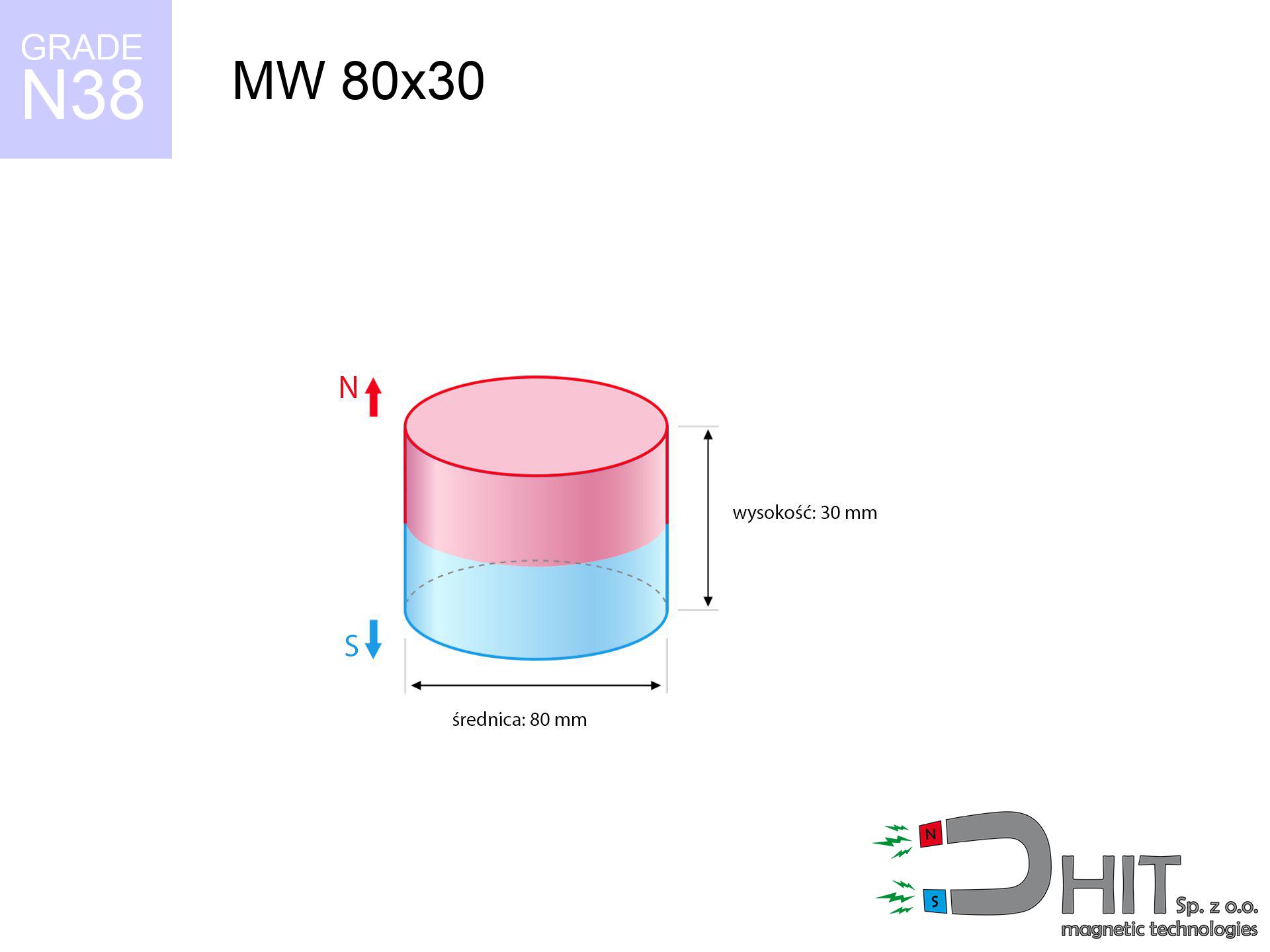

MW 80x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010100

GTIN/EAN: 5906301810995

Diameter Ø

80 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

1130.97 g

Magnetization Direction

↑ axial

Load capacity

170.64 kg / 1673.99 N

Magnetic Induction

371.95 mT / 3720 Gs

Coating

[NiCuNi] Nickel

415.00 ZŁ with VAT / pcs + price for transport

337.40 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

otherwise get in touch through

form

our website.

