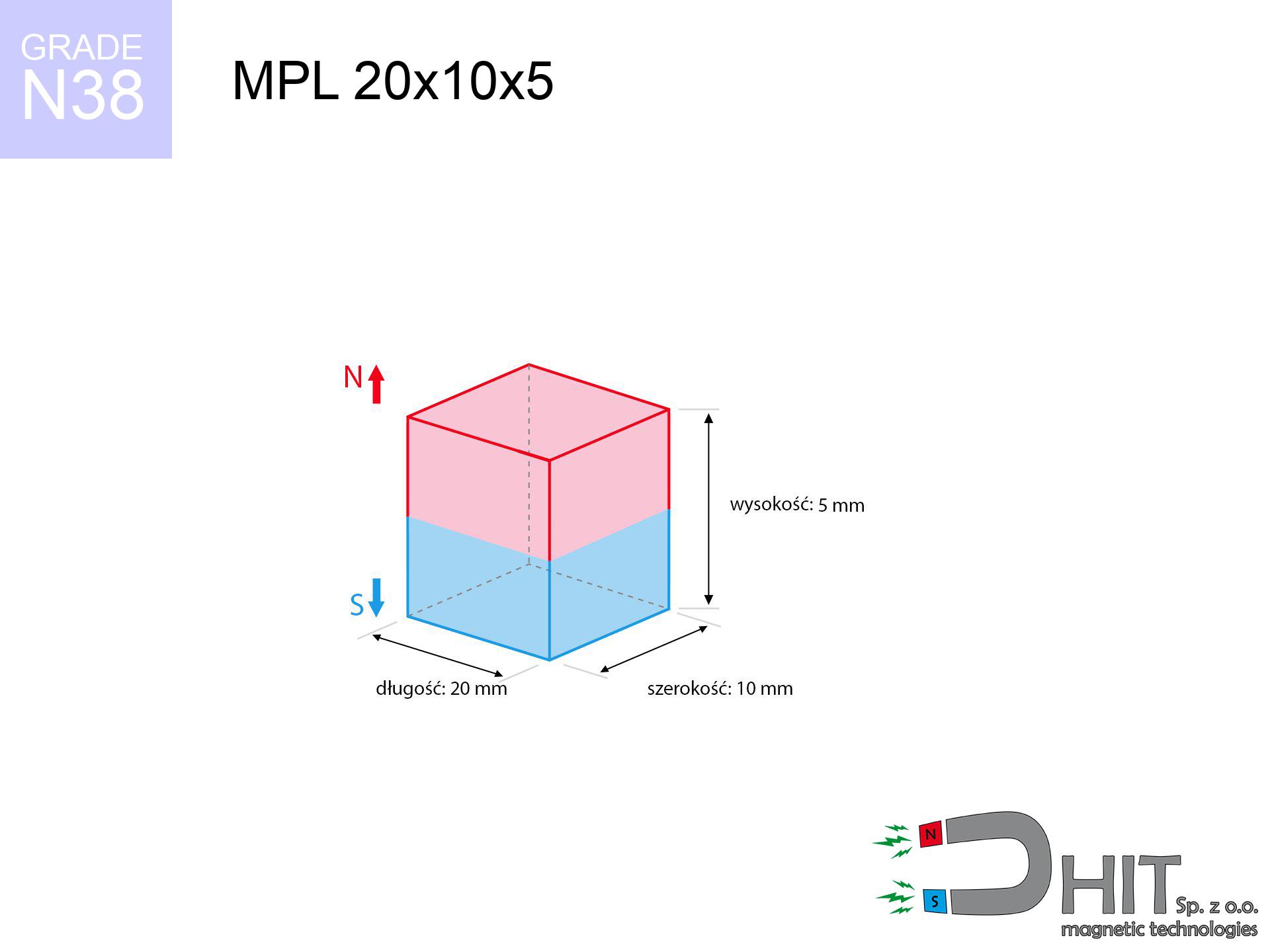

MPL 20x10x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020128

GTIN/EAN: 5906301811343

length

20 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

7.5 g

Magnetization Direction

↑ axial

Load capacity

6.15 kg / 60.31 N

Magnetic Induction

349.47 mT / 3495 Gs

Coating

[NiCuNi] Nickel

4.54 ZŁ with VAT / pcs + price for transport

3.69 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer send us a note via

our online form

the contact form page.

Lifting power along with form of a neodymium magnet can be reviewed using our

magnetic mass calculator.

Order by 14:00 and we’ll ship today!

Technical of the product - MPL 20x10x5 / N38 - lamellar magnet

Specification / characteristics - MPL 20x10x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020128 |

| GTIN/EAN | 5906301811343 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 7.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.15 kg / 60.31 N |

| Magnetic Induction ~ ? | 349.47 mT / 3495 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - report

These information constitute the direct effect of a mathematical calculation. Values were calculated on algorithms for the class Nd2Fe14B. Operational performance may differ from theoretical values. Please consider these calculations as a preliminary roadmap when designing systems.

