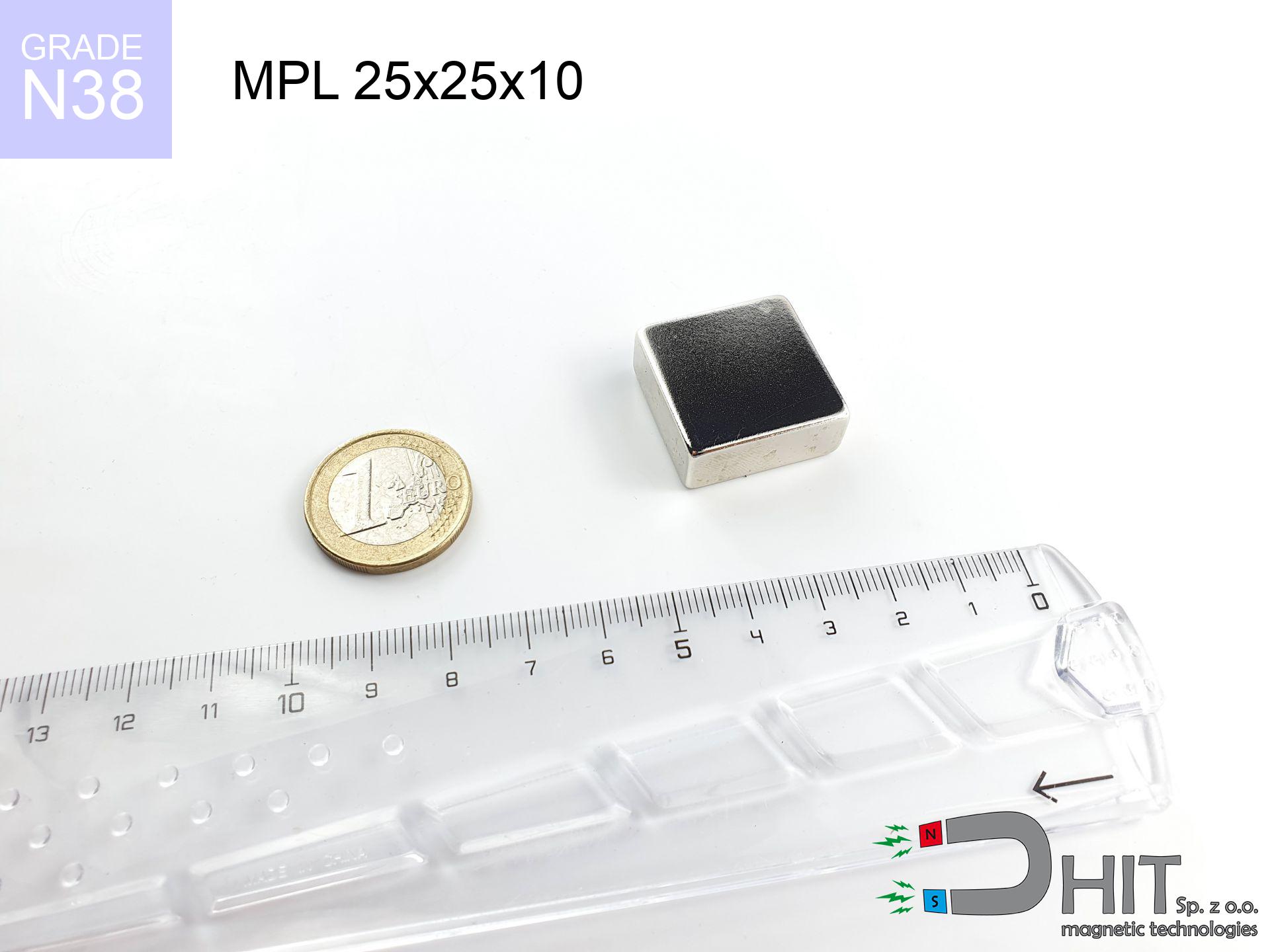

MPL 25x25x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020137

GTIN/EAN: 5906301811435

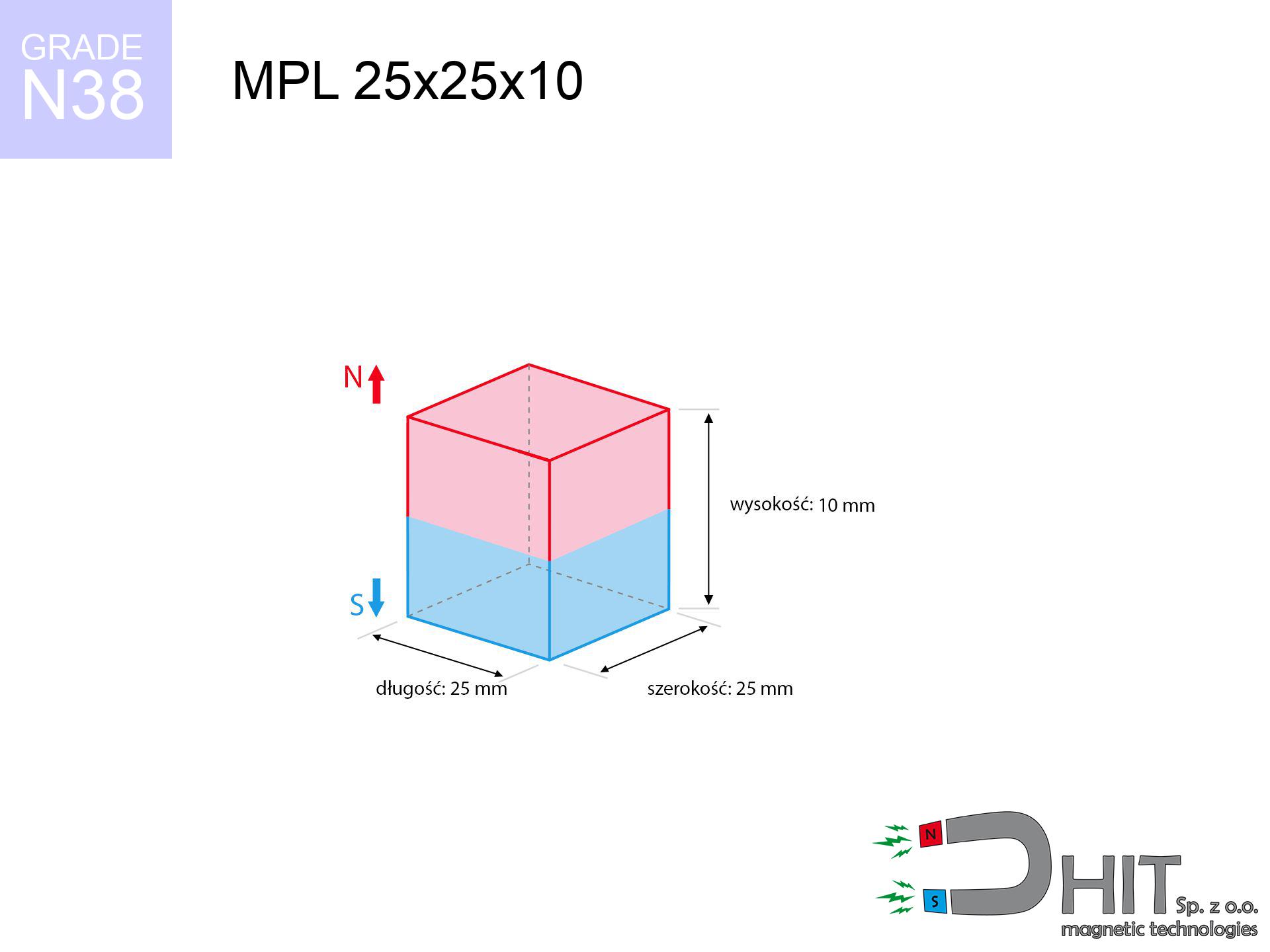

length

25 mm [±0,1 mm]

Width

25 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

46.88 g

Magnetization Direction

↑ axial

Load capacity

19.39 kg / 190.25 N

Magnetic Induction

361.04 mT / 3610 Gs

Coating

[NiCuNi] Nickel

20.29 ZŁ with VAT / pcs + price for transport

16.50 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise drop us a message via

request form

our website.

