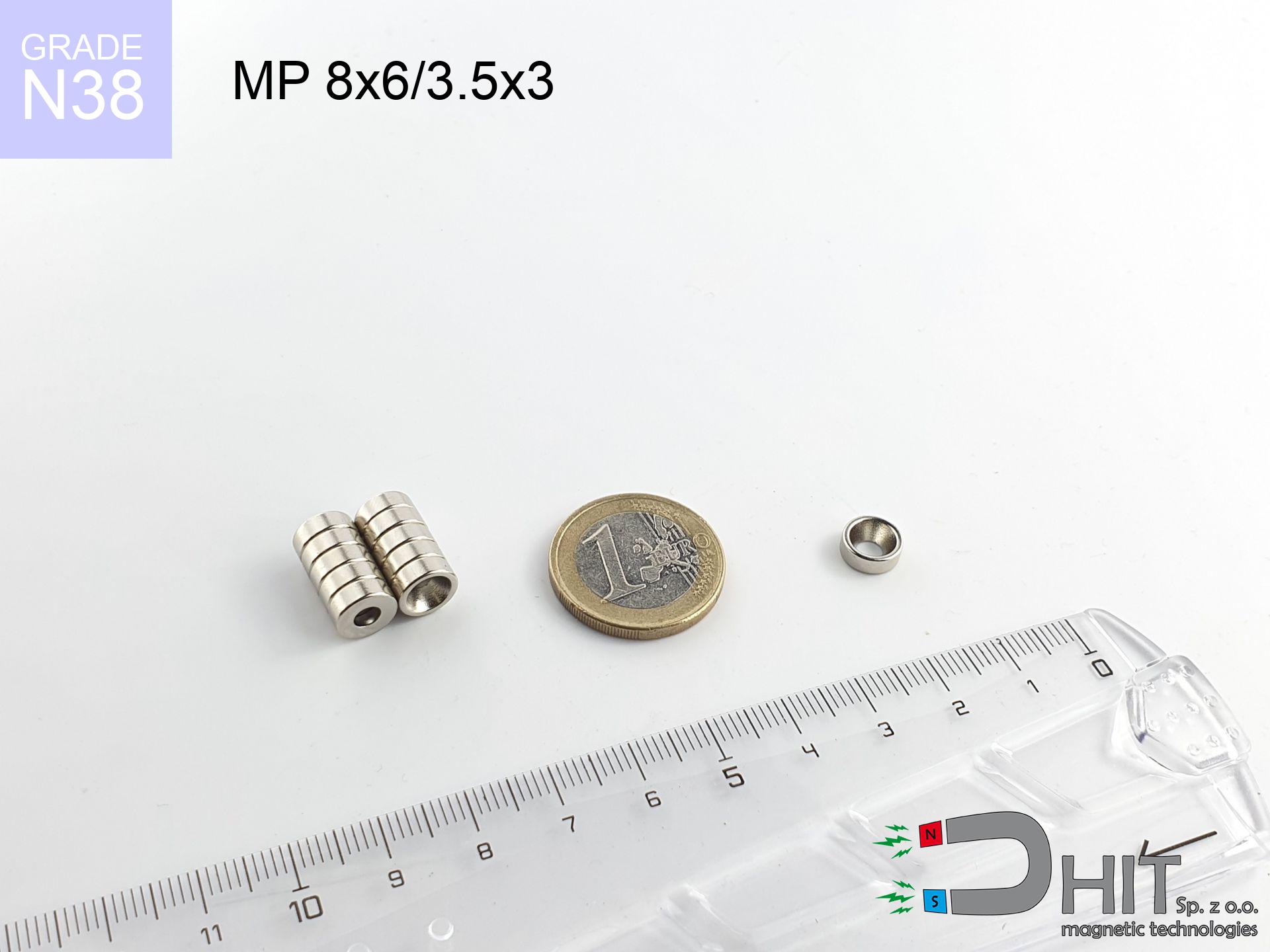

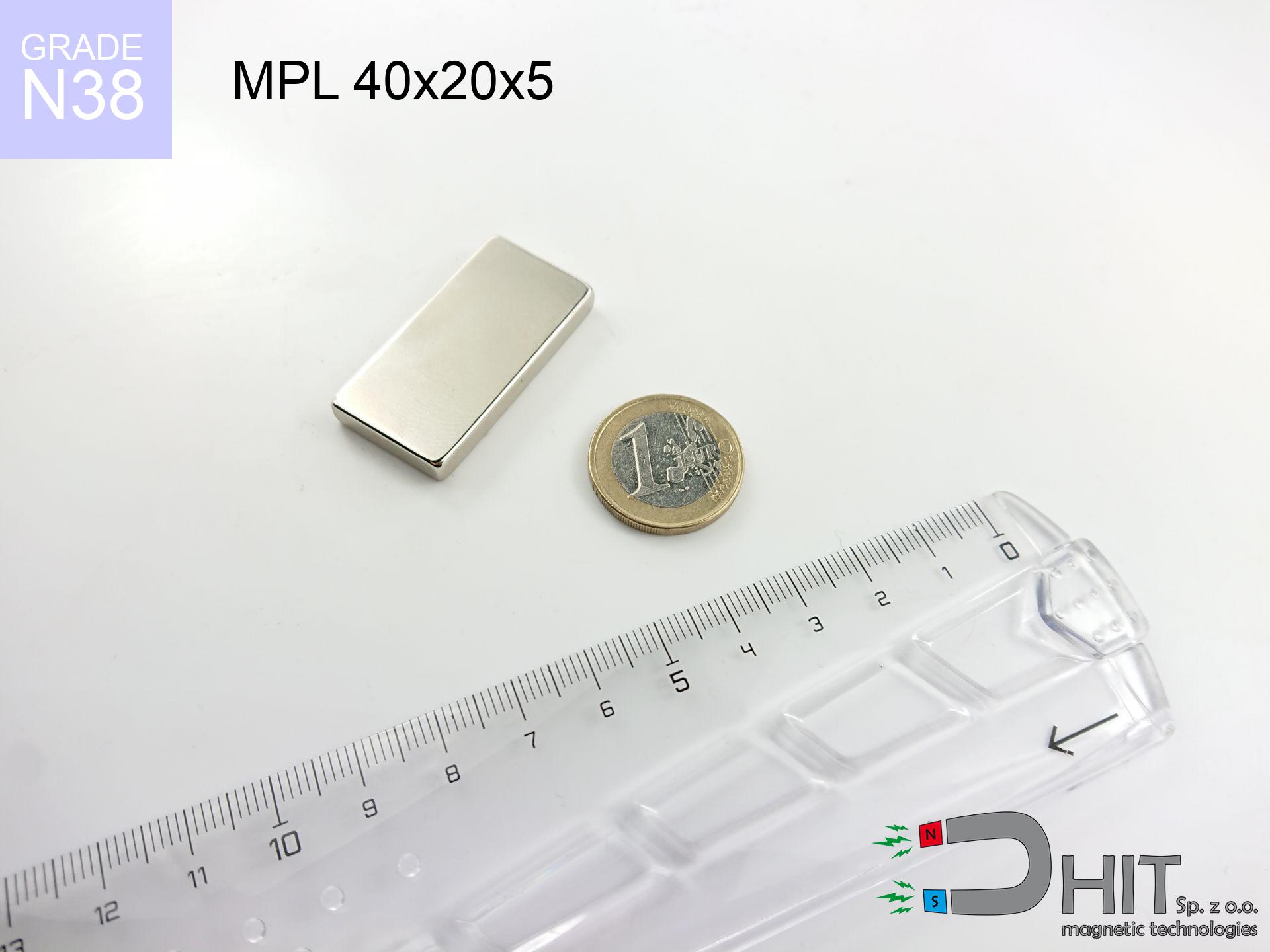

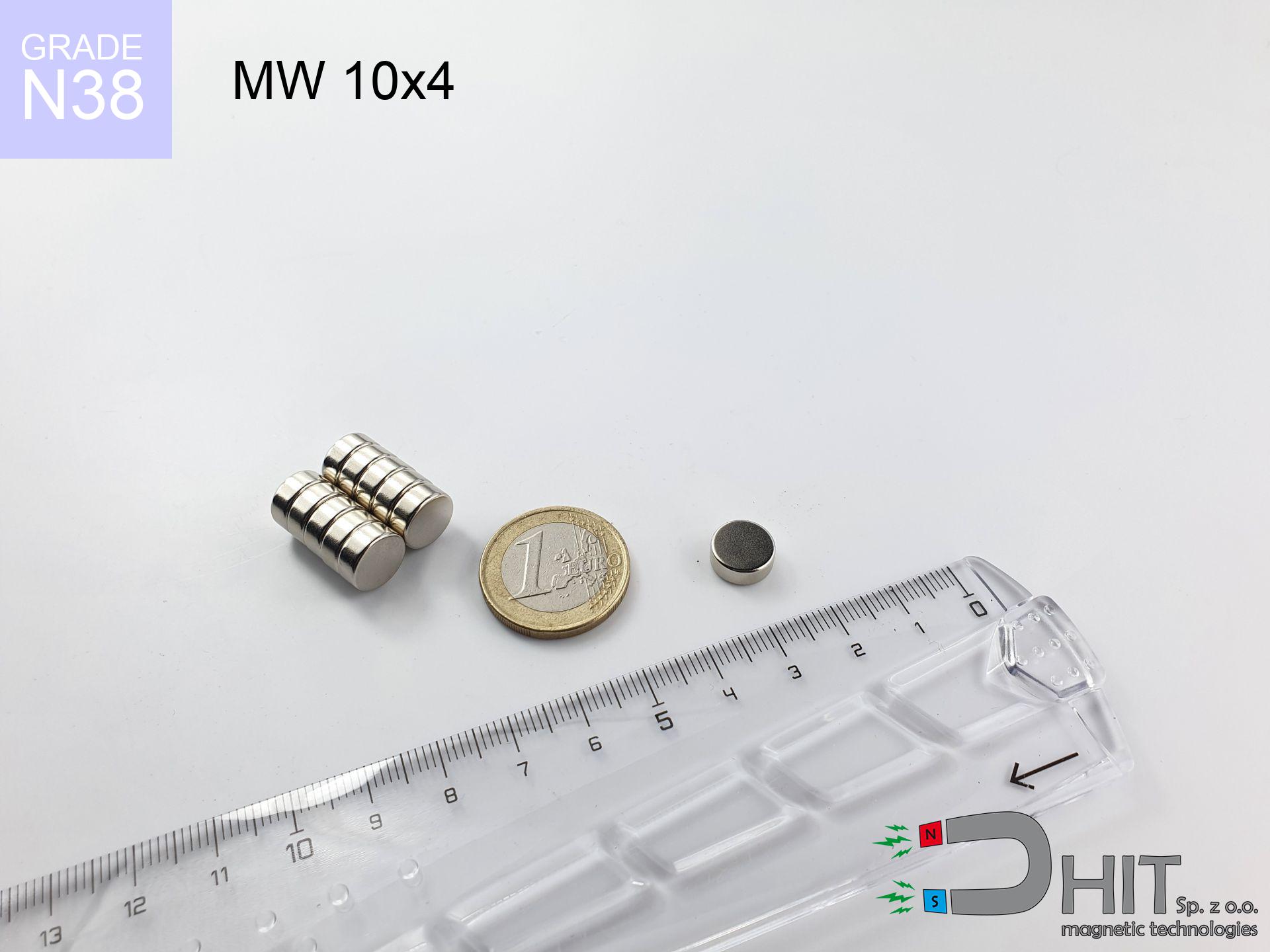

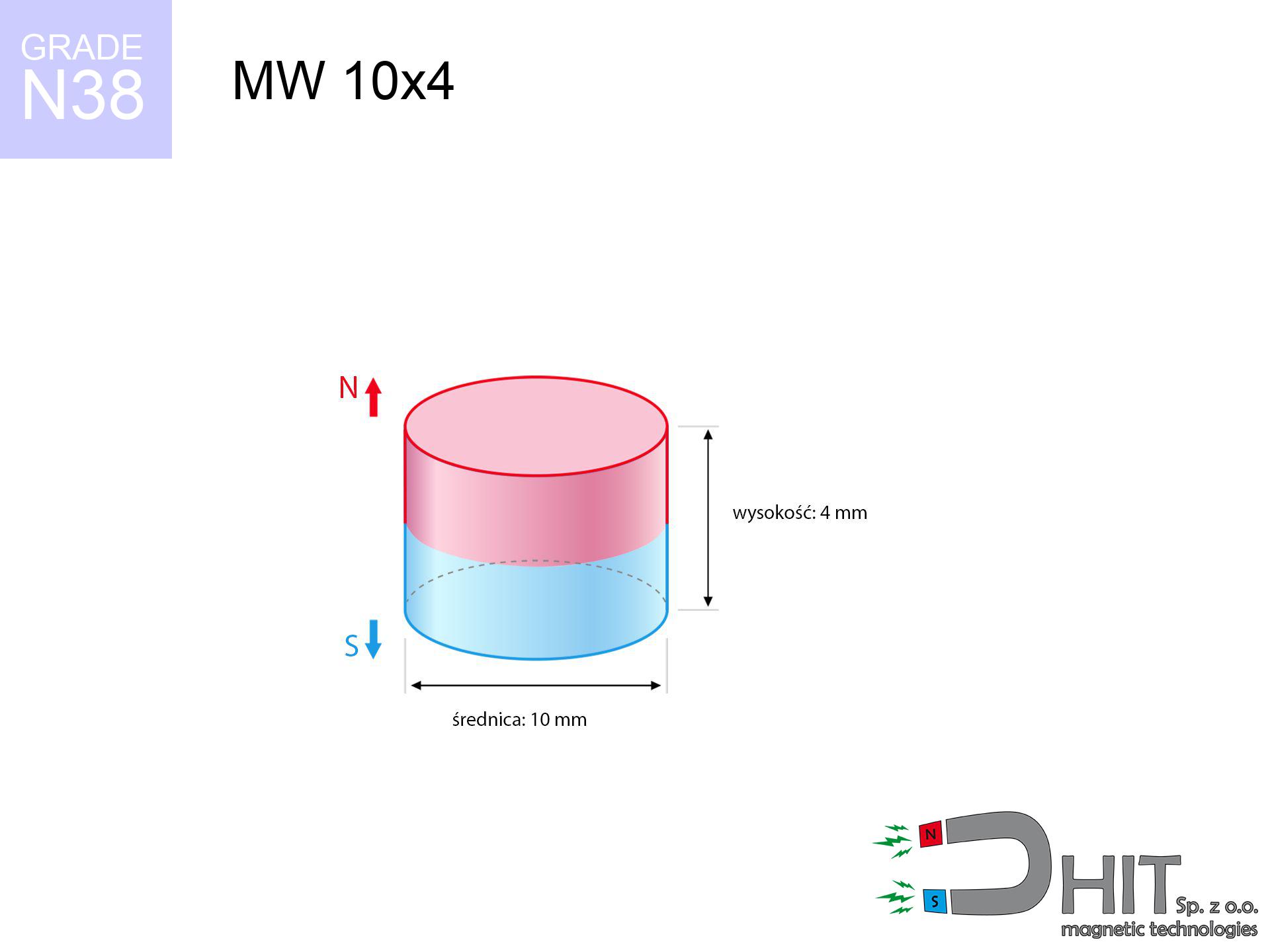

MW 10x4 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010010

GTIN/EAN: 5906301810094

Diameter Ø

10 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

2.36 g

Magnetization Direction

↑ axial

Load capacity

2.80 kg / 27.42 N

Magnetic Induction

386.91 mT / 3869 Gs

Coating

[NiCuNi] Nickel

1.021 ZŁ with VAT / pcs + price for transport

0.830 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise drop us a message by means of

our online form

the contact section.

Parameters along with appearance of a neodymium magnet can be verified using our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Technical data of the product - MW 10x4 / N38 - cylindrical magnet

Specification / characteristics - MW 10x4 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010010 |

| GTIN/EAN | 5906301810094 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 10 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 2.36 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.80 kg / 27.42 N |

| Magnetic Induction ~ ? | 386.91 mT / 3869 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - technical parameters

Presented information are the direct effect of a engineering analysis. Values rely on models for the class Nd2Fe14B. Actual parameters might slightly differ from theoretical values. Please consider these data as a reference point when designing systems.

