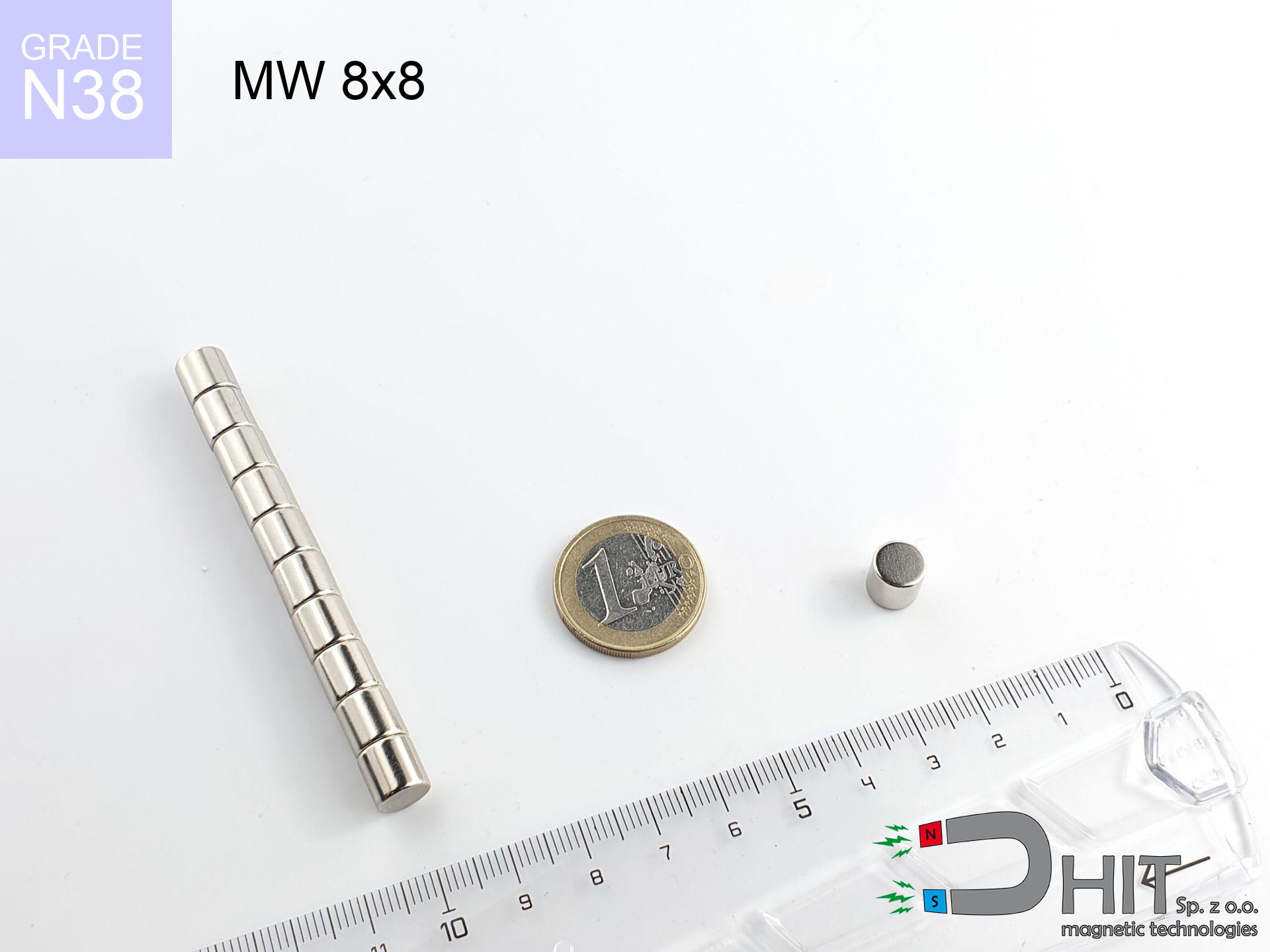

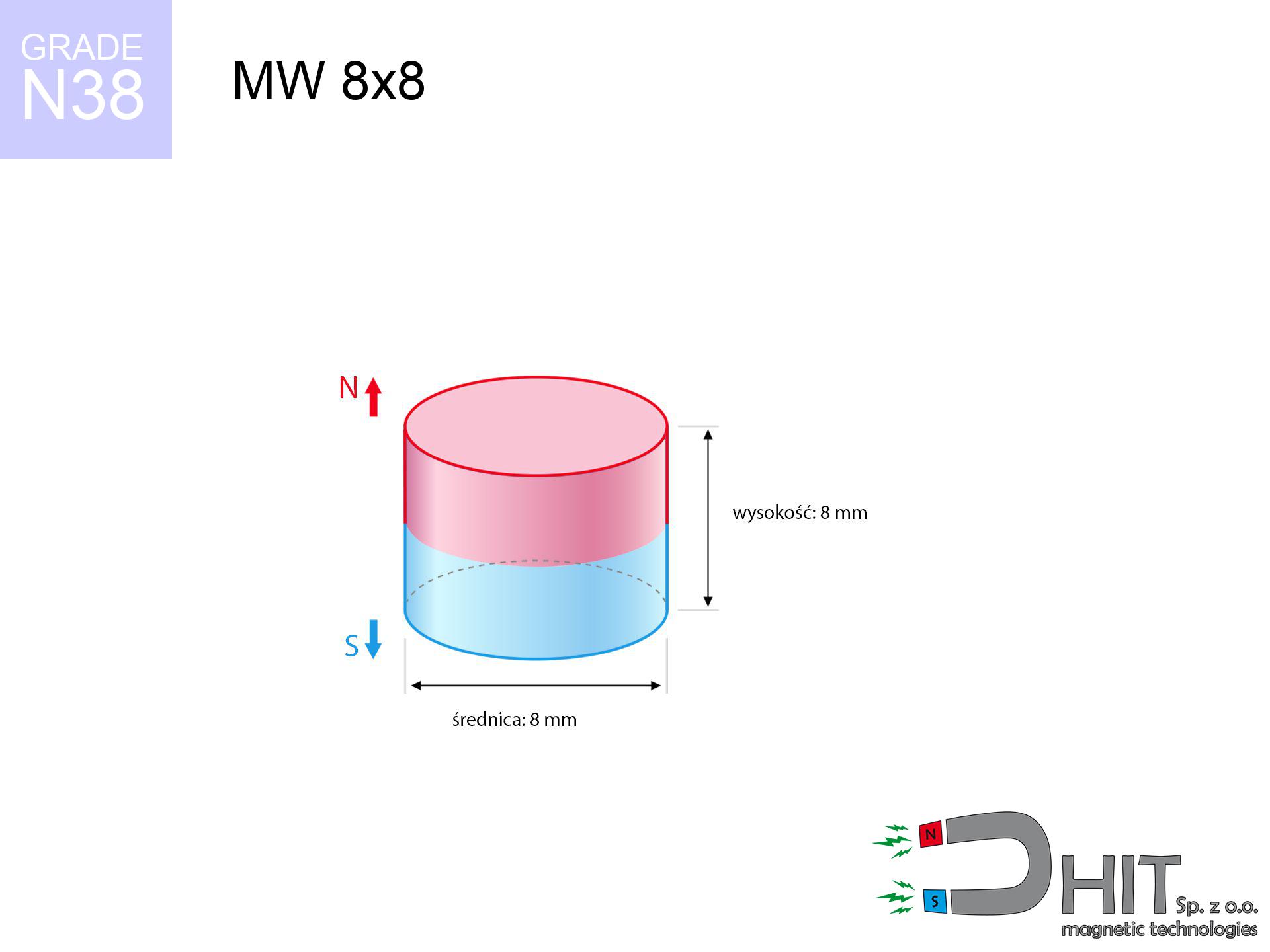

MW 8x8 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010106

GTIN/EAN: 5906301811053

Diameter Ø

8 mm [±0,1 mm]

Height

8 mm [±0,1 mm]

Weight

3.02 g

Magnetization Direction

↑ axial

Load capacity

2.03 kg / 19.92 N

Magnetic Induction

553.67 mT / 5537 Gs

Coating

[NiCuNi] Nickel

1.341 ZŁ with VAT / pcs + price for transport

1.090 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

or get in touch through

inquiry form

the contact form page.

