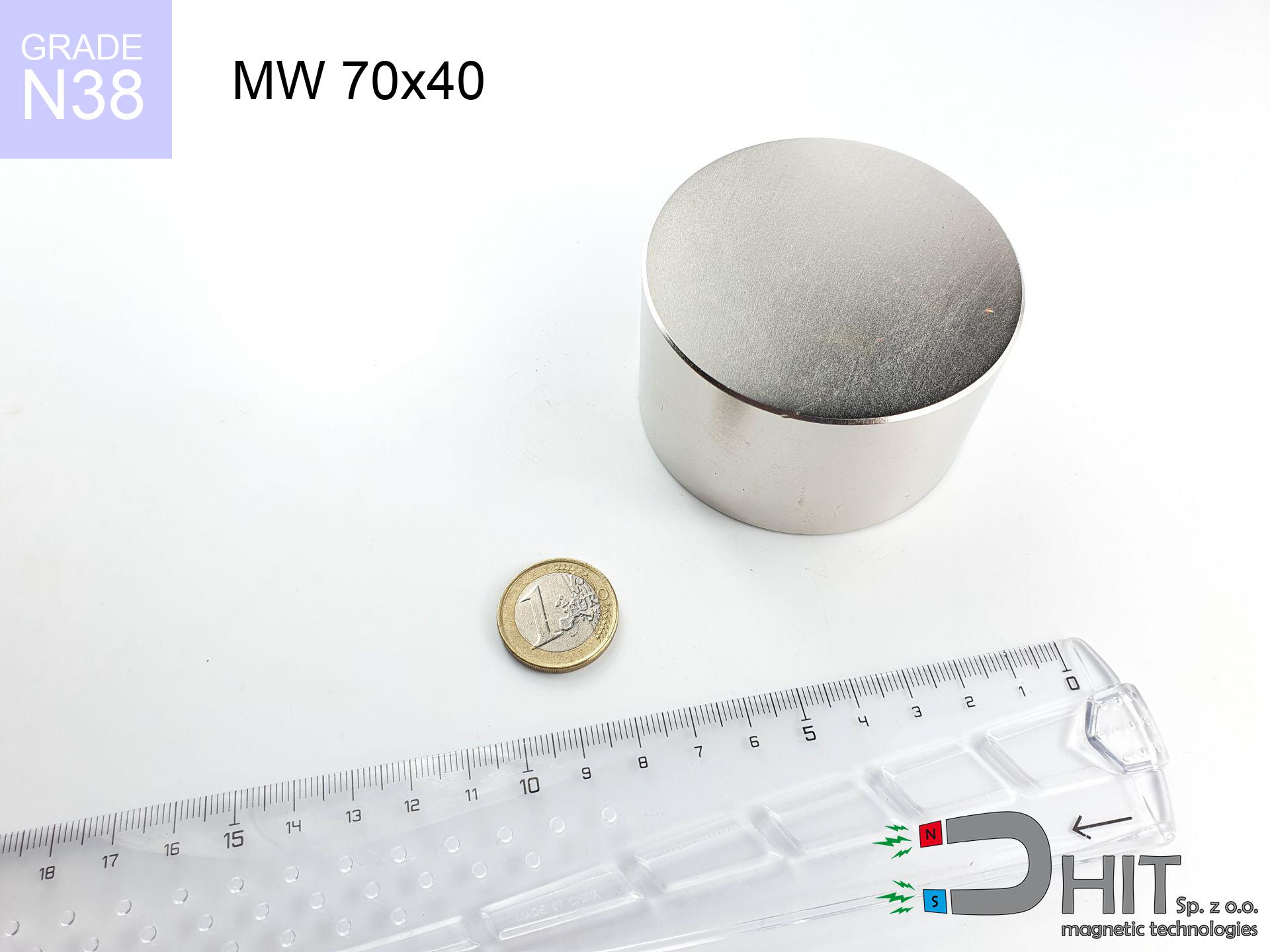

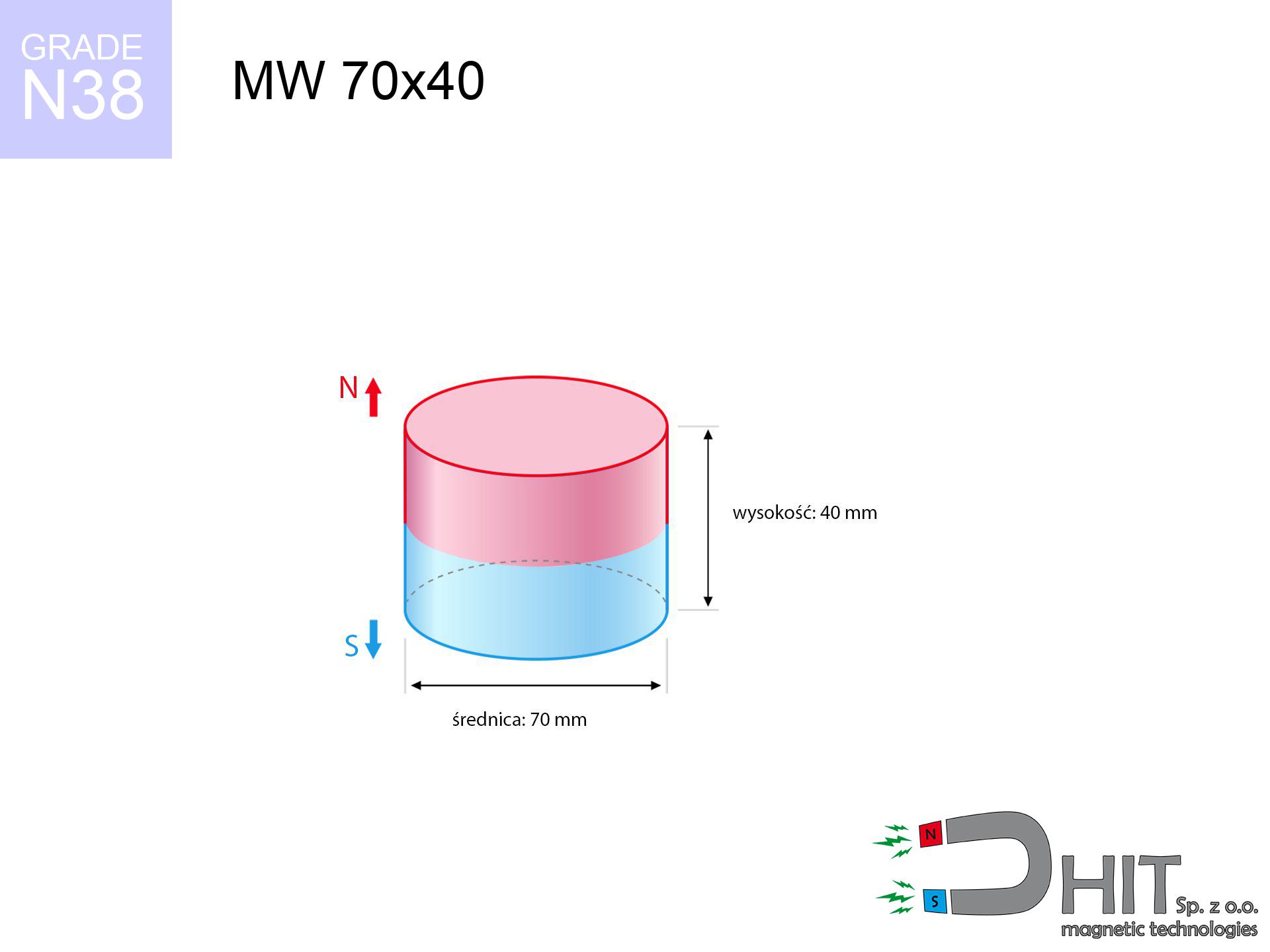

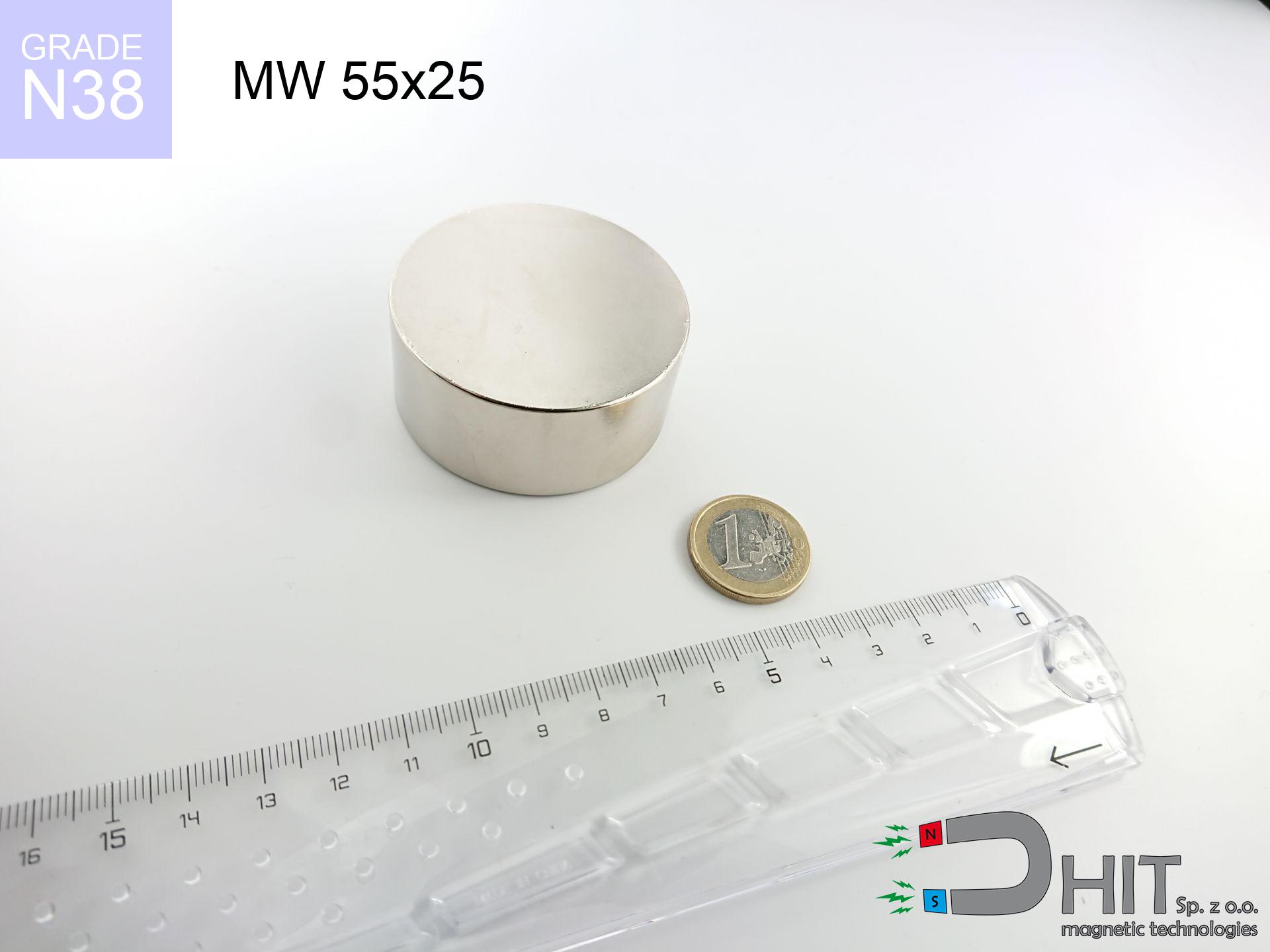

MW 70x40 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010097

GTIN/EAN: 5906301810964

Diameter Ø

70 mm [±0,1 mm]

Height

40 mm [±0,1 mm]

Weight

1154.54 g

Magnetization Direction

↑ axial

Load capacity

164.24 kg / 1611.16 N

Magnetic Induction

466.52 mT / 4665 Gs

Coating

[NiCuNi] Nickel

395.40 ZŁ with VAT / pcs + price for transport

321.46 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer let us know by means of

contact form

the contact section.