Table 1: Static force (force vs distance) - power drop

MW 10x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3867 Gs

386.7 mT

|

2.80 kg / 6.17 LBS

2800.0 g / 27.5 N

|

strong |

| 1 mm |

3168 Gs

316.8 mT

|

1.88 kg / 4.14 LBS

1879.8 g / 18.4 N

|

low risk |

| 2 mm |

2460 Gs

246.0 mT

|

1.13 kg / 2.50 LBS

1133.7 g / 11.1 N

|

low risk |

| 3 mm |

1855 Gs

185.5 mT

|

0.64 kg / 1.42 LBS

644.6 g / 6.3 N

|

low risk |

| 5 mm |

1036 Gs

103.6 mT

|

0.20 kg / 0.44 LBS

200.9 g / 2.0 N

|

low risk |

| 10 mm |

293 Gs

29.3 mT

|

0.02 kg / 0.04 LBS

16.1 g / 0.2 N

|

low risk |

| 15 mm |

114 Gs

11.4 mT

|

0.00 kg / 0.01 LBS

2.4 g / 0.0 N

|

low risk |

| 20 mm |

55 Gs

5.5 mT

|

0.00 kg / 0.00 LBS

0.6 g / 0.0 N

|

low risk |

| 30 mm |

18 Gs

1.8 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding capacity (wall)

MW 10x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

| 1 mm | Stal (~0.2) |

0.38 kg / 0.83 LBS

376.0 g / 3.7 N

|

| 2 mm | Stal (~0.2) |

0.23 kg / 0.50 LBS

226.0 g / 2.2 N

|

| 3 mm | Stal (~0.2) |

0.13 kg / 0.28 LBS

128.0 g / 1.3 N

|

| 5 mm | Stal (~0.2) |

0.04 kg / 0.09 LBS

40.0 g / 0.4 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - behavior on slippery surfaces

MW 10x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.84 kg / 1.85 LBS

840.0 g / 8.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.28 kg / 0.62 LBS

280.0 g / 2.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.40 kg / 3.09 LBS

1400.0 g / 13.7 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 10x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.28 kg / 0.62 LBS

280.0 g / 2.7 N

|

| 1 mm |

|

0.70 kg / 1.54 LBS

700.0 g / 6.9 N

|

| 2 mm |

|

1.40 kg / 3.09 LBS

1400.0 g / 13.7 N

|

| 3 mm |

|

2.10 kg / 4.63 LBS

2100.0 g / 20.6 N

|

| 5 mm |

|

2.80 kg / 6.17 LBS

2800.0 g / 27.5 N

|

| 10 mm |

|

2.80 kg / 6.17 LBS

2800.0 g / 27.5 N

|

| 11 mm |

|

2.80 kg / 6.17 LBS

2800.0 g / 27.5 N

|

| 12 mm |

|

2.80 kg / 6.17 LBS

2800.0 g / 27.5 N

|

Table 5: Working in heat (stability) - power drop

MW 10x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.80 kg / 6.17 LBS

2800.0 g / 27.5 N

|

OK |

| 40 °C | -2.2% |

2.74 kg / 6.04 LBS

2738.4 g / 26.9 N

|

OK |

| 60 °C | -4.4% |

2.68 kg / 5.90 LBS

2676.8 g / 26.3 N

|

|

| 80 °C | -6.6% |

2.62 kg / 5.77 LBS

2615.2 g / 25.7 N

|

|

| 100 °C | -28.8% |

1.99 kg / 4.40 LBS

1993.6 g / 19.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MW 10x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

7.24 kg / 15.96 LBS

5 247 Gs

|

1.09 kg / 2.39 LBS

1086 g / 10.7 N

|

N/A |

| 1 mm |

6.04 kg / 13.31 LBS

7 061 Gs

|

0.91 kg / 2.00 LBS

905 g / 8.9 N

|

5.43 kg / 11.98 LBS

~0 Gs

|

| 2 mm |

4.86 kg / 10.71 LBS

6 336 Gs

|

0.73 kg / 1.61 LBS

729 g / 7.2 N

|

4.37 kg / 9.64 LBS

~0 Gs

|

| 3 mm |

3.81 kg / 8.41 LBS

5 612 Gs

|

0.57 kg / 1.26 LBS

572 g / 5.6 N

|

3.43 kg / 7.56 LBS

~0 Gs

|

| 5 mm |

2.22 kg / 4.90 LBS

4 283 Gs

|

0.33 kg / 0.73 LBS

333 g / 3.3 N

|

2.00 kg / 4.41 LBS

~0 Gs

|

| 10 mm |

0.52 kg / 1.15 LBS

2 071 Gs

|

0.08 kg / 0.17 LBS

78 g / 0.8 N

|

0.47 kg / 1.03 LBS

~0 Gs

|

| 20 mm |

0.04 kg / 0.09 LBS

587 Gs

|

0.01 kg / 0.01 LBS

6 g / 0.1 N

|

0.04 kg / 0.08 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

61 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

37 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

24 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

9 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MW 10x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MW 10x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