Force as well as appearance of a magnet can be analyzed on our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical specification of the product - MW 80x30 / N38 - cylindrical magnet

Specification / characteristics - MW 80x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010100 |

| GTIN/EAN | 5906301810995 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 80 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 1130.97 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 170.64 kg / 1673.99 N |

| Magnetic Induction ~ ? | 371.95 mT / 3720 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - technical parameters

Presented values constitute the direct effect of a engineering analysis. Results are based on models for the class Nd2Fe14B. Operational performance may deviate from the simulation results. Please consider these data as a reference point during assembly planning.

Table 1: Static force (force vs distance) - interaction chart

MW 80x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3719 Gs

371.9 mT

|

170.64 kg / 376.20 LBS

170640.0 g / 1674.0 N

|

dangerous! |

| 1 mm |

3643 Gs

364.3 mT

|

163.71 kg / 360.93 LBS

163714.9 g / 1606.0 N

|

dangerous! |

| 2 mm |

3563 Gs

356.3 mT

|

156.65 kg / 345.35 LBS

156647.8 g / 1536.7 N

|

dangerous! |

| 3 mm |

3482 Gs

348.2 mT

|

149.55 kg / 329.71 LBS

149554.1 g / 1467.1 N

|

dangerous! |

| 5 mm |

3314 Gs

331.4 mT

|

135.46 kg / 298.63 LBS

135457.0 g / 1328.8 N

|

dangerous! |

| 10 mm |

2880 Gs

288.0 mT

|

102.34 kg / 225.63 LBS

102343.3 g / 1004.0 N

|

dangerous! |

| 15 mm |

2457 Gs

245.7 mT

|

74.47 kg / 164.17 LBS

74468.4 g / 730.5 N

|

dangerous! |

| 20 mm |

2069 Gs

206.9 mT

|

52.79 kg / 116.38 LBS

52789.9 g / 517.9 N

|

dangerous! |

| 30 mm |

1439 Gs

143.9 mT

|

25.53 kg / 56.29 LBS

25534.0 g / 250.5 N

|

dangerous! |

| 50 mm |

704 Gs

70.4 mT

|

6.11 kg / 13.48 LBS

6115.0 g / 60.0 N

|

warning |

Table 2: Shear force (vertical surface)

MW 80x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

34.13 kg / 75.24 LBS

34128.0 g / 334.8 N

|

| 1 mm | Stal (~0.2) |

32.74 kg / 72.18 LBS

32742.0 g / 321.2 N

|

| 2 mm | Stal (~0.2) |

31.33 kg / 69.07 LBS

31330.0 g / 307.3 N

|

| 3 mm | Stal (~0.2) |

29.91 kg / 65.94 LBS

29910.0 g / 293.4 N

|

| 5 mm | Stal (~0.2) |

27.09 kg / 59.73 LBS

27092.0 g / 265.8 N

|

| 10 mm | Stal (~0.2) |

20.47 kg / 45.12 LBS

20468.0 g / 200.8 N

|

| 15 mm | Stal (~0.2) |

14.89 kg / 32.84 LBS

14894.0 g / 146.1 N

|

| 20 mm | Stal (~0.2) |

10.56 kg / 23.28 LBS

10558.0 g / 103.6 N

|

| 30 mm | Stal (~0.2) |

5.11 kg / 11.26 LBS

5106.0 g / 50.1 N

|

| 50 mm | Stal (~0.2) |

1.22 kg / 2.69 LBS

1222.0 g / 12.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 80x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