Weight along with form of a magnet can be calculated with our

online calculation tool.

Order by 14:00 and we’ll ship today!

Technical of the product - MW 70x40 / N38 - cylindrical magnet

Specification / characteristics - MW 70x40 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010097 |

| GTIN/EAN | 5906301810964 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 70 mm [±0,1 mm] |

| Height | 40 mm [±0,1 mm] |

| Weight | 1154.54 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 164.24 kg / 1611.16 N |

| Magnetic Induction ~ ? | 466.52 mT / 4665 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - data

The following values constitute the direct effect of a physical calculation. Results were calculated on algorithms for the material Nd2Fe14B. Operational performance might slightly deviate from the simulation results. Use these calculations as a supplementary guide when designing systems.

Table 1: Static pull force (pull vs distance) - interaction chart

MW 70x40 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4665 Gs

466.5 mT

|

164.24 kg / 362.09 lbs

164240.0 g / 1611.2 N

|

critical level |

| 1 mm |

4538 Gs

453.8 mT

|

155.47 kg / 342.75 lbs

155467.9 g / 1525.1 N

|

critical level |

| 2 mm |

4409 Gs

440.9 mT

|

146.74 kg / 323.52 lbs

146744.5 g / 1439.6 N

|

critical level |

| 3 mm |

4279 Gs

427.9 mT

|

138.20 kg / 304.68 lbs

138201.8 g / 1355.8 N

|

critical level |

| 5 mm |

4017 Gs

401.7 mT

|

121.81 kg / 268.54 lbs

121806.5 g / 1194.9 N

|

critical level |

| 10 mm |

3376 Gs

337.6 mT

|

86.03 kg / 189.65 lbs

86025.3 g / 843.9 N

|

critical level |

| 15 mm |

2788 Gs

278.8 mT

|

58.69 kg / 129.38 lbs

58686.8 g / 575.7 N

|

critical level |

| 20 mm |

2279 Gs

227.9 mT

|

39.22 kg / 86.46 lbs

39215.6 g / 384.7 N

|

critical level |

| 30 mm |

1511 Gs

151.1 mT

|

17.22 kg / 37.97 lbs

17222.5 g / 169.0 N

|

critical level |

| 50 mm |

699 Gs

69.9 mT

|

3.69 kg / 8.13 lbs

3690.0 g / 36.2 N

|

medium risk |

Table 2: Shear load (wall)

MW 70x40 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

32.85 kg / 72.42 lbs

32848.0 g / 322.2 N

|

| 1 mm | Stal (~0.2) |

31.09 kg / 68.55 lbs

31094.0 g / 305.0 N

|

| 2 mm | Stal (~0.2) |

29.35 kg / 64.70 lbs

29348.0 g / 287.9 N

|

| 3 mm | Stal (~0.2) |

27.64 kg / 60.94 lbs

27640.0 g / 271.1 N

|

| 5 mm | Stal (~0.2) |

24.36 kg / 53.71 lbs

24362.0 g / 239.0 N

|

| 10 mm | Stal (~0.2) |

17.21 kg / 37.93 lbs

17206.0 g / 168.8 N

|

| 15 mm | Stal (~0.2) |

11.74 kg / 25.88 lbs

11738.0 g / 115.1 N

|

| 20 mm | Stal (~0.2) |

7.84 kg / 17.29 lbs

7844.0 g / 76.9 N

|

| 30 mm | Stal (~0.2) |

3.44 kg / 7.59 lbs

3444.0 g / 33.8 N

|

| 50 mm | Stal (~0.2) |

0.74 kg / 1.63 lbs

738.0 g / 7.2 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 70x40 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

49.27 kg / 108.63 lbs

49272.0 g / 483.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

32.85 kg / 72.42 lbs

32848.0 g / 322.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

16.42 kg / 36.21 lbs

16424.0 g / 161.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

82.12 kg / 181.04 lbs

82120.0 g / 805.6 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 70x40 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