Parameters along with form of a neodymium magnet can be tested on our

force calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - MW 8x8 / N38 - cylindrical magnet

Specification / characteristics - MW 8x8 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010106 |

| GTIN/EAN | 5906301811053 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 8 mm [±0,1 mm] |

| Weight | 3.02 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.03 kg / 19.92 N |

| Magnetic Induction ~ ? | 553.67 mT / 5537 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the assembly - data

Presented information represent the direct effect of a engineering calculation. Results were calculated on models for the material Nd2Fe14B. Operational parameters might slightly deviate from the simulation results. Please consider these data as a reference point during assembly planning.

Table 1: Static force (pull vs gap) - interaction chart

MW 8x8 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5531 Gs

553.1 mT

|

2.03 kg / 4.48 pounds

2030.0 g / 19.9 N

|

strong |

| 1 mm |

4162 Gs

416.2 mT

|

1.15 kg / 2.53 pounds

1149.3 g / 11.3 N

|

low risk |

| 2 mm |

2984 Gs

298.4 mT

|

0.59 kg / 1.30 pounds

590.7 g / 5.8 N

|

low risk |

| 3 mm |

2107 Gs

210.7 mT

|

0.29 kg / 0.65 pounds

294.5 g / 2.9 N

|

low risk |

| 5 mm |

1084 Gs

108.4 mT

|

0.08 kg / 0.17 pounds

78.0 g / 0.8 N

|

low risk |

| 10 mm |

296 Gs

29.6 mT

|

0.01 kg / 0.01 pounds

5.8 g / 0.1 N

|

low risk |

| 15 mm |

118 Gs

11.8 mT

|

0.00 kg / 0.00 pounds

0.9 g / 0.0 N

|

low risk |

| 20 mm |

58 Gs

5.8 mT

|

0.00 kg / 0.00 pounds

0.2 g / 0.0 N

|

low risk |

| 30 mm |

20 Gs

2.0 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding hold (wall)

MW 8x8 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.41 kg / 0.90 pounds

406.0 g / 4.0 N

|

| 1 mm | Stal (~0.2) |

0.23 kg / 0.51 pounds

230.0 g / 2.3 N

|

| 2 mm | Stal (~0.2) |

0.12 kg / 0.26 pounds

118.0 g / 1.2 N

|

| 3 mm | Stal (~0.2) |

0.06 kg / 0.13 pounds

58.0 g / 0.6 N

|

| 5 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

16.0 g / 0.2 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 8x8 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.61 kg / 1.34 pounds

609.0 g / 6.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.41 kg / 0.90 pounds

406.0 g / 4.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.20 kg / 0.45 pounds

203.0 g / 2.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.02 kg / 2.24 pounds

1015.0 g / 10.0 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 8x8 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.20 kg / 0.45 pounds

