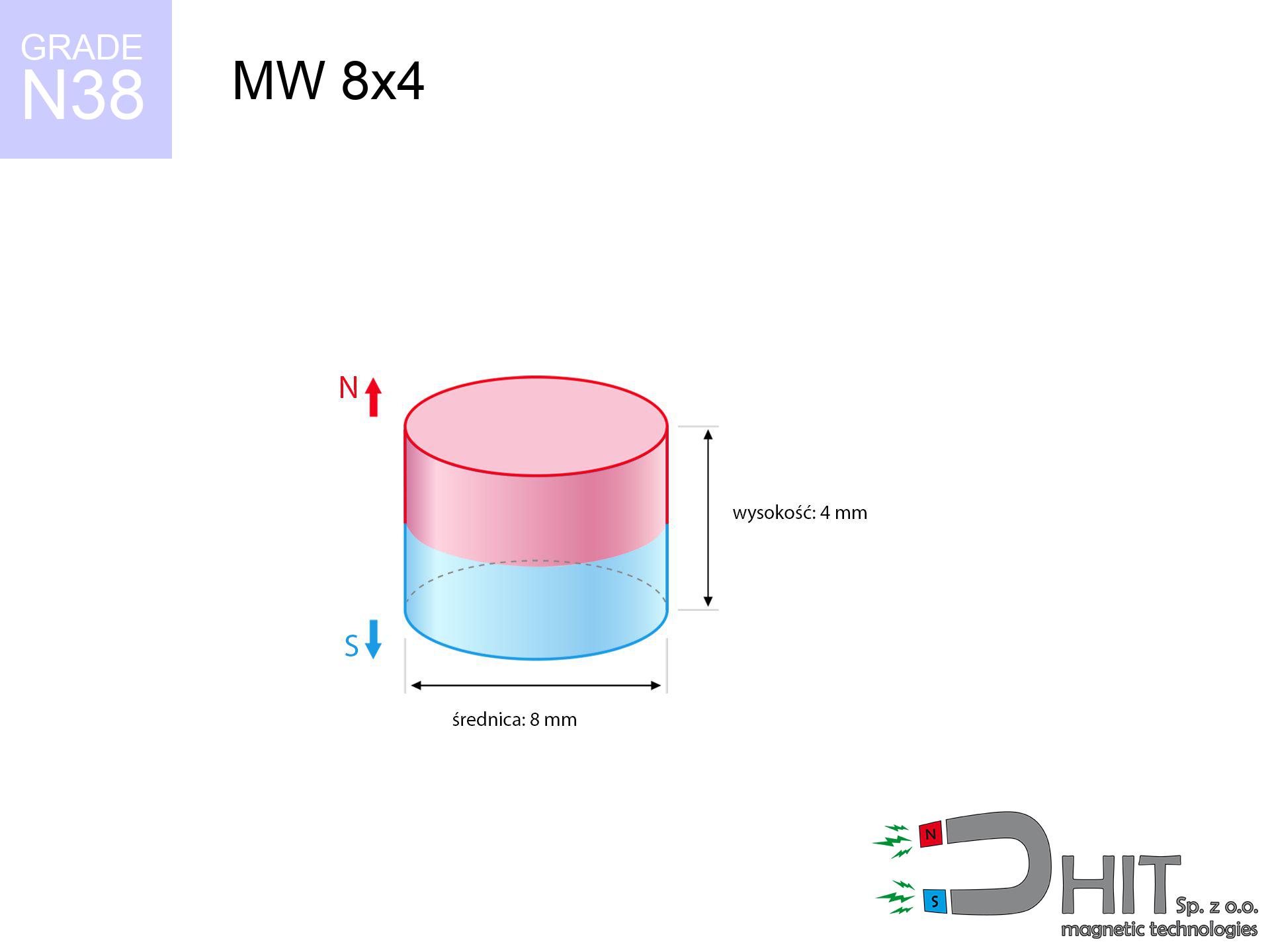

MW 8x4 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010104

GTIN/EAN: 5906301811039

Diameter Ø

8 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

1.51 g

Magnetization Direction

↑ axial

Load capacity

2.04 kg / 20.00 N

Magnetic Induction

437.78 mT / 4378 Gs

Coating

[NiCuNi] Nickel

0.701 ZŁ with VAT / pcs + price for transport

0.570 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer drop us a message by means of

inquiry form

through our site.