5.47 kg / 12.07 lbs

5474.7 g / 53.7 N

|

| 1 mm |

|

13.69 kg / 30.17 lbs

13686.7 g / 134.3 N

|

| 2 mm |

|

27.37 kg / 60.35 lbs

27373.3 g / 268.5 N

|

| 3 mm |

|

41.06 kg / 90.52 lbs

41060.0 g / 402.8 N

|

| 5 mm |

|

68.43 kg / 150.87 lbs

68433.3 g / 671.3 N

|

| 10 mm |

|

136.87 kg / 301.74 lbs

136866.7 g / 1342.7 N

|

| 11 mm |

|

150.55 kg / 331.91 lbs

150553.3 g / 1476.9 N

|

| 12 mm |

|

164.24 kg / 362.09 lbs

164240.0 g / 1611.2 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 70x40 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

164.24 kg / 362.09 lbs

164240.0 g / 1611.2 N

|

OK |

| 40 °C | -2.2% |

160.63 kg / 354.12 lbs

160626.7 g / 1575.7 N

|

OK |

| 60 °C | -4.4% |

157.01 kg / 346.15 lbs

157013.4 g / 1540.3 N

|

OK |

| 80 °C | -6.6% |

153.40 kg / 338.19 lbs

153400.2 g / 1504.9 N

|

|

| 100 °C | -28.8% |

116.94 kg / 257.81 lbs

116938.9 g / 1147.2 N

|

Table 6: Two magnets (attraction) - field collision

MW 70x40 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

516.26 kg / 1138.16 lbs

5 679 Gs

|

77.44 kg / 170.72 lbs

77439 g / 759.7 N

|

N/A |

| 1 mm |

502.57 kg / 1107.98 lbs

9 205 Gs

|

75.39 kg / 166.20 lbs

75385 g / 739.5 N

|

452.31 kg / 997.18 lbs

~0 Gs

|

| 2 mm |

488.69 kg / 1077.37 lbs

9 077 Gs

|

73.30 kg / 161.61 lbs

73303 g / 719.1 N

|

439.82 kg / 969.63 lbs

~0 Gs

|

| 3 mm |

474.91 kg / 1047.01 lbs

8 948 Gs

|

71.24 kg / 157.05 lbs

71237 g / 698.8 N

|

427.42 kg / 942.31 lbs

~0 Gs

|

| 5 mm |

447.76 kg / 987.15 lbs

8 688 Gs

|

67.16 kg / 148.07 lbs

67164 g / 658.9 N

|

402.99 kg / 888.43 lbs

~0 Gs

|

| 10 mm |

382.88 kg / 844.10 lbs

8 034 Gs

|

57.43 kg / 126.62 lbs

57432 g / 563.4 N

|

344.59 kg / 759.69 lbs

~0 Gs

|

| 20 mm |

270.41 kg / 596.14 lbs

6 752 Gs

|

40.56 kg / 89.42 lbs

40561 g / 397.9 N

|

243.37 kg / 536.53 lbs

~0 Gs

|

| 50 mm |

81.66 kg / 180.03 lbs

3 710 Gs

|

12.25 kg / 27.01 lbs

12249 g / 120.2 N

|

73.50 kg / 162.03 lbs

~0 Gs

|

| 60 mm |

54.14 kg / 119.35 lbs

3 021 Gs

|

8.12 kg / 17.90 lbs

8120 g / 79.7 N

|

48.72 kg / 107.41 lbs

~0 Gs

|

| 70 mm |

36.14 kg / 79.69 lbs

2 469 Gs

|

5.42 kg / 11.95 lbs

5422 g / 53.2 N

|

32.53 kg / 71.72 lbs

~0 Gs

|

| 80 mm |

24.40 kg / 53.80 lbs

2 028 Gs

|

3.66 kg / 8.07 lbs

3661 g / 35.9 N

|

21.96 kg / 48.42 lbs

~0 Gs

|

| 90 mm |

16.70 kg / 36.82 lbs

1 678 Gs

|

2.51 kg / 5.52 lbs

2505 g / 24.6 N

|

15.03 kg / 33.14 lbs

~0 Gs

|

| 100 mm |

11.60 kg / 25.57 lbs

1 398 Gs

|

1.74 kg / 3.84 lbs

1740 g / 17.1 N

|

10.44 kg / 23.01 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 70x40 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 37.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 29.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 23.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 17.5 cm |

| Car key | 50 Gs (5.0 mT) | 16.5 cm |

| Payment card | 400 Gs (40.0 mT) | 7.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 5.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 70x40 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