203.0 g / 2.0 N

|

| 1 mm |

|

0.51 kg / 1.12 pounds

507.5 g / 5.0 N

|

| 2 mm |

|

1.02 kg / 2.24 pounds

1015.0 g / 10.0 N

|

| 3 mm |

|

1.52 kg / 3.36 pounds

1522.5 g / 14.9 N

|

| 5 mm |

|

2.03 kg / 4.48 pounds

2030.0 g / 19.9 N

|

| 10 mm |

|

2.03 kg / 4.48 pounds

2030.0 g / 19.9 N

|

| 11 mm |

|

2.03 kg / 4.48 pounds

2030.0 g / 19.9 N

|

| 12 mm |

|

2.03 kg / 4.48 pounds

2030.0 g / 19.9 N

|

Table 5: Thermal stability (material behavior) - power drop

MW 8x8 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.03 kg / 4.48 pounds

2030.0 g / 19.9 N

|

OK |

| 40 °C | -2.2% |

1.99 kg / 4.38 pounds

1985.3 g / 19.5 N

|

OK |

| 60 °C | -4.4% |

1.94 kg / 4.28 pounds

1940.7 g / 19.0 N

|

OK |

| 80 °C | -6.6% |

1.90 kg / 4.18 pounds

1896.0 g / 18.6 N

|

|

| 100 °C | -28.8% |

1.45 kg / 3.19 pounds

1445.4 g / 14.2 N

|

Table 6: Two magnets (repulsion) - forces in the system

MW 8x8 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

9.48 kg / 20.90 pounds

6 000 Gs

|

1.42 kg / 3.14 pounds

1422 g / 14.0 N

|

N/A |

| 1 mm |

7.26 kg / 16.01 pounds

9 682 Gs

|

1.09 kg / 2.40 pounds

1089 g / 10.7 N

|

6.54 kg / 14.41 pounds

~0 Gs

|

| 2 mm |

5.37 kg / 11.83 pounds

8 324 Gs

|

0.81 kg / 1.78 pounds

805 g / 7.9 N

|

4.83 kg / 10.65 pounds

~0 Gs

|

| 3 mm |

3.88 kg / 8.55 pounds

7 074 Gs

|

0.58 kg / 1.28 pounds

582 g / 5.7 N

|

3.49 kg / 7.69 pounds

~0 Gs

|

| 5 mm |

1.95 kg / 4.30 pounds

5 016 Gs

|

0.29 kg / 0.64 pounds

292 g / 2.9 N

|

1.75 kg / 3.87 pounds

~0 Gs

|

| 10 mm |

0.36 kg / 0.80 pounds

2 169 Gs

|

0.05 kg / 0.12 pounds

55 g / 0.5 N

|

0.33 kg / 0.72 pounds

~0 Gs

|

| 20 mm |

0.03 kg / 0.06 pounds

592 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

66 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

41 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

27 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

19 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

14 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MW 8x8 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - warning

MW 8x8 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.19 km/h

(7.28 m/s)

|

0.08 J | |

| 30 mm |

45.29 km/h

(12.58 m/s)

|

0.24 J | |

| 50 mm |

58.47 km/h

(16.24 m/s)

|

0.40 J | |

| 100 mm |

82.68 km/h

(22.97 m/s)

|

0.80 J |

Table 9: Anti-corrosion coating durability

MW 8x8 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 8x8 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 868 Mx | 28.7 µWb |

| Pc Coefficient | 0.89 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 8x8 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.03 kg | Standard |

| Water (riverbed) |

2.32 kg

(+0.29 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet retains merely a fraction of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) severely limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.89

