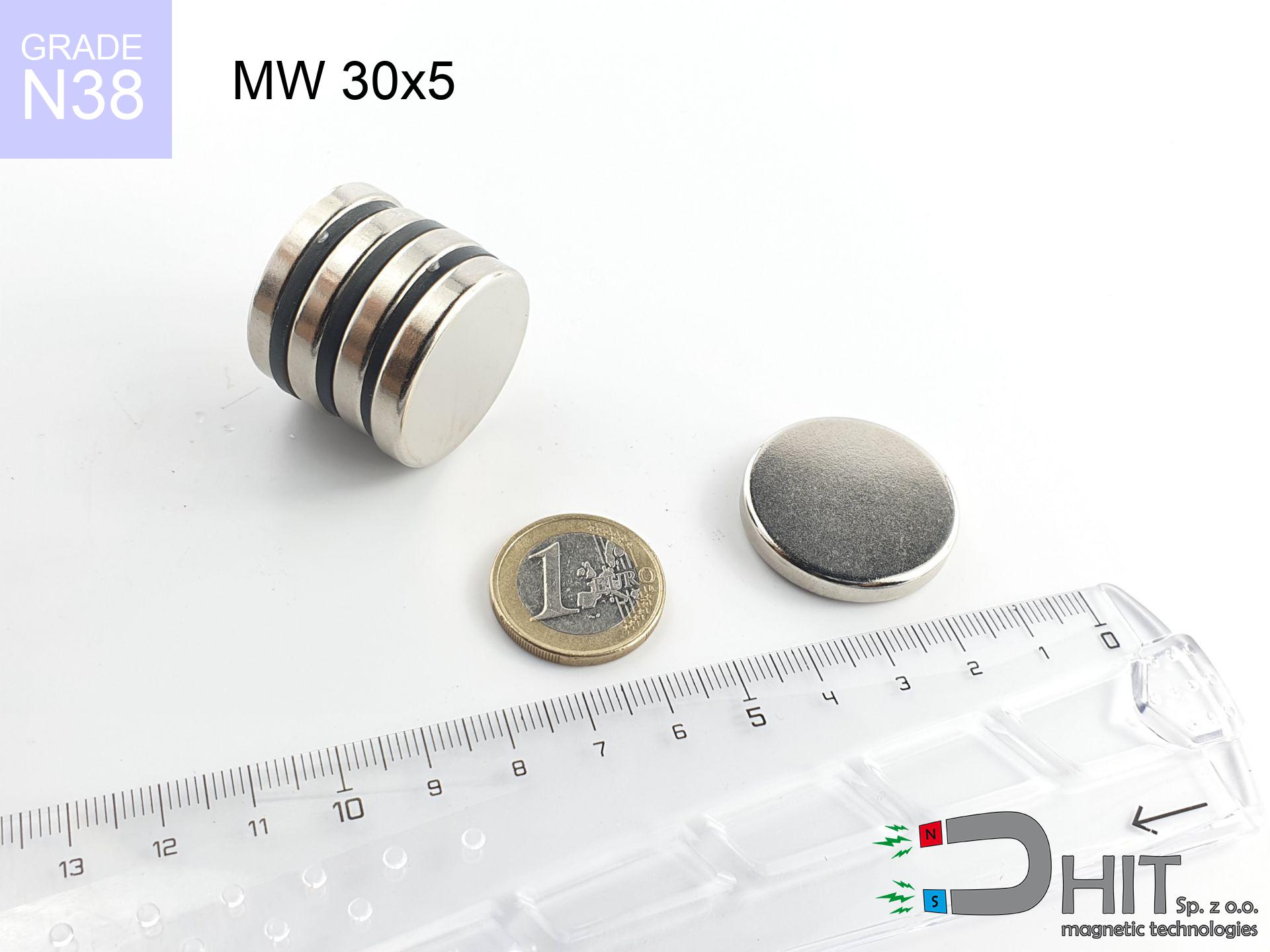

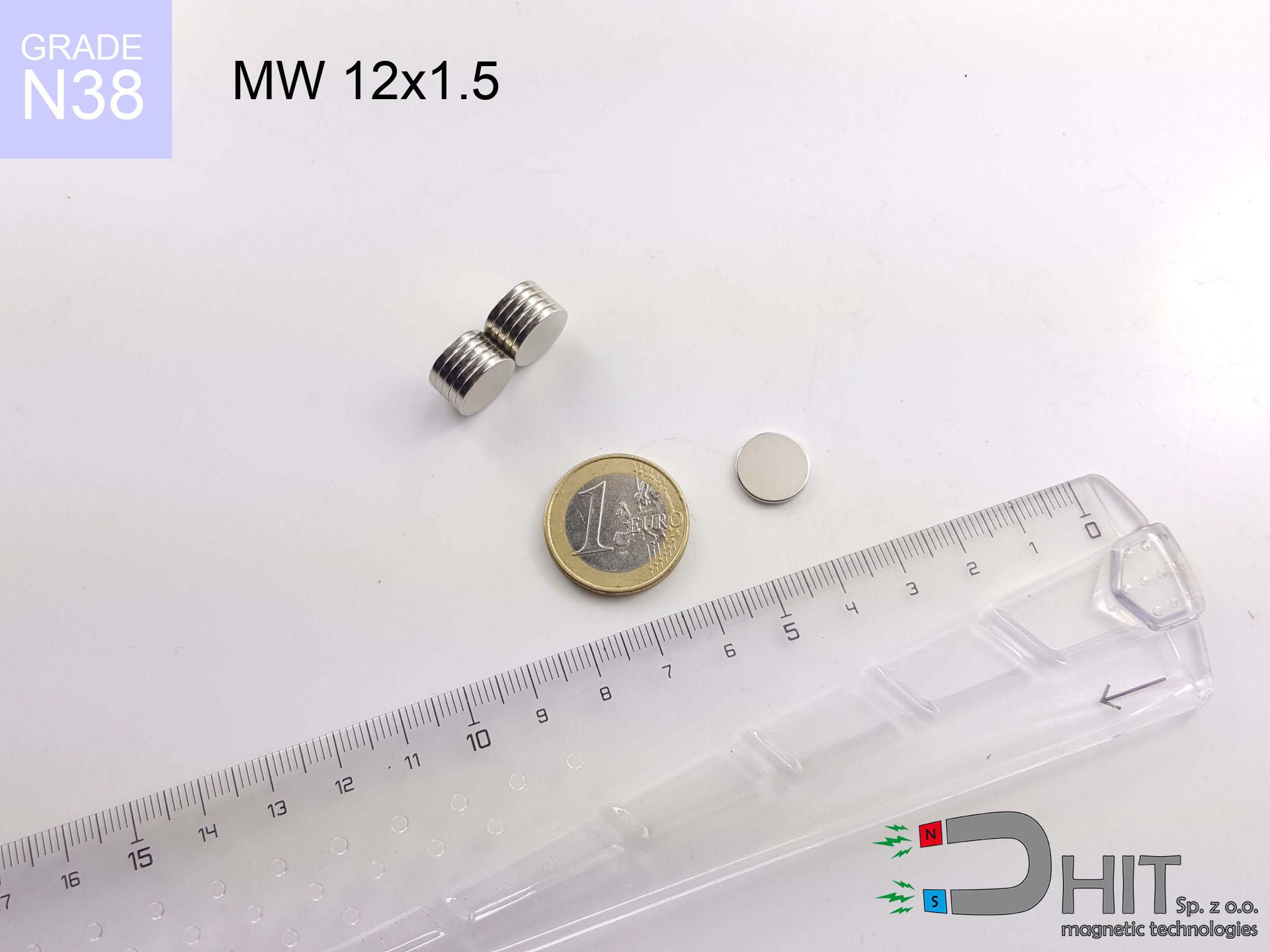

MW 12x1.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010442

GTIN/EAN: 5906301811114

Diameter Ø

12 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

1.27 g

Magnetization Direction

↑ axial

Load capacity

0.87 kg / 8.51 N

Magnetic Induction

150.32 mT / 1503 Gs

Coating

[NiCuNi] Nickel

0.431 ZŁ with VAT / pcs + price for transport

0.350 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise drop us a message using

contact form

the contact page.

Force along with form of neodymium magnets can be estimated using our

modular calculator.

Same-day processing for orders placed before 14:00.

Technical of the product - MW 12x1.5 / N38 - cylindrical magnet

Specification / characteristics - MW 12x1.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010442 |

| GTIN/EAN | 5906301811114 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 12 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 1.27 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.87 kg / 8.51 N |

| Magnetic Induction ~ ? | 150.32 mT / 1503 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the product - data

Presented data represent the result of a physical calculation. Values are based on models for the material Nd2Fe14B. Real-world conditions might slightly deviate from the simulation results. Use these data as a supplementary guide when designing systems.

