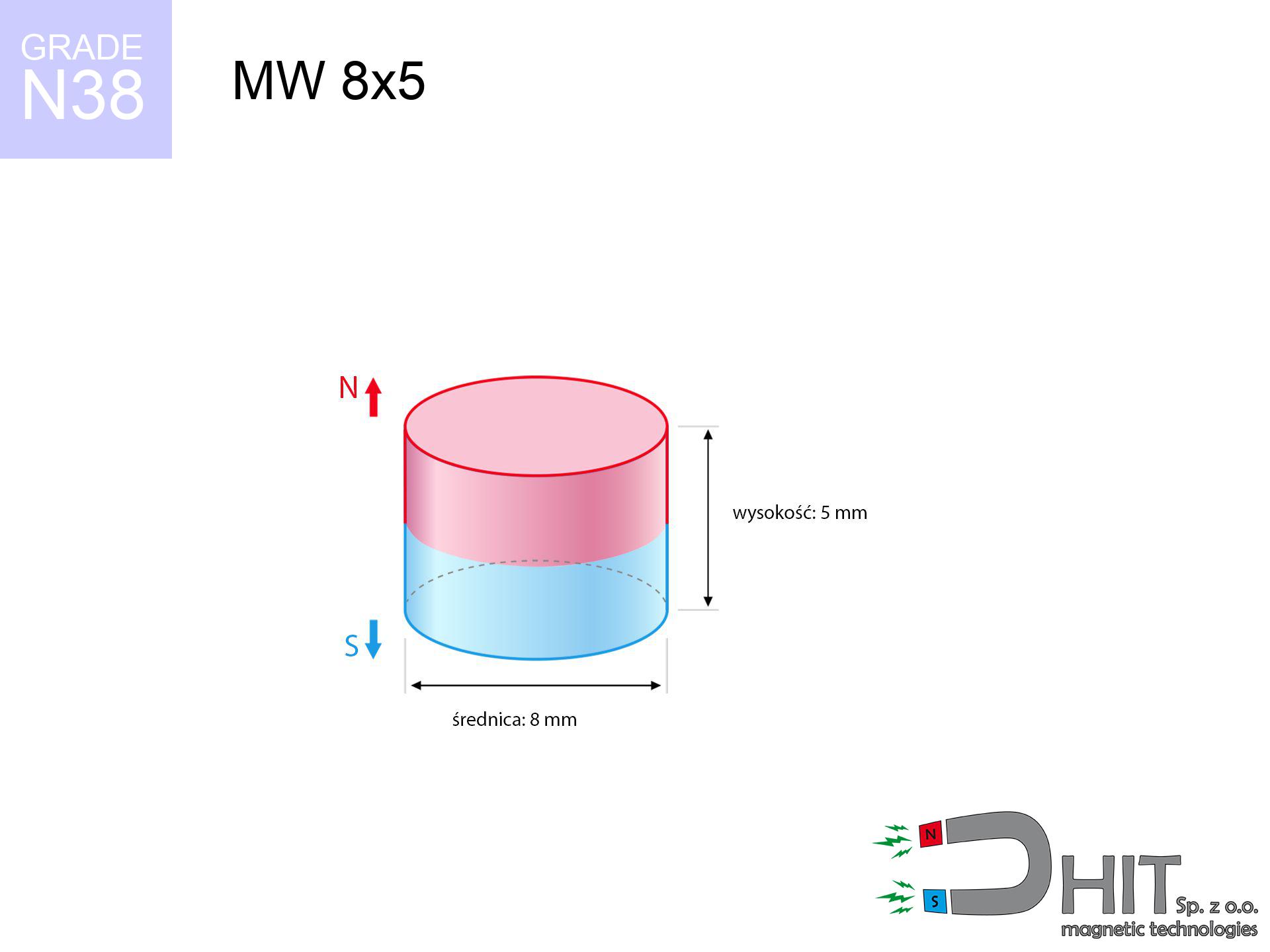

MW 8x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010105

GTIN/EAN: 5906301811046

Diameter Ø

8 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

1.88 g

Magnetization Direction

↑ axial

Load capacity

2.17 kg / 21.31 N

Magnetic Induction

483.41 mT / 4834 Gs

Coating

[NiCuNi] Nickel

0.836 ZŁ with VAT / pcs + price for transport

0.680 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

if you prefer contact us through

inquiry form

through our site.

Force and structure of magnetic components can be calculated with our

force calculator.

Order by 14:00 and we’ll ship today!