Strength along with structure of neodymium magnets can be checked on our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Product card - MW 8x4 / N38 - cylindrical magnet

Specification / characteristics - MW 8x4 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010104 |

| GTIN/EAN | 5906301811039 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 1.51 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.04 kg / 20.00 N |

| Magnetic Induction ~ ? | 437.78 mT / 4378 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - data

Presented information represent the result of a engineering calculation. Values were calculated on models for the class Nd2Fe14B. Actual parameters may deviate from the simulation results. Use these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (pull vs distance) - power drop

MW 8x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4374 Gs

437.4 mT

|

2.04 kg / 4.50 LBS

2040.0 g / 20.0 N

|

strong |

| 1 mm |

3338 Gs

333.8 mT

|

1.19 kg / 2.62 LBS

1187.8 g / 11.7 N

|

low risk |

| 2 mm |

2386 Gs

238.6 mT

|

0.61 kg / 1.34 LBS

607.0 g / 6.0 N

|

low risk |

| 3 mm |

1663 Gs

166.3 mT

|

0.29 kg / 0.65 LBS

294.9 g / 2.9 N

|

low risk |

| 5 mm |

824 Gs

82.4 mT

|

0.07 kg / 0.16 LBS

72.4 g / 0.7 N

|

low risk |

| 10 mm |

205 Gs

20.5 mT

|

0.00 kg / 0.01 LBS

4.5 g / 0.0 N

|

low risk |

| 15 mm |

76 Gs

7.6 mT

|

0.00 kg / 0.00 LBS

0.6 g / 0.0 N

|

low risk |

| 20 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

| 30 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage hold (vertical surface)

MW 8x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.41 kg / 0.90 LBS

408.0 g / 4.0 N

|

| 1 mm | Stal (~0.2) |

0.24 kg / 0.52 LBS

238.0 g / 2.3 N

|

| 2 mm | Stal (~0.2) |

0.12 kg / 0.27 LBS

122.0 g / 1.2 N

|

| 3 mm | Stal (~0.2) |

0.06 kg / 0.13 LBS

58.0 g / 0.6 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

14.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 8x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.61 kg / 1.35 LBS

612.0 g / 6.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.41 kg / 0.90 LBS

408.0 g / 4.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.20 kg / 0.45 LBS

204.0 g / 2.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.02 kg / 2.25 LBS

1020.0 g / 10.0 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 8x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.20 kg / 0.45 LBS

204.0 g / 2.0 N

|

| 1 mm |

|

0.51 kg / 1.12 LBS

510.0 g / 5.0 N

|

| 2 mm |

|

1.02 kg / 2.25 LBS

1020.0 g / 10.0 N

|

| 3 mm |

|

1.53 kg / 3.37 LBS

1530.0 g / 15.0 N

|

| 5 mm |

|

2.04 kg / 4.50 LBS

2040.0 g / 20.0 N

|

| 10 mm |

|

2.04 kg / 4.50 LBS

2040.0 g / 20.0 N

|

| 11 mm |

|

2.04 kg / 4.50 LBS

2040.0 g / 20.0 N

|

| 12 mm |

|

2.04 kg / 4.50 LBS

2040.0 g / 20.0 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 8x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.04 kg / 4.50 LBS

2040.0 g / 20.0 N

|

OK |

| 40 °C | -2.2% |

2.00 kg / 4.40 LBS

1995.1 g / 19.6 N

|

OK |

| 60 °C | -4.4% |

1.95 kg / 4.30 LBS

1950.2 g / 19.1 N

|

|

| 80 °C | -6.6% |

1.91 kg / 4.20 LBS

1905.4 g / 18.7 N

|

|

| 100 °C | -28.8% |

1.45 kg / 3.20 LBS

1452.5 g / 14.2 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 8x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.93 kg / 13.07 LBS

5 531 Gs

|

0.89 kg / 1.96 LBS

889 g / 8.7 N

|

N/A |

| 1 mm |

4.63 kg / 10.21 LBS

7 730 Gs

|

0.69 kg / 1.53 LBS

694 g / 6.8 N

|

4.17 kg / 9.18 LBS

~0 Gs

|

| 2 mm |

3.45 kg / 7.61 LBS

6 675 Gs

|

0.52 kg / 1.14 LBS

518 g / 5.1 N

|

3.11 kg / 6.85 LBS

~0 Gs

|

| 3 mm |

2.49 kg / 5.50 LBS

5 674 Gs

|

0.37 kg / 0.82 LBS

374 g / 3.7 N

|

2.25 kg / 4.95 LBS

~0 Gs

|

| 5 mm |

1.23 kg / 2.72 LBS

3 989 Gs

|

0.18 kg / 0.41 LBS

185 g / 1.8 N

|

1.11 kg / 2.45 LBS

~0 Gs

|

| 10 mm |

0.21 kg / 0.46 LBS

1 648 Gs

|

0.03 kg / 0.07 LBS

32 g / 0.3 N

|

0.19 kg / 0.42 LBS

~0 Gs

|

| 20 mm |

0.01 kg / 0.03 LBS

410 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.03 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

