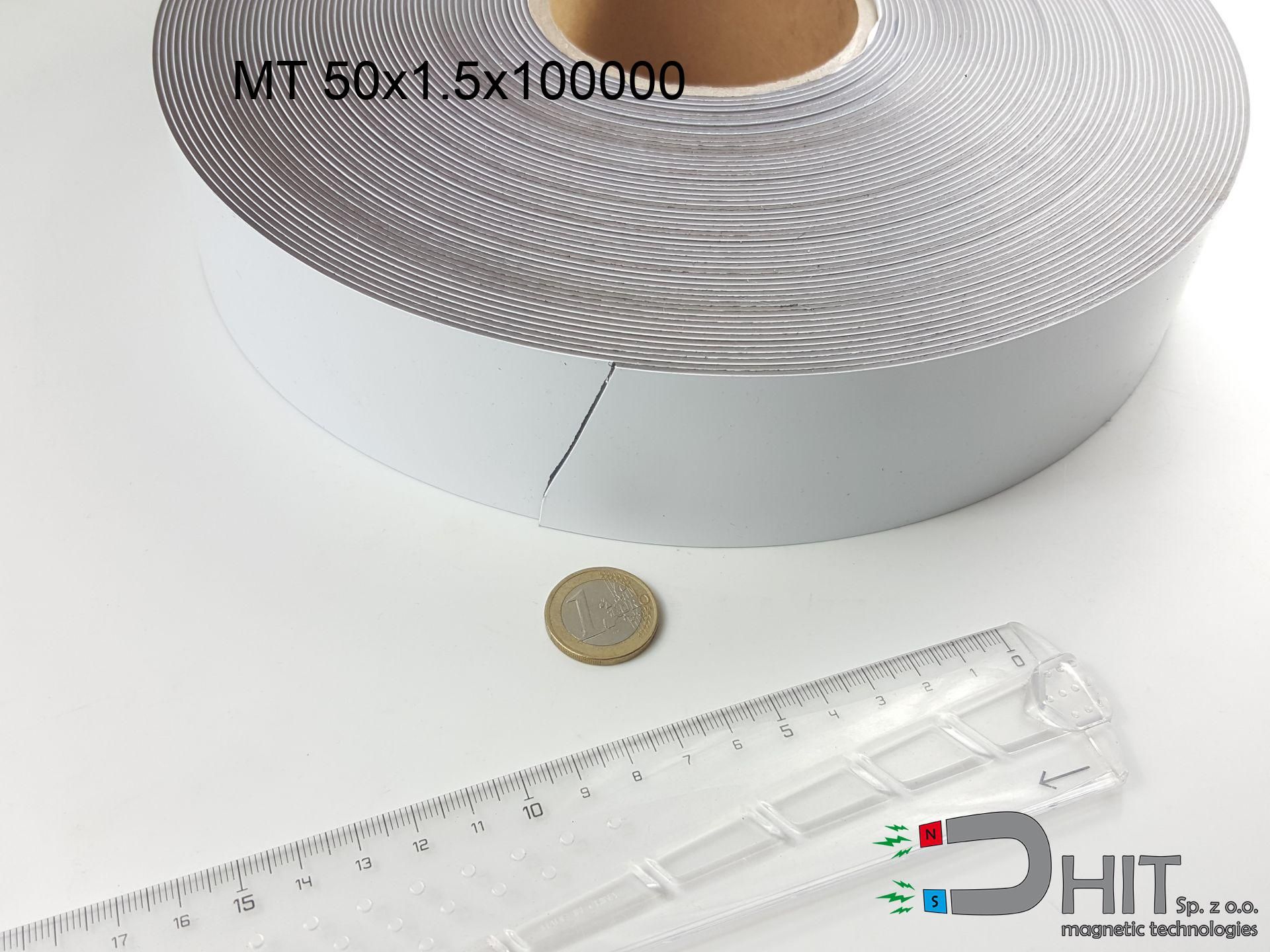

MT 50x1.5x100000 - magnetic tape

magnetic tape

Catalog no 380512

length

50 mm [±1 mm]

Width

1.5 mm [±1 mm]

Height

100000 mm [±1 mm]

861.00 ZŁ with VAT / pcs + price for transport

700.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

or get in touch via

request form

the contact form page.

