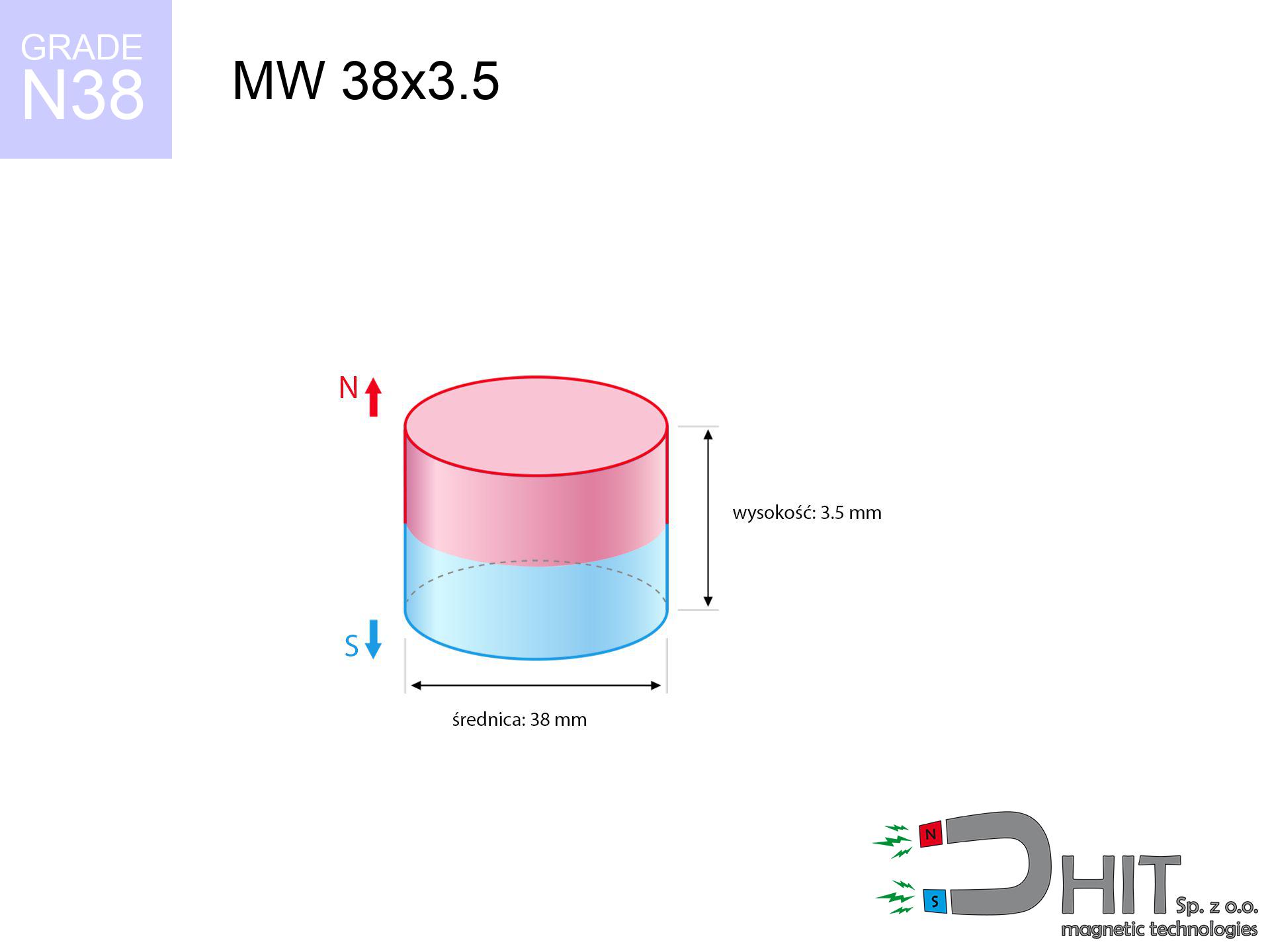

MW 38x3.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010062

GTIN/EAN: 5906301810612

Diameter Ø

38 mm [±0,1 mm]

Height

3.5 mm [±0,1 mm]

Weight

29.77 g

Magnetization Direction

↑ axial

Load capacity

5.09 kg / 49.91 N

Magnetic Induction

112.31 mT / 1123 Gs

Coating

[NiCuNi] Nickel

15.83 ZŁ with VAT / pcs + price for transport

12.87 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively drop us a message through

inquiry form

our website.

Lifting power and form of a neodymium magnet can be estimated on our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical data of the product - MW 38x3.5 / N38 - cylindrical magnet

Specification / characteristics - MW 38x3.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010062 |

| GTIN/EAN | 5906301810612 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 38 mm [±0,1 mm] |

| Height | 3.5 mm [±0,1 mm] |

| Weight | 29.77 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.09 kg / 49.91 N |

| Magnetic Induction ~ ? | 112.31 mT / 1123 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

The following information are the outcome of a mathematical analysis. Results rely on models for the material Nd2Fe14B. Actual parameters may differ from theoretical values. Treat these data as a preliminary roadmap for designers.

