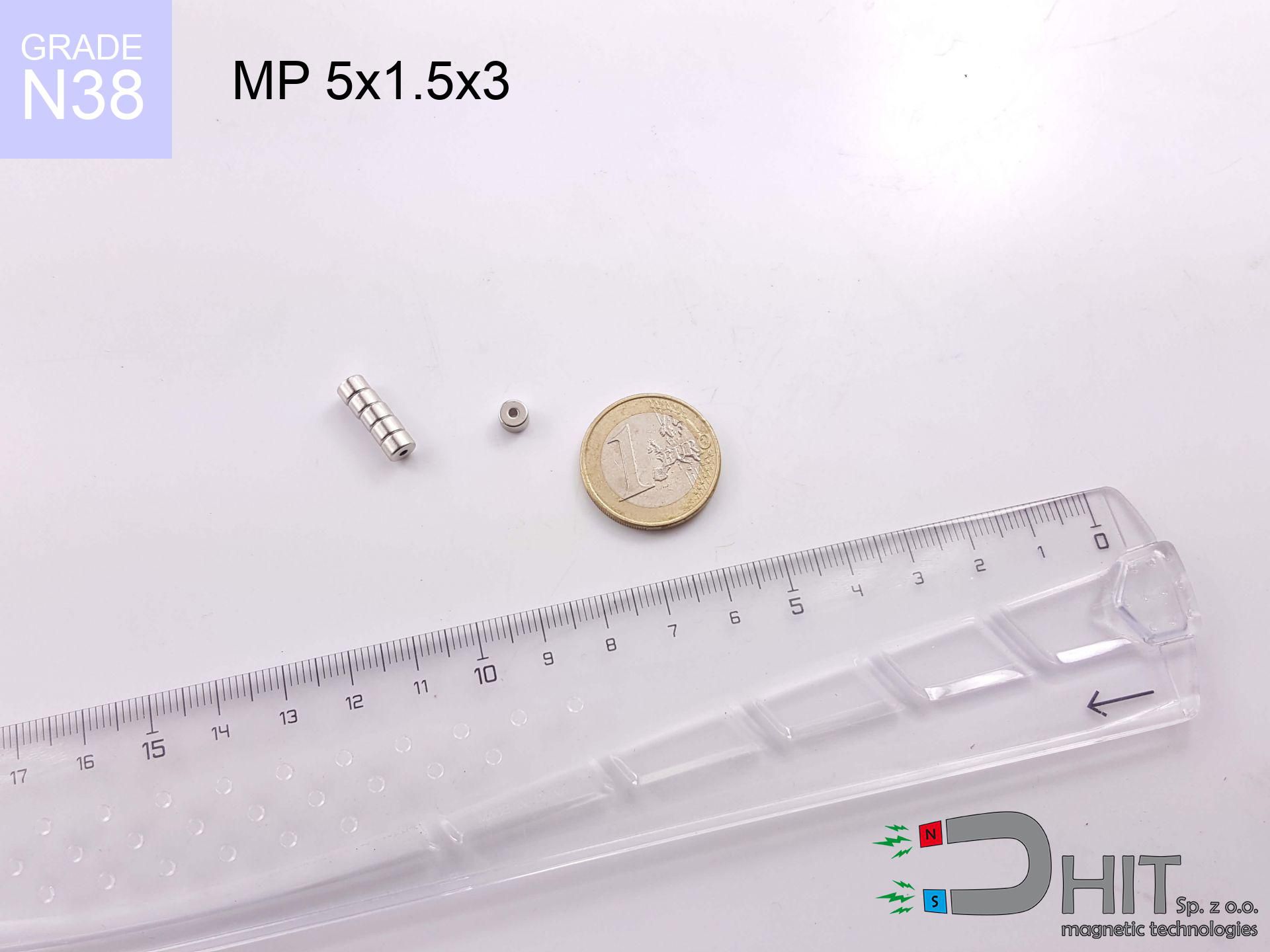

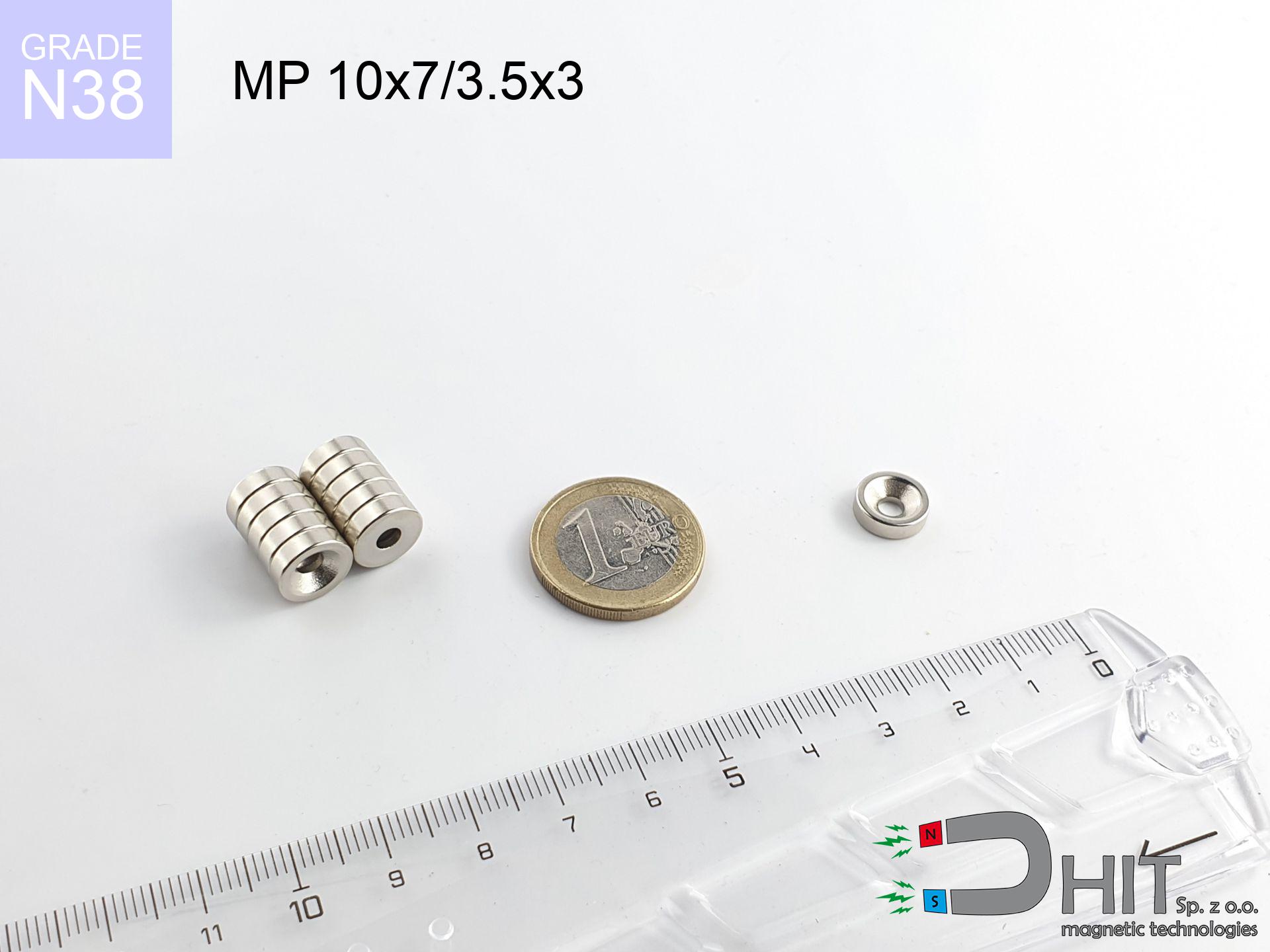

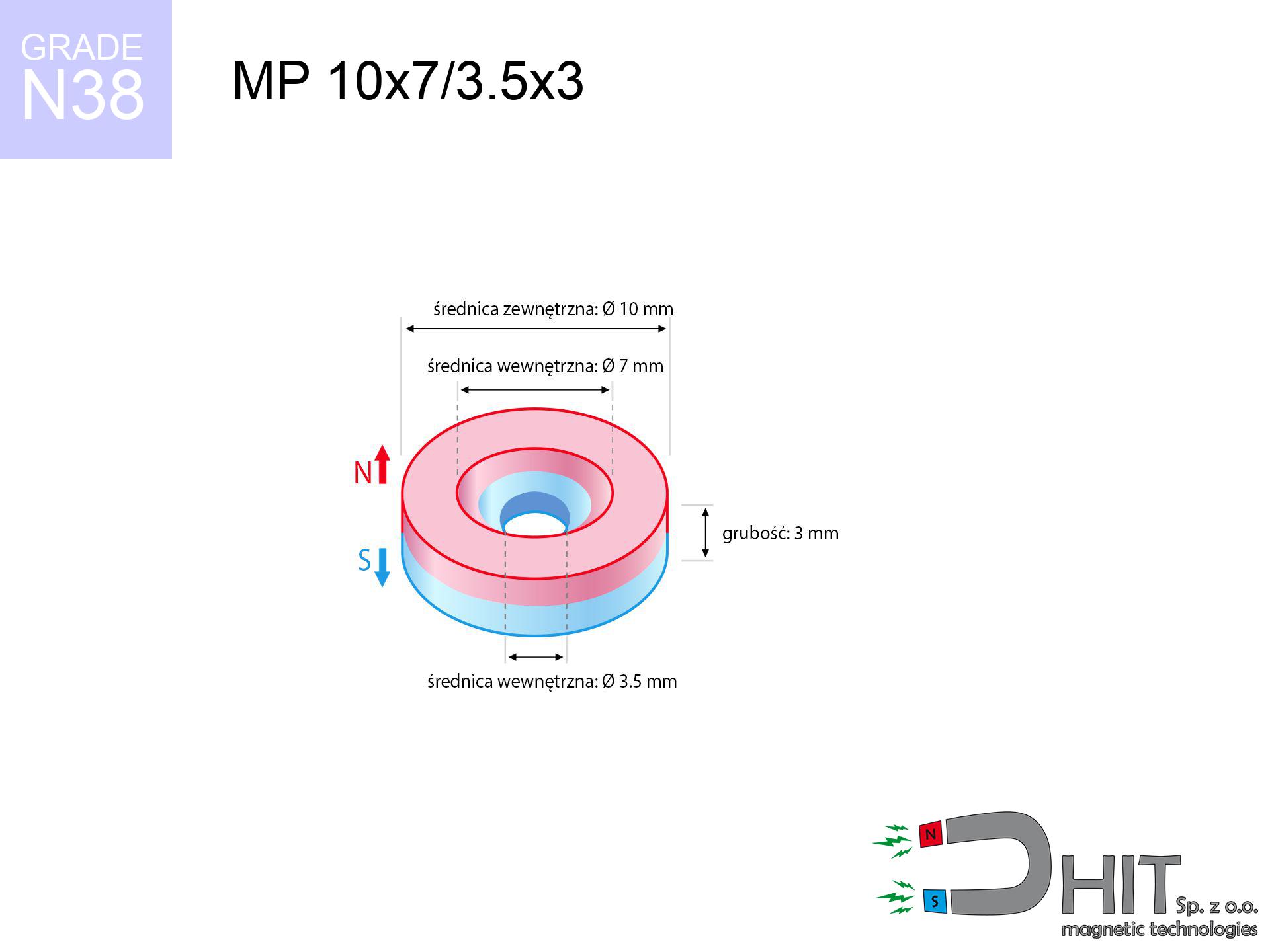

MP 10x7/3.5x3 / N38 - ring magnet

ring magnet

Catalog no 030180

GTIN/EAN: 5906301811978

Diameter

10 mm [±0,1 mm]

internal diameter Ø

7/3.5 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

1.55 g

Magnetization Direction

↑ axial

Load capacity

1.88 kg / 18.47 N

Magnetic Induction

318.70 mT / 3187 Gs

Coating

[NiCuNi] Nickel

0.824 ZŁ with VAT / pcs + price for transport

0.670 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer let us know via

request form

the contact page.

Lifting power along with appearance of neodymium magnets can be calculated with our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - MP 10x7/3.5x3 / N38 - ring magnet

Specification / characteristics - MP 10x7/3.5x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030180 |

| GTIN/EAN | 5906301811978 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 10 mm [±0,1 mm] |

| internal diameter Ø | 7/3.5 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 1.55 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.88 kg / 18.47 N |

| Magnetic Induction ~ ? | 318.70 mT / 3187 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

Presented information are the outcome of a mathematical simulation. Values are based on algorithms for the material Nd2Fe14B. Real-world parameters might slightly deviate from the simulation results. Use these calculations as a supplementary guide during assembly planning.