Table 1: Static force (pull vs gap) - characteristics

MW 12x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1503 Gs

150.3 mT

|

0.87 kg / 1.92 LBS

870.0 g / 8.5 N

|

low risk |

| 1 mm |

1365 Gs

136.5 mT

|

0.72 kg / 1.58 LBS

718.1 g / 7.0 N

|

low risk |

| 2 mm |

1163 Gs

116.3 mT

|

0.52 kg / 1.15 LBS

521.4 g / 5.1 N

|

low risk |

| 3 mm |

947 Gs

94.7 mT

|

0.35 kg / 0.76 LBS

345.7 g / 3.4 N

|

low risk |

| 5 mm |

587 Gs

58.7 mT

|

0.13 kg / 0.29 LBS

132.6 g / 1.3 N

|

low risk |

| 10 mm |

180 Gs

18.0 mT

|

0.01 kg / 0.03 LBS

12.5 g / 0.1 N

|

low risk |

| 15 mm |

70 Gs

7.0 mT

|

0.00 kg / 0.00 LBS

1.9 g / 0.0 N

|

low risk |

| 20 mm |

33 Gs

3.3 mT

|

0.00 kg / 0.00 LBS

0.4 g / 0.0 N

|

low risk |

| 30 mm |

11 Gs

1.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding hold (vertical surface)

MW 12x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.17 kg / 0.38 LBS

174.0 g / 1.7 N

|

| 1 mm | Stal (~0.2) |

0.14 kg / 0.32 LBS

144.0 g / 1.4 N

|

| 2 mm | Stal (~0.2) |

0.10 kg / 0.23 LBS

104.0 g / 1.0 N

|

| 3 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 12x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.26 kg / 0.58 LBS

261.0 g / 2.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.17 kg / 0.38 LBS

174.0 g / 1.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.09 kg / 0.19 LBS

87.0 g / 0.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.44 kg / 0.96 LBS

435.0 g / 4.3 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 12x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.09 kg / 0.19 LBS

87.0 g / 0.9 N

|

| 1 mm |

|

0.22 kg / 0.48 LBS

217.5 g / 2.1 N

|

| 2 mm |

|

0.44 kg / 0.96 LBS

435.0 g / 4.3 N

|

| 3 mm |

|

0.65 kg / 1.44 LBS

652.5 g / 6.4 N

|

| 5 mm |

|

0.87 kg / 1.92 LBS

870.0 g / 8.5 N

|

| 10 mm |

|

0.87 kg / 1.92 LBS

870.0 g / 8.5 N

|

| 11 mm |

|

0.87 kg / 1.92 LBS

870.0 g / 8.5 N

|

| 12 mm |

|

0.87 kg / 1.92 LBS

870.0 g / 8.5 N

|

Table 5: Thermal stability (stability) - power drop

MW 12x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.87 kg / 1.92 LBS

870.0 g / 8.5 N

|

OK |

| 40 °C | -2.2% |

0.85 kg / 1.88 LBS

850.9 g / 8.3 N

|

OK |

| 60 °C | -4.4% |

0.83 kg / 1.83 LBS

831.7 g / 8.2 N

|

|

| 80 °C | -6.6% |

0.81 kg / 1.79 LBS

812.6 g / 8.0 N

|

|

| 100 °C | -28.8% |

0.62 kg / 1.37 LBS

619.4 g / 6.1 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 12x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.57 kg / 3.47 LBS

2 770 Gs

|

0.24 kg / 0.52 LBS

236 g / 2.3 N

|

N/A |

| 1 mm |

1.46 kg / 3.21 LBS

2 891 Gs

|

0.22 kg / 0.48 LBS

219 g / 2.1 N

|

1.31 kg / 2.89 LBS

~0 Gs

|

| 2 mm |

1.30 kg / 2.87 LBS

2 731 Gs

|

0.19 kg / 0.43 LBS

195 g / 1.9 N

|

1.17 kg / 2.58 LBS

~0 Gs

|

| 3 mm |

1.12 kg / 2.48 LBS

2 538 Gs

|

0.17 kg / 0.37 LBS

168 g / 1.7 N

|

1.01 kg / 2.23 LBS

~0 Gs

|

| 5 mm |

0.78 kg / 1.71 LBS

2 109 Gs

|

0.12 kg / 0.26 LBS

116 g / 1.1 N

|

0.70 kg / 1.54 LBS

~0 Gs

|

| 10 mm |

0.24 kg / 0.53 LBS

1 173 Gs

|

0.04 kg / 0.08 LBS

36 g / 0.4 N

|

0.22 kg / 0.48 LBS

~0 Gs

|

| 20 mm |

0.02 kg / 0.05 LBS

361 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.05 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

