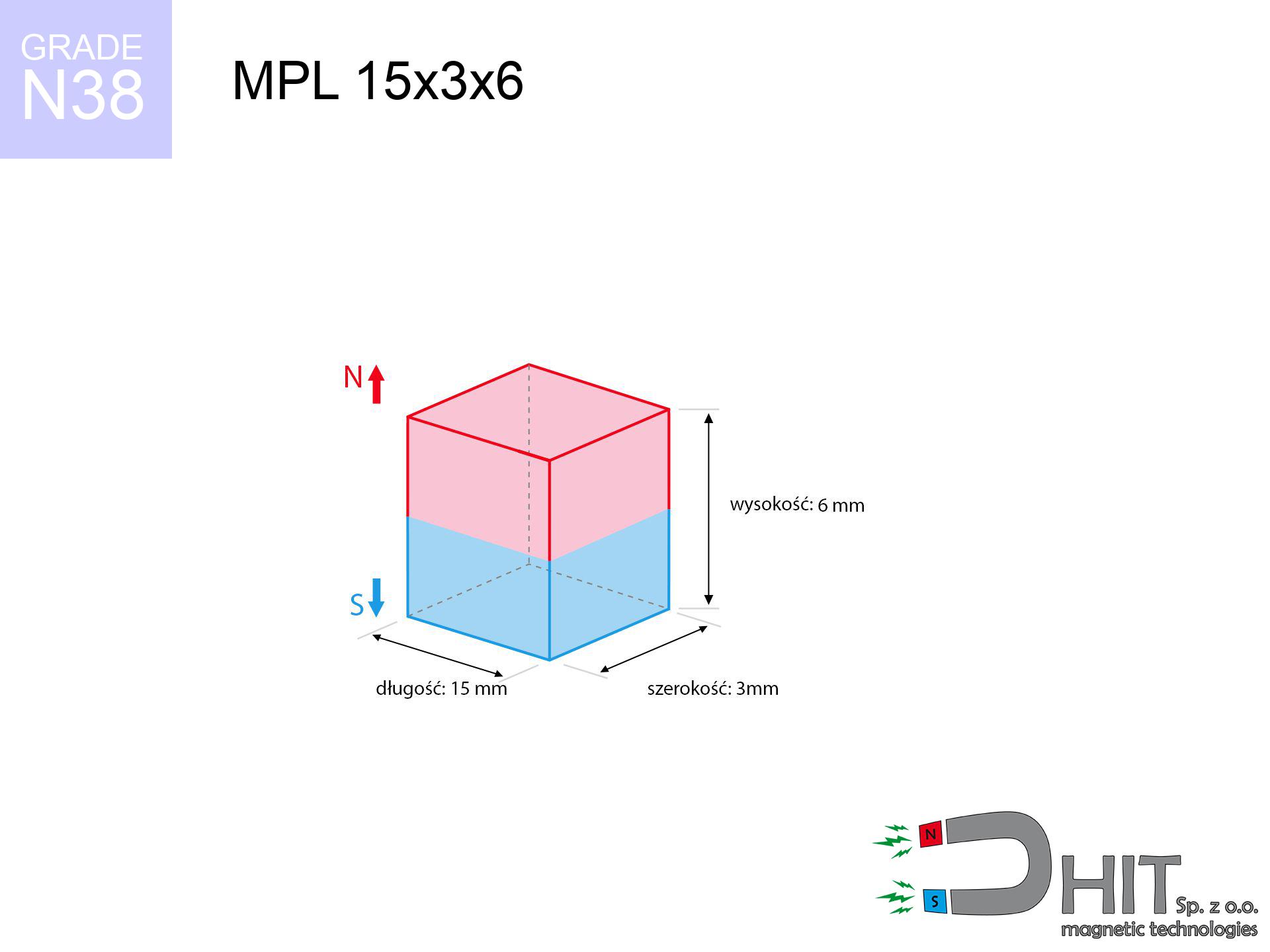

MPL 15x3x6 / N38 - lamellar magnet

lamellar magnet

Catalog no 020122

GTIN/EAN: 5906301811282

length

15 mm [±0,1 mm]

Width

3 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

2.03 g

Magnetization Direction

↑ axial

Load capacity

1.90 kg / 18.68 N

Magnetic Induction

543.23 mT / 5432 Gs

Coating

[NiCuNi] Nickel

0.726 ZŁ with VAT / pcs + price for transport

0.590 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise send us a note via

our online form

the contact section.

