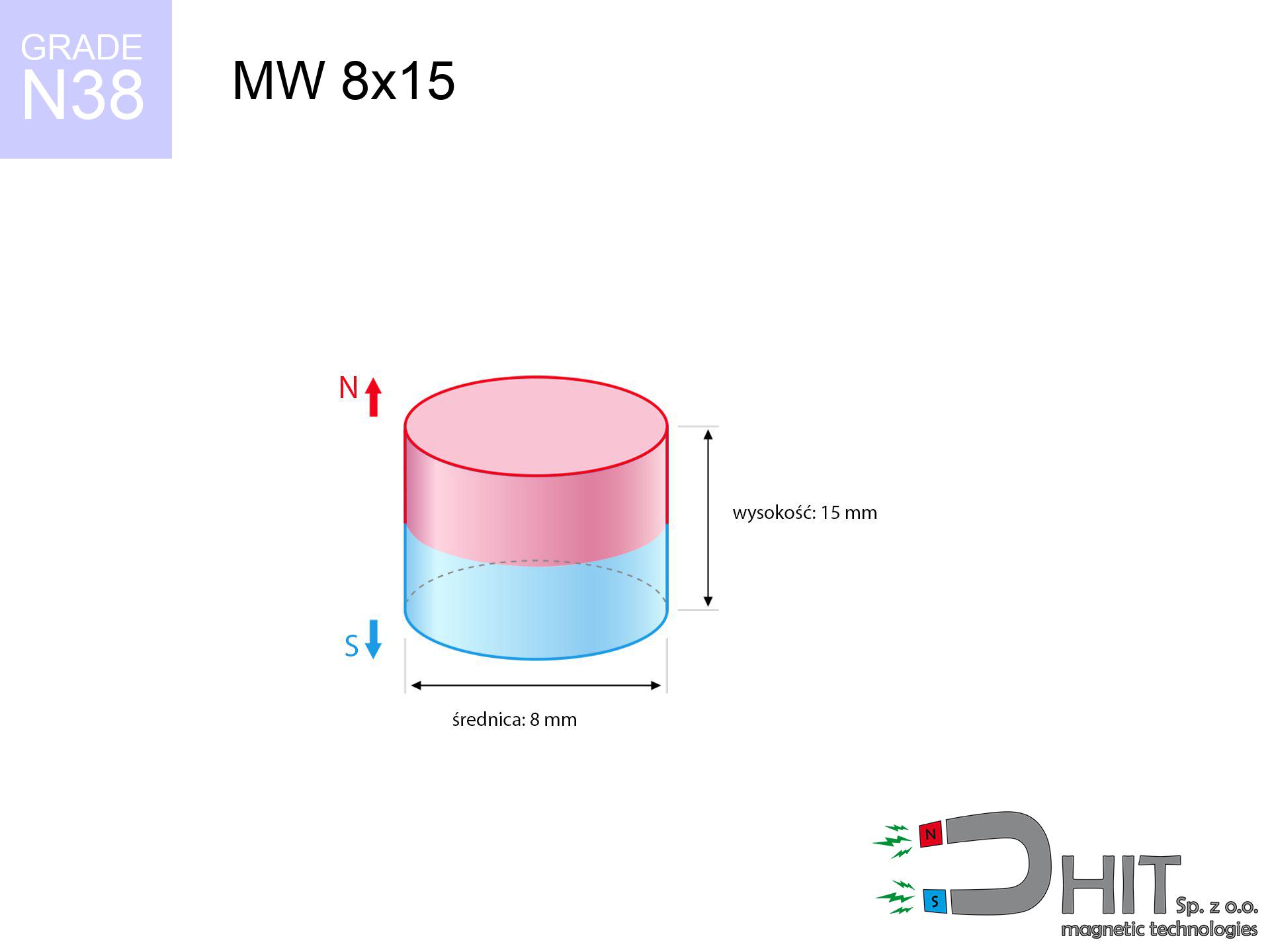

MW 8x15 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010102

GTIN/EAN: 5906301811015

Diameter Ø

8 mm [±0,1 mm]

Height

15 mm [±0,1 mm]

Weight

5.65 g

Magnetization Direction

↑ axial

Load capacity

1.47 kg / 14.45 N

Magnetic Induction

598.12 mT / 5981 Gs

Coating

[NiCuNi] Nickel

3.44 ZŁ with VAT / pcs + price for transport

2.80 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively drop us a message using

form

the contact form page.