51.19 kg / 112.86 LBS

51192.0 g / 502.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

34.13 kg / 75.24 LBS

34128.0 g / 334.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

17.06 kg / 37.62 LBS

17064.0 g / 167.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

85.32 kg / 188.10 LBS

85320.0 g / 837.0 N

|

Table 4: Steel thickness (saturation) - power losses

MW 80x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

5.69 kg / 12.54 LBS

5688.0 g / 55.8 N

|

| 1 mm |

|

14.22 kg / 31.35 LBS

14220.0 g / 139.5 N

|

| 2 mm |

|

28.44 kg / 62.70 LBS

28440.0 g / 279.0 N

|

| 3 mm |

|

42.66 kg / 94.05 LBS

42660.0 g / 418.5 N

|

| 5 mm |

|

71.10 kg / 156.75 LBS

71100.0 g / 697.5 N

|

| 10 mm |

|

142.20 kg / 313.50 LBS

142200.0 g / 1395.0 N

|

| 11 mm |

|

156.42 kg / 344.85 LBS

156420.0 g / 1534.5 N

|

| 12 mm |

|

170.64 kg / 376.20 LBS

170640.0 g / 1674.0 N

|

Table 5: Thermal stability (stability) - power drop

MW 80x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

170.64 kg / 376.20 LBS

170640.0 g / 1674.0 N

|

OK |

| 40 °C | -2.2% |

166.89 kg / 367.92 LBS

166885.9 g / 1637.2 N

|

OK |

| 60 °C | -4.4% |

163.13 kg / 359.64 LBS

163131.8 g / 1600.3 N

|

|

| 80 °C | -6.6% |

159.38 kg / 351.37 LBS

159377.8 g / 1563.5 N

|

|

| 100 °C | -28.8% |

121.50 kg / 267.85 LBS

121495.7 g / 1191.9 N

|

Table 6: Two magnets (repulsion) - field range

MW 80x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

428.66 kg / 945.03 LBS

5 157 Gs

|

64.30 kg / 141.76 LBS

64299 g / 630.8 N

|

N/A |

| 1 mm |

420.08 kg / 926.12 LBS

7 364 Gs

|

63.01 kg / 138.92 LBS

63012 g / 618.1 N

|

378.07 kg / 833.51 LBS

~0 Gs

|

| 2 mm |

411.26 kg / 906.68 LBS

7 286 Gs

|

61.69 kg / 136.00 LBS

61690 g / 605.2 N

|

370.14 kg / 816.01 LBS

~0 Gs

|

| 3 mm |

402.40 kg / 887.15 LBS

7 207 Gs

|

60.36 kg / 133.07 LBS

60360 g / 592.1 N

|

362.16 kg / 798.43 LBS

~0 Gs

|

| 5 mm |

384.60 kg / 847.90 LBS

7 046 Gs

|

57.69 kg / 127.19 LBS

57690 g / 565.9 N

|

346.14 kg / 763.11 LBS

~0 Gs

|

| 10 mm |

340.28 kg / 750.18 LBS

6 627 Gs

|

51.04 kg / 112.53 LBS

51042 g / 500.7 N

|

306.25 kg / 675.17 LBS

~0 Gs

|

| 20 mm |

257.09 kg / 566.80 LBS

5 761 Gs

|

38.56 kg / 85.02 LBS

38564 g / 378.3 N

|

231.38 kg / 510.12 LBS

~0 Gs

|

| 50 mm |

92.55 kg / 204.04 LBS

3 456 Gs

|

13.88 kg / 30.61 LBS

13883 g / 136.2 N

|

83.30 kg / 183.63 LBS

~0 Gs

|

| 60 mm |

64.14 kg / 141.41 LBS

2 877 Gs

|

9.62 kg / 21.21 LBS

9622 g / 94.4 N

|

57.73 kg / 127.27 LBS

~0 Gs

|

| 70 mm |

44.44 kg / 97.98 LBS

2 395 Gs

|

6.67 kg / 14.70 LBS

6666 g / 65.4 N

|

40.00 kg / 88.18 LBS

~0 Gs

|

| 80 mm |

30.93 kg / 68.19 LBS

1 998 Gs

|

4.64 kg / 10.23 LBS

4639 g / 45.5 N

|

27.84 kg / 61.37 LBS

~0 Gs

|

| 90 mm |

21.69 kg / 47.82 LBS

1 673 Gs

|

3.25 kg / 7.17 LBS

3254 g / 31.9 N

|

19.52 kg / 43.04 LBS

~0 Gs

|

| 100 mm |

15.36 kg / 33.87 LBS

1 408 Gs

|

2.30 kg / 5.08 LBS

2304 g / 22.6 N

|

13.83 kg / 30.48 LBS

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MW 80x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 37.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 29.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 23.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 18.0 cm |

| Car key | 50 Gs (5.0 mT) | 16.5 cm |

| Payment card | 400 Gs (40.0 mT) | 7.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 5.5 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 80x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.39 km/h

