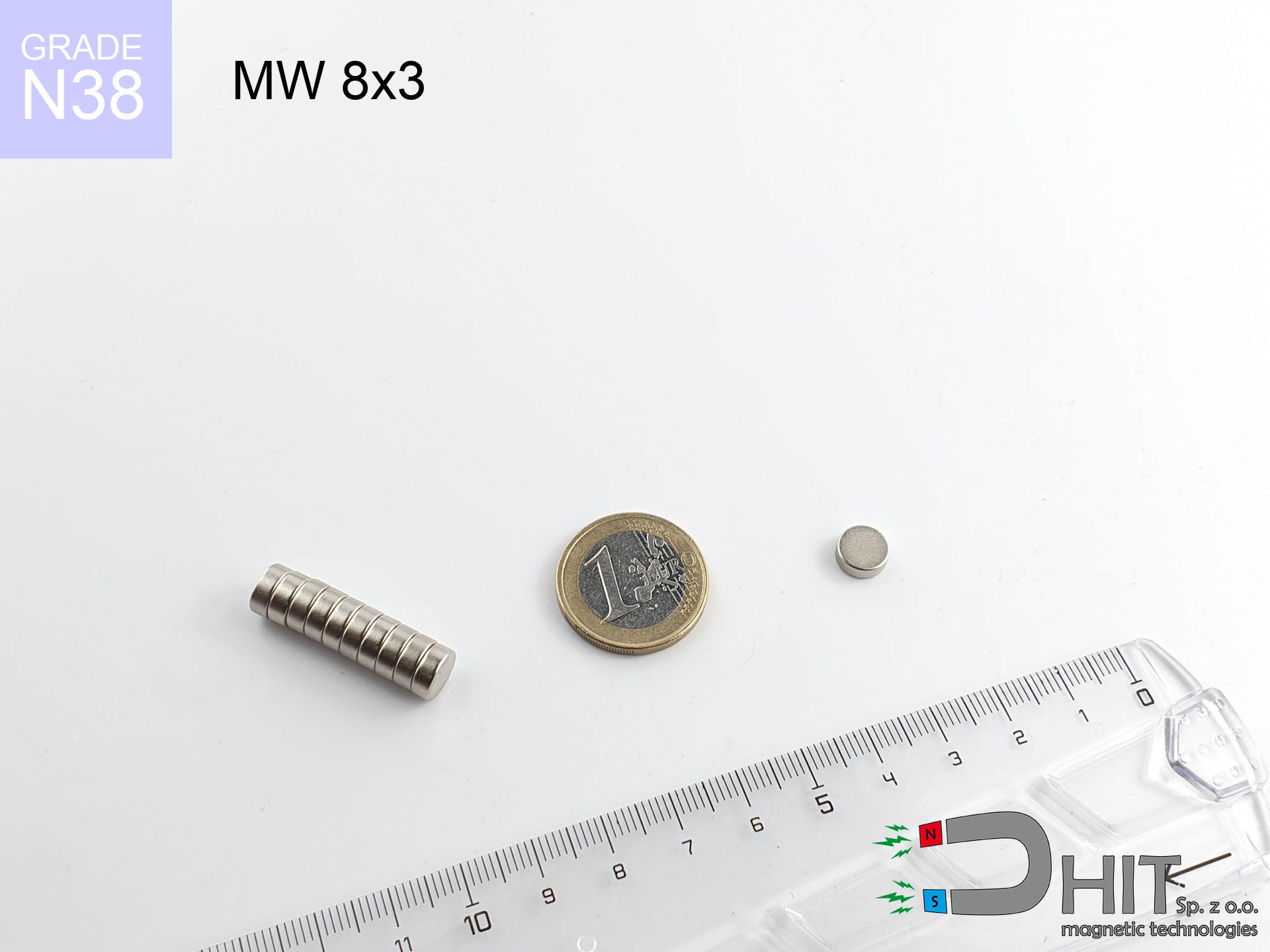

MW 8x3 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010103

GTIN/EAN: 5906301811022

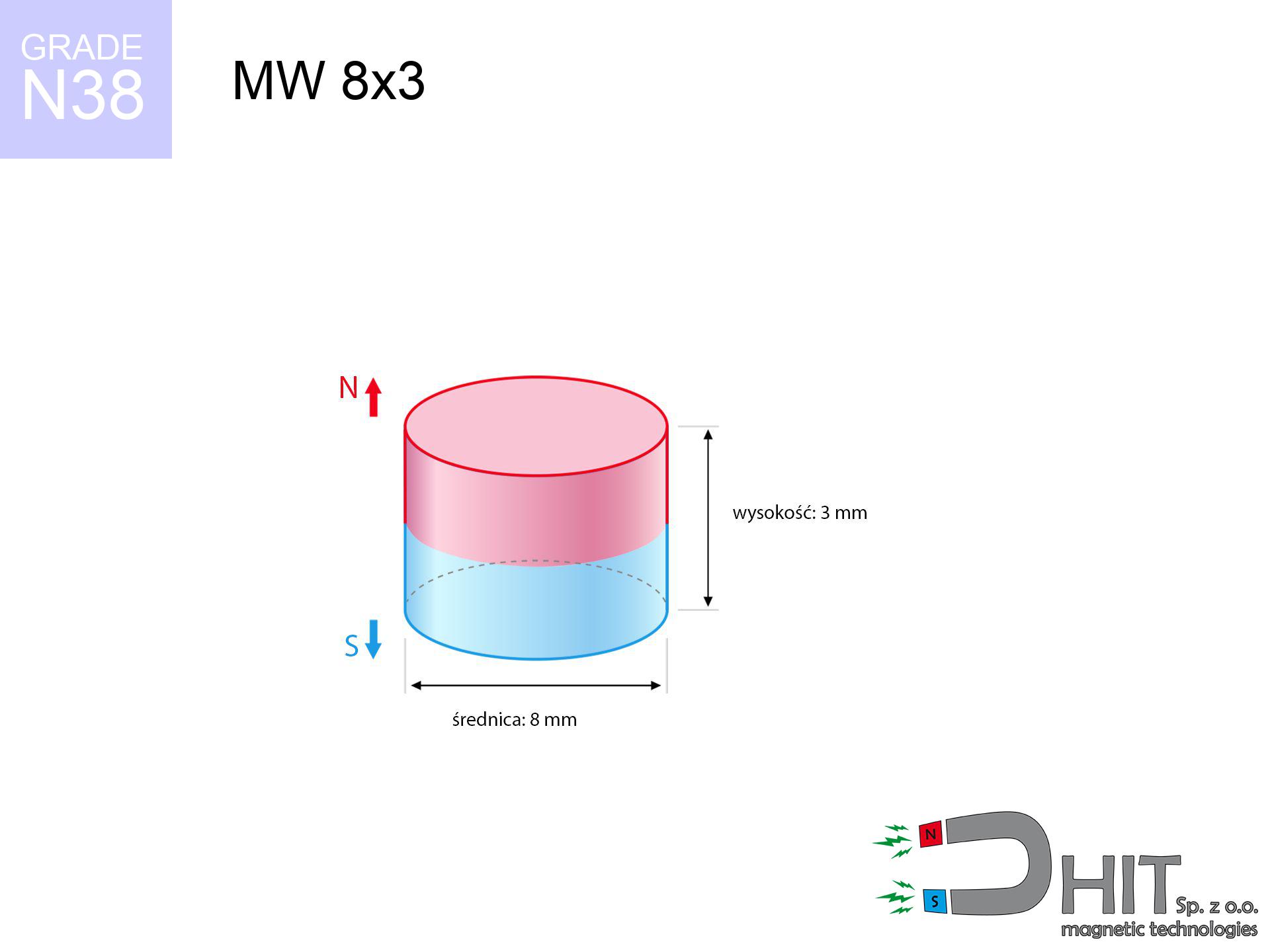

Diameter Ø

8 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

1.13 g

Magnetization Direction

↑ axial

Load capacity

1.70 kg / 16.67 N

Magnetic Induction

371.53 mT / 3715 Gs

Coating

[NiCuNi] Nickel

0.701 ZŁ with VAT / pcs + price for transport

0.570 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or send us a note using

contact form

the contact section.

