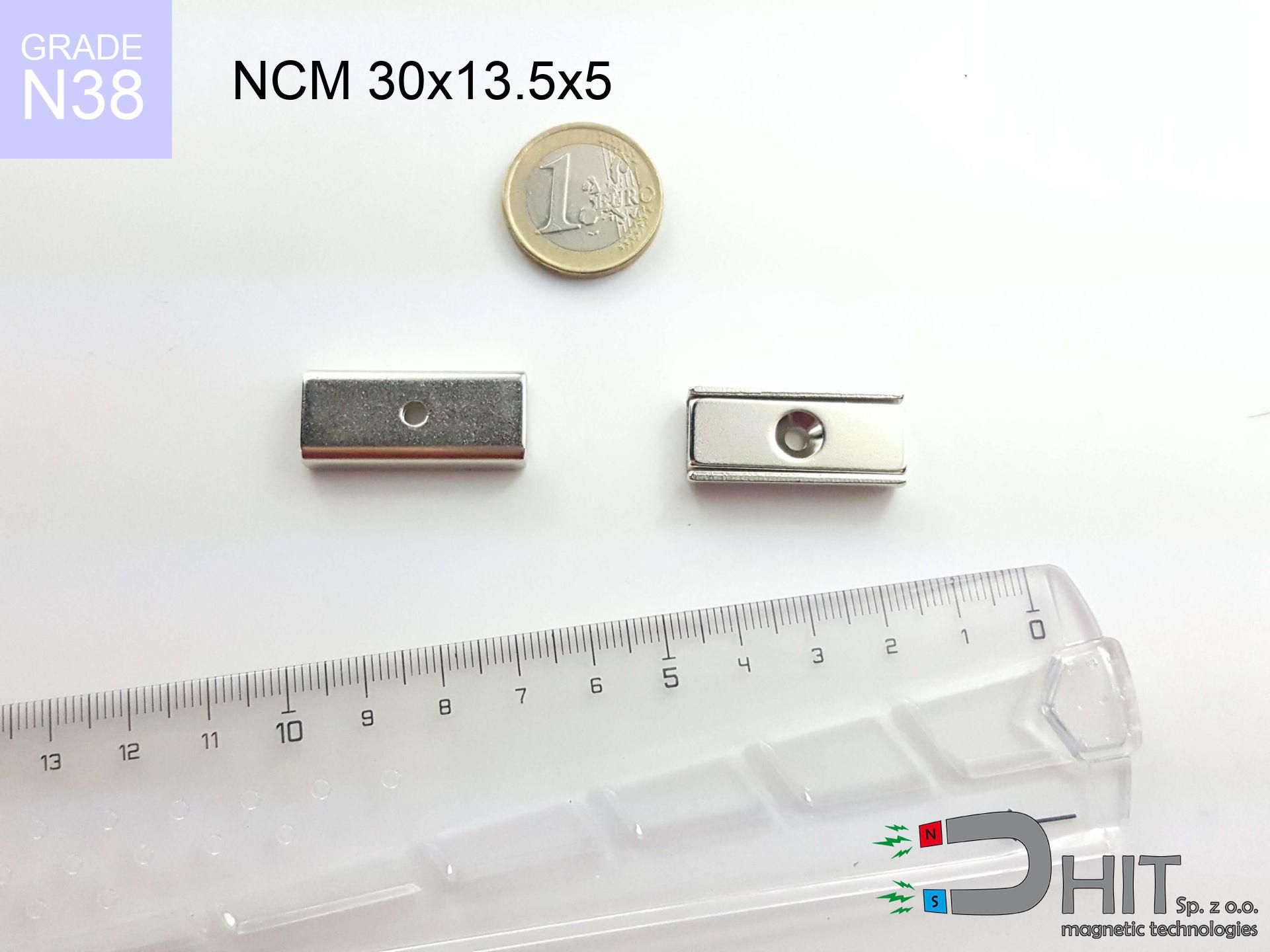

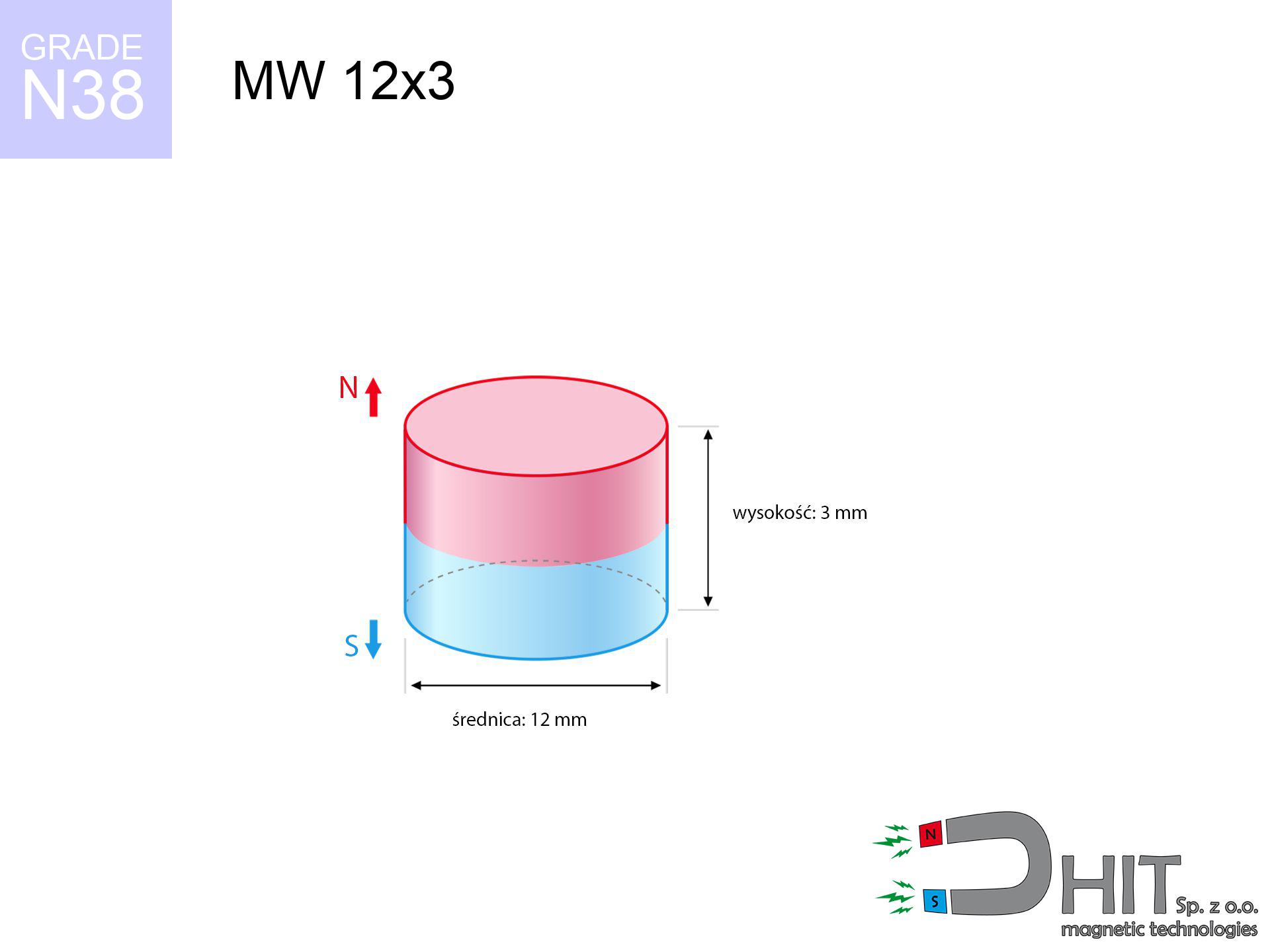

MW 12x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010018

GTIN/EAN: 5906301810179

Diameter Ø

12 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

2.54 g

Magnetization Direction

↑ axial

Load capacity

2.49 kg / 24.43 N

Magnetic Induction

277.09 mT / 2771 Gs

Coating

[NiCuNi] Nickel

1.648 ZŁ with VAT / pcs + price for transport

1.340 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or contact us through

inquiry form

the contact form page.

Force as well as shape of magnetic components can be checked with our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical parameters of the product - MW 12x3 / N38 - cylindrical magnet

Specification / characteristics - MW 12x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010018 |

| GTIN/EAN | 5906301810179 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 2.54 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.49 kg / 24.43 N |

| Magnetic Induction ~ ? | 277.09 mT / 2771 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the magnet - data

The following data constitute the direct effect of a mathematical calculation. Results were calculated on algorithms for the class Nd2Fe14B. Actual conditions may deviate from the simulation results. Treat these data as a supplementary guide during assembly planning.