(4.55 m/s)

|

11.72 J | |

| 30 mm |

23.38 km/h

(6.49 m/s)

|

23.85 J | |

| 50 mm |

28.31 km/h

(7.86 m/s)

|

34.98 J | |

| 100 mm |

39.22 km/h

(10.90 m/s)

|

67.13 J |

Table 9: Coating parameters (durability)

MW 80x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 80x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 194 600 Mx | 1946.0 µWb |

| Pc Coefficient | 0.48 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 80x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 170.64 kg | Standard |

| Water (riverbed) |

195.38 kg

(+24.74 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical wall, the magnet holds only ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.48

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also deals

Pros as well as cons of rare earth magnets.

Advantages

- Their magnetic field is maintained, and after around 10 years it drops only by ~1% (according to research),

- They possess excellent resistance to magnetism drop as a result of opposing magnetic fields,

- The use of an aesthetic layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- The surface of neodymium magnets generates a strong magnetic field – this is one of their assets,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can function (depending on the form) even at a temperature of 230°C or more...

- Thanks to flexibility in constructing and the capacity to modify to complex applications,

- Fundamental importance in innovative solutions – they are commonly used in mass storage devices, electric drive systems, precision medical tools, and technologically advanced constructions.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a special holder, which not only protects them against impacts but also raises their durability

- NdFeB magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- Due to limitations in producing threads and complex forms in magnets, we recommend using a housing - magnetic mechanism.

- Potential hazard to health – tiny shards of magnets are risky, if swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, tiny parts of these devices are able to disrupt the diagnostic process medical when they are in the body.

- Due to neodymium price, their price is relatively high,

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- using a plate made of low-carbon steel, serving as a magnetic yoke

- possessing a thickness of min. 10 mm to avoid saturation

- with an polished contact surface

- with total lack of distance (no coatings)

- for force acting at a right angle (in the magnet axis)

- at conditions approx. 20°C

Impact of factors on magnetic holding capacity in practice

- Space between surfaces – even a fraction of a millimeter of separation (caused e.g. by veneer or dirt) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the nominal value.

- Steel thickness – too thin sheet does not accept the full field, causing part of the flux to be lost to the other side.

- Chemical composition of the base – mild steel gives the best results. Alloy admixtures lower magnetic properties and lifting capacity.

- Surface structure – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Thermal factor – high temperature weakens magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, in contrast under parallel forces the holding force is lower. Additionally, even a small distance between the magnet and the plate lowers the load capacity.

H&S for magnets

Danger to pacemakers

Medical warning: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

Crushing force

Large magnets can smash fingers instantly. Under no circumstances place your hand betwixt two attracting surfaces.

Risk of cracking

Despite metallic appearance, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Swallowing risk

Only for adults. Tiny parts pose a choking risk, causing serious injuries. Store out of reach of kids and pets.

Electronic devices

Avoid bringing magnets close to a purse, computer, or TV. The magnetic field can destroy these devices and erase data from cards.

Dust is flammable

Fire warning: Neodymium dust is explosive. Do not process magnets without safety gear as this risks ignition.

Sensitization to coating

Nickel alert: The nickel-copper-nickel coating contains nickel. If skin irritation appears, cease working with magnets and use protective gear.

Maximum temperature

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. This process is irreversible.

Handling guide

Handle with care. Rare earth magnets act from a long distance and connect with huge force, often quicker than you can react.

Keep away from electronics

A powerful magnetic field interferes with the functioning of magnetometers in smartphones and navigation systems. Do not bring magnets close to a device to avoid breaking the sensors.

![SM 32x125 [2xM8] / N42 - magnetic separator SM 32x125 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x125-2xm8-pul.jpg)

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)