Weight as well as shape of magnetic components can be tested on our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical of the product - MW 8x3 / N38 - cylindrical magnet

Specification / characteristics - MW 8x3 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010103 |

| GTIN/EAN | 5906301811022 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 1.13 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.70 kg / 16.67 N |

| Magnetic Induction ~ ? | 371.53 mT / 3715 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - technical parameters

The following data constitute the direct effect of a physical analysis. Values rely on models for the material Nd2Fe14B. Real-world parameters may differ from theoretical values. Use these data as a supplementary guide when designing systems.

Table 1: Static pull force (force vs gap) - characteristics

MW 8x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3712 Gs

371.2 mT

|

1.70 kg / 3.75 LBS

1700.0 g / 16.7 N

|

safe |

| 1 mm |

2880 Gs

288.0 mT

|

1.02 kg / 2.26 LBS

1023.3 g / 10.0 N

|

safe |

| 2 mm |

2069 Gs

206.9 mT

|

0.53 kg / 1.16 LBS

527.9 g / 5.2 N

|

safe |

| 3 mm |

1439 Gs

143.9 mT

|

0.26 kg / 0.56 LBS

255.3 g / 2.5 N

|

safe |

| 5 mm |

704 Gs

70.4 mT

|

0.06 kg / 0.13 LBS

61.1 g / 0.6 N

|

safe |

| 10 mm |

169 Gs

16.9 mT

|

0.00 kg / 0.01 LBS

3.5 g / 0.0 N

|

safe |

| 15 mm |

62 Gs

6.2 mT

|

0.00 kg / 0.00 LBS

0.5 g / 0.0 N

|

safe |

| 20 mm |

29 Gs

2.9 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

safe |

| 30 mm |

9 Gs

0.9 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Slippage load (vertical surface)

MW 8x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

| 1 mm | Stal (~0.2) |

0.20 kg / 0.45 LBS

204.0 g / 2.0 N

|

| 2 mm | Stal (~0.2) |

0.11 kg / 0.23 LBS

106.0 g / 1.0 N

|

| 3 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

52.0 g / 0.5 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 8x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.51 kg / 1.12 LBS

510.0 g / 5.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.34 kg / 0.75 LBS

340.0 g / 3.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.17 kg / 0.37 LBS

170.0 g / 1.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.85 kg / 1.87 LBS

850.0 g / 8.3 N

|

Table 4: Material efficiency (saturation) - power losses

MW 8x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.17 kg / 0.37 LBS

170.0 g / 1.7 N

|

| 1 mm |

|

0.43 kg / 0.94 LBS

425.0 g / 4.2 N

|

| 2 mm |

|

0.85 kg / 1.87 LBS

850.0 g / 8.3 N

|

| 3 mm |

|

1.28 kg / 2.81 LBS

1275.0 g / 12.5 N

|

| 5 mm |

|

1.70 kg / 3.75 LBS

1700.0 g / 16.7 N

|

| 10 mm |

|

1.70 kg / 3.75 LBS

1700.0 g / 16.7 N

|

| 11 mm |

|

1.70 kg / 3.75 LBS

1700.0 g / 16.7 N

|

| 12 mm |

|

1.70 kg / 3.75 LBS

1700.0 g / 16.7 N

|

Table 5: Thermal stability (stability) - thermal limit

MW 8x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.70 kg / 3.75 LBS

1700.0 g / 16.7 N

|

OK |

| 40 °C | -2.2% |

1.66 kg / 3.67 LBS

1662.6 g / 16.3 N

|

OK |

| 60 °C | -4.4% |

1.63 kg / 3.58 LBS

1625.2 g / 15.9 N

|

|

| 80 °C | -6.6% |

1.59 kg / 3.50 LBS

1587.8 g / 15.6 N

|

|

| 100 °C | -28.8% |

1.21 kg / 2.67 LBS

1210.4 g / 11.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 8x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.27 kg / 9.42 LBS