Table 1: Static force (pull vs gap) - power drop

MPL 20x10x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3493 Gs

349.3 mT

|

6.15 kg / 13.56 lbs

6150.0 g / 60.3 N

|

warning |

| 1 mm |

3035 Gs

303.5 mT

|

4.64 kg / 10.23 lbs

4641.8 g / 45.5 N

|

warning |

| 2 mm |

2558 Gs

255.8 mT

|

3.30 kg / 7.27 lbs

3298.0 g / 32.4 N

|

warning |

| 3 mm |

2120 Gs

212.0 mT

|

2.26 kg / 4.99 lbs

2264.8 g / 22.2 N

|

warning |

| 5 mm |

1433 Gs

143.3 mT

|

1.03 kg / 2.28 lbs

1034.5 g / 10.1 N

|

low risk |

| 10 mm |

574 Gs

57.4 mT

|

0.17 kg / 0.37 lbs

166.1 g / 1.6 N

|

low risk |

| 15 mm |

267 Gs

26.7 mT

|

0.04 kg / 0.08 lbs

35.9 g / 0.4 N

|

low risk |

| 20 mm |

141 Gs

14.1 mT

|

0.01 kg / 0.02 lbs

10.1 g / 0.1 N

|

low risk |

| 30 mm |

52 Gs

5.2 mT

|

0.00 kg / 0.00 lbs

1.4 g / 0.0 N

|

low risk |

| 50 mm |

13 Gs

1.3 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

low risk |

Table 2: Sliding hold (vertical surface)

MPL 20x10x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.23 kg / 2.71 lbs

1230.0 g / 12.1 N

|

| 1 mm | Stal (~0.2) |

0.93 kg / 2.05 lbs

928.0 g / 9.1 N

|

| 2 mm | Stal (~0.2) |

0.66 kg / 1.46 lbs

660.0 g / 6.5 N

|

| 3 mm | Stal (~0.2) |

0.45 kg / 1.00 lbs

452.0 g / 4.4 N

|

| 5 mm | Stal (~0.2) |

0.21 kg / 0.45 lbs

206.0 g / 2.0 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

34.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 20x10x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.85 kg / 4.07 lbs

1845.0 g / 18.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.23 kg / 2.71 lbs

1230.0 g / 12.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.62 kg / 1.36 lbs

615.0 g / 6.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.08 kg / 6.78 lbs

3075.0 g / 30.2 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 20x10x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.62 kg / 1.36 lbs

615.0 g / 6.0 N

|

| 1 mm |

|

1.54 kg / 3.39 lbs

1537.5 g / 15.1 N

|

| 2 mm |

|

3.08 kg / 6.78 lbs

3075.0 g / 30.2 N

|

| 3 mm |

|

4.61 kg / 10.17 lbs

4612.5 g / 45.2 N

|

| 5 mm |

|

6.15 kg / 13.56 lbs

6150.0 g / 60.3 N

|

| 10 mm |

|

6.15 kg / 13.56 lbs

6150.0 g / 60.3 N

|

| 11 mm |

|

6.15 kg / 13.56 lbs

6150.0 g / 60.3 N

|

| 12 mm |

|

6.15 kg / 13.56 lbs

6150.0 g / 60.3 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MPL 20x10x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.15 kg / 13.56 lbs

6150.0 g / 60.3 N

|

OK |

| 40 °C | -2.2% |

6.01 kg / 13.26 lbs

6014.7 g / 59.0 N

|

OK |

| 60 °C | -4.4% |

5.88 kg / 12.96 lbs

5879.4 g / 57.7 N

|

|

| 80 °C | -6.6% |

5.74 kg / 12.66 lbs

5744.1 g / 56.3 N

|

|

| 100 °C | -28.8% |

4.38 kg / 9.65 lbs

4378.8 g / 43.0 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MPL 20x10x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

