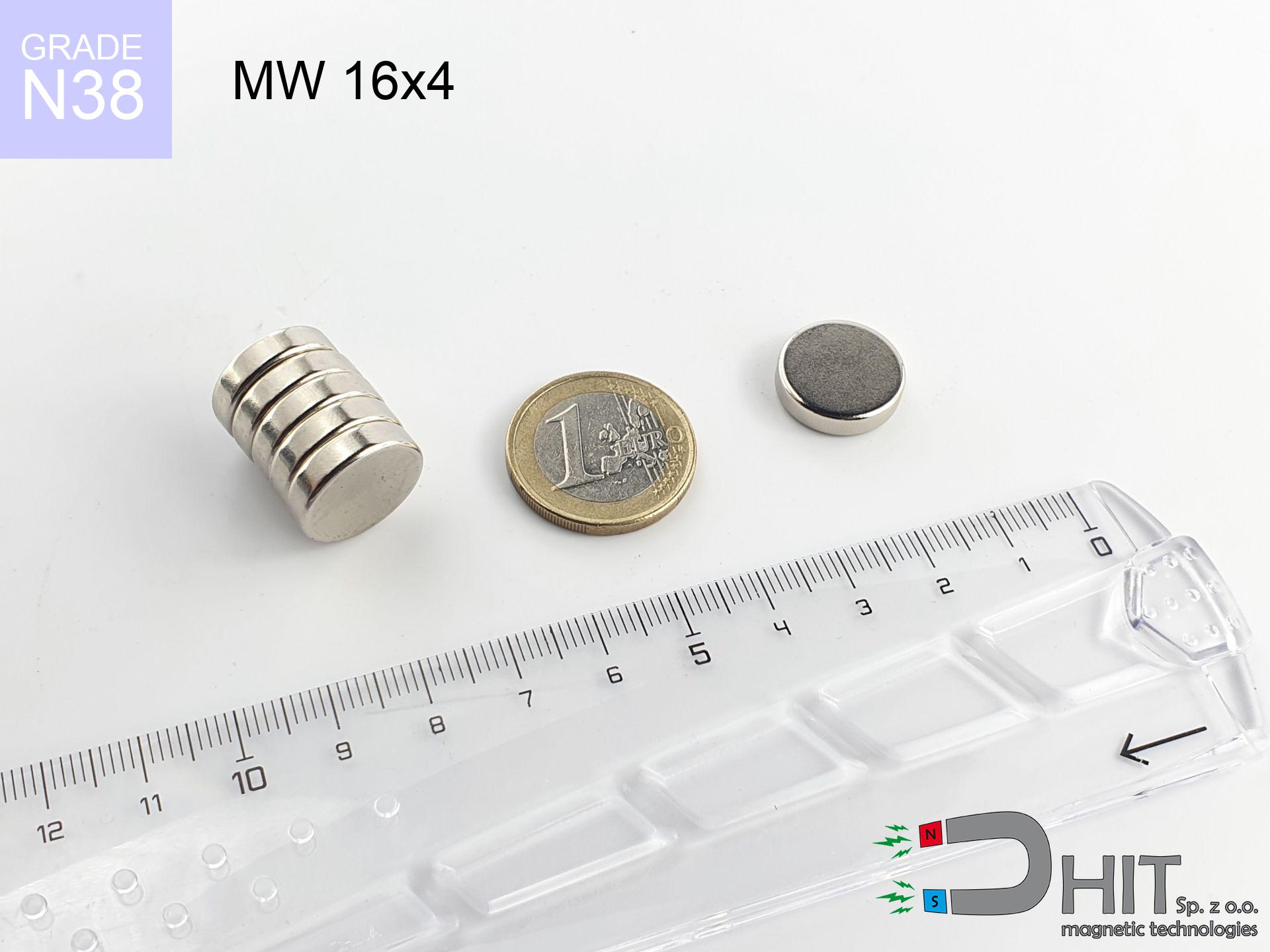

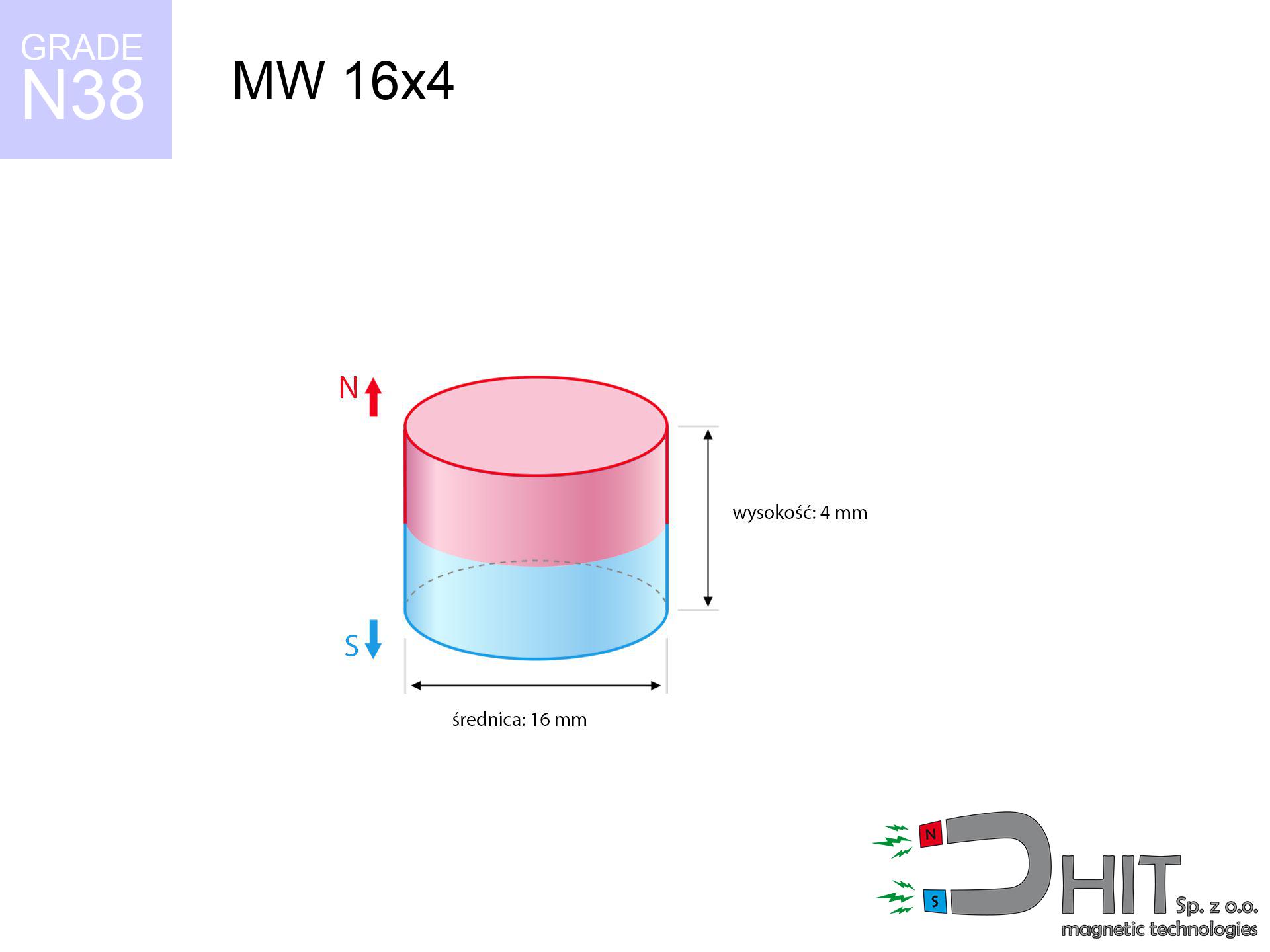

MW 16x4 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010034

GTIN/EAN: 5906301810339

Diameter Ø

16 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

6.03 g

Magnetization Direction

↑ axial

Load capacity

4.43 kg / 43.46 N

Magnetic Induction

277.14 mT / 2771 Gs

Coating

[NiCuNi] Nickel

3.39 ZŁ with VAT / pcs + price for transport

2.76 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise drop us a message using

inquiry form

the contact section.

Strength and appearance of neodymium magnets can be checked on our

force calculator.

Same-day processing for orders placed before 14:00.

Technical details - MW 16x4 / N38 - cylindrical magnet

Specification / characteristics - MW 16x4 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010034 |

| GTIN/EAN | 5906301810339 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 16 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 6.03 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.43 kg / 43.46 N |

| Magnetic Induction ~ ? | 277.14 mT / 2771 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - technical parameters

These data constitute the direct effect of a mathematical calculation. Values are based on models for the class Nd2Fe14B. Operational parameters may deviate from the simulation results. Please consider these data as a preliminary roadmap when designing systems.