Table 1: Static pull force (pull vs distance) - power drop

MP 10x7/3.5x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2813 Gs

281.3 mT

|

1.88 kg / 4.14 LBS

1880.0 g / 18.4 N

|

weak grip |

| 1 mm |

2373 Gs

237.3 mT

|

1.34 kg / 2.95 LBS

1338.1 g / 13.1 N

|

weak grip |

| 2 mm |

1870 Gs

187.0 mT

|

0.83 kg / 1.83 LBS

830.9 g / 8.2 N

|

weak grip |

| 3 mm |

1416 Gs

141.6 mT

|

0.48 kg / 1.05 LBS

476.6 g / 4.7 N

|

weak grip |

| 5 mm |

785 Gs

78.5 mT

|

0.15 kg / 0.32 LBS

146.4 g / 1.4 N

|

weak grip |

| 10 mm |

214 Gs

21.4 mT

|

0.01 kg / 0.02 LBS

10.9 g / 0.1 N

|

weak grip |

| 15 mm |

81 Gs

8.1 mT

|

0.00 kg / 0.00 LBS

1.6 g / 0.0 N

|

weak grip |

| 20 mm |

38 Gs

3.8 mT

|

0.00 kg / 0.00 LBS

0.3 g / 0.0 N

|

weak grip |

| 30 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding capacity (vertical surface)

MP 10x7/3.5x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.38 kg / 0.83 LBS

376.0 g / 3.7 N

|

| 1 mm | Stal (~0.2) |

0.27 kg / 0.59 LBS

268.0 g / 2.6 N

|

| 2 mm | Stal (~0.2) |

0.17 kg / 0.37 LBS

166.0 g / 1.6 N

|

| 3 mm | Stal (~0.2) |

0.10 kg / 0.21 LBS

96.0 g / 0.9 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.07 LBS

30.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MP 10x7/3.5x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.56 kg / 1.24 LBS

564.0 g / 5.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.38 kg / 0.83 LBS

376.0 g / 3.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.19 kg / 0.41 LBS

188.0 g / 1.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.94 kg / 2.07 LBS

940.0 g / 9.2 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 10x7/3.5x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.19 kg / 0.41 LBS

188.0 g / 1.8 N

|

| 1 mm |

|

0.47 kg / 1.04 LBS

470.0 g / 4.6 N

|

| 2 mm |

|

0.94 kg / 2.07 LBS

940.0 g / 9.2 N

|

| 3 mm |

|

1.41 kg / 3.11 LBS

1410.0 g / 13.8 N

|

| 5 mm |

|

1.88 kg / 4.14 LBS

1880.0 g / 18.4 N

|

| 10 mm |

|

1.88 kg / 4.14 LBS

1880.0 g / 18.4 N

|

| 11 mm |

|

1.88 kg / 4.14 LBS

1880.0 g / 18.4 N

|

| 12 mm |

|

1.88 kg / 4.14 LBS

1880.0 g / 18.4 N

|

Table 5: Thermal stability (stability) - resistance threshold

MP 10x7/3.5x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.88 kg / 4.14 LBS

1880.0 g / 18.4 N

|

OK |

| 40 °C | -2.2% |

1.84 kg / 4.05 LBS

1838.6 g / 18.0 N

|

OK |

| 60 °C | -4.4% |

1.80 kg / 3.96 LBS

1797.3 g / 17.6 N

|

|

| 80 °C | -6.6% |

1.76 kg / 3.87 LBS

1755.9 g / 17.2 N

|

|

| 100 °C | -28.8% |

1.34 kg / 2.95 LBS

1338.6 g / 13.1 N

|

Table 6: Two magnets (attraction) - field range

MP 10x7/3.5x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.86 kg / 6.30 LBS

4 419 Gs

|

0.43 kg / 0.95 LBS

429 g / 4.2 N

|

N/A |

| 1 mm |

2.46 kg / 5.43 LBS

5 224 Gs

|

0.37 kg / 0.81 LBS

370 g / 3.6 N

|

2.22 kg / 4.89 LBS

~0 Gs

|

| 2 mm |

2.03 kg / 4.49 LBS

4 747 Gs

|

0.31 kg / 0.67 LBS

305 g / 3.0 N

|

1.83 kg / 4.04 LBS

~0 Gs

|

| 3 mm |

1.62 kg / 3.58 LBS

4 242 Gs

|

0.24 kg / 0.54 LBS

244 g / 2.4 N

|

1.46 kg / 3.22 LBS

~0 Gs

|

| 5 mm |

0.96 kg / 2.12 LBS

3 266 Gs

|

0.14 kg / 0.32 LBS

144 g / 1.4 N

|

0.87 kg / 1.91 LBS

~0 Gs

|

| 10 mm |

0.22 kg / 0.49 LBS

1 570 Gs

|

0.03 kg / 0.07 LBS

33 g / 0.3 N

|

0.20 kg / 0.44 LBS

~0 Gs

|

| 20 mm |

0.02 kg / 0.04 LBS

429 Gs

|

0.00 kg / 0.01 LBS

2 g / 0.0 N

|

0.01 kg / 0.03 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

41 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

25 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

8 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MP 10x7/3.5x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - warning

