contact form page.

Parameters and appearance of neodymium magnets can be estimated with our

modular calculator.

Order by 14:00 and we’ll ship today!

Technical - MT 50x1.5x30000 - magnetic tape

Specification / characteristics - MT 50x1.5x30000 - magnetic tape

| properties | values |

|---|---|

| Cat. no. | 380510 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±1 mm] |

| Width | 1.5 mm [±1 mm] |

| Height | 30000 mm [±1 mm] |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Pros and cons of neodymium magnets.

Benefits

- They do not lose magnetism, even during approximately ten years – the reduction in strength is only ~1% (theoretically),

- Neodymium magnets are distinguished by extremely resistant to loss of magnetic properties caused by external interference,

- The use of an elegant finish of noble metals (nickel, gold, silver) causes the element to look better,

- The surface of neodymium magnets generates a powerful magnetic field – this is a key feature,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to freedom in forming and the ability to adapt to client solutions,

- Wide application in future technologies – they find application in mass storage devices, electric drive systems, precision medical tools, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which makes them useful in compact constructions

Cons

- At very strong impacts they can break, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated forms.

- Possible danger to health – tiny shards of magnets can be dangerous, if swallowed, which becomes key in the context of child health protection. Additionally, tiny parts of these magnets can disrupt the diagnostic process medical when they are in the body.

- With large orders the cost of neodymium magnets can be a barrier,

Holding force characteristics

Highest magnetic holding force – what it depends on?

- with the contact of a yoke made of special test steel, guaranteeing full magnetic saturation

- whose thickness equals approx. 10 mm

- characterized by smoothness

- without any clearance between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- at temperature room level

Magnet lifting force in use – key factors

- Distance (between the magnet and the plate), since even a tiny distance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to varnish, rust or dirt).

- Angle of force application – highest force is available only during pulling at a 90° angle. The force required to slide of the magnet along the surface is standardly several times lower (approx. 1/5 of the lifting capacity).

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Steel type – low-carbon steel attracts best. Alloy admixtures decrease magnetic properties and lifting capacity.

- Smoothness – full contact is obtained only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – temperature increase results in weakening of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was determined by applying a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a slight gap between the magnet and the plate decreases the load capacity.

Safe handling of neodymium magnets

Pinching danger

Pinching hazard: The pulling power is so great that it can cause blood blisters, pinching, and even bone fractures. Use thick gloves.

Power loss in heat

Regular neodymium magnets (grade N) lose magnetization when the temperature goes above 80°C. This process is irreversible.

Flammability

Mechanical processing of neodymium magnets carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Do not underestimate power

Exercise caution. Neodymium magnets act from a long distance and connect with huge force, often faster than you can move away.

Sensitization to coating

Some people experience a hypersensitivity to nickel, which is the standard coating for NdFeB magnets. Extended handling might lead to an allergic reaction. We strongly advise wear protective gloves.

Precision electronics

Be aware: neodymium magnets produce a field that disrupts sensitive sensors. Keep a separation from your mobile, tablet, and navigation systems.

Threat to electronics

Very strong magnetic fields can destroy records on payment cards, hard drives, and other magnetic media. Keep a distance of min. 10 cm.

Pacemakers

Medical warning: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have electronic implants.

Beware of splinters

Neodymium magnets are ceramic materials, which means they are prone to chipping. Collision of two magnets will cause them shattering into shards.

Swallowing risk

Neodymium magnets are not suitable for play. Swallowing several magnets can lead to them connecting inside the digestive tract, which poses a severe health hazard and requires urgent medical intervention.

![SM 32x175 [2xM8] / N52 - magnetic separator SM 32x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-cep.jpg)

![AM ucho [M8] - magnetic accessories AM ucho [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m8-lib.jpg)

![UMP 94x28 [3xM10] GW F300 GOLD / N38 - search holder UMP 94x28 [3xM10] GW F300 GOLD / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-94x28-m10-gw-f300-vux.jpg)