15.47 km/h

(4.30 m/s)

|

10.66 J | |

| 30 mm |

22.16 km/h

(6.15 m/s)

|

21.87 J | |

| 50 mm |

27.27 km/h

(7.58 m/s)

|

33.13 J | |

| 100 mm |

38.07 km/h

(10.57 m/s)

|

64.55 J |

Table 9: Coating parameters (durability)

MW 70x40 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 70x40 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 180 982 Mx | 1809.8 µWb |

| Pc Coefficient | 0.64 | High (Stable) |

Table 11: Physics of underwater searching

MW 70x40 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 164.24 kg | Standard |

| Water (riverbed) |

188.05 kg

(+23.81 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains merely approx. 20-30% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.64

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages and disadvantages of Nd2Fe14B magnets.

Pros

- They retain full power for around 10 years – the loss is just ~1% (according to analyses),

- They do not lose their magnetic properties even under external field action,

- Thanks to the shiny finish, the coating of Ni-Cu-Ni, gold-plated, or silver-plated gives an professional appearance,

- Magnets possess exceptionally strong magnetic induction on the active area,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Due to the ability of accurate shaping and adaptation to custom solutions, magnetic components can be produced in a broad palette of forms and dimensions, which expands the range of possible applications,

- Significant place in high-tech industry – they find application in magnetic memories, motor assemblies, precision medical tools, and complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which allows their use in small systems

Limitations

- At strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- Limited ability of making nuts in the magnet and complex forms - preferred is cover - mounting mechanism.

- Health risk resulting from small fragments of magnets pose a threat, in case of ingestion, which becomes key in the context of child health protection. Additionally, small elements of these magnets can disrupt the diagnostic process medical in case of swallowing.

- With budget limitations the cost of neodymium magnets is economically unviable,

Pull force analysis

Detachment force of the magnet in optimal conditions – what contributes to it?

- with the application of a sheet made of special test steel, guaranteeing maximum field concentration

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with a surface free of scratches

- under conditions of no distance (surface-to-surface)

- under perpendicular force direction (90-degree angle)

- at ambient temperature room level

Determinants of lifting force in real conditions

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) drastically reduces the pulling force, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet holds much less (often approx. 20-30% of nominal force).

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Metal type – different alloys attracts identically. High carbon content worsen the interaction with the magnet.

- Surface finish – ideal contact is possible only on smooth steel. Rough texture create air cushions, reducing force.

- Operating temperature – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under shearing force the lifting capacity is smaller. Moreover, even a slight gap between the magnet and the plate decreases the load capacity.

H&S for magnets

Magnet fragility

NdFeB magnets are sintered ceramics, meaning they are very brittle. Clashing of two magnets will cause them shattering into small pieces.

Crushing force

Protect your hands. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing anything in their path. Be careful!

Respect the power

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or injure your hand. Think ahead.

Danger to pacemakers

Patients with a ICD must maintain an absolute distance from magnets. The magnetic field can interfere with the operation of the implant.

Maximum temperature

Control the heat. Exposing the magnet above 80 degrees Celsius will ruin its properties and strength.

Keep away from computers

Data protection: Neodymium magnets can damage payment cards and delicate electronics (heart implants, medical aids, timepieces).

Combustion hazard

Combustion risk: Neodymium dust is explosive. Do not process magnets in home conditions as this risks ignition.

No play value

Always store magnets away from children. Choking hazard is significant, and the effects of magnets connecting inside the body are fatal.

Sensitization to coating

Some people experience a contact allergy to Ni, which is the typical protective layer for NdFeB magnets. Frequent touching might lead to a rash. We recommend use protective gloves.

Compass and GPS

Note: neodymium magnets produce a field that disrupts sensitive sensors. Maintain a separation from your mobile, device, and GPS.