SM 25x200 [2xM8] / N52 - magnetic separator

magnetic separator

Catalog no 130364

GTIN/EAN: 5906301813125

Diameter Ø

25 mm [±1 mm]

Height

200 mm [±1 mm]

Weight

760 g

Magnetic Flux

~ 8 500 Gauss [±5%]

615.00 ZŁ with VAT / pcs + price for transport

500.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

if you prefer get in touch through

inquiry form

the contact form page.

Weight as well as appearance of magnets can be reviewed with our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Technical details - SM 25x200 [2xM8] / N52 - magnetic separator

Specification / characteristics - SM 25x200 [2xM8] / N52 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130364 |

| GTIN/EAN | 5906301813125 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 25 mm [±1 mm] |

| Height | 200 mm [±1 mm] |

| Weight | 760 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 8 500 Gauss [±5%] |

| Size/Mount Quantity | M8x2 |

| Polarity | circumferential - 7 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

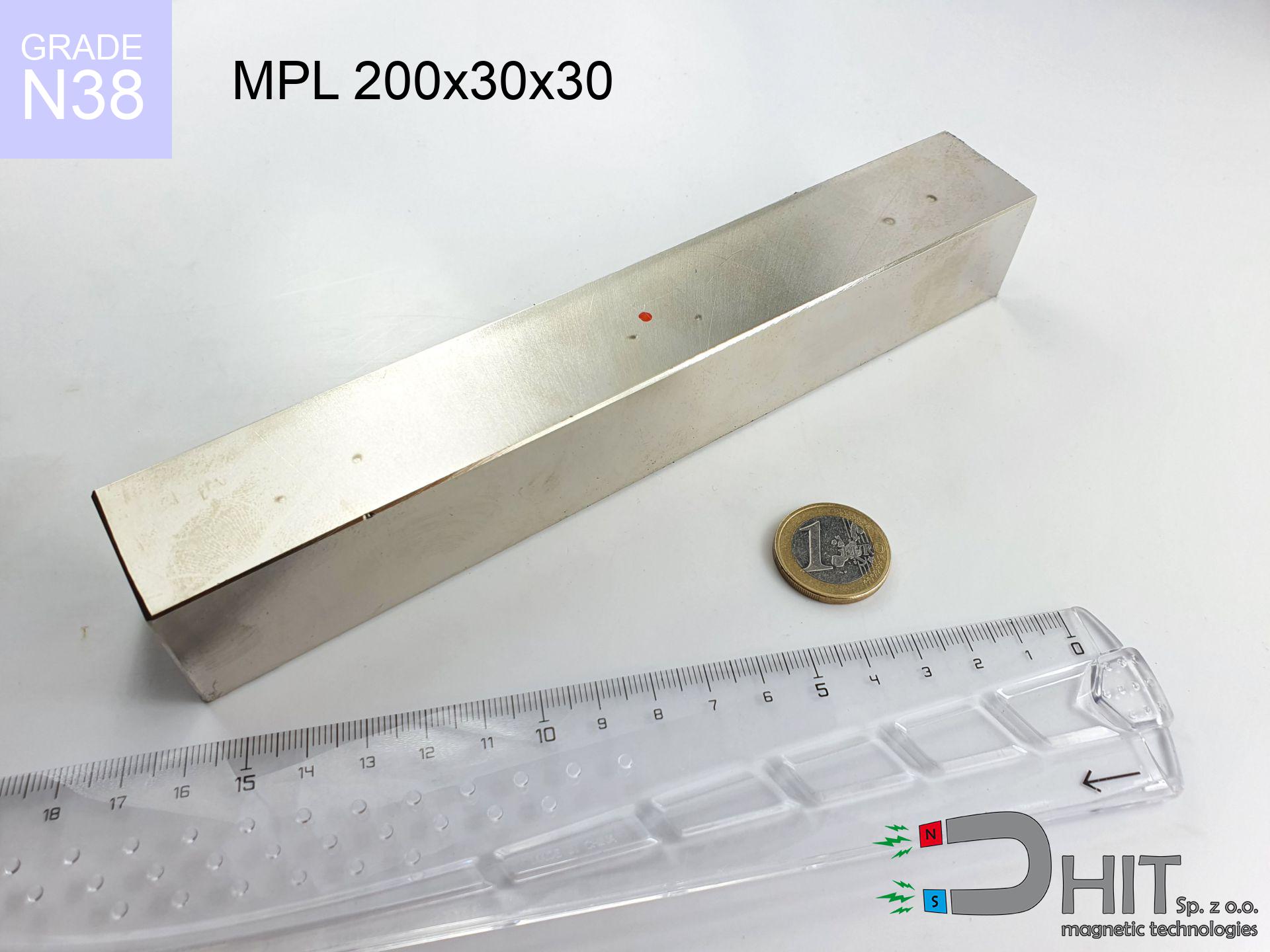

Table 1: Rod construction

SM 25x200 [2xM8] / N52

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 25 | mm |

| Total length | 200 | mm (L) |

| Active length | 164 | mm |

| Section count | 7 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~746 | g |

| Active area | 129 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 18.1 | kg (theor.) |

| Induction (surface) | ~8 500 | Gauss (Max) |

Chart 2: Field profile (7 sections)

Chart 3: Temperature performance

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Pros as well as cons of neodymium magnets.

Advantages

- They do not lose strength, even after nearly ten years – the drop in power is only ~1% (according to tests),

- They are noted for resistance to demagnetization induced by presence of other magnetic fields,

- Thanks to the elegant finish, the coating of nickel, gold-plated, or silver-plated gives an aesthetic appearance,

- The surface of neodymium magnets generates a maximum magnetic field – this is one of their assets,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Due to the option of accurate molding and adaptation to unique solutions, neodymium magnets can be produced in a variety of forms and dimensions, which makes them more universal,

- Wide application in future technologies – they are used in HDD drives, brushless drives, precision medical tools, also other advanced devices.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They oxidize in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of creating nuts in the magnet and complicated shapes - preferred is casing - magnet mounting.

- Health risk to health – tiny shards of magnets are risky, when accidentally swallowed, which becomes key in the context of child health protection. Furthermore, small components of these products can complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Maximum lifting force for a neodymium magnet – what it depends on?

