SM 25x175 [2xM8] / N52 - magnetic separator

magnetic separator

Catalog no 130369

GTIN/EAN: 5906301813170

Diameter Ø

25 mm [±1 mm]

Height

175 mm [±1 mm]

Weight

660 g

Magnetic Flux

~ 8 500 Gauss [±5%]

541.20 ZŁ with VAT / pcs + price for transport

440.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise let us know via

our online form

the contact section.

Weight and structure of magnets can be verified using our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - SM 25x175 [2xM8] / N52 - magnetic separator

Specification / characteristics - SM 25x175 [2xM8] / N52 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130369 |

| GTIN/EAN | 5906301813170 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 25 mm [±1 mm] |

| Height | 175 mm [±1 mm] |

| Weight | 660 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 8 500 Gauss [±5%] |

| Size/Mount Quantity | M8x2 |

| Polarity | circumferential - 6 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

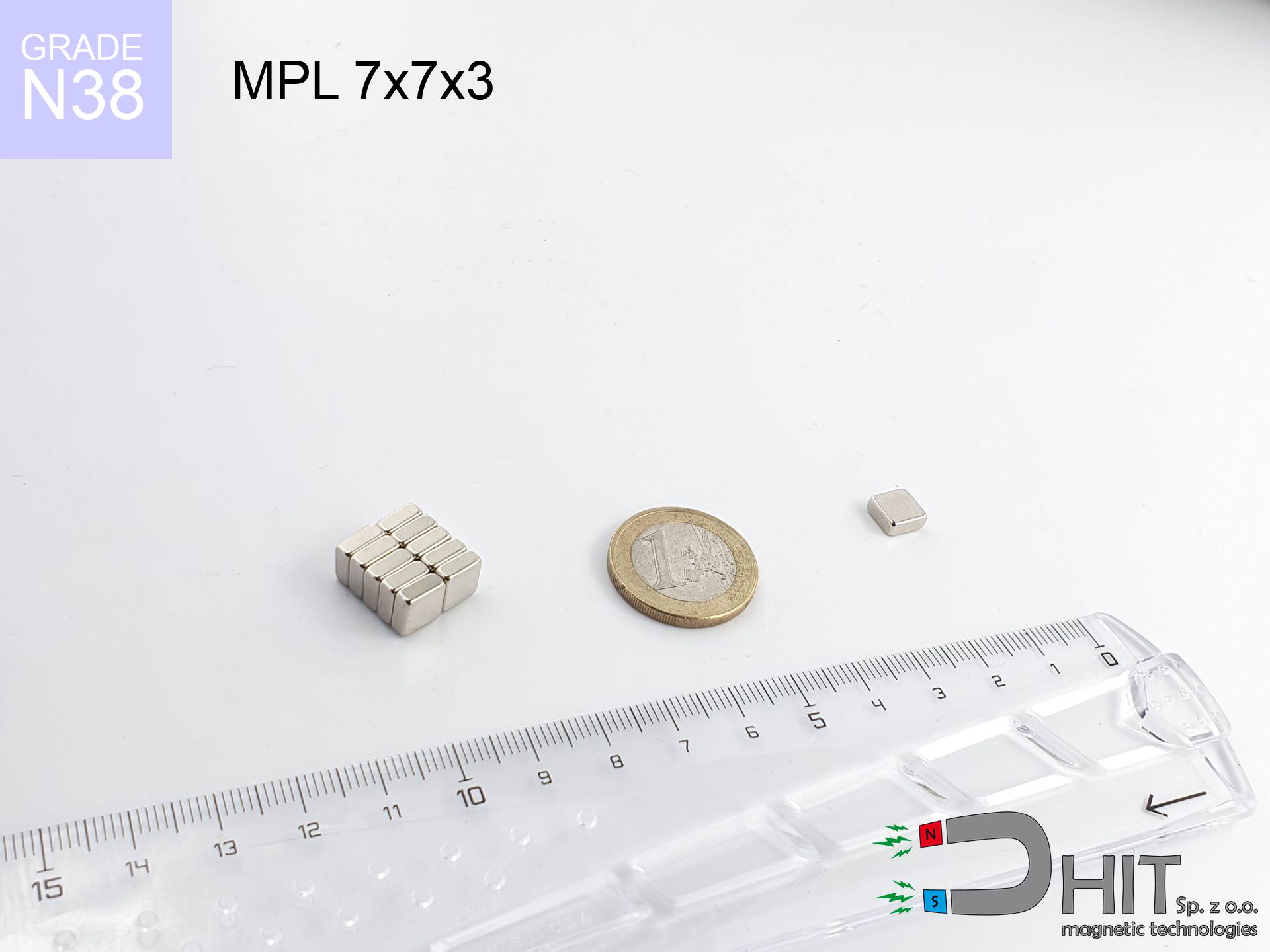

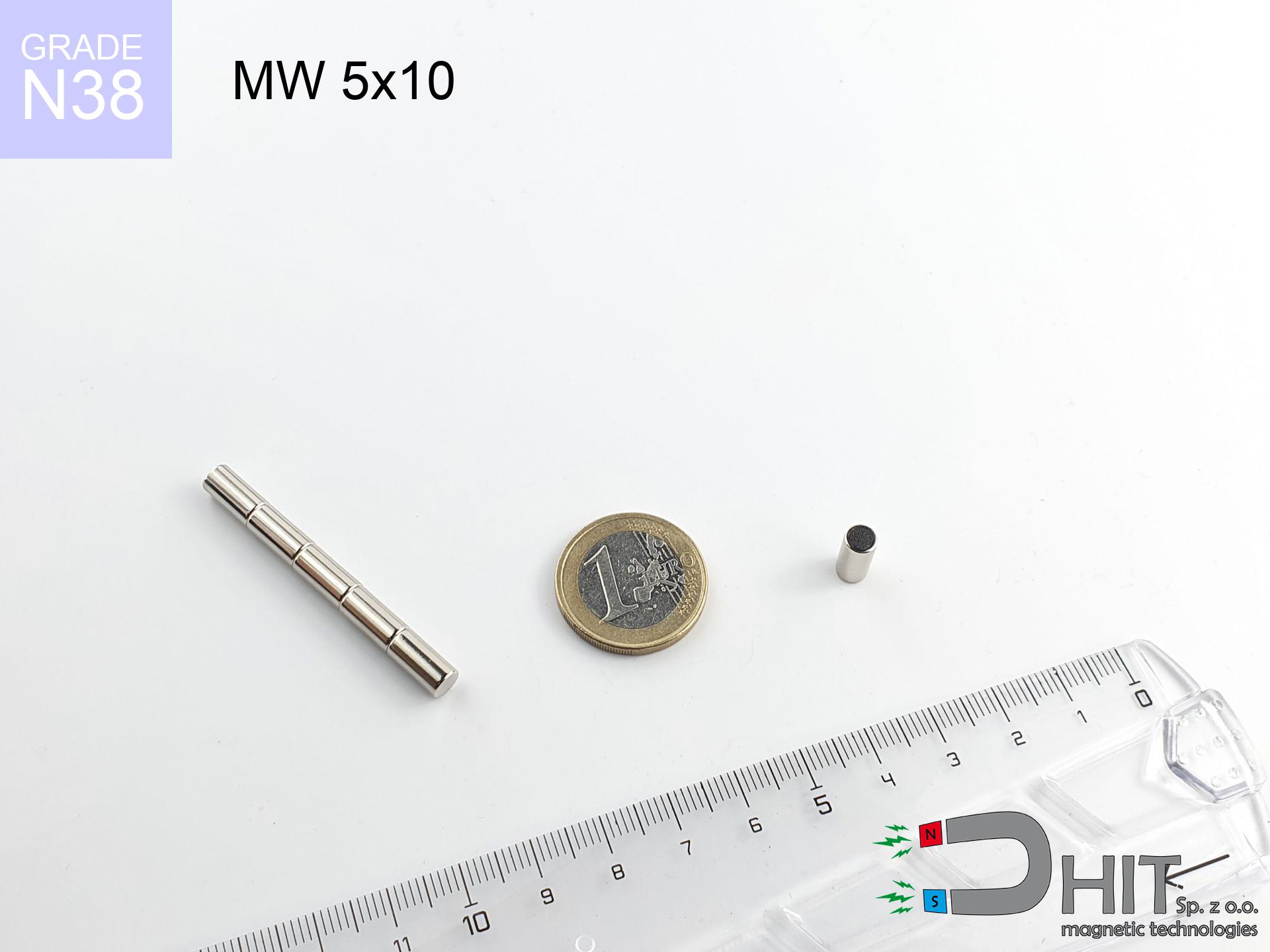

Table 1: Rod construction

SM 25x175 [2xM8] / N52

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 25 | mm |

| Total length | 175 | mm (L) |

| Active length | 139 | mm |

| Section count | 6 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~653 | g |

| Active area | 109 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 18.1 | kg (theor.) |

| Induction (surface) | ~8 500 | Gauss (Max) |

Chart 2: Field profile (6 sections)

Chart 3: Temperature performance

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of Nd2Fe14B magnets.

Benefits

- Their strength remains stable, and after around ten years it drops only by ~1% (theoretically),

- Neodymium magnets prove to be highly resistant to magnetic field loss caused by external field sources,

