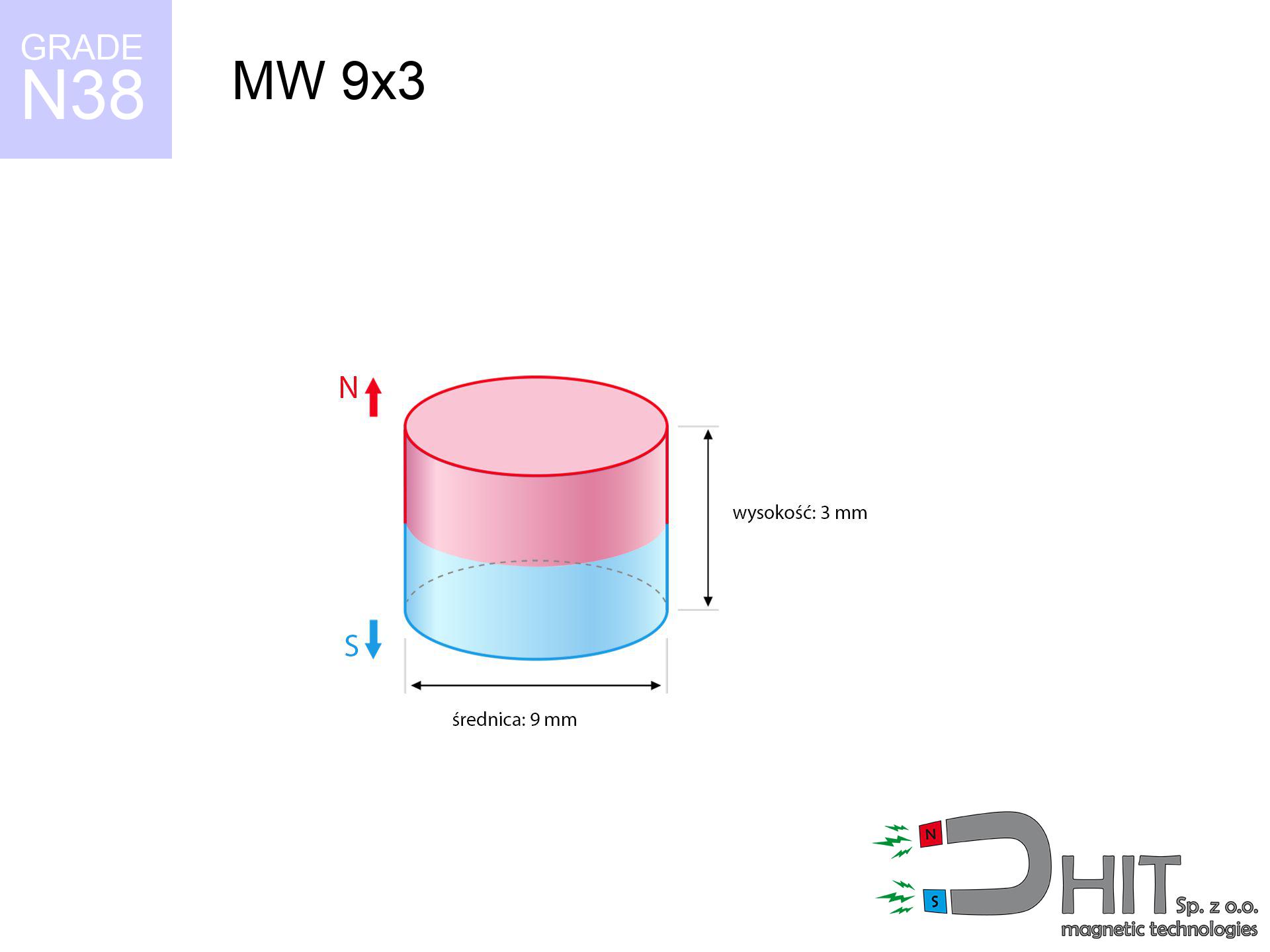

MW 9x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010108

GTIN/EAN: 5906301811077

Diameter Ø

9 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

1.43 g

Magnetization Direction

↑ axial

Load capacity

1.94 kg / 18.99 N

Magnetic Induction

343.55 mT / 3436 Gs

Coating

[NiCuNi] Nickel

1.132 ZŁ with VAT / pcs + price for transport

0.920 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer let us know using

contact form

the contact section.

