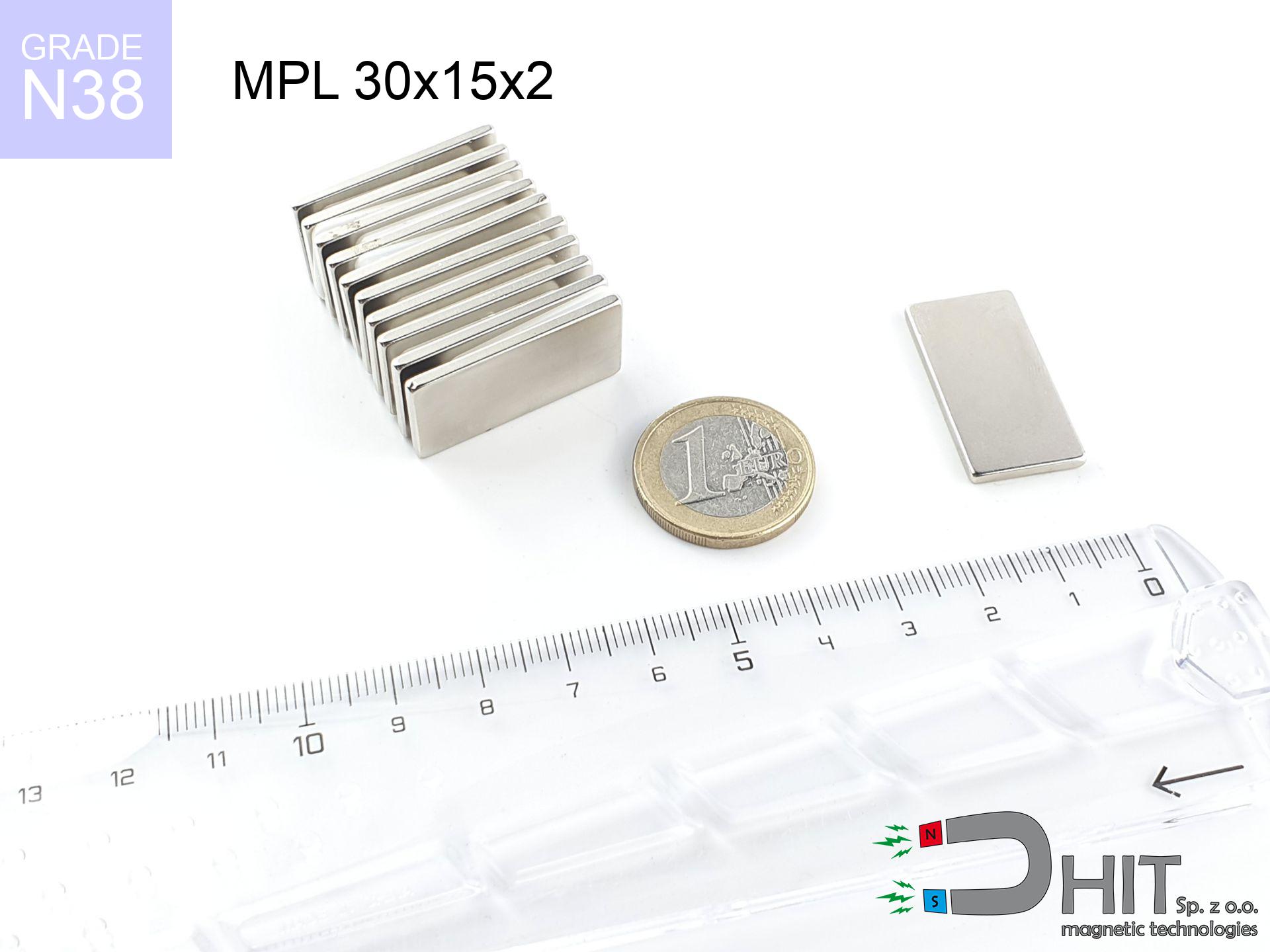

MPL 30x15x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020140

GTIN/EAN: 5906301811466

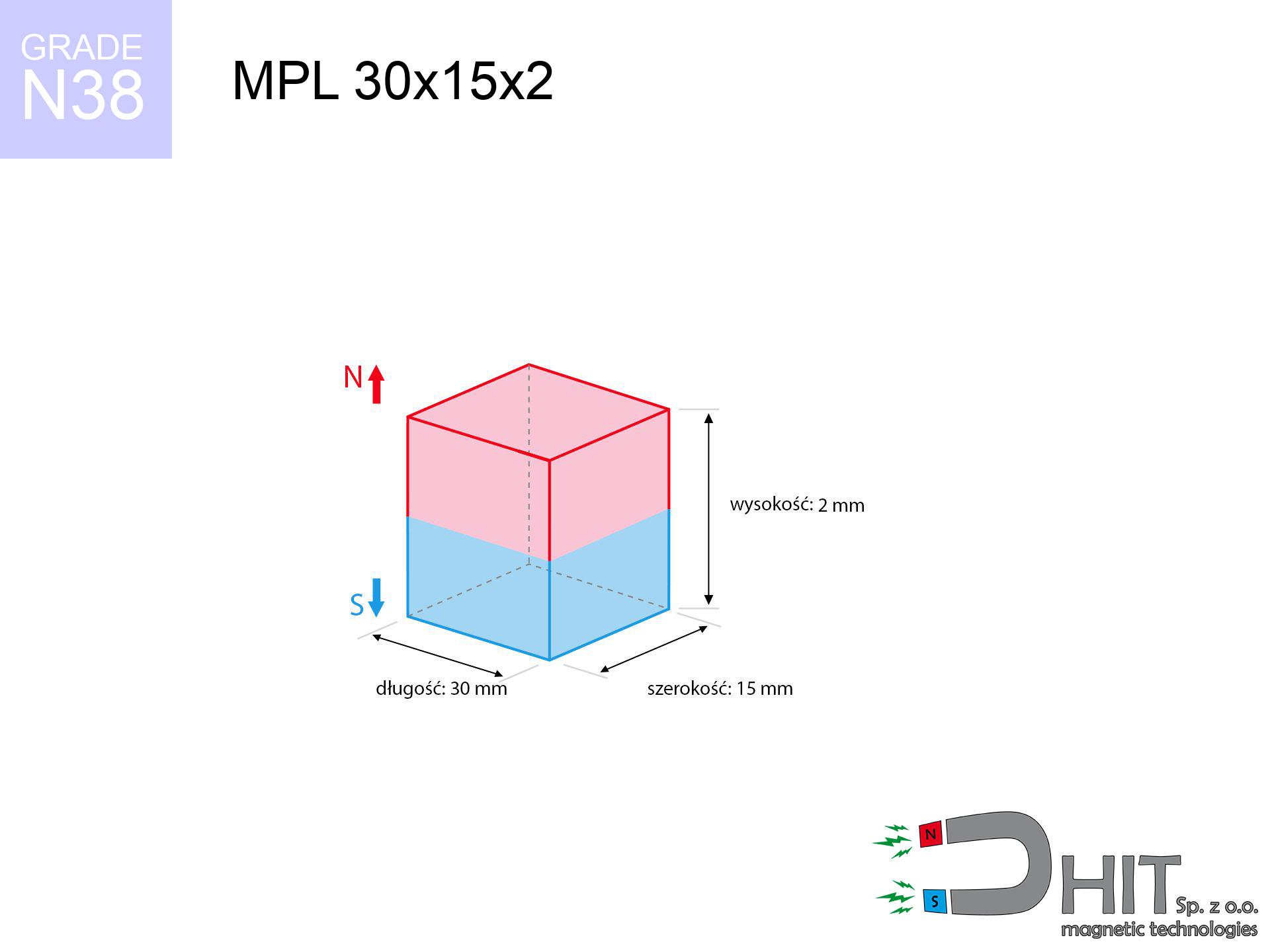

length

30 mm [±0,1 mm]

Width

15 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

6.75 g

Magnetization Direction

↑ axial

Load capacity

2.11 kg / 20.74 N

Magnetic Induction

115.11 mT / 1151 Gs

Coating

[NiCuNi] Nickel

3.89 ZŁ with VAT / pcs + price for transport

3.16 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

alternatively get in touch through

form

the contact page.

Weight as well as form of magnetic components can be reviewed with our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical parameters - MPL 30x15x2 / N38 - lamellar magnet

Specification / characteristics - MPL 30x15x2 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020140 |

| GTIN/EAN | 5906301811466 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 30 mm [±0,1 mm] |

| Width | 15 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 6.75 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.11 kg / 20.74 N |

| Magnetic Induction ~ ? | 115.11 mT / 1151 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the assembly - data

Presented values constitute the direct effect of a mathematical analysis. Results were calculated on models for the material Nd2Fe14B. Actual parameters may differ from theoretical values. Please consider these calculations as a reference point when designing systems.

