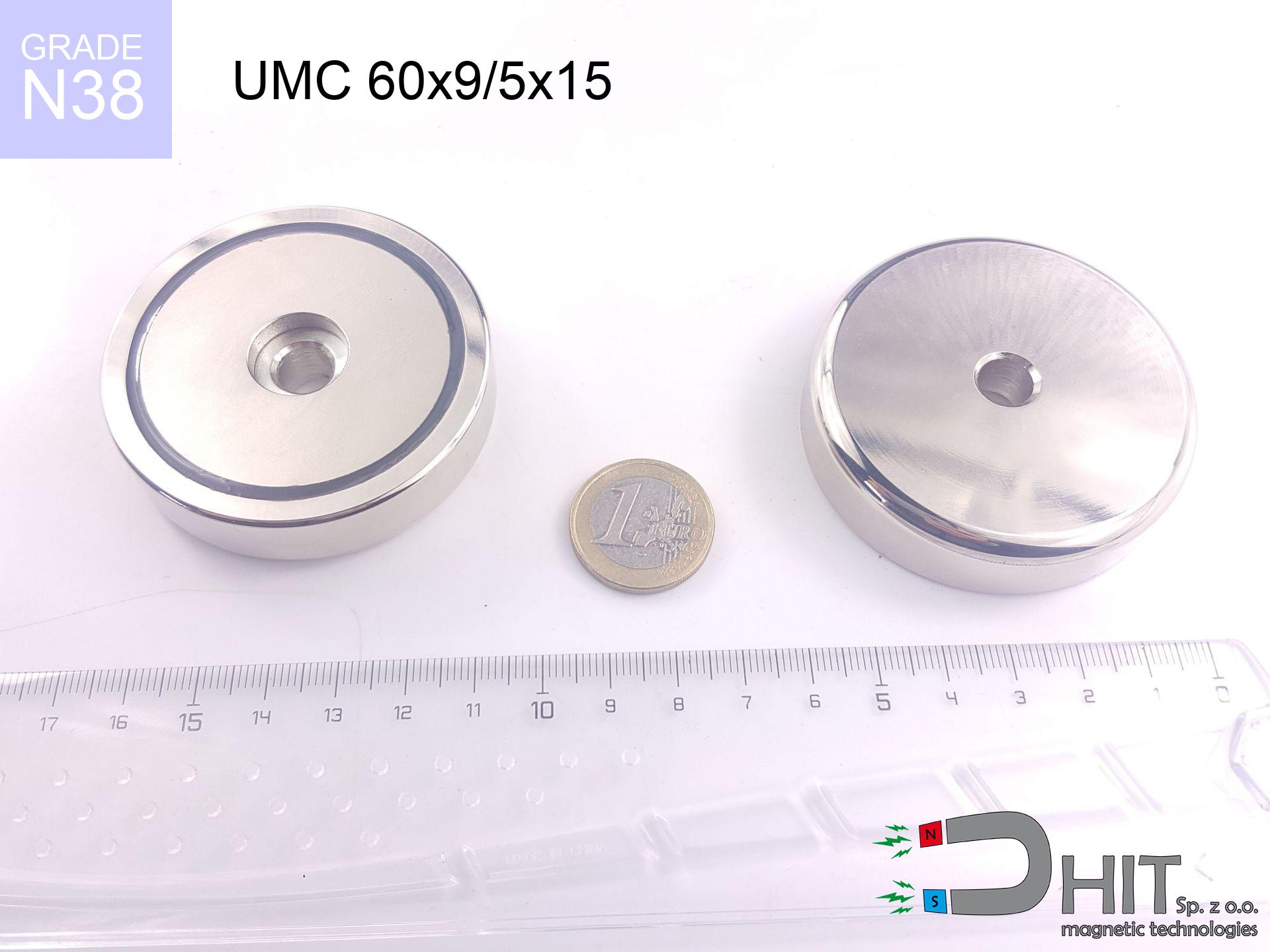

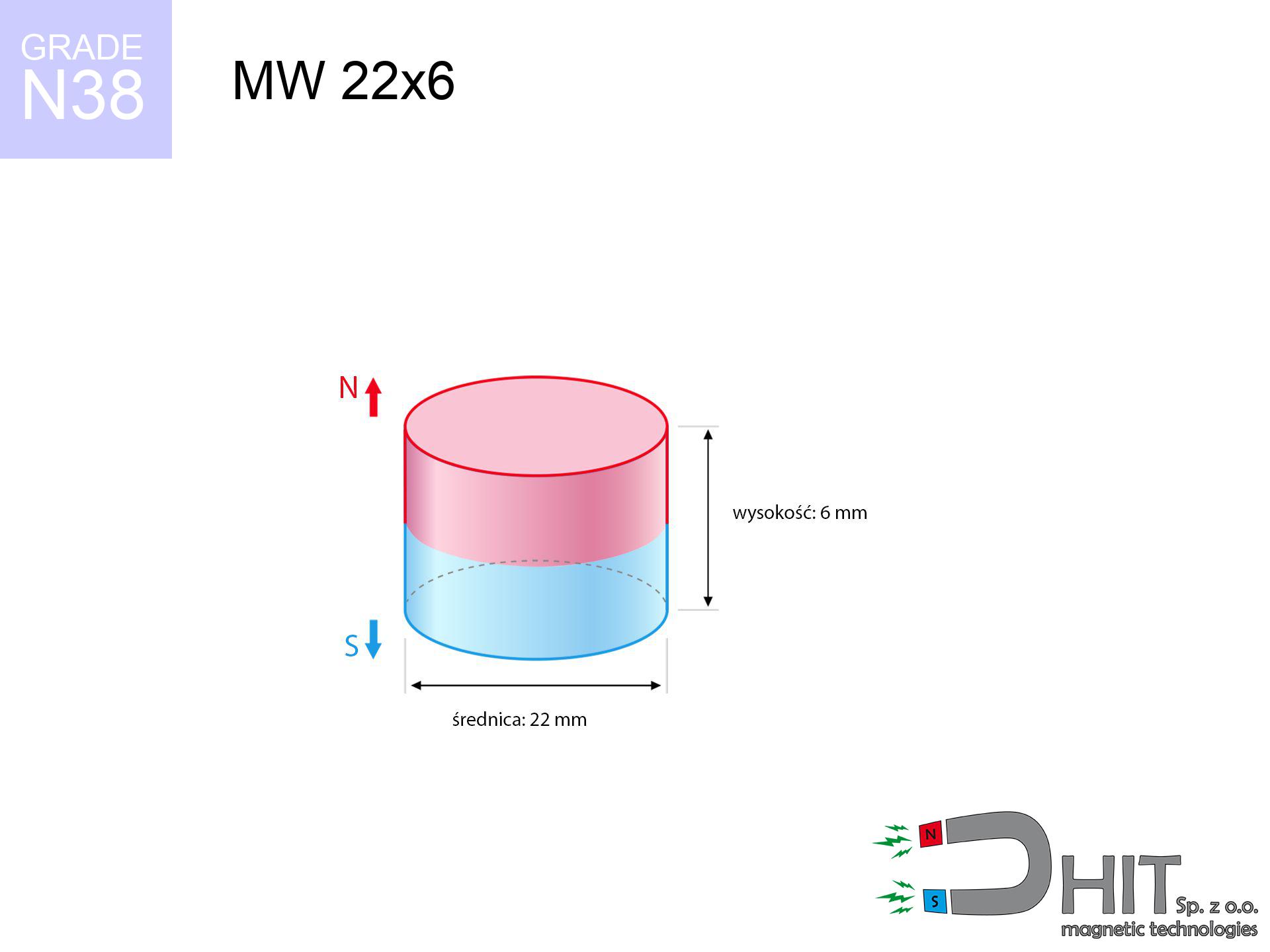

MW 22x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010047

GTIN/EAN: 5906301810469

Diameter Ø

22 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

17.11 g

Magnetization Direction

↑ axial

Load capacity

9.33 kg / 91.51 N

Magnetic Induction

296.78 mT / 2968 Gs

Coating

[NiCuNi] Nickel

6.11 ZŁ with VAT / pcs + price for transport

4.97 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer drop us a message via

inquiry form

the contact section.

Parameters as well as appearance of neodymium magnets can be verified with our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Product card - MW 22x6 / N38 - cylindrical magnet

Specification / characteristics - MW 22x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010047 |

| GTIN/EAN | 5906301810469 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 22 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 17.11 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 9.33 kg / 91.51 N |

| Magnetic Induction ~ ? | 296.78 mT / 2968 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - data

Presented information represent the result of a mathematical simulation. Results rely on algorithms for the material Nd2Fe14B. Operational conditions might slightly differ. Use these data as a reference point when designing systems.