Table 1: Static pull force (pull vs distance) - power drop

MW 38x3.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1123 Gs

112.3 mT

|

5.09 kg / 11.22 lbs

5090.0 g / 49.9 N

|

strong |

| 1 mm |

1103 Gs

110.3 mT

|

4.91 kg / 10.82 lbs

4910.1 g / 48.2 N

|

strong |

| 2 mm |

1075 Gs

107.5 mT

|

4.66 kg / 10.28 lbs

4663.0 g / 45.7 N

|

strong |

| 3 mm |

1040 Gs

104.0 mT

|

4.36 kg / 9.62 lbs

4364.2 g / 42.8 N

|

strong |

| 5 mm |

954 Gs

95.4 mT

|

3.67 kg / 8.10 lbs

3673.1 g / 36.0 N

|

strong |

| 10 mm |

703 Gs

70.3 mT

|

2.00 kg / 4.40 lbs

1997.1 g / 19.6 N

|

low risk |

| 15 mm |

483 Gs

48.3 mT

|

0.94 kg / 2.08 lbs

943.2 g / 9.3 N

|

low risk |

| 20 mm |

326 Gs

32.6 mT

|

0.43 kg / 0.95 lbs

429.7 g / 4.2 N

|

low risk |

| 30 mm |

155 Gs

15.5 mT

|

0.10 kg / 0.21 lbs

97.1 g / 1.0 N

|

low risk |

| 50 mm |

47 Gs

4.7 mT

|

0.01 kg / 0.02 lbs

8.9 g / 0.1 N

|

low risk |

Table 2: Slippage capacity (wall)

MW 38x3.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.02 kg / 2.24 lbs

1018.0 g / 10.0 N

|

| 1 mm | Stal (~0.2) |

0.98 kg / 2.16 lbs

982.0 g / 9.6 N

|

| 2 mm | Stal (~0.2) |

0.93 kg / 2.05 lbs

932.0 g / 9.1 N

|

| 3 mm | Stal (~0.2) |

0.87 kg / 1.92 lbs

872.0 g / 8.6 N

|

| 5 mm | Stal (~0.2) |

0.73 kg / 1.62 lbs

734.0 g / 7.2 N

|

| 10 mm | Stal (~0.2) |

0.40 kg / 0.88 lbs

400.0 g / 3.9 N

|

| 15 mm | Stal (~0.2) |

0.19 kg / 0.41 lbs

188.0 g / 1.8 N

|

| 20 mm | Stal (~0.2) |

0.09 kg / 0.19 lbs

86.0 g / 0.8 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

20.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MW 38x3.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.53 kg / 3.37 lbs

1527.0 g / 15.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.02 kg / 2.24 lbs

1018.0 g / 10.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.51 kg / 1.12 lbs

509.0 g / 5.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.55 kg / 5.61 lbs

2545.0 g / 25.0 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 38x3.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.51 kg / 1.12 lbs