15.04 kg / 33.17 lbs

4 923 Gs

|

2.26 kg / 4.98 lbs

2257 g / 22.1 N

|

N/A |

| 1 mm |

13.20 kg / 29.11 lbs

6 544 Gs

|

1.98 kg / 4.37 lbs

1980 g / 19.4 N

|

11.88 kg / 26.19 lbs

~0 Gs

|

| 2 mm |

11.36 kg / 25.03 lbs

6 069 Gs

|

1.70 kg / 3.76 lbs

1703 g / 16.7 N

|

10.22 kg / 22.53 lbs

~0 Gs

|

| 3 mm |

9.63 kg / 21.22 lbs

5 588 Gs

|

1.44 kg / 3.18 lbs

1444 g / 14.2 N

|

8.66 kg / 19.10 lbs

~0 Gs

|

| 5 mm |

6.71 kg / 14.78 lbs

4 664 Gs

|

1.01 kg / 2.22 lbs

1006 g / 9.9 N

|

6.03 kg / 13.30 lbs

~0 Gs

|

| 10 mm |

2.53 kg / 5.58 lbs

2 865 Gs

|

0.38 kg / 0.84 lbs

380 g / 3.7 N

|

2.28 kg / 5.02 lbs

~0 Gs

|

| 20 mm |

0.41 kg / 0.90 lbs

1 148 Gs

|

0.06 kg / 0.13 lbs

61 g / 0.6 N

|

0.37 kg / 0.81 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.02 lbs

165 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 lbs

104 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

69 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

48 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

35 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

26 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - warnings

MPL 20x10x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MPL 20x10x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.36 km/h

(8.16 m/s)

|

0.25 J | |

| 30 mm |

50.03 km/h

(13.90 m/s)

|

0.72 J | |

| 50 mm |

64.58 km/h

(17.94 m/s)

|

1.21 J | |

| 100 mm |

91.32 km/h

(25.37 m/s)

|

2.41 J |

Table 9: Coating parameters (durability)

MPL 20x10x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 20x10x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 7 031 Mx | 70.3 µWb |

| Pc Coefficient | 0.42 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 20x10x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.15 kg | Standard |

| Water (riverbed) |

7.04 kg

(+0.89 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet retains merely ~20% of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) severely reduces the holding force.

3. Thermal stability

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.42

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more offers

Advantages as well as disadvantages of rare earth magnets.

Pros

- Their power is maintained, and after around 10 years it drops only by ~1% (theoretically),

- Magnets perfectly resist against demagnetization caused by foreign field sources,

- Thanks to the smooth finish, the plating of Ni-Cu-Ni, gold, or silver gives an modern appearance,

- Magnetic induction on the working layer of the magnet is strong,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Thanks to the possibility of free molding and adaptation to individualized needs, neodymium magnets can be created in a wide range of forms and dimensions, which makes them more universal,

- Significant place in innovative solutions – they are utilized in mass storage devices, motor assemblies, advanced medical instruments, also industrial machines.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Disadvantages

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a strong case, which not only protects them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation as well as corrosion.

- Due to limitations in creating threads and complex shapes in magnets, we recommend using casing - magnetic holder.

- Health risk to health – tiny shards of magnets pose a threat, if swallowed, which gains importance in the context of child safety. It is also worth noting that small elements of these products can be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Magnetic strength at its maximum – what contributes to it?

- with the use of a yoke made of special test steel, guaranteeing maximum field concentration

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- with an ideally smooth contact surface

- under conditions of gap-free contact (surface-to-surface)

- under perpendicular force vector (90-degree angle)

- at standard ambient temperature

Impact of factors on magnetic holding capacity in practice

- Space between magnet and steel – every millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to pulling vertically. When slipping, the magnet holds much less (often approx. 20-30% of maximum force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of generating force.

- Plate material – low-carbon steel attracts best. Alloy steels lower magnetic permeability and holding force.

- Surface condition – ground elements guarantee perfect abutment, which improves field saturation. Uneven metal reduce efficiency.

- Thermal factor – hot environment weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was determined by applying a smooth steel plate of suitable thickness (min. 20 mm), under vertically applied force, in contrast under parallel forces the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate decreases the lifting capacity.

Precautions when working with neodymium magnets

Power loss in heat

Watch the temperature. Exposing the magnet above 80 degrees Celsius will ruin its magnetic structure and strength.

Conscious usage

Handle with care. Neodymium magnets act from a long distance and connect with massive power, often faster than you can move away.

Fragile material

Protect your eyes. Magnets can explode upon uncontrolled impact, ejecting shards into the air. Wear goggles.

Impact on smartphones

GPS units and smartphones are highly susceptible to magnetic fields. Direct contact with a powerful NdFeB magnet can decalibrate the internal compass in your phone.

Medical interference

Life threat: Neodymium magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Magnetic media

Data protection: Neodymium magnets can damage payment cards and delicate electronics (pacemakers, medical aids, mechanical watches).

Pinching danger

Risk of injury: The pulling power is so great that it can result in hematomas, pinching, and broken bones. Protective gloves are recommended.

Fire risk

Fire hazard: Neodymium dust is explosive. Do not process magnets without safety gear as this risks ignition.

Swallowing risk

Product intended for adults. Tiny parts can be swallowed, leading to intestinal necrosis. Store out of reach of children and animals.

Skin irritation risks

It is widely known that nickel (the usual finish) is a common allergen. If your skin reacts to metals, prevent touching magnets with bare hands or select coated magnets.