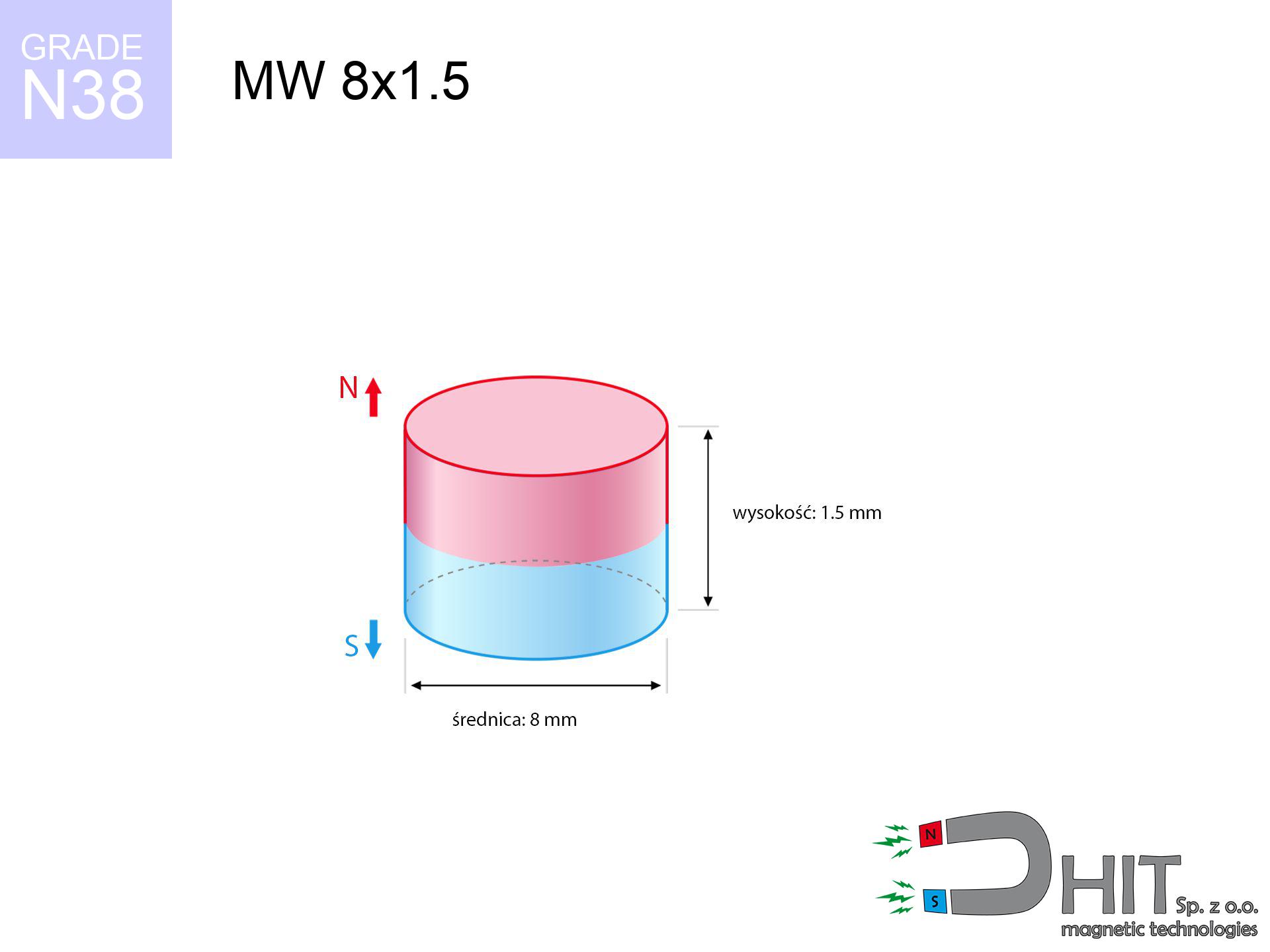

MW 8x1.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010101

GTIN/EAN: 5906301811008

Diameter Ø

8 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

0.57 g

Magnetization Direction

↑ axial

Load capacity

0.74 kg / 7.27 N

Magnetic Induction

217.52 mT / 2175 Gs

Coating

[NiCuNi] Nickel

0.455 ZŁ with VAT / pcs + price for transport

0.370 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or let us know via

contact form

through our site.