Physical properties - MW 8x5 / N38 - cylindrical magnet

Specification / characteristics - MW 8x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010105 |

| GTIN/EAN | 5906301811046 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 1.88 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.17 kg / 21.31 N |

| Magnetic Induction ~ ? | 483.41 mT / 4834 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - report

The following information represent the direct effect of a mathematical simulation. Values are based on algorithms for the class Nd2Fe14B. Actual parameters might slightly differ from theoretical values. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs gap) - power drop

MW 8x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4830 Gs

483.0 mT

|

2.17 kg / 4.78 lbs

2170.0 g / 21.3 N

|

medium risk |

| 1 mm |

3655 Gs

365.5 mT

|

1.24 kg / 2.74 lbs

1242.8 g / 12.2 N

|

safe |

| 2 mm |

2610 Gs

261.0 mT

|

0.63 kg / 1.40 lbs

633.9 g / 6.2 N

|

safe |

| 3 mm |

1825 Gs

182.5 mT

|

0.31 kg / 0.68 lbs

310.0 g / 3.0 N

|

safe |

| 5 mm |

915 Gs

91.5 mT

|

0.08 kg / 0.17 lbs

77.9 g / 0.8 N

|

safe |

| 10 mm |

234 Gs

23.4 mT

|

0.01 kg / 0.01 lbs

5.1 g / 0.1 N

|

safe |

| 15 mm |

89 Gs

8.9 mT

|

0.00 kg / 0.00 lbs

0.7 g / 0.0 N

|

safe |

| 20 mm |

43 Gs

4.3 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

safe |

| 30 mm |

14 Gs

1.4 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Sliding force (vertical surface)

MW 8x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.43 kg / 0.96 lbs

434.0 g / 4.3 N

|

| 1 mm | Stal (~0.2) |

0.25 kg / 0.55 lbs

248.0 g / 2.4 N

|

| 2 mm | Stal (~0.2) |

0.13 kg / 0.28 lbs

126.0 g / 1.2 N

|

| 3 mm | Stal (~0.2) |

0.06 kg / 0.14 lbs

62.0 g / 0.6 N

|

| 5 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

16.0 g / 0.2 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 8x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.65 kg / 1.44 lbs

651.0 g / 6.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.43 kg / 0.96 lbs

434.0 g / 4.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.22 kg / 0.48 lbs

217.0 g / 2.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.09 kg / 2.39 lbs

1085.0 g / 10.6 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 8x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.22 kg / 0.48 lbs

217.0 g / 2.1 N

|

| 1 mm |

|

0.54 kg / 1.20 lbs

542.5 g / 5.3 N

|

| 2 mm |

|

1.09 kg / 2.39 lbs

1085.0 g / 10.6 N

|

| 3 mm |

|

1.63 kg / 3.59 lbs

1627.5 g / 16.0 N

|

| 5 mm |

|

2.17 kg / 4.78 lbs

2170.0 g / 21.3 N

|

| 10 mm |

|

2.17 kg / 4.78 lbs

2170.0 g / 21.3 N

|

| 11 mm |

|

2.17 kg / 4.78 lbs

2170.0 g / 21.3 N

|

| 12 mm |

|

2.17 kg / 4.78 lbs

2170.0 g / 21.3 N

|

Table 5: Thermal stability (stability) - thermal limit

MW 8x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.17 kg / 4.78 lbs

2170.0 g / 21.3 N

|

OK |

| 40 °C | -2.2% |

2.12 kg / 4.68 lbs

2122.3 g / 20.8 N

|

OK |

| 60 °C | -4.4% |

2.07 kg / 4.57 lbs

2074.5 g / 20.4 N

|

OK |

| 80 °C | -6.6% |

2.03 kg / 4.47 lbs

2026.8 g / 19.9 N

|

|

| 100 °C | -28.8% |

1.55 kg / 3.41 lbs

1545.0 g / 15.2 N

|

Table 6: Two magnets (attraction) - field range

MW 8x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

7.23 kg / 15.94 lbs

5 742 Gs

|

1.08 kg / 2.39 lbs

1084 g / 10.6 N

|

N/A |

| 1 mm |

5.58 kg / 12.31 lbs

8 490 Gs

|

0.84 kg / 1.85 lbs

838 g / 8.2 N

|

5.03 kg / 11.08 lbs

~0 Gs

|

| 2 mm |

4.14 kg / 9.13 lbs

7 310 Gs

|

0.62 kg / 1.37 lbs

621 g / 6.1 N

|

3.73 kg / 8.21 lbs

~0 Gs

|

| 3 mm |

2.98 kg / 6.58 lbs

6 207 Gs

|

0.45 kg / 0.99 lbs

448 g / 4.4 N

|

2.69 kg / 5.92 lbs

~0 Gs

|

| 5 mm |

1.48 kg / 3.26 lbs

4 369 Gs

|

0.22 kg / 0.49 lbs

222 g / 2.2 N

|

1.33 kg / 2.93 lbs

~0 Gs

|

| 10 mm |

0.26 kg / 0.57 lbs

1 830 Gs

|

0.04 kg / 0.09 lbs

39 g / 0.4 N

|

0.23 kg / 0.51 lbs

~0 Gs

|

| 20 mm |

0.02 kg / 0.04 lbs

468 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.03 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