Specifications and structure of magnets can be estimated using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical of the product - MPL 15x3x6 / N38 - lamellar magnet

Specification / characteristics - MPL 15x3x6 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020122 |

| GTIN/EAN | 5906301811282 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 15 mm [±0,1 mm] |

| Width | 3 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 2.03 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.90 kg / 18.68 N |

| Magnetic Induction ~ ? | 543.23 mT / 5432 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - data

Presented data are the result of a mathematical calculation. Values were calculated on algorithms for the material Nd2Fe14B. Actual conditions might slightly differ from theoretical values. Treat these calculations as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs distance) - characteristics

MPL 15x3x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5423 Gs

542.3 mT

|

1.90 kg / 4.19 LBS

1900.0 g / 18.6 N

|

weak grip |

| 1 mm |

3221 Gs

322.1 mT

|

0.67 kg / 1.48 LBS

670.2 g / 6.6 N

|

weak grip |

| 2 mm |

1942 Gs

194.2 mT

|

0.24 kg / 0.54 LBS

243.7 g / 2.4 N

|

weak grip |

| 3 mm |

1274 Gs

127.4 mT

|

0.10 kg / 0.23 LBS

104.9 g / 1.0 N

|

weak grip |

| 5 mm |

652 Gs

65.2 mT

|

0.03 kg / 0.06 LBS

27.5 g / 0.3 N

|

weak grip |

| 10 mm |

195 Gs

19.5 mT

|

0.00 kg / 0.01 LBS

2.5 g / 0.0 N

|

weak grip |

| 15 mm |

81 Gs

8.1 mT

|

0.00 kg / 0.00 LBS

0.4 g / 0.0 N

|

weak grip |

| 20 mm |

41 Gs

4.1 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 30 mm |

14 Gs

1.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding capacity (wall)

MPL 15x3x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.38 kg / 0.84 LBS

380.0 g / 3.7 N

|

| 1 mm | Stal (~0.2) |

0.13 kg / 0.30 LBS

134.0 g / 1.3 N

|

| 2 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

48.0 g / 0.5 N

|

| 3 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

20.0 g / 0.2 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 15x3x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.57 kg / 1.26 LBS

570.0 g / 5.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.38 kg / 0.84 LBS

380.0 g / 3.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.19 kg / 0.42 LBS

190.0 g / 1.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.95 kg / 2.09 LBS

950.0 g / 9.3 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 15x3x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.19 kg / 0.42 LBS