Table 1: Static force (pull vs gap) - characteristics

MW 16x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2771 Gs

277.1 mT

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

medium risk |

| 1 mm |

2517 Gs

251.7 mT

|

3.66 kg / 8.06 lbs

3656.3 g / 35.9 N

|

medium risk |

| 2 mm |

2216 Gs

221.6 mT

|

2.83 kg / 6.25 lbs

2834.9 g / 27.8 N

|

medium risk |

| 3 mm |

1906 Gs

190.6 mT

|

2.10 kg / 4.62 lbs

2096.1 g / 20.6 N

|

medium risk |

| 5 mm |

1348 Gs

134.8 mT

|

1.05 kg / 2.31 lbs

1048.6 g / 10.3 N

|

safe |

| 10 mm |

542 Gs

54.2 mT

|

0.17 kg / 0.37 lbs

169.4 g / 1.7 N

|

safe |

| 15 mm |

244 Gs

24.4 mT

|

0.03 kg / 0.08 lbs

34.2 g / 0.3 N

|

safe |

| 20 mm |

125 Gs

12.5 mT

|

0.01 kg / 0.02 lbs

9.1 g / 0.1 N

|

safe |

| 30 mm |

45 Gs

4.5 mT

|

0.00 kg / 0.00 lbs

1.1 g / 0.0 N

|

safe |

| 50 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

Table 2: Shear force (vertical surface)

MW 16x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.89 kg / 1.95 lbs

886.0 g / 8.7 N

|

| 1 mm | Stal (~0.2) |

0.73 kg / 1.61 lbs

732.0 g / 7.2 N

|

| 2 mm | Stal (~0.2) |

0.57 kg / 1.25 lbs

566.0 g / 5.6 N

|

| 3 mm | Stal (~0.2) |

0.42 kg / 0.93 lbs

420.0 g / 4.1 N

|

| 5 mm | Stal (~0.2) |

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

34.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 16x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.33 kg / 2.93 lbs

1329.0 g / 13.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.89 kg / 1.95 lbs

886.0 g / 8.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.44 kg / 0.98 lbs

443.0 g / 4.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.22 kg / 4.88 lbs

2215.0 g / 21.7 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 16x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.44 kg / 0.98 lbs

443.0 g / 4.3 N

|

| 1 mm |

|

1.11 kg / 2.44 lbs

1107.5 g / 10.9 N

|

| 2 mm |

|

2.22 kg / 4.88 lbs

2215.0 g / 21.7 N

|

| 3 mm |

|

3.32 kg / 7.32 lbs

3322.5 g / 32.6 N

|

| 5 mm |

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

| 10 mm |

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

| 11 mm |

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

| 12 mm |

|

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MW 16x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.43 kg / 9.77 lbs