34.86 km/h

(9.68 m/s)

|

0.11 J | |

| 30 mm |

60.17 km/h

(16.71 m/s)

|

0.33 J | |

| 50 mm |

77.68 km/h

(21.58 m/s)

|

0.55 J | |

| 100 mm |

109.85 km/h

(30.51 m/s)

|

1.10 J |

Table 9: Anti-corrosion coating durability

MW 10x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 10x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 142 Mx | 31.4 µWb |

| Pc Coefficient | 0.50 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 10x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.80 kg | Standard |

| Water (riverbed) |

3.21 kg

(+0.41 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds merely a fraction of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) drastically weakens the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.50

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also products

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They do not lose magnetism, even during nearly ten years – the reduction in strength is only ~1% (theoretically),

- Magnets perfectly resist against demagnetization caused by foreign field sources,

- Thanks to the elegant finish, the surface of nickel, gold-plated, or silver gives an modern appearance,

- Magnets are distinguished by excellent magnetic induction on the outer side,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Possibility of precise machining and modifying to complex conditions,

- Fundamental importance in modern industrial fields – they are commonly used in mass storage devices, electric drive systems, precision medical tools, also complex engineering applications.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- They are fragile upon heavy impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also increases its resistance to damage

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in creating threads and complex shapes in magnets, we propose using casing - magnetic mechanism.

- Health risk related to microscopic parts of magnets can be dangerous, in case of ingestion, which becomes key in the aspect of protecting the youngest. It is also worth noting that tiny parts of these products are able to be problematic in diagnostics medical in case of swallowing.

- With large orders the cost of neodymium magnets can be a barrier,

Holding force characteristics

Maximum lifting force for a neodymium magnet – what contributes to it?

- using a plate made of mild steel, functioning as a magnetic yoke

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with an polished contact surface

- under conditions of no distance (surface-to-surface)

- for force applied at a right angle (pull-off, not shear)

- at ambient temperature room level

Impact of factors on magnetic holding capacity in practice

- Distance (between the magnet and the metal), because even a tiny clearance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to varnish, rust or debris).

- Load vector – highest force is available only during perpendicular pulling. The resistance to sliding of the magnet along the surface is usually many times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Steel grade – ideal substrate is pure iron steel. Stainless steels may attract less.

- Smoothness – full contact is obtained only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – heating the magnet causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the lifting capacity is smaller. Moreover, even a small distance between the magnet’s surface and the plate reduces the holding force.

H&S for magnets

Caution required

Use magnets consciously. Their powerful strength can surprise even professionals. Stay alert and do not underestimate their power.

No play value

NdFeB magnets are not intended for children. Eating several magnets may result in them connecting inside the digestive tract, which poses a severe health hazard and requires immediate surgery.

Cards and drives

Very strong magnetic fields can erase data on payment cards, hard drives, and other magnetic media. Stay away of at least 10 cm.

Fire risk

Machining of neodymium magnets carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Phone sensors

Be aware: rare earth magnets produce a field that disrupts sensitive sensors. Keep a safe distance from your phone, tablet, and GPS.

Power loss in heat

Keep cool. Neodymium magnets are susceptible to temperature. If you need operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Nickel coating and allergies

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction happens, cease working with magnets and wear gloves.

Risk of cracking

NdFeB magnets are ceramic materials, which means they are fragile like glass. Impact of two magnets will cause them breaking into shards.

Life threat

Warning for patients: Strong magnetic fields affect medical devices. Keep minimum 30 cm distance or request help to work with the magnets.

Bodily injuries

Pinching hazard: The attraction force is so immense that it can cause blood blisters, pinching, and broken bones. Protective gloves are recommended.

![UMP 75x25 [M10x3] GW F200 PLATINIUM Lina / N52 - search holder UMP 75x25 [M10x3] GW F200 PLATINIUM Lina / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-platinium-lina-wiz.jpg)