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

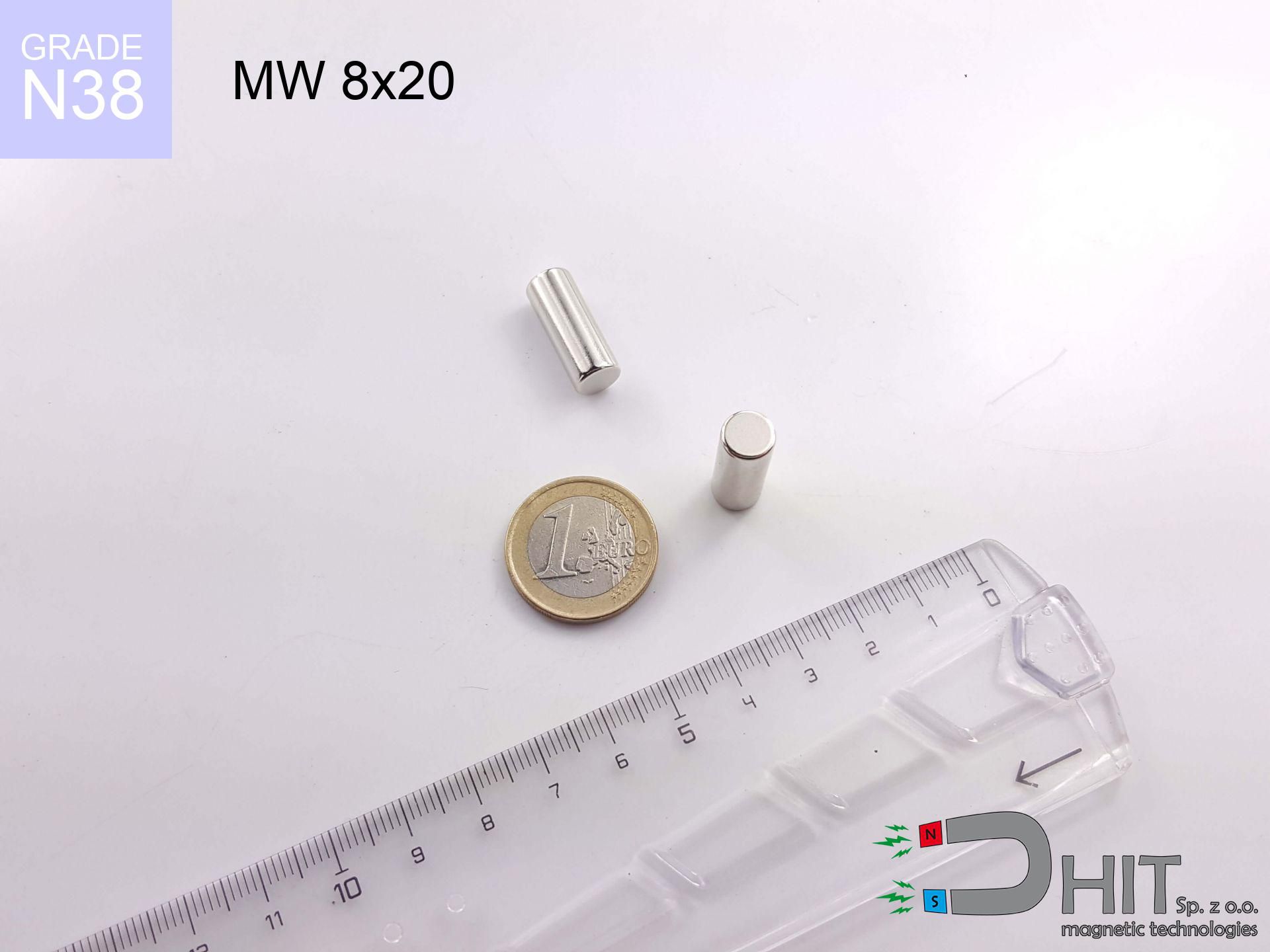

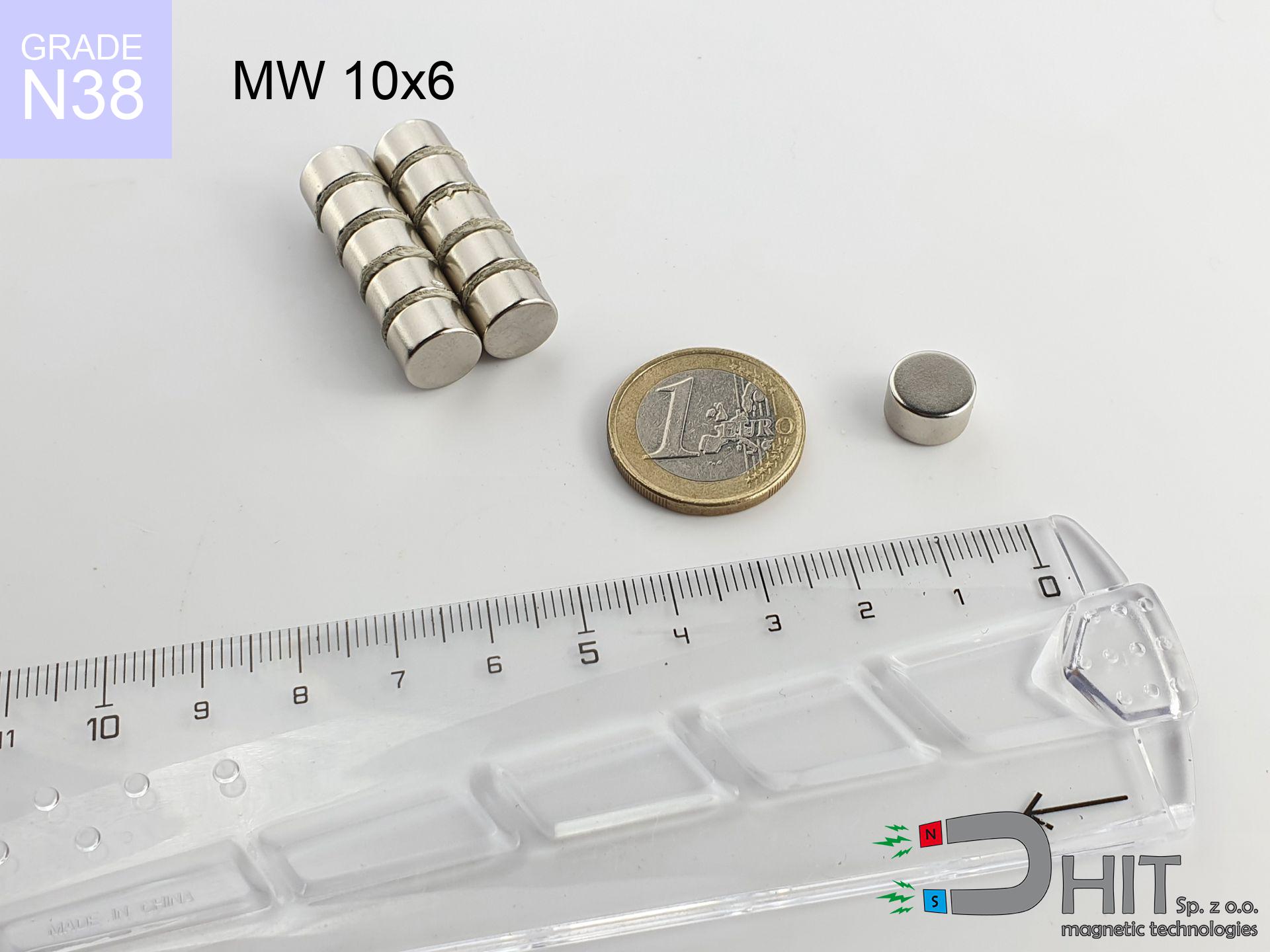

View also deals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Pros

- Their strength is durable, and after around 10 years it decreases only by ~1% (according to research),

- They do not lose their magnetic properties even under close interference source,

- By using a shiny coating of silver, the element has an proper look,

- The surface of neodymium magnets generates a strong magnetic field – this is a key feature,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of accurate machining and adjusting to atypical conditions,

- Key role in advanced technology sectors – they are utilized in mass storage devices, brushless drives, diagnostic systems, also modern systems.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- At very strong impacts they can crack, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation as well as corrosion.

- Limited possibility of creating nuts in the magnet and complex shapes - preferred is a housing - mounting mechanism.

- Possible danger related to microscopic parts of magnets pose a threat, in case of ingestion, which becomes key in the context of child health protection. Additionally, small components of these devices can complicate diagnosis medical when they are in the body.

- With large orders the cost of neodymium magnets can be a barrier,

Lifting parameters

Maximum holding power of the magnet – what it depends on?

- using a base made of low-carbon steel, acting as a ideal flux conductor

- whose thickness is min. 10 mm

- characterized by lack of roughness

- under conditions of ideal adhesion (surface-to-surface)

- during pulling in a direction perpendicular to the plane

- in stable room temperature

Practical aspects of lifting capacity – factors

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Load vector – highest force is reached only during perpendicular pulling. The resistance to sliding of the magnet along the surface is typically many times lower (approx. 1/5 of the lifting capacity).

- Base massiveness – too thin plate does not accept the full field, causing part of the flux to be escaped to the other side.