Weight as well as appearance of a neodymium magnet can be calculated with our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Physical properties - MW 8x15 / N38 - cylindrical magnet

Specification / characteristics - MW 8x15 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010102 |

| GTIN/EAN | 5906301811015 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 15 mm [±0,1 mm] |

| Weight | 5.65 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.47 kg / 14.45 N |

| Magnetic Induction ~ ? | 598.12 mT / 5981 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the magnet - data

Presented information constitute the result of a physical calculation. Values were calculated on algorithms for the class Nd2Fe14B. Operational parameters may deviate from the simulation results. Please consider these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (force vs distance) - characteristics

MW 8x15 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5975 Gs

597.5 mT

|

1.47 kg / 3.24 LBS

1470.0 g / 14.4 N

|

safe |

| 1 mm |

4511 Gs

451.1 mT

|

0.84 kg / 1.85 LBS

837.8 g / 8.2 N

|

safe |

| 2 mm |

3262 Gs

326.2 mT

|

0.44 kg / 0.97 LBS

438.2 g / 4.3 N

|

safe |

| 3 mm |

2332 Gs

233.2 mT

|

0.22 kg / 0.49 LBS

224.0 g / 2.2 N

|

safe |

| 5 mm |

1238 Gs

123.8 mT

|

0.06 kg / 0.14 LBS

63.1 g / 0.6 N

|

safe |

| 10 mm |

366 Gs

36.6 mT

|

0.01 kg / 0.01 LBS

5.5 g / 0.1 N

|

safe |

| 15 mm |

155 Gs

15.5 mT

|

0.00 kg / 0.00 LBS

1.0 g / 0.0 N

|

safe |

| 20 mm |

80 Gs

8.0 mT

|

0.00 kg / 0.00 LBS

0.3 g / 0.0 N

|

safe |

| 30 mm |

30 Gs

3.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

| 50 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Slippage load (wall)

MW 8x15 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.29 kg / 0.65 LBS

294.0 g / 2.9 N

|

| 1 mm | Stal (~0.2) |

0.17 kg / 0.37 LBS

168.0 g / 1.6 N

|

| 2 mm | Stal (~0.2) |

0.09 kg / 0.19 LBS

88.0 g / 0.9 N

|

| 3 mm | Stal (~0.2) |

0.04 kg / 0.10 LBS

44.0 g / 0.4 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 8x15 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.44 kg / 0.97 LBS

441.0 g / 4.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.29 kg / 0.65 LBS

294.0 g / 2.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.15 kg / 0.32 LBS

147.0 g / 1.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.74 kg / 1.62 LBS

735.0 g / 7.2 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 8x15 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.15 kg / 0.32 LBS

147.0 g / 1.4 N

|

| 1 mm |

|

0.37 kg / 0.81 LBS

367.5 g / 3.6 N

|

| 2 mm |

|

0.74 kg / 1.62 LBS

735.0 g / 7.2 N

|

| 3 mm |

|

1.10 kg / 2.43 LBS

1102.5 g / 10.8 N

|

| 5 mm |

|

1.47 kg / 3.24 LBS

1470.0 g / 14.4 N

|

| 10 mm |

|

1.47 kg / 3.24 LBS

1470.0 g / 14.4 N

|

| 11 mm |

|

1.47 kg / 3.24 LBS

1470.0 g / 14.4 N

|

| 12 mm |

|

1.47 kg / 3.24 LBS

1470.0 g / 14.4 N

|

Table 5: Working in heat (stability) - thermal limit

MW 8x15 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.47 kg / 3.24 LBS

1470.0 g / 14.4 N

|

OK |

| 40 °C | -2.2% |

1.44 kg / 3.17 LBS

1437.7 g / 14.1 N

|

OK |

| 60 °C | -4.4% |

1.41 kg / 3.10 LBS

1405.3 g / 13.8 N

|

OK |

| 80 °C | -6.6% |

1.37 kg / 3.03 LBS

1373.0 g / 13.5 N

|

|

| 100 °C | -28.8% |

1.05 kg / 2.31 LBS

1046.6 g / 10.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MW 8x15 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