Parameters as well as structure of magnetic components can be reviewed on our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical data of the product - MW 8x1.5 / N38 - cylindrical magnet

Specification / characteristics - MW 8x1.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010101 |

| GTIN/EAN | 5906301811008 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 0.57 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.74 kg / 7.27 N |

| Magnetic Induction ~ ? | 217.52 mT / 2175 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the assembly - report

Presented values are the result of a physical analysis. Values were calculated on models for the class Nd2Fe14B. Actual conditions may differ from theoretical values. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static force (pull vs distance) - characteristics

MW 8x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2174 Gs

217.4 mT

|

0.74 kg / 1.63 pounds

740.0 g / 7.3 N

|

safe |

| 1 mm |

1782 Gs

178.2 mT

|

0.50 kg / 1.10 pounds

497.3 g / 4.9 N

|

safe |

| 2 mm |

1310 Gs

131.0 mT

|

0.27 kg / 0.59 pounds

268.7 g / 2.6 N

|

safe |

| 3 mm |

914 Gs

91.4 mT

|

0.13 kg / 0.29 pounds

130.8 g / 1.3 N

|

safe |

| 5 mm |

439 Gs

43.9 mT

|

0.03 kg / 0.07 pounds

30.2 g / 0.3 N

|

safe |

| 10 mm |

99 Gs

9.9 mT

|

0.00 kg / 0.00 pounds

1.5 g / 0.0 N

|

safe |

| 15 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 pounds

0.2 g / 0.0 N

|

safe |

| 20 mm |

16 Gs

1.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Slippage load (wall)

MW 8x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.15 kg / 0.33 pounds

148.0 g / 1.5 N

|

| 1 mm | Stal (~0.2) |

0.10 kg / 0.22 pounds

100.0 g / 1.0 N

|

| 2 mm | Stal (~0.2) |

0.05 kg / 0.12 pounds

54.0 g / 0.5 N

|

| 3 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

26.0 g / 0.3 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 8x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.22 kg / 0.49 pounds

222.0 g / 2.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.15 kg / 0.33 pounds

148.0 g / 1.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.07 kg / 0.16 pounds

74.0 g / 0.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.37 kg / 0.82 pounds

370.0 g / 3.6 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 8x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.07 kg / 0.16 pounds

74.0 g / 0.7 N

|

| 1 mm |

|

0.19 kg / 0.41 pounds

185.0 g / 1.8 N

|

| 2 mm |

|

0.37 kg / 0.82 pounds

370.0 g / 3.6 N

|

| 3 mm |

|

0.55 kg / 1.22 pounds

555.0 g / 5.4 N

|

| 5 mm |

|

0.74 kg / 1.63 pounds

740.0 g / 7.3 N

|

| 10 mm |

|

0.74 kg / 1.63 pounds

740.0 g / 7.3 N

|

| 11 mm |

|

0.74 kg / 1.63 pounds

740.0 g / 7.3 N

|

| 12 mm |

|

0.74 kg / 1.63 pounds

740.0 g / 7.3 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MW 8x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.74 kg / 1.63 pounds

740.0 g / 7.3 N

|

OK |

| 40 °C | -2.2% |

0.72 kg / 1.60 pounds

723.7 g / 7.1 N

|

OK |

| 60 °C | -4.4% |

0.71 kg / 1.56 pounds

707.4 g / 6.9 N

|

|

| 80 °C | -6.6% |

0.69 kg / 1.52 pounds

691.2 g / 6.8 N

|

|

| 100 °C | -28.8% |

0.53 kg / 1.16 pounds

526.9 g / 5.2 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 8x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.46 kg / 3.23 pounds

3 712 Gs

|

0.22 kg / 0.48 pounds

220 g / 2.2 N

|

N/A |

| 1 mm |

1.24 kg / 2.74 pounds

4 007 Gs

|

0.19 kg / 0.41 pounds

187 g / 1.8 N

|

1.12 kg / 2.47 pounds

~0 Gs

|

| 2 mm |

0.98 kg / 2.17 pounds

3 565 Gs

|

0.15 kg / 0.33 pounds

148 g / 1.4 N

|

0.89 kg / 1.95 pounds

~0 Gs

|

| 3 mm |

0.74 kg / 1.63 pounds

3 086 Gs

|

0.11 kg / 0.24 pounds

111 g / 1.1 N

|

0.66 kg / 1.46 pounds

~0 Gs

|

| 5 mm |

0.37 kg / 0.82 pounds

2 196 Gs

|

0.06 kg / 0.12 pounds

56 g / 0.5 N

|

0.34 kg / 0.74 pounds

~0 Gs

|

| 10 mm |

0.06 kg / 0.13 pounds

878 Gs

|

0.01 kg / 0.02 pounds

9 g / 0.1 N

|

0.05 kg / 0.12 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 pounds

199 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

17 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

6 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

4 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

3 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 8x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 1.5 cm |

| Remote | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MW 8x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