509.0 g / 5.0 N

|

| 1 mm |

|

1.27 kg / 2.81 lbs

1272.5 g / 12.5 N

|

| 2 mm |

|

2.55 kg / 5.61 lbs

2545.0 g / 25.0 N

|

| 3 mm |

|

3.82 kg / 8.42 lbs

3817.5 g / 37.4 N

|

| 5 mm |

|

5.09 kg / 11.22 lbs

5090.0 g / 49.9 N

|

| 10 mm |

|

5.09 kg / 11.22 lbs

5090.0 g / 49.9 N

|

| 11 mm |

|

5.09 kg / 11.22 lbs

5090.0 g / 49.9 N

|

| 12 mm |

|

5.09 kg / 11.22 lbs

5090.0 g / 49.9 N

|

Table 5: Thermal resistance (material behavior) - thermal limit

MW 38x3.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.09 kg / 11.22 lbs

5090.0 g / 49.9 N

|

OK |

| 40 °C | -2.2% |

4.98 kg / 10.97 lbs

4978.0 g / 48.8 N

|

OK |

| 60 °C | -4.4% |

4.87 kg / 10.73 lbs

4866.0 g / 47.7 N

|

|

| 80 °C | -6.6% |

4.75 kg / 10.48 lbs

4754.1 g / 46.6 N

|

|

| 100 °C | -28.8% |

3.62 kg / 7.99 lbs

3624.1 g / 35.6 N

|

Table 6: Two magnets (attraction) - field range

MW 38x3.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

8.82 kg / 19.44 lbs

2 143 Gs

|

1.32 kg / 2.92 lbs

1323 g / 13.0 N

|

N/A |

| 1 mm |

8.68 kg / 19.13 lbs

2 228 Gs

|

1.30 kg / 2.87 lbs

1302 g / 12.8 N

|

7.81 kg / 17.22 lbs

~0 Gs

|

| 2 mm |

8.51 kg / 18.75 lbs

2 206 Gs

|

1.28 kg / 2.81 lbs

1276 g / 12.5 N

|

7.66 kg / 16.88 lbs

~0 Gs

|

| 3 mm |

8.31 kg / 18.31 lbs

2 180 Gs

|

1.25 kg / 2.75 lbs

1246 g / 12.2 N

|

7.47 kg / 16.48 lbs

~0 Gs

|

| 5 mm |

7.83 kg / 17.26 lbs

2 116 Gs

|

1.17 kg / 2.59 lbs

1174 g / 11.5 N

|

7.05 kg / 15.53 lbs

~0 Gs

|

| 10 mm |

6.36 kg / 14.03 lbs

1 908 Gs

|

0.95 kg / 2.10 lbs

955 g / 9.4 N

|

5.73 kg / 12.63 lbs

~0 Gs

|

| 20 mm |

3.46 kg / 7.63 lbs

1 407 Gs

|

0.52 kg / 1.14 lbs

519 g / 5.1 N

|

3.11 kg / 6.87 lbs

~0 Gs

|

| 50 mm |

0.35 kg / 0.76 lbs

445 Gs

|

0.05 kg / 0.11 lbs

52 g / 0.5 N

|

0.31 kg / 0.69 lbs

~0 Gs

|

| 60 mm |

0.17 kg / 0.37 lbs

310 Gs

|

0.03 kg / 0.06 lbs

25 g / 0.2 N

|

0.15 kg / 0.33 lbs

~0 Gs

|

| 70 mm |

0.09 kg / 0.19 lbs

222 Gs

|

0.01 kg / 0.03 lbs

13 g / 0.1 N

|

0.08 kg / 0.17 lbs

~0 Gs

|

| 80 mm |

0.05 kg / 0.10 lbs

163 Gs

|

0.01 kg / 0.02 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 90 mm |

0.03 kg / 0.06 lbs

122 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 100 mm |

0.02 kg / 0.03 lbs

94 Gs

|

0.00 kg / 0.01 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 38x3.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 7.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.5 cm |

| Remote | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 38x3.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.10 km/h

(4.47 m/s)

|

0.30 J | |

| 30 mm |

23.11 km/h

(6.42 m/s)

|

0.61 J | |

| 50 mm |

29.52 km/h

(8.20 m/s)

|

1.00 J | |

| 100 mm |

41.70 km/h

(11.58 m/s)

|

2.00 J |

Table 9: Coating parameters (durability)

MW 38x3.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 38x3.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 17 022 Mx | 170.2 µWb |

| Pc Coefficient | 0.14 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 38x3.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.09 kg | Standard |

| Water (riverbed) |

5.83 kg

(+0.74 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical wall, the magnet holds just a fraction of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.14

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also proposals

Strengths and weaknesses of Nd2Fe14B magnets.

Benefits

- They virtually do not lose power, because even after ten years the performance loss is only ~1% (according to literature),

- They maintain their magnetic properties even under strong external field,

- By applying a lustrous coating of nickel, the element gains an aesthetic look,

- Neodymium magnets achieve maximum magnetic induction on a small surface, which allows for strong attraction,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of detailed creating as well as modifying to individual needs,

- Universal use in innovative solutions – they are commonly used in data components, brushless drives, medical devices, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which enables their usage in small systems

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We recommend cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complicated forms.

- Health risk to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which becomes key in the context of child health protection. It is also worth noting that small elements of these magnets can be problematic in diagnostics medical after entering the body.

- Due to expensive raw materials, their price is higher than average,

Pull force analysis

Detachment force of the magnet in optimal conditions – what affects it?

- using a base made of low-carbon steel, functioning as a ideal flux conductor

- whose thickness reaches at least 10 mm

- characterized by even structure

- with direct contact (no paint)

- during pulling in a direction vertical to the plane

- at room temperature

Practical aspects of lifting capacity – factors

- Clearance – the presence of any layer (paint, dirt, air) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Direction of force – maximum parameter is available only during pulling at a 90° angle. The resistance to sliding of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of converting into lifting capacity.

- Material type – the best choice is high-permeability steel. Cast iron may have worse magnetic properties.

- Surface quality – the smoother and more polished the surface, the better the adhesion and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under shearing force the lifting capacity is smaller. In addition, even a small distance between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of NdFeB magnets

Phone sensors

Navigation devices and smartphones are extremely sensitive to magnetic fields. Close proximity with a strong magnet can ruin the sensors in your phone.

Magnets are brittle

Despite the nickel coating, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Do not underestimate power

Use magnets consciously. Their huge power can surprise even professionals. Be vigilant and respect their power.

Bone fractures

Risk of injury: The pulling power is so immense that it can cause blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

Adults only

Absolutely store magnets away from children. Choking hazard is significant, and the consequences of magnets clamping inside the body are fatal.

Cards and drives

Equipment safety: Neodymium magnets can ruin data carriers and delicate electronics (heart implants, medical aids, timepieces).

Fire warning

Fire hazard: Rare earth powder is highly flammable. Do not process magnets without safety gear as this may cause fire.

Thermal limits

Standard neodymium magnets (N-type) lose power when the temperature goes above 80°C. The loss of strength is permanent.

Allergic reactions

Studies show that the nickel plating (standard magnet coating) is a common allergen. For allergy sufferers, avoid touching magnets with bare hands or choose versions in plastic housing.

Life threat

Warning for patients: Strong magnetic fields affect medical devices. Maintain minimum 30 cm distance or ask another person to handle the magnets.