- The use of an metallic layer of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- Magnetic induction on the surface of the magnet turns out to be very high,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of exact shaping as well as optimizing to specific applications,

- Key role in advanced technology sectors – they are commonly used in computer drives, drive modules, precision medical tools, as well as technologically advanced constructions.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- We suggest a housing - magnetic holder, due to difficulties in producing nuts inside the magnet and complicated shapes.

- Possible danger resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. Additionally, small components of these products can be problematic in diagnostics medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Detachment force of the magnet in optimal conditions – what contributes to it?

- with the use of a sheet made of low-carbon steel, ensuring full magnetic saturation

- whose thickness is min. 10 mm

- characterized by even structure

- without the slightest air gap between the magnet and steel

- under perpendicular force vector (90-degree angle)

- at ambient temperature room level

Determinants of practical lifting force of a magnet

- Distance – the presence of foreign body (paint, dirt, air) acts as an insulator, which lowers power rapidly (even by 50% at 0.5 mm).

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Steel thickness – too thin steel causes magnetic saturation, causing part of the power to be wasted to the other side.

- Material type – the best choice is pure iron steel. Cast iron may have worse magnetic properties.

- Plate texture – ground elements guarantee perfect abutment, which improves field saturation. Uneven metal reduce efficiency.

- Operating temperature – neodymium magnets have a negative temperature coefficient. At higher temperatures they lose power, and in frost they can be stronger (up to a certain limit).