36.39 km/h

(10.11 m/s)

|

0.03 J | |

| 30 mm |

62.94 km/h

(17.48 m/s)

|

0.09 J | |

| 50 mm |

81.25 km/h

(22.57 m/s)

|

0.15 J | |

| 100 mm |

114.91 km/h

(31.92 m/s)

|

0.29 J |

Table 9: Surface protection spec

MW 8x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 8x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 285 Mx | 12.9 µWb |

| Pc Coefficient | 0.27 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 8x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.74 kg | Standard |

| Water (riverbed) |

0.85 kg

(+0.11 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet retains merely ~20% of its perpendicular strength.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) drastically limits the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.27

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also deals

Strengths and weaknesses of Nd2Fe14B magnets.

Advantages

- They do not lose strength, even over around 10 years – the decrease in power is only ~1% (theoretically),

- They retain their magnetic properties even under external field action,

- A magnet with a shiny silver surface looks better,

- The surface of neodymium magnets generates a powerful magnetic field – this is a key feature,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, enabling operation at temperatures reaching 230°C and above...

- Thanks to freedom in constructing and the capacity to modify to complex applications,

- Wide application in modern technologies – they are utilized in mass storage devices, electric motors, medical devices, and technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which allows their use in miniature devices

Limitations

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in realizing threads and complicated forms in magnets, we recommend using a housing - magnetic holder.

- Possible danger related to microscopic parts of magnets are risky, in case of ingestion, which is particularly important in the context of child health protection. Additionally, tiny parts of these devices are able to disrupt the diagnostic process medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which can limit application in large quantities

Lifting parameters

Maximum holding power of the magnet – what contributes to it?

- on a base made of structural steel, effectively closing the magnetic flux

- whose thickness is min. 10 mm

- with a plane cleaned and smooth

- under conditions of ideal adhesion (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Gap (betwixt the magnet and the plate), because even a very small clearance (e.g. 0.5 mm) leads to a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops drastically, often to levels of 20-30% of the nominal value.

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of generating force.

- Steel grade – the best choice is pure iron steel. Cast iron may generate lower lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which improves force. Uneven metal weaken the grip.

- Operating temperature – neodymium magnets have a sensitivity to temperature. When it is hot they lose power, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was assessed by applying a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, however under parallel forces the load capacity is reduced by as much as 5 times. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the holding force.

Safety rules for work with neodymium magnets

Magnetic media

Device Safety: Strong magnets can damage payment cards and sensitive devices (heart implants, hearing aids, timepieces).

Material brittleness

Neodymium magnets are sintered ceramics, meaning they are fragile like glass. Collision of two magnets will cause them cracking into small pieces.

Immense force

Before use, check safety instructions. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Fire risk

Powder generated during grinding of magnets is flammable. Do not drill into magnets unless you are an expert.

Metal Allergy

Studies show that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, refrain from direct skin contact and choose versions in plastic housing.

Product not for children

Absolutely keep magnets away from children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are tragic.

Keep away from electronics

GPS units and mobile phones are extremely susceptible to magnetic fields. Close proximity with a strong magnet can permanently damage the sensors in your phone.

Maximum temperature

Standard neodymium magnets (N-type) lose power when the temperature surpasses 80°C. This process is irreversible.

Medical interference

Warning for patients: Powerful magnets affect medical devices. Maintain minimum 30 cm distance or ask another person to work with the magnets.

Bone fractures

Watch your fingers. Two powerful magnets will snap together instantly with a force of massive weight, crushing anything in their path. Exercise extreme caution!

![SM 25x100 [2xM8] / N42 - magnetic separator SM 25x100 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-feg.jpg)

![BM 700x180x75 [8xM10] - magnetic beam BM 700x180x75 [8xM10] - magnetic beam](https://cdn3.dhit.pl/graphics/blank.jpg)