- Material type – the best choice is pure iron steel. Cast iron may generate lower lifting capacity.

- Smoothness – full contact is obtained only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature influence – high temperature weakens pulling force. Exceeding the limit temperature can permanently damage the magnet.

Holding force was checked on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a slight gap between the magnet and the plate decreases the load capacity.

H&S for magnets

Do not give to children

NdFeB magnets are not suitable for play. Eating several magnets can lead to them attracting across intestines, which constitutes a direct threat to life and necessitates urgent medical intervention.

Hand protection

Protect your hands. Two large magnets will snap together immediately with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

Phone sensors

GPS units and smartphones are extremely susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can ruin the internal compass in your phone.

Cards and drives

Device Safety: Neodymium magnets can damage payment cards and delicate electronics (heart implants, medical aids, timepieces).

Danger to pacemakers

Warning for patients: Strong magnetic fields disrupt medical devices. Keep minimum 30 cm distance or ask another person to handle the magnets.

Protective goggles

NdFeB magnets are ceramic materials, which means they are very brittle. Impact of two magnets will cause them shattering into shards.

Heat warning

Avoid heat. Neodymium magnets are sensitive to temperature. If you require operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Warning for allergy sufferers

It is widely known that nickel (the usual finish) is a strong allergen. If you have an allergy, prevent touching magnets with bare hands and choose encased magnets.

Fire risk

Mechanical processing of neodymium magnets carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Do not underestimate power

Handle magnets consciously. Their huge power can surprise even professionals. Plan your moves and do not underestimate their force.

![BM 750x180x70 [4x M8] - magnetic beam BM 750x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-750x180x70-4x-m8-zif.jpg)

![SM 32x375 [2xM8] / N42 - magnetic separator SM 32x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-nif.jpg)