Table 1: Static force (pull vs gap) - power drop

MW 12x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2770 Gs

277.0 mT

|

2.49 kg / 5.49 LBS

2490.0 g / 24.4 N

|

strong |

| 1 mm |

2420 Gs

242.0 mT

|

1.90 kg / 4.19 LBS

1900.6 g / 18.6 N

|

weak grip |

| 2 mm |

2009 Gs

200.9 mT

|

1.31 kg / 2.89 LBS

1309.4 g / 12.8 N

|

weak grip |

| 3 mm |

1611 Gs

161.1 mT

|

0.84 kg / 1.86 LBS

842.7 g / 8.3 N

|

weak grip |

| 5 mm |

991 Gs

99.1 mT

|

0.32 kg / 0.70 LBS

318.7 g / 3.1 N

|

weak grip |

| 10 mm |

313 Gs

31.3 mT

|

0.03 kg / 0.07 LBS

31.8 g / 0.3 N

|

weak grip |

| 15 mm |

125 Gs

12.5 mT

|

0.01 kg / 0.01 LBS

5.1 g / 0.0 N

|

weak grip |

| 20 mm |

61 Gs

6.1 mT

|

0.00 kg / 0.00 LBS

1.2 g / 0.0 N

|

weak grip |

| 30 mm |

20 Gs

2.0 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Shear hold (vertical surface)

MW 12x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.50 kg / 1.10 LBS

498.0 g / 4.9 N

|

| 1 mm | Stal (~0.2) |

0.38 kg / 0.84 LBS

380.0 g / 3.7 N

|

| 2 mm | Stal (~0.2) |

0.26 kg / 0.58 LBS

262.0 g / 2.6 N

|

| 3 mm | Stal (~0.2) |

0.17 kg / 0.37 LBS

168.0 g / 1.6 N

|

| 5 mm | Stal (~0.2) |

0.06 kg / 0.14 LBS

64.0 g / 0.6 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 12x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.75 kg / 1.65 LBS

747.0 g / 7.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.50 kg / 1.10 LBS

498.0 g / 4.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.25 kg / 0.55 LBS

249.0 g / 2.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.25 kg / 2.74 LBS

1245.0 g / 12.2 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 12x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.25 kg / 0.55 LBS

249.0 g / 2.4 N

|

| 1 mm |

|

0.62 kg / 1.37 LBS

622.5 g / 6.1 N

|

| 2 mm |

|

1.25 kg / 2.74 LBS

1245.0 g / 12.2 N

|

| 3 mm |

|

1.87 kg / 4.12 LBS

1867.5 g / 18.3 N

|

| 5 mm |

|

2.49 kg / 5.49 LBS

2490.0 g / 24.4 N

|

| 10 mm |

|

2.49 kg / 5.49 LBS

2490.0 g / 24.4 N

|

| 11 mm |

|

2.49 kg / 5.49 LBS

2490.0 g / 24.4 N

|

| 12 mm |

|

2.49 kg / 5.49 LBS

2490.0 g / 24.4 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MW 12x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.49 kg / 5.49 LBS