Table 1: Static pull force (force vs distance) - characteristics

MPL 30x15x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1151 Gs

115.1 mT

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

medium risk |

| 1 mm |

1098 Gs

109.8 mT

|

1.92 kg / 4.23 lbs

1920.5 g / 18.8 N

|

weak grip |

| 2 mm |

1019 Gs

101.9 mT

|

1.65 kg / 3.65 lbs

1654.9 g / 16.2 N

|

weak grip |

| 3 mm |

926 Gs

92.6 mT

|

1.37 kg / 3.01 lbs

1365.9 g / 13.4 N

|

weak grip |

| 5 mm |

733 Gs

73.3 mT

|

0.86 kg / 1.89 lbs

855.2 g / 8.4 N

|

weak grip |

| 10 mm |

379 Gs

37.9 mT

|

0.23 kg / 0.50 lbs

228.8 g / 2.2 N

|

weak grip |

| 15 mm |

203 Gs

20.3 mT

|

0.07 kg / 0.14 lbs

65.6 g / 0.6 N

|

weak grip |

| 20 mm |

116 Gs

11.6 mT

|

0.02 kg / 0.05 lbs

21.6 g / 0.2 N

|

weak grip |

| 30 mm |

46 Gs

4.6 mT

|

0.00 kg / 0.01 lbs

3.4 g / 0.0 N

|

weak grip |

| 50 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

weak grip |

Table 2: Vertical hold (vertical surface)

MPL 30x15x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.42 kg / 0.93 lbs

422.0 g / 4.1 N

|

| 1 mm | Stal (~0.2) |

0.38 kg / 0.85 lbs

384.0 g / 3.8 N

|

| 2 mm | Stal (~0.2) |

0.33 kg / 0.73 lbs

330.0 g / 3.2 N

|

| 3 mm | Stal (~0.2) |

0.27 kg / 0.60 lbs

274.0 g / 2.7 N

|

| 5 mm | Stal (~0.2) |

0.17 kg / 0.38 lbs

172.0 g / 1.7 N

|

| 10 mm | Stal (~0.2) |

0.05 kg / 0.10 lbs

46.0 g / 0.5 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

14.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MPL 30x15x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.63 kg / 1.40 lbs

633.0 g / 6.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.42 kg / 0.93 lbs

422.0 g / 4.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.21 kg / 0.47 lbs

211.0 g / 2.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.06 kg / 2.33 lbs

1055.0 g / 10.3 N

|

Table 4: Steel thickness (substrate influence) - power losses

MPL 30x15x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.21 kg / 0.47 lbs

211.0 g / 2.1 N

|

| 1 mm |

|

0.53 kg / 1.16 lbs

527.5 g / 5.2 N

|

| 2 mm |

|

1.06 kg / 2.33 lbs

1055.0 g / 10.3 N

|

| 3 mm |

|

1.58 kg / 3.49 lbs

1582.5 g / 15.5 N

|

| 5 mm |

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

| 10 mm |

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

| 11 mm |

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

| 12 mm |

|

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

Table 5: Working in heat (stability) - power drop

MPL 30x15x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.11 kg / 4.65 lbs

2110.0 g / 20.7 N

|

OK |

| 40 °C | -2.2% |

2.06 kg / 4.55 lbs

2063.6 g / 20.2 N

|

OK |

| 60 °C | -4.4% |

2.02 kg / 4.45 lbs

2017.2 g / 19.8 N

|

|

| 80 °C | -6.6% |

1.97 kg / 4.34 lbs

1970.7 g / 19.3 N

|

|

| 100 °C | -28.8% |

1.50 kg / 3.31 lbs

1502.3 g / 14.7 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MPL 30x15x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.67 kg / 8.10 lbs

2 169 Gs

|

0.55 kg / 1.22 lbs

551 g / 5.4 N

|

N/A |

| 1 mm |

3.53 kg / 7.79 lbs

2 257 Gs

|

0.53 kg / 1.17 lbs

530 g / 5.2 N

|

3.18 kg / 7.01 lbs

~0 Gs

|

| 2 mm |

3.34 kg / 7.37 lbs

2 196 Gs

|

0.50 kg / 1.11 lbs

502 g / 4.9 N

|

3.01 kg / 6.64 lbs

~0 Gs

|

| 3 mm |

3.12 kg / 6.89 lbs

2 122 Gs

|

0.47 kg / 1.03 lbs

469 g / 4.6 N

|

2.81 kg / 6.20 lbs

~0 Gs

|

| 5 mm |

2.63 kg / 5.80 lbs

1 948 Gs

|

0.39 kg / 0.87 lbs

395 g / 3.9 N

|

2.37 kg / 5.22 lbs

~0 Gs

|

| 10 mm |

1.49 kg / 3.28 lbs

1 465 Gs

|

0.22 kg / 0.49 lbs

223 g / 2.2 N

|

1.34 kg / 2.96 lbs

~0 Gs

|

| 20 mm |

0.40 kg / 0.88 lbs

758 Gs

|

0.06 kg / 0.13 lbs

60 g / 0.6 N

|

0.36 kg / 0.79 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.03 lbs

142 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 60 mm |

0.01 kg / 0.01 lbs

92 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 lbs

63 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

44 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

32 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MPL 30x15x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 30x15x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.00 km/h