Strength as well as appearance of magnetic components can be estimated on our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical parameters - MPL 25x25x10 / N38 - lamellar magnet

Specification / characteristics - MPL 25x25x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020137 |

| GTIN/EAN | 5906301811435 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 25 mm [±0,1 mm] |

| Width | 25 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 46.88 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 19.39 kg / 190.25 N |

| Magnetic Induction ~ ? | 361.04 mT / 3610 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the product - technical parameters

Presented values are the direct effect of a engineering analysis. Values are based on algorithms for the class Nd2Fe14B. Operational performance might slightly differ. Treat these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs gap) - interaction chart

MPL 25x25x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3610 Gs

361.0 mT

|

19.39 kg / 42.75 lbs

19390.0 g / 190.2 N

|

dangerous! |

| 1 mm |

3392 Gs

339.2 mT

|

17.12 kg / 37.74 lbs

17117.7 g / 167.9 N

|

dangerous! |

| 2 mm |

3156 Gs

315.6 mT

|

14.82 kg / 32.68 lbs

14822.5 g / 145.4 N

|

dangerous! |

| 3 mm |

2913 Gs

291.3 mT

|

12.63 kg / 27.85 lbs

12631.8 g / 123.9 N

|

dangerous! |

| 5 mm |

2436 Gs

243.6 mT

|

8.83 kg / 19.46 lbs

8827.9 g / 86.6 N

|

medium risk |

| 10 mm |

1464 Gs

146.4 mT

|

3.19 kg / 7.04 lbs

3191.5 g / 31.3 N

|

medium risk |

| 15 mm |

872 Gs

87.2 mT

|

1.13 kg / 2.49 lbs

1131.5 g / 11.1 N

|

weak grip |

| 20 mm |

538 Gs

53.8 mT

|

0.43 kg / 0.95 lbs

430.4 g / 4.2 N

|

weak grip |

| 30 mm |

234 Gs

23.4 mT

|

0.08 kg / 0.18 lbs

81.8 g / 0.8 N

|

weak grip |

| 50 mm |

68 Gs

6.8 mT

|

0.01 kg / 0.02 lbs

6.9 g / 0.1 N

|

weak grip |

Table 2: Sliding force (wall)

MPL 25x25x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.88 kg / 8.55 lbs

3878.0 g / 38.0 N

|

| 1 mm | Stal (~0.2) |

3.42 kg / 7.55 lbs

3424.0 g / 33.6 N

|

| 2 mm | Stal (~0.2) |

2.96 kg / 6.53 lbs

2964.0 g / 29.1 N

|

| 3 mm | Stal (~0.2) |

2.53 kg / 5.57 lbs

2526.0 g / 24.8 N

|

| 5 mm | Stal (~0.2) |

1.77 kg / 3.89 lbs

1766.0 g / 17.3 N

|

| 10 mm | Stal (~0.2) |

0.64 kg / 1.41 lbs

638.0 g / 6.3 N

|

| 15 mm | Stal (~0.2) |

0.23 kg / 0.50 lbs

226.0 g / 2.2 N

|

| 20 mm | Stal (~0.2) |

0.09 kg / 0.19 lbs

86.0 g / 0.8 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

16.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MPL 25x25x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.82 kg / 12.82 lbs

5817.0 g / 57.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.88 kg / 8.55 lbs

3878.0 g / 38.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.94 kg / 4.27 lbs

1939.0 g / 19.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

9.70 kg / 21.37 lbs

9695.0 g / 95.1 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 25x25x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.97 kg / 2.14 lbs