Force and form of magnets can be estimated using our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical data - MW 9x3 / N38 - cylindrical magnet

Specification / characteristics - MW 9x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010108 |

| GTIN/EAN | 5906301811077 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 9 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 1.43 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.94 kg / 18.99 N |

| Magnetic Induction ~ ? | 343.55 mT / 3436 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

Presented values are the result of a engineering analysis. Results rely on models for the class Nd2Fe14B. Real-world parameters may differ. Use these data as a reference point when designing systems.

Table 1: Static force (pull vs distance) - characteristics

MW 9x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3433 Gs

343.3 mT

|

1.94 kg / 4.28 lbs

1940.0 g / 19.0 N

|

safe |

| 1 mm |

2774 Gs

277.4 mT

|

1.27 kg / 2.79 lbs

1266.5 g / 12.4 N

|

safe |

| 2 mm |

2090 Gs

209.0 mT

|

0.72 kg / 1.59 lbs

719.2 g / 7.1 N

|

safe |

| 3 mm |

1521 Gs

152.1 mT

|

0.38 kg / 0.84 lbs

380.7 g / 3.7 N

|

safe |

| 5 mm |

795 Gs

79.5 mT

|

0.10 kg / 0.23 lbs

104.1 g / 1.0 N

|

safe |

| 10 mm |

205 Gs

20.5 mT

|

0.01 kg / 0.02 lbs

6.9 g / 0.1 N

|

safe |

| 15 mm |

76 Gs

7.6 mT

|

0.00 kg / 0.00 lbs

1.0 g / 0.0 N

|

safe |

| 20 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

safe |

| 30 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Sliding load (vertical surface)

MW 9x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.39 kg / 0.86 lbs

388.0 g / 3.8 N

|

| 1 mm | Stal (~0.2) |

0.25 kg / 0.56 lbs

254.0 g / 2.5 N

|

| 2 mm | Stal (~0.2) |

0.14 kg / 0.32 lbs

144.0 g / 1.4 N

|

| 3 mm | Stal (~0.2) |

0.08 kg / 0.17 lbs

76.0 g / 0.7 N

|

| 5 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

20.0 g / 0.2 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 9x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.58 kg / 1.28 lbs

582.0 g / 5.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.39 kg / 0.86 lbs

388.0 g / 3.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.19 kg / 0.43 lbs

194.0 g / 1.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.97 kg / 2.14 lbs

970.0 g / 9.5 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 9x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.19 kg / 0.43 lbs

194.0 g / 1.9 N

|

| 1 mm |

|

0.49 kg / 1.07 lbs

485.0 g / 4.8 N

|

| 2 mm |

|

0.97 kg / 2.14 lbs

970.0 g / 9.5 N

|

| 3 mm |

|

1.46 kg / 3.21 lbs

1455.0 g / 14.3 N

|

| 5 mm |

|

1.94 kg / 4.28 lbs

1940.0 g / 19.0 N

|

| 10 mm |

|

1.94 kg / 4.28 lbs

1940.0 g / 19.0 N

|

| 11 mm |

|

1.94 kg / 4.28 lbs

1940.0 g / 19.0 N

|

| 12 mm |

|

1.94 kg / 4.28 lbs

1940.0 g / 19.0 N

|

Table 5: Thermal stability (stability) - thermal limit

MW 9x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.94 kg / 4.28 lbs

1940.0 g / 19.0 N

|

OK |

| 40 °C | -2.2% |

1.90 kg / 4.18 lbs

1897.3 g / 18.6 N

|

OK |

| 60 °C | -4.4% |

1.85 kg / 4.09 lbs

1854.6 g / 18.2 N

|

|

| 80 °C | -6.6% |

1.81 kg / 3.99 lbs

1812.0 g / 17.8 N

|

|

| 100 °C | -28.8% |

1.38 kg / 3.05 lbs

1381.3 g / 13.6 N

|

Table 6: Two magnets (repulsion) - field range

MW 9x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.62 kg / 10.19 lbs

4 949 Gs

|

0.69 kg / 1.53 lbs

693 g / 6.8 N

|

N/A |

| 1 mm |

3.82 kg / 8.43 lbs

6 244 Gs

|

0.57 kg / 1.26 lbs

573 g / 5.6 N

|

3.44 kg / 7.58 lbs

~0 Gs

|

| 2 mm |

3.02 kg / 6.65 lbs

5 548 Gs

|

0.45 kg / 1.00 lbs

453 g / 4.4 N

|

2.72 kg / 5.99 lbs

~0 Gs

|

| 3 mm |

2.30 kg / 5.08 lbs

4 847 Gs

|

0.35 kg / 0.76 lbs

346 g / 3.4 N

|

2.07 kg / 4.57 lbs

~0 Gs

|

| 5 mm |

1.25 kg / 2.76 lbs

3 575 Gs

|

0.19 kg / 0.41 lbs

188 g / 1.8 N

|

1.13 kg / 2.49 lbs

~0 Gs

|

| 10 mm |

0.25 kg / 0.55 lbs

1 591 Gs

|

0.04 kg / 0.08 lbs

37 g / 0.4 N

|

0.22 kg / 0.49 lbs

~0 Gs

|

| 20 mm |

0.02 kg / 0.04 lbs

410 Gs

|

0.00 kg / 0.01 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

39 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

23 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

15 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

10 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

7 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

5 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MW 9x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - warning