(5.28 m/s)

|

0.09 J | |

| 30 mm |

30.91 km/h

(8.59 m/s)

|

0.25 J | |

| 50 mm |

39.87 km/h

(11.08 m/s)

|

0.41 J | |

| 100 mm |

56.39 km/h

(15.66 m/s)

|

0.83 J |

Table 9: Anti-corrosion coating durability

MPL 30x15x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 30x15x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 236 Mx | 62.4 µWb |

| Pc Coefficient | 0.13 | Low (Flat) |

Table 11: Submerged application

MPL 30x15x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.11 kg | Standard |

| Water (riverbed) |

2.42 kg

(+0.31 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical wall, the magnet retains merely ~20% of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Power loss vs temp

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.13

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also offers

Pros as well as cons of neodymium magnets.

Advantages

- They do not lose power, even after around 10 years – the decrease in power is only ~1% (based on measurements),

- Neodymium magnets are characterized by remarkably resistant to demagnetization caused by magnetic disturbances,

- In other words, due to the shiny layer of gold, the element is aesthetically pleasing,

- They feature high magnetic induction at the operating surface, which increases their power,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Possibility of custom shaping and adapting to individual needs,

- Wide application in modern industrial fields – they are utilized in hard drives, electric motors, precision medical tools, as well as multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Cons

- To avoid cracks under impact, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Limited possibility of making threads in the magnet and complicated shapes - preferred is a housing - mounting mechanism.

- Possible danger related to microscopic parts of magnets pose a threat, if swallowed, which is particularly important in the context of child health protection. It is also worth noting that small elements of these devices can disrupt the diagnostic process medical when they are in the body.

- With large orders the cost of neodymium magnets is a challenge,

Holding force characteristics

Maximum lifting force for a neodymium magnet – what contributes to it?

- on a base made of structural steel, perfectly concentrating the magnetic field

- whose transverse dimension equals approx. 10 mm

- with an polished touching surface

- with direct contact (without impurities)

- during pulling in a direction vertical to the mounting surface

- in stable room temperature

What influences lifting capacity in practice

- Distance (betwixt the magnet and the plate), since even a microscopic distance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to paint, rust or dirt).

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Metal type – different alloys reacts the same. High carbon content worsen the interaction with the magnet.

- Smoothness – full contact is obtained only on smooth steel. Any scratches and bumps create air cushions, reducing force.

- Temperature influence – hot environment reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the holding force is lower. Additionally, even a minimal clearance between the magnet and the plate reduces the holding force.

Safety rules for work with NdFeB magnets

GPS and phone interference

A powerful magnetic field interferes with the functioning of magnetometers in phones and GPS navigation. Keep magnets near a device to avoid damaging the sensors.

Data carriers

Do not bring magnets close to a wallet, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Handling guide

Exercise caution. Neodymium magnets act from a long distance and snap with huge force, often quicker than you can move away.

Life threat

Medical warning: Strong magnets can turn off heart devices and defibrillators. Do not approach if you have electronic implants.

Machining danger

Drilling and cutting of NdFeB material carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Heat warning

Standard neodymium magnets (N-type) undergo demagnetization when the temperature exceeds 80°C. This process is irreversible.

Hand protection

Large magnets can break fingers instantly. Do not place your hand betwixt two strong magnets.

This is not a toy

Only for adults. Tiny parts pose a choking risk, causing severe trauma. Store out of reach of kids and pets.

Metal Allergy

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If redness appears, immediately stop handling magnets and use protective gear.

Eye protection

NdFeB magnets are sintered ceramics, meaning they are very brittle. Impact of two magnets leads to them cracking into shards.

![UMP 75x25 [M10x3] GW F200 GOLD DUAL / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD DUAL / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-dual-xoc.jpg)

![UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread UMGZ 75x34x18 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-75x34x18-m10-gz-xid.jpg)

![UMP 107x40 [M8+M10] GW F 400 kg / N38 - search holder UMP 107x40 [M8+M10] GW F 400 kg / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump107x40-m8+m10-gw-f-400-kg-mup.jpg)