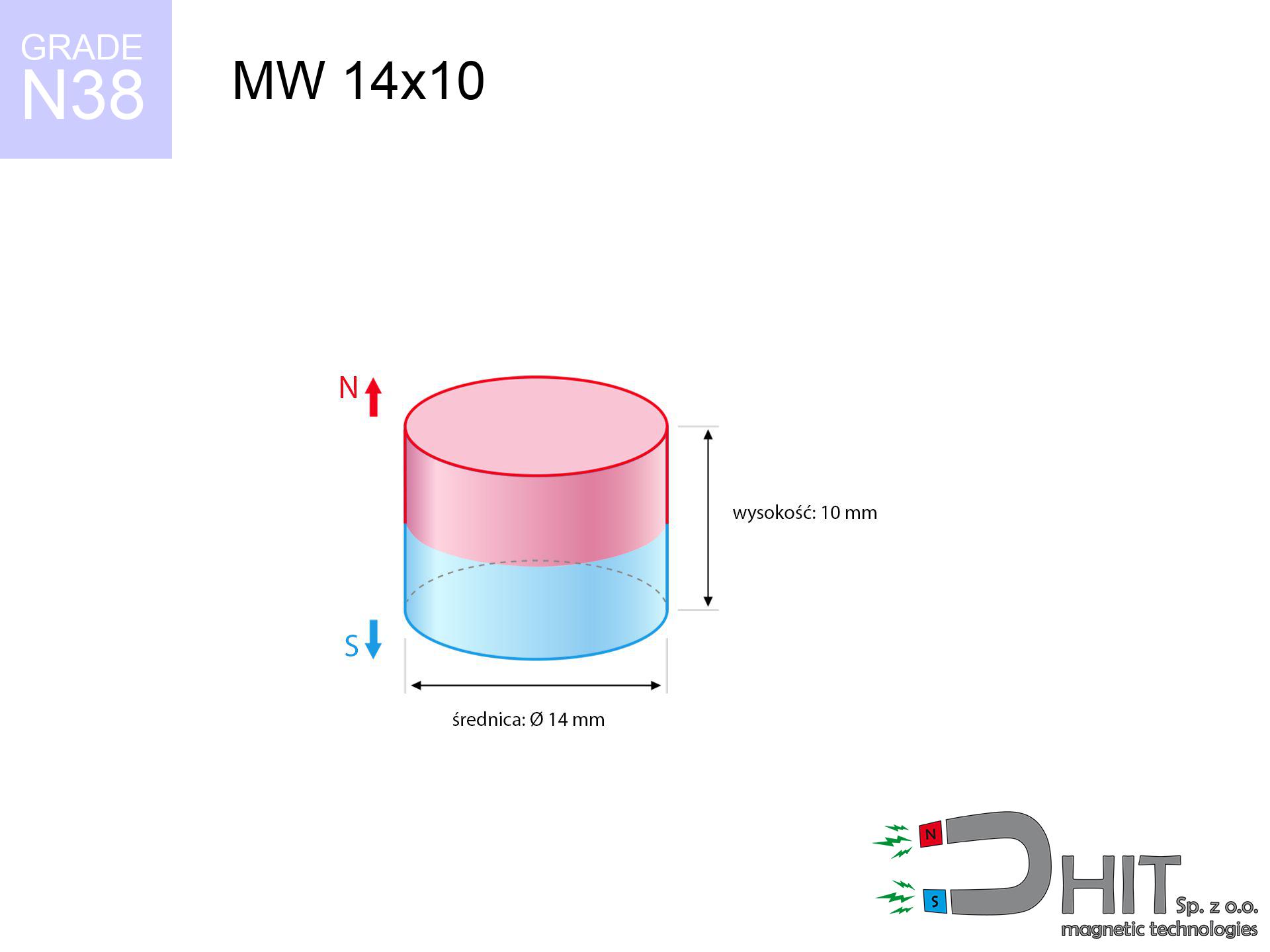

MW 14x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010391

GTIN/EAN: 5906301811084

Diameter Ø

14 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

11.55 g

Magnetization Direction

↑ axial

Load capacity

6.71 kg / 65.83 N

Magnetic Induction

507.48 mT / 5075 Gs

Coating

[NiCuNi] Nickel

6.84 ZŁ with VAT / pcs + price for transport

5.56 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively let us know using

our online form

through our site.

Strength and form of magnetic components can be checked with our

modular calculator.

Order by 14:00 and we’ll ship today!

Technical details - MW 14x10 / N38 - cylindrical magnet

Specification / characteristics - MW 14x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010391 |

| GTIN/EAN | 5906301811084 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 14 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 11.55 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.71 kg / 65.83 N |

| Magnetic Induction ~ ? | 507.48 mT / 5075 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the product - data

The following data represent the outcome of a engineering calculation. Values rely on models for the class Nd2Fe14B. Operational conditions might slightly differ. Treat these data as a reference point when designing systems.