MW 9x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

37.23 km/h

(10.34 m/s)

|

0.08 J | |

| 30 mm |

64.34 km/h

(17.87 m/s)

|

0.23 J | |

| 50 mm |

83.06 km/h

(23.07 m/s)

|

0.38 J | |

| 100 mm |

117.47 km/h

(32.63 m/s)

|

0.76 J |

Table 9: Coating parameters (durability)

MW 9x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 9x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 314 Mx | 23.1 µWb |

| Pc Coefficient | 0.44 | Low (Flat) |

Table 11: Physics of underwater searching

MW 9x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.94 kg | Standard |

| Water (riverbed) |

2.22 kg

(+0.28 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical wall, the magnet retains just a fraction of its max power.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically reduces the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.44

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of rare earth magnets.

Benefits

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- They have excellent resistance to weakening of magnetic properties due to external magnetic sources,

- A magnet with a shiny gold surface looks better,

- The surface of neodymium magnets generates a strong magnetic field – this is one of their assets,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to modularity in designing and the capacity to customize to client solutions,

- Huge importance in modern technologies – they are used in mass storage devices, drive modules, advanced medical instruments, also industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which allows their use in miniature devices

Disadvantages

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Limited possibility of producing threads in the magnet and complex shapes - preferred is casing - magnet mounting.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which gains importance in the context of child safety. Additionally, small components of these devices are able to complicate diagnosis medical in case of swallowing.

- Due to complex production process, their price is relatively high,

Pull force analysis

Best holding force of the magnet in ideal parameters – what affects it?

- using a plate made of low-carbon steel, functioning as a circuit closing element

- with a thickness of at least 10 mm

- with an ground contact surface

- under conditions of ideal adhesion (surface-to-surface)

- for force applied at a right angle (pull-off, not shear)

- at standard ambient temperature

Determinants of lifting force in real conditions

- Gap between surfaces – every millimeter of separation (caused e.g. by veneer or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Load vector – highest force is reached only during perpendicular pulling. The resistance to sliding of the magnet along the plate is usually many times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Material composition – different alloys reacts the same. Alloy additives weaken the attraction effect.

- Surface condition – smooth surfaces guarantee perfect abutment, which improves force. Uneven metal weaken the grip.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and in frost gain strength (up to a certain limit).

Lifting capacity testing was performed on a smooth plate of optimal thickness, under a perpendicular pulling force, in contrast under parallel forces the load capacity is reduced by as much as 75%. Additionally, even a small distance between the magnet and the plate reduces the lifting capacity.

Safety rules for work with neodymium magnets

Crushing risk

Mind your fingers. Two large magnets will join immediately with a force of several hundred kilograms, destroying anything in their path. Be careful!

Phone sensors

An intense magnetic field negatively affects the functioning of magnetometers in phones and GPS navigation. Keep magnets close to a device to avoid damaging the sensors.

Swallowing risk

Absolutely keep magnets away from children. Ingestion danger is significant, and the consequences of magnets clamping inside the body are tragic.

Protective goggles

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Nickel coating and allergies

Certain individuals have a hypersensitivity to nickel, which is the typical protective layer for NdFeB magnets. Frequent touching might lead to an allergic reaction. We strongly advise wear safety gloves.

Dust is flammable

Fire warning: Neodymium dust is explosive. Do not process magnets in home conditions as this risks ignition.

Caution required

Before starting, check safety instructions. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Medical interference

Life threat: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have medical devices.

Heat sensitivity

Do not overheat. Neodymium magnets are susceptible to heat. If you require resistance above 80°C, ask us about HT versions (H, SH, UH).

Protect data

Device Safety: Strong magnets can damage payment cards and sensitive devices (heart implants, hearing aids, mechanical watches).

![UI 45x13x6 [C321] / N38 - badge holder UI 45x13x6 [C321] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui45x13x6-c321-jic.jpg)