969.5 g / 9.5 N

|

| 1 mm |

|

2.42 kg / 5.34 lbs

2423.8 g / 23.8 N

|

| 2 mm |

|

4.85 kg / 10.69 lbs

4847.5 g / 47.6 N

|

| 3 mm |

|

7.27 kg / 16.03 lbs

7271.3 g / 71.3 N

|

| 5 mm |

|

12.12 kg / 26.72 lbs

12118.8 g / 118.9 N

|

| 10 mm |

|

19.39 kg / 42.75 lbs

19390.0 g / 190.2 N

|

| 11 mm |

|

19.39 kg / 42.75 lbs

19390.0 g / 190.2 N

|

| 12 mm |

|

19.39 kg / 42.75 lbs

19390.0 g / 190.2 N

|

Table 5: Thermal resistance (material behavior) - power drop

MPL 25x25x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

19.39 kg / 42.75 lbs

19390.0 g / 190.2 N

|

OK |

| 40 °C | -2.2% |

18.96 kg / 41.81 lbs

18963.4 g / 186.0 N

|

OK |

| 60 °C | -4.4% |

18.54 kg / 40.87 lbs

18536.8 g / 181.8 N

|

|

| 80 °C | -6.6% |

18.11 kg / 39.93 lbs

18110.3 g / 177.7 N

|

|

| 100 °C | -28.8% |

13.81 kg / 30.44 lbs

13805.7 g / 135.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 25x25x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

50.20 kg / 110.68 lbs

5 073 Gs

|

7.53 kg / 16.60 lbs

7531 g / 73.9 N

|

N/A |

| 1 mm |

47.31 kg / 104.30 lbs

7 008 Gs

|

7.10 kg / 15.65 lbs

7097 g / 69.6 N

|

42.58 kg / 93.87 lbs

~0 Gs

|

| 2 mm |

44.32 kg / 97.71 lbs

6 783 Gs

|

6.65 kg / 14.66 lbs

6648 g / 65.2 N

|

39.89 kg / 87.94 lbs

~0 Gs

|

| 3 mm |

41.33 kg / 91.12 lbs

6 550 Gs

|

6.20 kg / 13.67 lbs

6200 g / 60.8 N

|

37.20 kg / 82.01 lbs

~0 Gs

|

| 5 mm |

35.49 kg / 78.25 lbs

6 070 Gs

|

5.32 kg / 11.74 lbs

5324 g / 52.2 N

|

31.94 kg / 70.43 lbs

~0 Gs

|

| 10 mm |

22.86 kg / 50.39 lbs

4 871 Gs

|

3.43 kg / 7.56 lbs

3429 g / 33.6 N

|

20.57 kg / 45.35 lbs

~0 Gs

|

| 20 mm |

8.26 kg / 18.22 lbs

2 929 Gs

|

1.24 kg / 2.73 lbs

1240 g / 12.2 N

|

7.44 kg / 16.40 lbs

~0 Gs

|

| 50 mm |

0.46 kg / 1.02 lbs

695 Gs

|

0.07 kg / 0.15 lbs

70 g / 0.7 N

|

0.42 kg / 0.92 lbs

~0 Gs

|

| 60 mm |

0.21 kg / 0.47 lbs

469 Gs

|

0.03 kg / 0.07 lbs

32 g / 0.3 N

|

0.19 kg / 0.42 lbs

~0 Gs

|

| 70 mm |

0.10 kg / 0.23 lbs

329 Gs

|

0.02 kg / 0.03 lbs

16 g / 0.2 N

|

0.09 kg / 0.21 lbs

~0 Gs

|

| 80 mm |

0.05 kg / 0.12 lbs

239 Gs

|

0.01 kg / 0.02 lbs

8 g / 0.1 N

|

0.05 kg / 0.11 lbs

~0 Gs

|

| 90 mm |

0.03 kg / 0.07 lbs

178 Gs

|

0.00 kg / 0.01 lbs

5 g / 0.0 N

|

0.03 kg / 0.06 lbs

~0 Gs

|

| 100 mm |

0.02 kg / 0.04 lbs

136 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 25x25x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 8.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 6.5 cm |

| Remote | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 25x25x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.52 km/h