- on a block made of structural steel, perfectly concentrating the magnetic flux

- possessing a massiveness of min. 10 mm to avoid saturation

- with an ground contact surface

- under conditions of no distance (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- at temperature room level

Determinants of practical lifting force of a magnet

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Load vector – highest force is available only during perpendicular pulling. The shear force of the magnet along the surface is typically many times smaller (approx. 1/5 of the lifting capacity).

- Base massiveness – insufficiently thick sheet does not close the flux, causing part of the flux to be wasted into the air.

- Steel grade – ideal substrate is pure iron steel. Cast iron may have worse magnetic properties.

- Smoothness – full contact is obtained only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Temperature influence – high temperature weakens magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under a perpendicular pulling force, however under parallel forces the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate decreases the lifting capacity.

Precautions when working with neodymium magnets

Choking Hazard

Neodymium magnets are not suitable for play. Swallowing multiple magnets can lead to them attracting across intestines, which poses a critical condition and necessitates urgent medical intervention.

Risk of cracking

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. Wear goggles.

Nickel coating and allergies

Nickel alert: The Ni-Cu-Ni coating contains nickel. If redness appears, cease working with magnets and wear gloves.

Power loss in heat

Regular neodymium magnets (grade N) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Hand protection

Pinching hazard: The pulling power is so immense that it can result in blood blisters, pinching, and broken bones. Use thick gloves.

Dust explosion hazard

Dust generated during grinding of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

Immense force

Before use, read the rules. Sudden snapping can break the magnet or hurt your hand. Be predictive.

GPS and phone interference

GPS units and smartphones are highly sensitive to magnetism. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

Pacemakers

Warning for patients: Strong magnetic fields disrupt medical devices. Keep minimum 30 cm distance or ask another person to handle the magnets.

Safe distance

Equipment safety: Neodymium magnets can ruin payment cards and sensitive devices (heart implants, hearing aids, mechanical watches).

![Separation magnetic rod SM 25x200 [2xM8] / N52 Separation magnetic rod SM 25x200 [2xM8] / N52](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 25x200 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x200-2xm8-jas.jpg)