190.0 g / 1.9 N

|

| 1 mm |

|

0.48 kg / 1.05 LBS

475.0 g / 4.7 N

|

| 2 mm |

|

0.95 kg / 2.09 LBS

950.0 g / 9.3 N

|

| 3 mm |

|

1.42 kg / 3.14 LBS

1425.0 g / 14.0 N

|

| 5 mm |

|

1.90 kg / 4.19 LBS

1900.0 g / 18.6 N

|

| 10 mm |

|

1.90 kg / 4.19 LBS

1900.0 g / 18.6 N

|

| 11 mm |

|

1.90 kg / 4.19 LBS

1900.0 g / 18.6 N

|

| 12 mm |

|

1.90 kg / 4.19 LBS

1900.0 g / 18.6 N

|

Table 5: Thermal stability (material behavior) - thermal limit

MPL 15x3x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.90 kg / 4.19 LBS

1900.0 g / 18.6 N

|

OK |

| 40 °C | -2.2% |

1.86 kg / 4.10 LBS

1858.2 g / 18.2 N

|

OK |

| 60 °C | -4.4% |

1.82 kg / 4.00 LBS

1816.4 g / 17.8 N

|

OK |

| 80 °C | -6.6% |

1.77 kg / 3.91 LBS

1774.6 g / 17.4 N

|

|

| 100 °C | -28.8% |

1.35 kg / 2.98 LBS

1352.8 g / 13.3 N

|

Table 6: Two magnets (attraction) - forces in the system

MPL 15x3x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

8.16 kg / 17.99 LBS

5 914 Gs

|

1.22 kg / 2.70 LBS

1224 g / 12.0 N

|

N/A |

| 1 mm |

4.96 kg / 10.94 LBS

8 460 Gs

|

0.74 kg / 1.64 LBS

745 g / 7.3 N

|

4.47 kg / 9.85 LBS

~0 Gs

|

| 2 mm |

2.88 kg / 6.34 LBS

6 441 Gs

|

0.43 kg / 0.95 LBS

432 g / 4.2 N

|

2.59 kg / 5.71 LBS

~0 Gs

|

| 3 mm |

1.70 kg / 3.75 LBS

4 950 Gs

|

0.25 kg / 0.56 LBS

255 g / 2.5 N

|

1.53 kg / 3.37 LBS

~0 Gs

|

| 5 mm |

0.67 kg / 1.48 LBS

3 116 Gs

|

0.10 kg / 0.22 LBS

101 g / 1.0 N

|

0.61 kg / 1.34 LBS

~0 Gs

|

| 10 mm |

0.12 kg / 0.26 LBS

1 304 Gs

|

0.02 kg / 0.04 LBS

18 g / 0.2 N

|

0.11 kg / 0.23 LBS

~0 Gs

|

| 20 mm |

0.01 kg / 0.02 LBS

391 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

46 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

29 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

19 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

13 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

9 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MPL 15x3x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 15x3x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

30.88 km/h

(8.58 m/s)

|

0.07 J | |

| 30 mm |

53.44 km/h

(14.84 m/s)

|

0.22 J | |

| 50 mm |

68.99 km/h

(19.16 m/s)

|

0.37 J | |

| 100 mm |

97.57 km/h

(27.10 m/s)

|

0.75 J |

Table 9: Anti-corrosion coating durability

MPL 15x3x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 15x3x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 390 Mx | 23.9 µWb |

| Pc Coefficient | 0.79 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MPL 15x3x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.90 kg | Standard |

| Water (riverbed) |

2.18 kg

(+0.28 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet holds merely approx. 20-30% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.79

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Advantages and disadvantages of rare earth magnets.

Strengths

- They do not lose power, even over approximately 10 years – the drop in power is only ~1% (according to tests),

- They do not lose their magnetic properties even under close interference source,

- Thanks to the metallic finish, the surface of Ni-Cu-Ni, gold-plated, or silver-plated gives an aesthetic appearance,

- Magnetic induction on the working part of the magnet remains impressive,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of accurate creating and adapting to specific requirements,

- Universal use in high-tech industry – they serve a role in hard drives, brushless drives, medical equipment, and modern systems.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation and corrosion.

- Limited possibility of producing threads in the magnet and complex forms - recommended is a housing - mounting mechanism.

- Possible danger to health – tiny shards of magnets pose a threat, in case of ingestion, which gains importance in the aspect of protecting the youngest. It is also worth noting that small elements of these products are able to complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Magnetic strength at its maximum – what it depends on?

- on a block made of mild steel, optimally conducting the magnetic field

- whose transverse dimension reaches at least 10 mm

- characterized by smoothness

- without the slightest clearance between the magnet and steel

- under vertical application of breakaway force (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Determinants of practical lifting force of a magnet

- Gap between surfaces – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – note that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material composition – different alloys attracts identically. High carbon content weaken the attraction effect.

- Surface condition – ground elements guarantee perfect abutment, which increases field saturation. Uneven metal reduce efficiency.

- Temperature – temperature increase causes a temporary drop of induction. Check the maximum operating temperature for a given model.

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the lifting capacity is smaller. In addition, even a minimal clearance between the magnet and the plate decreases the load capacity.

Safe handling of neodymium magnets

Swallowing risk

Always store magnets out of reach of children. Choking hazard is high, and the effects of magnets connecting inside the body are very dangerous.

Medical implants

For implant holders: Powerful magnets disrupt medical devices. Maintain at least 30 cm distance or request help to work with the magnets.

Bodily injuries

Protect your hands. Two powerful magnets will snap together immediately with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

GPS Danger

GPS units and mobile phones are highly sensitive to magnetic fields. Close proximity with a strong magnet can decalibrate the internal compass in your phone.

Machining danger

Fire hazard: Rare earth powder is explosive. Do not process magnets in home conditions as this may cause fire.

Do not underestimate power

Use magnets consciously. Their immense force can surprise even experienced users. Plan your moves and respect their force.

Protective goggles

Despite metallic appearance, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may crumble into hazardous fragments.

Protect data

Powerful magnetic fields can corrupt files on payment cards, hard drives, and storage devices. Keep a distance of min. 10 cm.

Permanent damage

Monitor thermal conditions. Heating the magnet to high heat will destroy its properties and pulling force.

Nickel allergy

A percentage of the population experience a sensitization to Ni, which is the common plating for neodymium magnets. Extended handling may cause a rash. We suggest wear protective gloves.

![SM 32x325 [2xM8] / N52 - magnetic separator SM 32x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-xec.jpg)

![MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl40x10x4x27-3.5-suw.jpg)

![SM 32x475 [2xM8] / N52 - magnetic separator SM 32x475 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x475-2xm8-wef.jpg)