Parameters as well as structure of a neodymium magnet can be calculated on our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Technical specification of the product - MT 50x1.5x100000 - magnetic tape

Specification / characteristics - MT 50x1.5x100000 - magnetic tape

| properties | values |

|---|---|

| Cat. no. | 380512 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±1 mm] |

| Width | 1.5 mm [±1 mm] |

| Height | 100000 mm [±1 mm] |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages and disadvantages of neodymium magnets.

Benefits

- They retain attractive force for around ten years – the drop is just ~1% (according to analyses),

- They do not lose their magnetic properties even under close interference source,

- By applying a reflective coating of silver, the element presents an professional look,

- The surface of neodymium magnets generates a intense magnetic field – this is a distinguishing feature,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Thanks to versatility in designing and the ability to adapt to unusual requirements,

- Huge importance in electronics industry – they are utilized in computer drives, electromotive mechanisms, advanced medical instruments, also technologically advanced constructions.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in creating threads and complicated shapes in magnets, we recommend using casing - magnetic mount.

- Health risk related to microscopic parts of magnets are risky, if swallowed, which becomes key in the context of child safety. It is also worth noting that small components of these magnets are able to complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Pull force analysis

Detachment force of the magnet in optimal conditions – what affects it?

- using a plate made of low-carbon steel, functioning as a circuit closing element

- whose transverse dimension reaches at least 10 mm

- characterized by even structure

- under conditions of ideal adhesion (surface-to-surface)

- under axial force vector (90-degree angle)

- at temperature approx. 20 degrees Celsius

Magnet lifting force in use – key factors

- Gap (between the magnet and the metal), since even a tiny distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to varnish, corrosion or dirt).

- Pull-off angle – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of generating force.

- Steel grade – ideal substrate is high-permeability steel. Cast iron may attract less.

- Base smoothness – the more even the plate, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal environment – heating the magnet results in weakening of induction. It is worth remembering the thermal limit for a given model.

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under parallel forces the load capacity is reduced by as much as 75%. Additionally, even a minimal clearance between the magnet’s surface and the plate decreases the load capacity.

Precautions when working with neodymium magnets

Compass and GPS

GPS units and mobile phones are highly susceptible to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the sensors in your phone.

Powerful field

Handle with care. Rare earth magnets act from a long distance and connect with huge force, often faster than you can move away.

Sensitization to coating

Medical facts indicate that the nickel plating (standard magnet coating) is a potent allergen. If your skin reacts to metals, prevent touching magnets with bare hands or opt for versions in plastic housing.

Danger to the youngest

Product intended for adults. Small elements can be swallowed, leading to serious injuries. Keep away from children and animals.

Threat to electronics

Avoid bringing magnets close to a purse, computer, or TV. The magnetic field can irreversibly ruin these devices and wipe information from cards.

Bodily injuries

Protect your hands. Two powerful magnets will snap together instantly with a force of massive weight, destroying everything in their path. Be careful!

Fire warning

Combustion risk: Neodymium dust is explosive. Avoid machining magnets without safety gear as this risks ignition.

Do not overheat magnets

Keep cool. NdFeB magnets are susceptible to temperature. If you need operation above 80°C, look for HT versions (H, SH, UH).

Protective goggles

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Life threat

Individuals with a heart stimulator must maintain an large gap from magnets. The magnetic field can stop the operation of the life-saving device.

![SM 32x250 [2xM8] / N52 - magnetic separator SM 32x250 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-guf.jpg)

![BM 850x180x70 [4x M8] - magnetic beam BM 850x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-850x180x70-4x-m8-mep.jpg)