Table 1: Static pull force (force vs gap) - power drop

MW 22x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2967 Gs

296.7 mT

|

9.33 kg / 20.57 pounds

9330.0 g / 91.5 N

|

warning |

| 1 mm |

2767 Gs

276.7 mT

|

8.12 kg / 17.89 pounds

8116.0 g / 79.6 N

|

warning |

| 2 mm |

2538 Gs

253.8 mT

|

6.82 kg / 15.05 pounds

6824.4 g / 66.9 N

|

warning |

| 3 mm |

2295 Gs

229.5 mT

|

5.58 kg / 12.30 pounds

5580.8 g / 54.7 N

|

warning |

| 5 mm |

1818 Gs

181.8 mT

|

3.50 kg / 7.73 pounds

3504.7 g / 34.4 N

|

warning |

| 10 mm |

938 Gs

93.8 mT

|

0.93 kg / 2.06 pounds

933.4 g / 9.2 N

|

weak grip |

| 15 mm |

492 Gs

49.2 mT

|

0.26 kg / 0.57 pounds

257.0 g / 2.5 N

|

weak grip |

| 20 mm |

277 Gs

27.7 mT

|

0.08 kg / 0.18 pounds

81.6 g / 0.8 N

|

weak grip |

| 30 mm |

108 Gs

10.8 mT

|

0.01 kg / 0.03 pounds

12.4 g / 0.1 N

|

weak grip |

| 50 mm |

29 Gs

2.9 mT

|

0.00 kg / 0.00 pounds

0.9 g / 0.0 N

|

weak grip |

Table 2: Slippage hold (wall)

MW 22x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.87 kg / 4.11 pounds

1866.0 g / 18.3 N

|

| 1 mm | Stal (~0.2) |

1.62 kg / 3.58 pounds

1624.0 g / 15.9 N

|

| 2 mm | Stal (~0.2) |

1.36 kg / 3.01 pounds

1364.0 g / 13.4 N

|

| 3 mm | Stal (~0.2) |

1.12 kg / 2.46 pounds

1116.0 g / 10.9 N

|

| 5 mm | Stal (~0.2) |

0.70 kg / 1.54 pounds

700.0 g / 6.9 N

|

| 10 mm | Stal (~0.2) |

0.19 kg / 0.41 pounds

186.0 g / 1.8 N

|

| 15 mm | Stal (~0.2) |

0.05 kg / 0.11 pounds

52.0 g / 0.5 N

|

| 20 mm | Stal (~0.2) |

0.02 kg / 0.04 pounds

16.0 g / 0.2 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 22x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.80 kg / 6.17 pounds

2799.0 g / 27.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.87 kg / 4.11 pounds

1866.0 g / 18.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.93 kg / 2.06 pounds

933.0 g / 9.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.67 kg / 10.28 pounds

4665.0 g / 45.8 N

|

Table 4: Material efficiency (saturation) - power losses

MW 22x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.93 kg / 2.06 pounds

933.0 g / 9.2 N

|

| 1 mm |

|

2.33 kg / 5.14 pounds

2332.5 g / 22.9 N

|

| 2 mm |

|

4.67 kg / 10.28 pounds

4665.0 g / 45.8 N

|

| 3 mm |

|

7.00 kg / 15.43 pounds

6997.5 g / 68.6 N

|

| 5 mm |

|

9.33 kg / 20.57 pounds

9330.0 g / 91.5 N

|

| 10 mm |

|

9.33 kg / 20.57 pounds

9330.0 g / 91.5 N

|

| 11 mm |

|

9.33 kg / 20.57 pounds

9330.0 g / 91.5 N

|

| 12 mm |

|

9.33 kg / 20.57 pounds

9330.0 g / 91.5 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 22x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

9.33 kg / 20.57 pounds

9330.0 g / 91.5 N

|

OK |

| 40 °C | -2.2% |

9.12 kg / 20.12 pounds

9124.7 g / 89.5 N

|

OK |

| 60 °C | -4.4% |

8.92 kg / 19.66 pounds

8919.5 g / 87.5 N

|

|

| 80 °C | -6.6% |

8.71 kg / 19.21 pounds

8714.2 g / 85.5 N

|

|

| 100 °C | -28.8% |

6.64 kg / 14.65 pounds

6643.0 g / 65.2 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MW 22x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