2490.0 g / 24.4 N

|

OK |

| 40 °C | -2.2% |

2.44 kg / 5.37 LBS

2435.2 g / 23.9 N

|

OK |

| 60 °C | -4.4% |

2.38 kg / 5.25 LBS

2380.4 g / 23.4 N

|

|

| 80 °C | -6.6% |

2.33 kg / 5.13 LBS

2325.7 g / 22.8 N

|

|

| 100 °C | -28.8% |

1.77 kg / 3.91 LBS

1772.9 g / 17.4 N

|

Table 6: Two magnets (attraction) - field collision

MW 12x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

5.35 kg / 11.79 LBS

4 377 Gs

|

0.80 kg / 1.77 LBS

802 g / 7.9 N

|

N/A |

| 1 mm |

4.75 kg / 10.46 LBS

5 218 Gs

|

0.71 kg / 1.57 LBS

712 g / 7.0 N

|

4.27 kg / 9.42 LBS

~0 Gs

|

| 2 mm |

4.08 kg / 9.00 LBS

4 840 Gs

|

0.61 kg / 1.35 LBS

612 g / 6.0 N

|

3.67 kg / 8.10 LBS

~0 Gs

|

| 3 mm |

3.42 kg / 7.55 LBS

4 433 Gs

|

0.51 kg / 1.13 LBS

514 g / 5.0 N

|

3.08 kg / 6.80 LBS

~0 Gs

|

| 5 mm |

2.27 kg / 5.01 LBS

3 610 Gs

|

0.34 kg / 0.75 LBS

341 g / 3.3 N

|

2.04 kg / 4.51 LBS

~0 Gs

|

| 10 mm |

0.68 kg / 1.51 LBS

1 982 Gs

|

0.10 kg / 0.23 LBS

103 g / 1.0 N

|

0.62 kg / 1.36 LBS

~0 Gs

|

| 20 mm |

0.07 kg / 0.15 LBS

626 Gs

|

0.01 kg / 0.02 LBS

10 g / 0.1 N

|

0.06 kg / 0.14 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

67 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

41 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

27 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

18 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

13 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

10 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 12x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - warning

MW 12x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

31.83 km/h

(8.84 m/s)

|

0.10 J | |

| 30 mm |

54.69 km/h

(15.19 m/s)

|

0.29 J | |

| 50 mm |

70.61 km/h

(19.61 m/s)

|

0.49 J | |

| 100 mm |

99.85 km/h

(27.74 m/s)

|

0.98 J |

Table 9: Anti-corrosion coating durability

MW 12x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 12x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 483 Mx | 34.8 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Submerged application

MW 12x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.49 kg | Standard |

| Water (riverbed) |

2.85 kg

(+0.36 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet holds merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly reduces the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Strengths and weaknesses of neodymium magnets.

Advantages

- Their power remains stable, and after around ten years it decreases only by ~1% (according to research),

- They show high resistance to demagnetization induced by external field influence,

- By covering with a reflective coating of gold, the element gains an elegant look,

- Magnetic induction on the working layer of the magnet turns out to be maximum,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to the potential of precise forming and customization to specialized needs, neodymium magnets can be produced in a wide range of geometric configurations, which increases their versatility,

- Significant place in advanced technology sectors – they are commonly used in magnetic memories, electromotive mechanisms, medical devices, as well as modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- To avoid cracks under impact, we suggest using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We recommend cover - magnetic holder, due to difficulties in realizing nuts inside the magnet and complicated forms.

- Potential hazard resulting from small fragments of magnets pose a threat, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, small elements of these magnets are able to be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting capacity of the magnet – what it depends on?

- on a block made of mild steel, effectively closing the magnetic flux

- possessing a thickness of min. 10 mm to avoid saturation

- characterized by even structure

- under conditions of gap-free contact (surface-to-surface)

- under vertical force direction (90-degree angle)

- in neutral thermal conditions

Lifting capacity in real conditions – factors

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Direction of force – highest force is reached only during perpendicular pulling. The force required to slide of the magnet along the plate is typically many times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux penetrates through instead of generating force.

- Metal type – not every steel reacts the same. High carbon content worsen the attraction effect.

- Base smoothness – the more even the plate, the better the adhesion and stronger the hold. Unevenness creates an air distance.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under perpendicular forces, however under shearing force the holding force is lower. Moreover, even a small distance between the magnet and the plate decreases the load capacity.

Safety rules for work with neodymium magnets

Medical implants

For implant holders: Powerful magnets affect electronics. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Product not for children

Neodymium magnets are not intended for children. Eating a few magnets can lead to them connecting inside the digestive tract, which constitutes a critical condition and necessitates urgent medical intervention.

Bone fractures

Large magnets can smash fingers instantly. Under no circumstances put your hand between two strong magnets.

Do not overheat magnets

Do not overheat. NdFeB magnets are susceptible to temperature. If you require operation above 80°C, ask us about HT versions (H, SH, UH).

Fire risk

Fire hazard: Neodymium dust is explosive. Avoid machining magnets in home conditions as this risks ignition.

Immense force

Handle magnets consciously. Their huge power can shock even professionals. Be vigilant and do not underestimate their force.

Protective goggles

NdFeB magnets are sintered ceramics, meaning they are fragile like glass. Collision of two magnets will cause them cracking into shards.

Skin irritation risks

Studies show that nickel (standard magnet coating) is a strong allergen. If your skin reacts to metals, refrain from direct skin contact and opt for versions in plastic housing.

Keep away from electronics

Remember: neodymium magnets produce a field that disrupts precision electronics. Keep a separation from your phone, device, and GPS.

Electronic hazard

Intense magnetic fields can destroy records on payment cards, HDDs, and storage devices. Stay away of at least 10 cm.

![UMH 16x5x32 [M4] / N38 - magnetic holder with hook UMH 16x5x32 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-16x5x32-m4-lak.jpg)