Table 1: Static pull force (force vs distance) - interaction chart

MW 14x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5072 Gs

507.2 mT

|

6.71 kg / 14.79 pounds

6710.0 g / 65.8 N

|

strong |

| 1 mm |

4354 Gs

435.4 mT

|

4.94 kg / 10.90 pounds

4944.4 g / 48.5 N

|

strong |

| 2 mm |

3652 Gs

365.2 mT

|

3.48 kg / 7.67 pounds

3479.0 g / 34.1 N

|

strong |

| 3 mm |

3017 Gs

301.7 mT

|

2.37 kg / 5.23 pounds

2373.5 g / 23.3 N

|

strong |

| 5 mm |

2015 Gs

201.5 mT

|

1.06 kg / 2.33 pounds

1058.7 g / 10.4 N

|

weak grip |

| 10 mm |

773 Gs

77.3 mT

|

0.16 kg / 0.34 pounds

155.7 g / 1.5 N

|

weak grip |

| 15 mm |

352 Gs

35.2 mT

|

0.03 kg / 0.07 pounds

32.3 g / 0.3 N

|

weak grip |

| 20 mm |

186 Gs

18.6 mT

|

0.01 kg / 0.02 pounds

9.0 g / 0.1 N

|

weak grip |

| 30 mm |

69 Gs

6.9 mT

|

0.00 kg / 0.00 pounds

1.3 g / 0.0 N

|

weak grip |

| 50 mm |

18 Gs

1.8 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

weak grip |

Table 2: Slippage capacity (vertical surface)

MW 14x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.34 kg / 2.96 pounds

1342.0 g / 13.2 N

|

| 1 mm | Stal (~0.2) |

0.99 kg / 2.18 pounds

988.0 g / 9.7 N

|

| 2 mm | Stal (~0.2) |

0.70 kg / 1.53 pounds

696.0 g / 6.8 N

|

| 3 mm | Stal (~0.2) |

0.47 kg / 1.04 pounds

474.0 g / 4.6 N

|

| 5 mm | Stal (~0.2) |

0.21 kg / 0.47 pounds

212.0 g / 2.1 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 14x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.01 kg / 4.44 pounds

2013.0 g / 19.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.34 kg / 2.96 pounds

1342.0 g / 13.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.67 kg / 1.48 pounds

671.0 g / 6.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.36 kg / 7.40 pounds

3355.0 g / 32.9 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 14x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.67 kg / 1.48 pounds

671.0 g / 6.6 N

|

| 1 mm |

|

1.68 kg / 3.70 pounds

1677.5 g / 16.5 N

|

| 2 mm |

|

3.36 kg / 7.40 pounds

3355.0 g / 32.9 N

|

| 3 mm |

|

5.03 kg / 11.09 pounds

5032.5 g / 49.4 N

|

| 5 mm |

|

6.71 kg / 14.79 pounds

6710.0 g / 65.8 N

|

| 10 mm |

|

6.71 kg / 14.79 pounds

6710.0 g / 65.8 N

|

| 11 mm |

|

6.71 kg / 14.79 pounds

6710.0 g / 65.8 N

|

| 12 mm |

|

6.71 kg / 14.79 pounds

6710.0 g / 65.8 N

|

Table 5: Thermal stability (stability) - resistance threshold

MW 14x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.71 kg / 14.79 pounds

6710.0 g / 65.8 N

|

OK |

| 40 °C | -2.2% |

6.56 kg / 14.47 pounds

6562.4 g / 64.4 N

|

OK |

| 60 °C | -4.4% |

6.41 kg / 14.14 pounds

6414.8 g / 62.9 N

|

OK |

| 80 °C | -6.6% |

6.27 kg / 13.82 pounds

6267.1 g / 61.5 N

|

|

| 100 °C | -28.8% |

4.78 kg / 10.53 pounds

4777.5 g / 46.9 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 14x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