47 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

29 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

19 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

13 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

9 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

7 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MW 8x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 8x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.31 km/h

(9.53 m/s)

|

0.09 J | |

| 30 mm |

59.35 km/h

(16.49 m/s)

|

0.26 J | |

| 50 mm |

76.62 km/h

(21.28 m/s)

|

0.43 J | |

| 100 mm |

108.35 km/h

(30.10 m/s)

|

0.85 J |

Table 9: Coating parameters (durability)

MW 8x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 8x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 450 Mx | 24.5 µWb |

| Pc Coefficient | 0.68 | High (Stable) |

Table 11: Submerged application

MW 8x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.17 kg | Standard |

| Water (riverbed) |

2.48 kg

(+0.31 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet holds merely approx. 20-30% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) significantly weakens the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.68

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Strengths as well as weaknesses of neodymium magnets.

Strengths

- They have constant strength, and over around ten years their attraction force decreases symbolically – ~1% (in testing),

- They show high resistance to demagnetization induced by presence of other magnetic fields,

- By using a lustrous layer of nickel, the element gains an elegant look,

- Magnets are distinguished by extremely high magnetic induction on the outer side,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Possibility of accurate modeling as well as adjusting to specific applications,

- Huge importance in future technologies – they find application in computer drives, motor assemblies, medical devices, as well as industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which allows their use in compact constructions

Disadvantages

- To avoid cracks under impact, we recommend using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Limited ability of producing threads in the magnet and complex shapes - recommended is casing - magnet mounting.

- Potential hazard resulting from small fragments of magnets are risky, if swallowed, which is particularly important in the context of child safety. Furthermore, tiny parts of these products are able to complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- on a plate made of structural steel, perfectly concentrating the magnetic flux

- with a cross-section minimum 10 mm

- with an polished contact surface

- under conditions of gap-free contact (surface-to-surface)

- for force acting at a right angle (in the magnet axis)

- at room temperature

Determinants of practical lifting force of a magnet

- Air gap (betwixt the magnet and the plate), since even a microscopic clearance (e.g. 0.5 mm) results in a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Direction of force – maximum parameter is reached only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is typically many times lower (approx. 1/5 of the lifting capacity).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Stainless steels may generate lower lifting capacity.

- Surface quality – the smoother and more polished the plate, the larger the contact zone and stronger the hold. Unevenness acts like micro-gaps.

- Thermal environment – temperature increase results in weakening of force. Check the thermal limit for a given model.

Lifting capacity was determined using a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under shearing force the load capacity is reduced by as much as fivefold. Additionally, even a small distance between the magnet’s surface and the plate decreases the holding force.

Precautions when working with neodymium magnets

Fire risk

Combustion risk: Neodymium dust is highly flammable. Do not process magnets in home conditions as this risks ignition.

Implant safety

People with a ICD should keep an safe separation from magnets. The magnetism can interfere with the operation of the life-saving device.

Permanent damage

Monitor thermal conditions. Exposing the magnet above 80 degrees Celsius will ruin its properties and pulling force.

Handling guide

Handle magnets with awareness. Their immense force can shock even experienced users. Stay alert and do not underestimate their power.

GPS Danger

A strong magnetic field negatively affects the operation of compasses in phones and navigation systems. Keep magnets near a smartphone to prevent breaking the sensors.

No play value

Product intended for adults. Small elements pose a choking risk, leading to serious injuries. Store away from kids and pets.

Electronic devices

Very strong magnetic fields can corrupt files on payment cards, hard drives, and other magnetic media. Keep a distance of min. 10 cm.

Nickel allergy

Some people suffer from a hypersensitivity to nickel, which is the typical protective layer for NdFeB magnets. Frequent touching might lead to dermatitis. It is best to wear safety gloves.

Serious injuries

Big blocks can smash fingers in a fraction of a second. Never place your hand betwixt two strong magnets.

Shattering risk

Protect your eyes. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

![UI 40x12x7 [CA] - badge holder UI 40x12x7 [CA] - badge holder](https://cdn3.dhit.pl/graphics/products/ui40x12x7-vop.jpg)

![SM 18x150 [2xM5] / N42 - magnetic separator SM 18x150 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x150-2xm5-pec.jpg)