Lifting capacity was assessed with the use of a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, whereas under shearing force the holding force is lower. Moreover, even a slight gap between the magnet and the plate reduces the lifting capacity.

Warnings

Do not drill into magnets

Powder generated during cutting of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

This is not a toy

NdFeB magnets are not suitable for play. Swallowing multiple magnets can lead to them attracting across intestines, which poses a critical condition and necessitates urgent medical intervention.

Electronic hazard

Do not bring magnets near a wallet, computer, or TV. The magnetism can destroy these devices and erase data from cards.

Do not underestimate power

Handle magnets consciously. Their immense force can shock even experienced users. Plan your moves and respect their force.

Phone sensors

Remember: rare earth magnets produce a field that interferes with precision electronics. Keep a safe distance from your mobile, tablet, and GPS.

Sensitization to coating

It is widely known that nickel (standard magnet coating) is a common allergen. If you have an allergy, refrain from direct skin contact and opt for versions in plastic housing.

Crushing force

Mind your fingers. Two large magnets will snap together instantly with a force of massive weight, crushing everything in their path. Exercise extreme caution!

Operating temperature

Watch the temperature. Heating the magnet above 80 degrees Celsius will permanently weaken its properties and pulling force.

ICD Warning

People with a pacemaker must keep an safe separation from magnets. The magnetic field can disrupt the functioning of the implant.

Magnet fragility

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

![Separation magnetic rod SM 25x175 [2xM8] / N52 Separation magnetic rod SM 25x175 [2xM8] / N52](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 25x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x175-2xm8-gif.jpg)