24.41 kg / 53.82 pounds

5 843 Gs

|

3.66 kg / 8.07 pounds

3662 g / 35.9 N

|

N/A |

| 1 mm |

21.12 kg / 46.55 pounds

9 434 Gs

|

3.17 kg / 6.98 pounds

3167 g / 31.1 N

|

19.00 kg / 41.90 pounds

~0 Gs

|

| 2 mm |

17.99 kg / 39.66 pounds

8 708 Gs

|

2.70 kg / 5.95 pounds

2699 g / 26.5 N

|

16.19 kg / 35.70 pounds

~0 Gs

|

| 3 mm |

15.16 kg / 33.43 pounds

7 994 Gs

|

2.27 kg / 5.01 pounds

2274 g / 22.3 N

|

13.65 kg / 30.08 pounds

~0 Gs

|

| 5 mm |

10.49 kg / 23.12 pounds

6 649 Gs

|

1.57 kg / 3.47 pounds

1573 g / 15.4 N

|

9.44 kg / 20.81 pounds

~0 Gs

|

| 10 mm |

3.85 kg / 8.49 pounds

4 029 Gs

|

0.58 kg / 1.27 pounds

578 g / 5.7 N

|

3.47 kg / 7.64 pounds

~0 Gs

|

| 20 mm |

0.57 kg / 1.25 pounds

1 545 Gs

|

0.08 kg / 0.19 pounds

85 g / 0.8 N

|

0.51 kg / 1.12 pounds

~0 Gs

|

| 50 mm |

0.01 kg / 0.02 pounds

218 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.02 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 pounds

139 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

93 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

66 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

48 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

36 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MW 14x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 14x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.66 km/h

(6.85 m/s)

|

0.27 J | |

| 30 mm |

42.11 km/h

(11.70 m/s)

|

0.79 J | |

| 50 mm |

54.36 km/h

(15.10 m/s)

|

1.32 J | |

| 100 mm |

76.87 km/h

(21.35 m/s)

|

2.63 J |

Table 9: Coating parameters (durability)

MW 14x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 14x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 7 886 Mx | 78.9 µWb |

| Pc Coefficient | 0.74 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MW 14x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.71 kg | Standard |

| Water (riverbed) |

7.68 kg

(+0.97 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical surface, the magnet retains just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.74

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages and disadvantages of Nd2Fe14B magnets.

Advantages

- They retain magnetic properties for around 10 years – the loss is just ~1% (based on simulations),

- Neodymium magnets prove to be remarkably resistant to demagnetization caused by magnetic disturbances,

- By applying a lustrous coating of nickel, the element has an aesthetic look,

- The surface of neodymium magnets generates a unique magnetic field – this is a distinguishing feature,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to flexibility in designing and the ability to customize to complex applications,

- Key role in high-tech industry – they serve a role in data components, electric drive systems, medical devices, also multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which makes them useful in compact constructions

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in producing threads and complex shapes in magnets, we propose using a housing - magnetic holder.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which gains importance in the context of child safety. Furthermore, small components of these products can complicate diagnosis medical after entering the body.

- With large orders the cost of neodymium magnets is economically unviable,

Holding force characteristics

Maximum lifting capacity of the magnet – what affects it?

- using a plate made of mild steel, functioning as a magnetic yoke

- possessing a massiveness of at least 10 mm to avoid saturation

- characterized by smoothness

- under conditions of gap-free contact (metal-to-metal)

- for force acting at a right angle (in the magnet axis)

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in real conditions – factors

- Clearance – existence of any layer (paint, tape, gap) acts as an insulator, which reduces power rapidly (even by 50% at 0.5 mm).

- Force direction – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Material composition – different alloys reacts the same. Alloy additives worsen the attraction effect.

- Surface condition – ground elements ensure maximum contact, which improves force. Rough surfaces reduce efficiency.

- Temperature influence – hot environment weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. Moreover, even a small distance between the magnet and the plate lowers the load capacity.

Safe handling of NdFeB magnets

Crushing risk

Mind your fingers. Two powerful magnets will join instantly with a force of massive weight, destroying everything in their path. Be careful!

Threat to navigation

Remember: neodymium magnets generate a field that interferes with sensitive sensors. Keep a safe distance from your mobile, tablet, and navigation systems.

Product not for children

Strictly keep magnets away from children. Choking hazard is significant, and the consequences of magnets clamping inside the body are life-threatening.

Threat to electronics

Avoid bringing magnets close to a wallet, computer, or screen. The magnetism can permanently damage these devices and erase data from cards.

Warning for heart patients

Warning for patients: Powerful magnets affect medical devices. Keep minimum 30 cm distance or ask another person to work with the magnets.

Do not underestimate power

Before starting, check safety instructions. Sudden snapping can destroy the magnet or hurt your hand. Be predictive.

Mechanical processing

Drilling and cutting of NdFeB material poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Demagnetization risk

Control the heat. Exposing the magnet above 80 degrees Celsius will destroy its magnetic structure and strength.

Material brittleness

Watch out for shards. Magnets can explode upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Metal Allergy

Medical facts indicate that the nickel plating (standard magnet coating) is a strong allergen. If your skin reacts to metals, prevent direct skin contact and opt for encased magnets.

![SM 32x175 [2xM8] / N52 - magnetic separator SM 32x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-cep.jpg)

![UMGW 20x15x7 [M4] GW / N38 - magnetic holder internal thread UMGW 20x15x7 [M4] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um-20x15x7-m4-gw-big.jpg)