20.63 kg / 45.48 pounds

4 566 Gs

|

3.09 kg / 6.82 pounds

3095 g / 30.4 N

|

N/A |

| 1 mm |

19.34 kg / 42.63 pounds

5 745 Gs

|

2.90 kg / 6.40 pounds

2901 g / 28.5 N

|

17.40 kg / 38.37 pounds

~0 Gs

|

| 2 mm |

17.95 kg / 39.57 pounds

5 535 Gs

|

2.69 kg / 5.93 pounds

2692 g / 26.4 N

|

16.15 kg / 35.61 pounds

~0 Gs

|

| 3 mm |

16.52 kg / 36.42 pounds

5 310 Gs

|

2.48 kg / 5.46 pounds

2478 g / 24.3 N

|

14.87 kg / 32.78 pounds

~0 Gs

|

| 5 mm |

13.69 kg / 30.18 pounds

4 834 Gs

|

2.05 kg / 4.53 pounds

2053 g / 20.1 N

|

12.32 kg / 27.16 pounds

~0 Gs

|

| 10 mm |

7.75 kg / 17.09 pounds

3 637 Gs

|

1.16 kg / 2.56 pounds

1162 g / 11.4 N

|

6.97 kg / 15.38 pounds

~0 Gs

|

| 20 mm |

2.06 kg / 4.55 pounds

1 877 Gs

|

0.31 kg / 0.68 pounds

310 g / 3.0 N

|

1.86 kg / 4.10 pounds

~0 Gs

|

| 50 mm |

0.07 kg / 0.15 pounds

336 Gs

|

0.01 kg / 0.02 pounds

10 g / 0.1 N

|

0.06 kg / 0.13 pounds

~0 Gs

|

| 60 mm |

0.03 kg / 0.06 pounds

217 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 70 mm |

0.01 kg / 0.03 pounds

147 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 80 mm |

0.01 kg / 0.01 pounds

104 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 pounds

76 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

57 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 22x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 9.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 6.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.5 cm |

| Remote | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 22x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.98 km/h

(6.94 m/s)

|

0.41 J | |

| 30 mm |

40.82 km/h

(11.34 m/s)

|

1.10 J | |

| 50 mm |

52.66 km/h

(14.63 m/s)

|

1.83 J | |

| 100 mm |

74.47 km/h

(20.69 m/s)

|

3.66 J |

Table 9: Surface protection spec

MW 22x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 22x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 12 337 Mx | 123.4 µWb |

| Pc Coefficient | 0.37 | Low (Flat) |

Table 11: Submerged application

MW 22x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 9.33 kg | Standard |

| Water (riverbed) |

10.68 kg

(+1.35 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet retains merely ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely reduces the holding force.

3. Heat tolerance

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.37

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages and disadvantages of rare earth magnets.

Benefits

- They retain magnetic properties for around 10 years – the drop is just ~1% (based on simulations),

- Neodymium magnets prove to be exceptionally resistant to demagnetization caused by external magnetic fields,

- By using a decorative layer of nickel, the element presents an nice look,

- They are known for high magnetic induction at the operating surface, which increases their power,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Thanks to versatility in designing and the capacity to customize to specific needs,

- Significant place in high-tech industry – they are commonly used in HDD drives, brushless drives, diagnostic systems, also technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which makes them useful in miniature devices

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also raises their durability

- Neodymium magnets lose power when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They rust in a humid environment. For use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- We suggest casing - magnetic mount, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Health risk resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child health protection. It is also worth noting that small components of these products can complicate diagnosis medical when they are in the body.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Maximum magnetic pulling force – what affects it?

- with the application of a sheet made of special test steel, guaranteeing full magnetic saturation

- possessing a thickness of minimum 10 mm to avoid saturation

- with an polished touching surface

- under conditions of gap-free contact (metal-to-metal)

- for force applied at a right angle (in the magnet axis)

- at conditions approx. 20°C

Lifting capacity in real conditions – factors

- Gap (between the magnet and the plate), as even a microscopic clearance (e.g. 0.5 mm) can cause a reduction in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Loading method – catalog parameter refers to detachment vertically. When applying parallel force, the magnet exhibits much less (often approx. 20-30% of nominal force).

- Base massiveness – insufficiently thick steel does not close the flux, causing part of the power to be wasted into the air.

- Metal type – different alloys reacts the same. Alloy additives weaken the attraction effect.

- Surface structure – the smoother and more polished the plate, the better the adhesion and stronger the hold. Unevenness creates an air distance.

- Thermal environment – temperature increase causes a temporary drop of force. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, however under parallel forces the holding force is lower. Additionally, even a minimal clearance between the magnet and the plate lowers the load capacity.

H&S for magnets

Fragile material

Beware of splinters. Magnets can explode upon violent connection, launching sharp fragments into the air. Wear goggles.

This is not a toy

Product intended for adults. Small elements pose a choking risk, causing serious injuries. Store away from children and animals.

Safe distance

Data protection: Neodymium magnets can ruin data carriers and sensitive devices (pacemakers, medical aids, timepieces).

Fire warning

Mechanical processing of neodymium magnets poses a fire risk. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Safe operation

Before use, read the rules. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Bone fractures

Mind your fingers. Two powerful magnets will join immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

ICD Warning

Medical warning: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Phone sensors

GPS units and smartphones are extremely susceptible to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Do not overheat magnets

Avoid heat. NdFeB magnets are sensitive to temperature. If you need operation above 80°C, ask us about special high-temperature series (H, SH, UH).

Warning for allergy sufferers

A percentage of the population suffer from a hypersensitivity to Ni, which is the typical protective layer for neodymium magnets. Frequent touching might lead to an allergic reaction. We suggest wear safety gloves.

![SM 32x325 [2xM8] / N52 - magnetic separator SM 32x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-xec.jpg)