5 146 Gs

|

0.64 kg / 1.41 LBS

641 g / 6.3 N

|

N/A |

| 1 mm |

3.40 kg / 7.50 LBS

6 627 Gs

|

0.51 kg / 1.13 LBS

510 g / 5.0 N

|

3.06 kg / 6.75 LBS

~0 Gs

|

| 2 mm |

2.57 kg / 5.67 LBS

5 761 Gs

|

0.39 kg / 0.85 LBS

386 g / 3.8 N

|

2.31 kg / 5.10 LBS

~0 Gs

|

| 3 mm |

1.87 kg / 4.12 LBS

4 914 Gs

|

0.28 kg / 0.62 LBS

281 g / 2.8 N

|

1.68 kg / 3.71 LBS

~0 Gs

|

| 5 mm |

0.93 kg / 2.04 LBS

3 456 Gs

|

0.14 kg / 0.31 LBS

139 g / 1.4 N

|

0.83 kg / 1.84 LBS

~0 Gs

|

| 10 mm |

0.15 kg / 0.34 LBS

1 408 Gs

|

0.02 kg / 0.05 LBS

23 g / 0.2 N

|

0.14 kg / 0.30 LBS

~0 Gs

|

| 20 mm |

0.01 kg / 0.02 LBS

339 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

31 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

19 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

8 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MW 8x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 8x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

39.17 km/h

(10.88 m/s)

|

0.07 J | |

| 30 mm |

67.75 km/h

(18.82 m/s)

|

0.20 J | |

| 50 mm |

87.47 km/h

(24.30 m/s)

|

0.33 J | |

| 100 mm |

123.70 km/h

(34.36 m/s)

|

0.67 J |

Table 9: Surface protection spec

MW 8x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 8x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 946 Mx | 19.5 µWb |

| Pc Coefficient | 0.48 | Low (Flat) |

Table 11: Submerged application

MW 8x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.70 kg | Standard |

| Water (riverbed) |

1.95 kg

(+0.25 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet retains merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.48

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Advantages as well as disadvantages of rare earth magnets.

Strengths

- They do not lose strength, even during approximately 10 years – the decrease in power is only ~1% (based on measurements),

- They are noted for resistance to demagnetization induced by external field influence,

- In other words, due to the reflective finish of silver, the element looks attractive,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of custom forming and adapting to individual applications,

- Fundamental importance in modern technologies – they serve a role in computer drives, brushless drives, medical equipment, and complex engineering applications.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Due to limitations in producing nuts and complex forms in magnets, we propose using a housing - magnetic mechanism.

- Potential hazard resulting from small fragments of magnets are risky, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small components of these products are able to disrupt the diagnostic process medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Highest magnetic holding force – what it depends on?

- on a base made of structural steel, effectively closing the magnetic flux

- with a thickness of at least 10 mm

- characterized by even structure

- under conditions of gap-free contact (surface-to-surface)

- during pulling in a direction vertical to the plane

- in temp. approx. 20°C

Practical aspects of lifting capacity – factors

- Space between surfaces – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Substrate thickness – for full efficiency, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material composition – not every steel attracts identically. High carbon content worsen the attraction effect.

- Smoothness – full contact is possible only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under attempts to slide the magnet the lifting capacity is smaller. Moreover, even a small distance between the magnet’s surface and the plate lowers the lifting capacity.

H&S for magnets

Safe distance

Do not bring magnets near a purse, laptop, or screen. The magnetic field can irreversibly ruin these devices and wipe information from cards.

Dust is flammable

Powder generated during grinding of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Danger to pacemakers

Individuals with a heart stimulator should keep an absolute distance from magnets. The magnetism can interfere with the operation of the implant.

Danger to the youngest

Only for adults. Tiny parts can be swallowed, leading to serious injuries. Store away from children and animals.

Metal Allergy

A percentage of the population experience a hypersensitivity to nickel, which is the common plating for NdFeB magnets. Extended handling might lead to a rash. We strongly advise wear safety gloves.

Risk of cracking

Protect your eyes. Magnets can explode upon violent connection, ejecting sharp fragments into the air. Wear goggles.

Heat sensitivity

Keep cool. Neodymium magnets are susceptible to heat. If you need resistance above 80°C, ask us about HT versions (H, SH, UH).

Threat to navigation

Remember: rare earth magnets generate a field that disrupts precision electronics. Maintain a safe distance from your mobile, tablet, and navigation systems.

Conscious usage

Before starting, check safety instructions. Sudden snapping can break the magnet or hurt your hand. Be predictive.

Finger safety

Mind your fingers. Two large magnets will snap together immediately with a force of massive weight, destroying everything in their path. Exercise extreme caution!