4430.0 g / 43.5 N

|

OK |

| 40 °C | -2.2% |

4.33 kg / 9.55 lbs

4332.5 g / 42.5 N

|

OK |

| 60 °C | -4.4% |

4.24 kg / 9.34 lbs

4235.1 g / 41.5 N

|

|

| 80 °C | -6.6% |

4.14 kg / 9.12 lbs

4137.6 g / 40.6 N

|

|

| 100 °C | -28.8% |

3.15 kg / 6.95 lbs

3154.2 g / 30.9 N

|

Table 6: Two magnets (repulsion) - field collision

MW 16x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

9.51 kg / 20.98 lbs

4 379 Gs

|

1.43 kg / 3.15 lbs

1427 g / 14.0 N

|

N/A |

| 1 mm |

8.72 kg / 19.23 lbs

5 306 Gs

|

1.31 kg / 2.88 lbs

1309 g / 12.8 N

|

7.85 kg / 17.31 lbs

~0 Gs

|

| 2 mm |

7.85 kg / 17.31 lbs

5 034 Gs

|

1.18 kg / 2.60 lbs

1178 g / 11.6 N

|

7.07 kg / 15.58 lbs

~0 Gs

|

| 3 mm |

6.96 kg / 15.35 lbs

4 740 Gs

|

1.04 kg / 2.30 lbs

1044 g / 10.2 N

|

6.27 kg / 13.81 lbs

~0 Gs

|

| 5 mm |

5.26 kg / 11.60 lbs

4 121 Gs

|

0.79 kg / 1.74 lbs

789 g / 7.7 N

|

4.74 kg / 10.44 lbs

~0 Gs

|

| 10 mm |

2.25 kg / 4.97 lbs

2 696 Gs

|

0.34 kg / 0.74 lbs

338 g / 3.3 N

|

2.03 kg / 4.47 lbs

~0 Gs

|

| 20 mm |

0.36 kg / 0.80 lbs

1 083 Gs

|

0.05 kg / 0.12 lbs

55 g / 0.5 N

|

0.33 kg / 0.72 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.01 lbs

143 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 lbs

89 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

59 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

41 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

29 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

22 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MW 16x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - warning

MW 16x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.98 km/h

(7.77 m/s)

|

0.18 J | |

| 30 mm |

47.35 km/h

(13.15 m/s)

|

0.52 J | |

| 50 mm |

61.12 km/h

(16.98 m/s)

|

0.87 J | |

| 100 mm |

86.44 km/h

(24.01 m/s)

|

1.74 J |

Table 9: Surface protection spec

MW 16x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 16x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 192 Mx | 61.9 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 16x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.43 kg | Standard |

| Water (riverbed) |

5.07 kg

(+0.64 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds only approx. 20-30% of its nominal pull.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) severely weakens the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Pros and cons of neodymium magnets.

Pros

- They do not lose magnetism, even over nearly ten years – the reduction in power is only ~1% (based on measurements),

- They retain their magnetic properties even under strong external field,

- By using a lustrous layer of gold, the element presents an proper look,

- They show high magnetic induction at the operating surface, which increases their power,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Thanks to modularity in forming and the capacity to modify to unusual requirements,

- Versatile presence in modern technologies – they serve a role in mass storage devices, motor assemblies, diagnostic systems, as well as multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which enables their usage in small systems

Cons

- To avoid cracks under impact, we suggest using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Limited possibility of making nuts in the magnet and complex shapes - preferred is cover - magnet mounting.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. Additionally, small elements of these magnets can disrupt the diagnostic process medical after entering the body.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Highest magnetic holding force – what affects it?

- on a block made of mild steel, perfectly concentrating the magnetic field

- with a thickness minimum 10 mm

- with an ideally smooth touching surface

- with direct contact (no impurities)

- during pulling in a direction vertical to the mounting surface

- at conditions approx. 20°C

Practical aspects of lifting capacity – factors

- Air gap (betwixt the magnet and the metal), since even a tiny distance (e.g. 0.5 mm) results in a decrease in force by up to 50% (this also applies to paint, corrosion or debris).

- Angle of force application – maximum parameter is available only during perpendicular pulling. The force required to slide of the magnet along the surface is standardly many times lower (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Chemical composition of the base – mild steel attracts best. Higher carbon content decrease magnetic properties and lifting capacity.

- Smoothness – ideal contact is obtained only on polished steel. Rough texture create air cushions, weakening the magnet.

- Operating temperature – neodymium magnets have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a small distance between the magnet’s surface and the plate reduces the lifting capacity.

Precautions when working with NdFeB magnets

Implant safety

People with a pacemaker must keep an safe separation from magnets. The magnetic field can disrupt the functioning of the life-saving device.

Nickel allergy

It is widely known that nickel (standard magnet coating) is a common allergen. If your skin reacts to metals, prevent touching magnets with bare hands and choose coated magnets.

Powerful field

Handle magnets consciously. Their huge power can shock even professionals. Plan your moves and do not underestimate their power.

Protect data

Very strong magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Stay away of at least 10 cm.

Heat warning

Keep cool. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).

Serious injuries

Big blocks can smash fingers instantly. Do not place your hand between two strong magnets.

Compass and GPS

A powerful magnetic field negatively affects the functioning of compasses in phones and navigation systems. Maintain magnets close to a device to avoid damaging the sensors.

Flammability

Fire warning: Neodymium dust is highly flammable. Avoid machining magnets in home conditions as this risks ignition.

Magnets are brittle

Despite the nickel coating, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Do not give to children

Always keep magnets out of reach of children. Choking hazard is significant, and the effects of magnets clamping inside the body are life-threatening.

![MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x15x5x27-3.5-cas.jpg)

![SM 32x400 [2xM8] / N52 - magnetic separator SM 32x400 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-led.jpg)