36 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

22 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

14 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

10 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MW 12x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (cracking risk) - warning

MW 12x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.63 km/h

(7.40 m/s)

|

0.03 J | |

| 30 mm |

45.72 km/h

(12.70 m/s)

|

0.10 J | |

| 50 mm |

59.02 km/h

(16.40 m/s)

|

0.17 J | |

| 100 mm |

83.47 km/h

(23.19 m/s)

|

0.34 J |

Table 9: Anti-corrosion coating durability

MW 12x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 12x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 159 Mx | 21.6 µWb |

| Pc Coefficient | 0.19 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 12x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.87 kg | Standard |

| Water (riverbed) |

1.00 kg

(+0.13 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical wall, the magnet holds just a fraction of its max power.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) severely limits the holding force.

3. Thermal stability

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.19

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Advantages and disadvantages of rare earth magnets.

Advantages

- They retain attractive force for around ten years – the drop is just ~1% (in theory),

- They are extremely resistant to demagnetization induced by external magnetic fields,

- A magnet with a smooth gold surface has an effective appearance,

- They feature high magnetic induction at the operating surface, which increases their power,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to the potential of free forming and adaptation to custom projects, neodymium magnets can be produced in a variety of shapes and sizes, which amplifies use scope,

- Significant place in future technologies – they find application in HDD drives, brushless drives, advanced medical instruments, also technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which enables their usage in compact constructions

Cons

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also increases its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing threads and complex forms in magnets, we recommend using cover - magnetic holder.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child safety. It is also worth noting that tiny parts of these devices can be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum magnetic pulling force – what contributes to it?

- using a base made of high-permeability steel, serving as a ideal flux conductor

- with a cross-section minimum 10 mm

- characterized by lack of roughness

- without any air gap between the magnet and steel

- under vertical application of breakaway force (90-degree angle)

- in stable room temperature

Impact of factors on magnetic holding capacity in practice

- Distance – existence of foreign body (rust, dirt, gap) acts as an insulator, which lowers power rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to detachment vertically. When slipping, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Base massiveness – insufficiently thick steel causes magnetic saturation, causing part of the power to be wasted into the air.

- Metal type – not every steel reacts the same. Alloy additives weaken the interaction with the magnet.

- Surface finish – ideal contact is obtained only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal environment – temperature increase causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, whereas under attempts to slide the magnet the load capacity is reduced by as much as 5 times. In addition, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

Safe handling of neodymium magnets

Powerful field

Handle with care. Rare earth magnets act from a long distance and connect with huge force, often faster than you can move away.

Material brittleness

Despite metallic appearance, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Compass and GPS

Remember: neodymium magnets produce a field that disrupts sensitive sensors. Maintain a separation from your phone, tablet, and navigation systems.

Danger to the youngest

Neodymium magnets are not suitable for play. Swallowing multiple magnets can lead to them pinching intestinal walls, which constitutes a direct threat to life and necessitates urgent medical intervention.

Combustion hazard

Powder created during grinding of magnets is flammable. Do not drill into magnets unless you are an expert.

Metal Allergy

Medical facts indicate that the nickel plating (the usual finish) is a strong allergen. If your skin reacts to metals, avoid touching magnets with bare hands or select coated magnets.

Pinching danger

Big blocks can smash fingers in a fraction of a second. Under no circumstances put your hand betwixt two attracting surfaces.

Magnetic media

Device Safety: Strong magnets can ruin payment cards and sensitive devices (pacemakers, medical aids, timepieces).

Danger to pacemakers

Patients with a pacemaker have to maintain an absolute distance from magnets. The magnetism can disrupt the functioning of the implant.

Heat sensitivity

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. Damage is permanent.

![HH 25x7.7 [M5] / N38 - through hole magnetic holder HH 25x7.7 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-25x7.7-m5-pov.jpg)

![UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gw-jek.jpg)