(6.26 m/s)

|

0.92 J | |

| 30 mm |

35.62 km/h

(9.89 m/s)

|

2.29 J | |

| 50 mm |

45.87 km/h

(12.74 m/s)

|

3.81 J | |

| 100 mm |

64.86 km/h

(18.02 m/s)

|

7.61 J |

Table 9: Coating parameters (durability)

MPL 25x25x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 25x25x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 23 497 Mx | 235.0 µWb |

| Pc Coefficient | 0.46 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 25x25x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 19.39 kg | Standard |

| Water (riverbed) |

22.20 kg

(+2.81 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds merely ~20% of its max power.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.46

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Strengths and weaknesses of rare earth magnets.

Benefits

- Their strength is durable, and after approximately 10 years it decreases only by ~1% (theoretically),

- Neodymium magnets are distinguished by extremely resistant to demagnetization caused by external field sources,

- The use of an refined finish of noble metals (nickel, gold, silver) causes the element to look better,

- They show high magnetic induction at the operating surface, making them more effective,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of custom creating as well as modifying to specific applications,

- Wide application in advanced technology sectors – they are used in HDD drives, brushless drives, medical devices, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer high power in tiny dimensions, which enables their usage in miniature devices

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also increases their durability

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Limited ability of creating nuts in the magnet and complicated shapes - recommended is casing - magnetic holder.

- Health risk resulting from small fragments of magnets pose a threat, if swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small components of these products are able to complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Best holding force of the magnet in ideal parameters – what it depends on?

- using a plate made of low-carbon steel, acting as a magnetic yoke

- possessing a massiveness of min. 10 mm to ensure full flux closure

- with a surface perfectly flat

- with total lack of distance (without impurities)

- during detachment in a direction perpendicular to the plane

- at ambient temperature room level

Determinants of lifting force in real conditions

- Gap (betwixt the magnet and the plate), as even a microscopic clearance (e.g. 0.5 mm) results in a decrease in force by up to 50% (this also applies to varnish, rust or dirt).

- Load vector – maximum parameter is reached only during pulling at a 90° angle. The force required to slide of the magnet along the plate is typically several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux penetrates through instead of generating force.

- Plate material – mild steel attracts best. Alloy admixtures decrease magnetic permeability and holding force.

- Plate texture – ground elements guarantee perfect abutment, which increases force. Rough surfaces weaken the grip.

- Temperature influence – hot environment reduces magnetic field. Too high temperature can permanently demagnetize the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Moreover, even a minimal clearance between the magnet and the plate reduces the load capacity.

Warnings

Do not drill into magnets

Dust created during grinding of magnets is combustible. Do not drill into magnets without proper cooling and knowledge.

Keep away from electronics

A powerful magnetic field interferes with the operation of magnetometers in phones and GPS navigation. Do not bring magnets near a smartphone to avoid breaking the sensors.

Nickel allergy

A percentage of the population suffer from a sensitization to Ni, which is the common plating for NdFeB magnets. Prolonged contact can result in a rash. It is best to wear protective gloves.

Beware of splinters

Watch out for shards. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

Conscious usage

Exercise caution. Rare earth magnets attract from a long distance and connect with massive power, often quicker than you can react.

Electronic devices

Device Safety: Strong magnets can ruin payment cards and delicate electronics (heart implants, medical aids, timepieces).

Choking Hazard

Only for adults. Tiny parts can be swallowed, causing serious injuries. Store away from kids and pets.

Life threat

Medical warning: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Thermal limits

Watch the temperature. Heating the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Crushing risk

Large magnets can break fingers in a fraction of a second. Never put your hand betwixt two attracting surfaces.