11.06 kg / 24.39 LBS

6 130 Gs

|

1.66 kg / 3.66 LBS

1660 g / 16.3 N

|

N/A |

| 1 mm |

8.49 kg / 18.72 LBS

10 469 Gs

|

1.27 kg / 2.81 LBS

1274 g / 12.5 N

|

7.64 kg / 16.85 LBS

~0 Gs

|

| 2 mm |

6.31 kg / 13.90 LBS

9 022 Gs

|

0.95 kg / 2.09 LBS

946 g / 9.3 N

|

5.68 kg / 12.51 LBS

~0 Gs

|

| 3 mm |

4.59 kg / 10.12 LBS

7 697 Gs

|

0.69 kg / 1.52 LBS

688 g / 6.8 N

|

4.13 kg / 9.11 LBS

~0 Gs

|

| 5 mm |

2.36 kg / 5.20 LBS

5 516 Gs

|

0.35 kg / 0.78 LBS

354 g / 3.5 N

|

2.12 kg / 4.68 LBS

~0 Gs

|

| 10 mm |

0.48 kg / 1.05 LBS

2 476 Gs

|

0.07 kg / 0.16 LBS

71 g / 0.7 N

|

0.43 kg / 0.94 LBS

~0 Gs

|

| 20 mm |

0.04 kg / 0.09 LBS

731 Gs

|

0.01 kg / 0.01 LBS

6 g / 0.1 N

|

0.04 kg / 0.08 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

94 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

60 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

41 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

29 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

21 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 8x15 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 8x15 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.31 km/h

(4.53 m/s)

|

0.06 J | |

| 30 mm |

28.18 km/h

(7.83 m/s)

|

0.17 J | |

| 50 mm |

36.37 km/h

(10.10 m/s)

|

0.29 J | |

| 100 mm |

51.44 km/h

(14.29 m/s)

|

0.58 J |

Table 9: Corrosion resistance

MW 8x15 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 8x15 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 306 Mx | 33.1 µWb |

| Pc Coefficient | 1.19 | High (Stable) |

Table 11: Submerged application

MW 8x15 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.47 kg | Standard |

| Water (riverbed) |

1.68 kg

(+0.21 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet holds merely approx. 20-30% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) severely reduces the holding force.

3. Heat tolerance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.19

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Pros and cons of neodymium magnets.

Advantages

- They do not lose magnetism, even after nearly ten years – the drop in lifting capacity is only ~1% (based on measurements),

- They have excellent resistance to weakening of magnetic properties as a result of opposing magnetic fields,

- In other words, due to the reflective layer of silver, the element looks attractive,

- They show high magnetic induction at the operating surface, making them more effective,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to modularity in designing and the capacity to adapt to individual projects,

- Key role in electronics industry – they find application in data components, brushless drives, advanced medical instruments, and industrial machines.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- At strong impacts they can break, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of making threads in the magnet and complex shapes - recommended is a housing - magnetic holder.

- Possible danger to health – tiny shards of magnets are risky, if swallowed, which becomes key in the aspect of protecting the youngest. Furthermore, small components of these magnets are able to disrupt the diagnostic process medical when they are in the body.

- Due to expensive raw materials, their price is relatively high,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a block made of structural steel, optimally conducting the magnetic field

- whose transverse dimension equals approx. 10 mm

- with a plane perfectly flat

- without any insulating layer between the magnet and steel

- during detachment in a direction vertical to the mounting surface

- in stable room temperature

What influences lifting capacity in practice

- Air gap (between the magnet and the plate), because even a very small clearance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to varnish, rust or debris).

- Direction of force – highest force is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the plate is usually many times lower (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Material composition – different alloys attracts identically. Alloy additives worsen the interaction with the magnet.

- Surface condition – smooth surfaces ensure maximum contact, which increases field saturation. Rough surfaces reduce efficiency.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and in frost they can be stronger (up to a certain limit).

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

H&S for magnets

Allergic reactions

Some people suffer from a sensitization to Ni, which is the common plating for neodymium magnets. Prolonged contact may cause a rash. We recommend use safety gloves.

Magnetic interference

Navigation devices and mobile phones are highly sensitive to magnetic fields. Direct contact with a powerful NdFeB magnet can ruin the sensors in your phone.

Conscious usage

Before use, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

Dust explosion hazard

Powder produced during machining of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Pinching danger

Mind your fingers. Two large magnets will snap together immediately with a force of several hundred kilograms, destroying anything in their path. Be careful!

Medical implants

Warning for patients: Powerful magnets disrupt medical devices. Keep minimum 30 cm distance or ask another person to handle the magnets.

Safe distance

Data protection: Neodymium magnets can damage payment cards and delicate electronics (heart implants, medical aids, timepieces).

Adults only

Neodymium magnets are not suitable for play. Eating several magnets can lead to them pinching intestinal walls, which poses a critical condition and necessitates urgent medical intervention.

Demagnetization risk

Avoid heat. Neodymium magnets are susceptible to temperature. If you require resistance above 80°C, inquire about HT versions (H, SH, UH).

Magnet fragility

Despite metallic appearance, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

![UI 45x13x6 [Z323] / N38 - badge holder UI 45x13x6 [Z323] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui45x13x6-z323-fap.jpg)

![UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-88x8.5-m8-gz-waf.jpg)