39 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

24 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

15 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

8 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 8x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - warning

MW 8x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

37.12 km/h

(10.31 m/s)

|

0.08 J | |

| 30 mm |

64.21 km/h

(17.83 m/s)

|

0.24 J | |

| 50 mm |

82.89 km/h

(23.02 m/s)

|

0.40 J | |

| 100 mm |

117.22 km/h

(32.56 m/s)

|

0.80 J |

Table 9: Corrosion resistance

MW 8x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 8x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 233 Mx | 22.3 µWb |

| Pc Coefficient | 0.59 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 8x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.04 kg | Standard |

| Water (riverbed) |

2.34 kg

(+0.30 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet retains only ~20% of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) severely weakens the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.59

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more proposals

Advantages and disadvantages of neodymium magnets.

Strengths

- They virtually do not lose power, because even after ten years the performance loss is only ~1% (according to literature),

- Neodymium magnets prove to be exceptionally resistant to loss of magnetic properties caused by external magnetic fields,

- By applying a smooth layer of gold, the element gains an proper look,

- Neodymium magnets ensure maximum magnetic induction on a small surface, which allows for strong attraction,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of custom creating as well as adapting to specific conditions,

- Significant place in modern technologies – they serve a role in data components, electromotive mechanisms, medical equipment, as well as multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Weaknesses

- At strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We suggest cover - magnetic mount, due to difficulties in realizing threads inside the magnet and complex shapes.

- Possible danger resulting from small fragments of magnets can be dangerous, if swallowed, which gains importance in the aspect of protecting the youngest. Furthermore, small elements of these products can be problematic in diagnostics medical when they are in the body.

- Due to neodymium price, their price is relatively high,

Lifting parameters

Maximum magnetic pulling force – what it depends on?

- using a base made of high-permeability steel, serving as a ideal flux conductor

- whose thickness is min. 10 mm

- with a plane free of scratches

- without any air gap between the magnet and steel

- for force acting at a right angle (in the magnet axis)

- at conditions approx. 20°C

Impact of factors on magnetic holding capacity in practice

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to detachment vertically. When slipping, the magnet holds much less (often approx. 20-30% of nominal force).

- Plate thickness – too thin plate does not accept the full field, causing part of the flux to be lost to the other side.

- Material composition – different alloys reacts the same. Alloy additives worsen the interaction with the magnet.

- Smoothness – full contact is possible only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – heating the magnet results in weakening of induction. Check the thermal limit for a given model.

Lifting capacity was measured with the use of a steel plate with a smooth surface of suitable thickness (min. 20 mm), under vertically applied force, however under parallel forces the holding force is lower. In addition, even a minimal clearance between the magnet and the plate decreases the holding force.

Warnings

Mechanical processing

Mechanical processing of neodymium magnets carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Fragile material

Watch out for shards. Magnets can fracture upon uncontrolled impact, launching sharp fragments into the air. Wear goggles.

Serious injuries

Danger of trauma: The pulling power is so great that it can cause hematomas, crushing, and broken bones. Protective gloves are recommended.

Heat warning

Regular neodymium magnets (grade N) lose power when the temperature exceeds 80°C. Damage is permanent.

Data carriers

Avoid bringing magnets close to a purse, laptop, or screen. The magnetism can destroy these devices and erase data from cards.

Sensitization to coating

Some people have a contact allergy to Ni, which is the common plating for neodymium magnets. Prolonged contact may cause dermatitis. We suggest wear protective gloves.

Respect the power

Before use, read the rules. Sudden snapping can destroy the magnet or hurt your hand. Be predictive.

Swallowing risk

Always store magnets out of reach of children. Risk of swallowing is significant, and the consequences of magnets connecting inside the body are fatal.

Compass and GPS

A powerful magnetic field disrupts the functioning of compasses in phones and navigation systems. Maintain magnets close to a smartphone to prevent damaging the sensors.

ICD Warning

People with a heart stimulator should maintain an safe separation from magnets. The magnetism can disrupt the functioning of the implant.

![SM 25x400 [2xM8] / N42 - magnetic separator SM 25x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x400-2xm8-daj.jpg)