MP 10x7/3.5x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

35.25 km/h

(9.79 m/s)

|

0.07 J | |

| 30 mm |

60.84 km/h

(16.90 m/s)

|

0.22 J | |

| 50 mm |

78.54 km/h

(21.82 m/s)

|

0.37 J | |

| 100 mm |

111.07 km/h

(30.85 m/s)

|

0.74 J |

Table 9: Coating parameters (durability)

MP 10x7/3.5x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MP 10x7/3.5x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 899 Mx | 19.0 µWb |

| Pc Coefficient | 0.37 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MP 10x7/3.5x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.88 kg | Standard |

| Water (riverbed) |

2.15 kg

(+0.27 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains just ~20% of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Thermal stability

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.37

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros and cons of neodymium magnets.

Advantages

- Their strength remains stable, and after approximately 10 years it drops only by ~1% (theoretically),

- Magnets very well protect themselves against demagnetization caused by external fields,

- By using a lustrous coating of nickel, the element has an elegant look,

- Magnets are characterized by excellent magnetic induction on the outer layer,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of individual creating as well as modifying to individual needs,

- Versatile presence in electronics industry – they are utilized in mass storage devices, drive modules, advanced medical instruments, as well as multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Disadvantages

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also increases their durability

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in producing threads and complicated forms in magnets, we propose using casing - magnetic mechanism.

- Possible danger resulting from small fragments of magnets pose a threat, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Additionally, small components of these devices can complicate diagnosis medical when they are in the body.

- With large orders the cost of neodymium magnets is economically unviable,

Pull force analysis

Maximum magnetic pulling force – what contributes to it?

- using a base made of high-permeability steel, acting as a ideal flux conductor

- possessing a massiveness of at least 10 mm to avoid saturation

- characterized by smoothness

- with zero gap (without paint)

- during detachment in a direction perpendicular to the mounting surface

- at ambient temperature room level

Lifting capacity in real conditions – factors

- Gap between magnet and steel – every millimeter of distance (caused e.g. by veneer or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When slipping, the magnet exhibits significantly lower power (typically approx. 20-30% of nominal force).

- Steel thickness – insufficiently thick sheet does not close the flux, causing part of the power to be wasted to the other side.

- Steel grade – the best choice is pure iron steel. Hardened steels may attract less.

- Surface structure – the more even the plate, the better the adhesion and stronger the hold. Unevenness creates an air distance.

- Thermal environment – temperature increase results in weakening of induction. Check the maximum operating temperature for a given model.

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under attempts to slide the magnet the load capacity is reduced by as much as 5 times. In addition, even a small distance between the magnet’s surface and the plate reduces the holding force.

Warnings

Product not for children

These products are not suitable for play. Eating a few magnets may result in them attracting across intestines, which poses a critical condition and requires immediate surgery.

Cards and drives

Very strong magnetic fields can destroy records on credit cards, HDDs, and other magnetic media. Keep a distance of at least 10 cm.

Life threat

Health Alert: Neodymium magnets can turn off pacemakers and defibrillators. Stay away if you have medical devices.

Hand protection

Protect your hands. Two large magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Safe operation

Use magnets with awareness. Their immense force can surprise even professionals. Stay alert and respect their power.

Thermal limits

Control the heat. Exposing the magnet to high heat will destroy its properties and strength.

Sensitization to coating

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If redness occurs, immediately stop handling magnets and wear gloves.

Combustion hazard

Dust produced during machining of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Precision electronics

GPS units and smartphones are highly susceptible to magnetic fields. Close proximity with a strong magnet can ruin the sensors in your phone.

Material brittleness

NdFeB magnets are sintered ceramics, meaning they are very brittle. Impact of two magnets will cause them shattering into shards.

![SM 32x350 [2xM8] / N42 - magnetic separator SM 32x350 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x350-2xm8-nih.jpg)