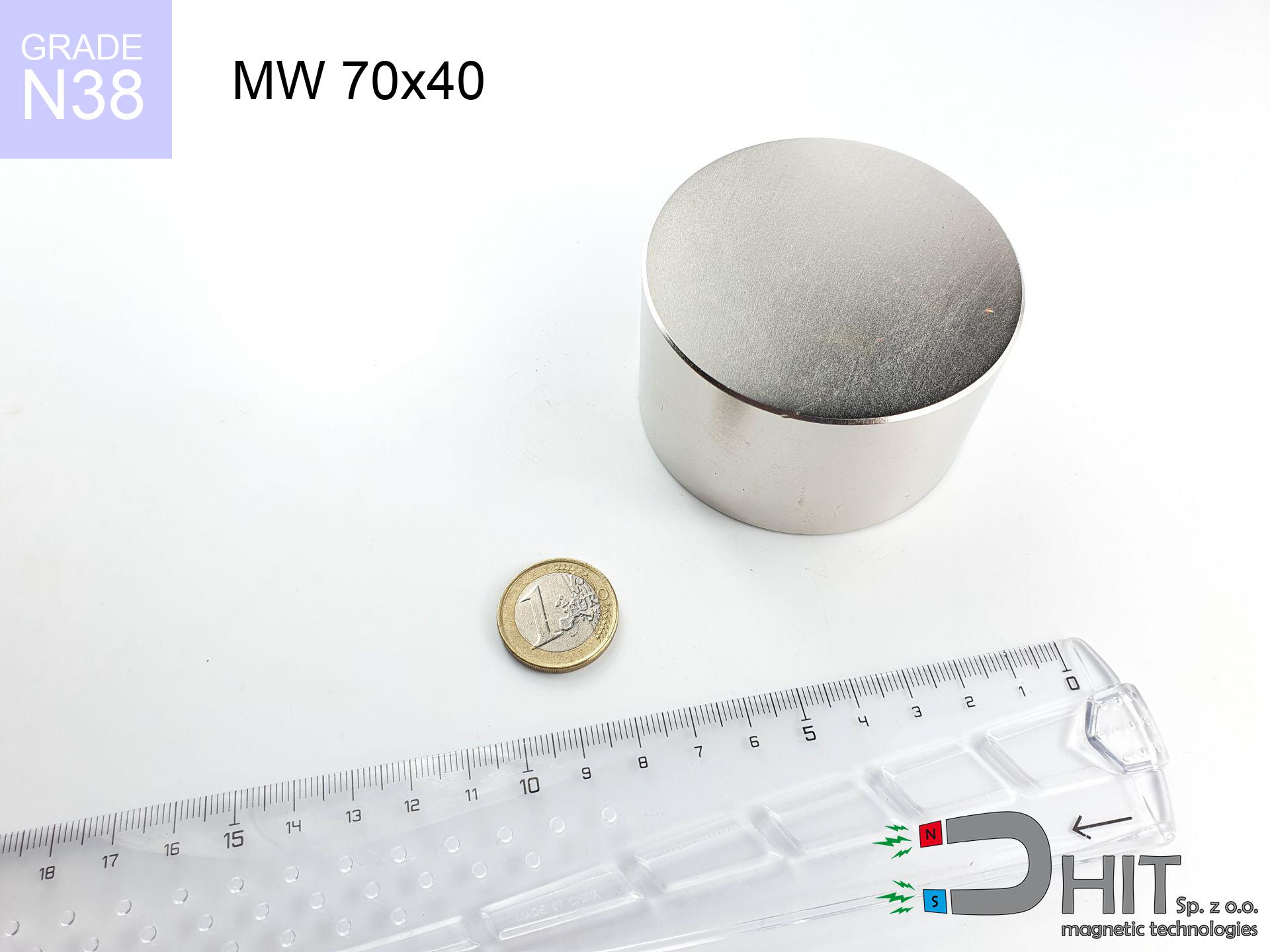

MW 70x50 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010496

GTIN/EAN: 5906301811145

Diameter Ø

70 mm [±0,1 mm]

Height

50 mm [±0,1 mm]

Weight

1443.17 g

Magnetization Direction

↑ axial

Load capacity

168.21 kg / 1650.14 N

Magnetic Induction

507.83 mT / 5078 Gs

Coating

[NiCuNi] Nickel

516.60 ZŁ with VAT / pcs + price for transport

420.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

alternatively let us know using

request form

our website.

Parameters along with appearance of a magnet can be estimated on our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - MW 70x50 / N38 - cylindrical magnet

Specification / characteristics - MW 70x50 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010496 |

| GTIN/EAN | 5906301811145 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 70 mm [±0,1 mm] |

| Height | 50 mm [±0,1 mm] |

| Weight | 1443.17 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 168.21 kg / 1650.14 N |

| Magnetic Induction ~ ? | 507.83 mT / 5078 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - data

Presented data constitute the result of a mathematical analysis. Results were calculated on algorithms for the class Nd2Fe14B. Actual performance may differ. Use these calculations as a supplementary guide during assembly planning.

Table 1: Static pull force (pull vs distance) - power drop

MW 70x50 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5078 Gs

507.8 mT

|

168.21 kg / 370.84 LBS

168210.0 g / 1650.1 N

|

critical level |

| 1 mm |

4935 Gs

493.5 mT

|

158.88 kg / 350.26 LBS

158876.4 g / 1558.6 N

|

critical level |

| 2 mm |

4790 Gs

479.0 mT

|

149.67 kg / 329.96 LBS

149666.1 g / 1468.2 N

|

critical level |

| 3 mm |

4644 Gs

464.4 mT

|

140.71 kg / 310.21 LBS

140708.8 g / 1380.4 N

|

critical level |

| 5 mm |

4354 Gs

435.4 mT

|

123.67 kg / 272.64 LBS

123667.4 g / 1213.2 N

|

critical level |

| 10 mm |

3652 Gs

365.2 mT

|

87.02 kg / 191.84 LBS

87016.1 g / 853.6 N

|

critical level |

| 15 mm |

3017 Gs

301.7 mT

|

59.37 kg / 130.88 LBS

59366.6 g / 582.4 N

|

critical level |

| 20 mm |

2469 Gs

246.9 mT

|

39.78 kg / 87.70 LBS

39781.3 g / 390.3 N

|

critical level |

| 30 mm |

1645 Gs

164.5 mT

|

17.66 kg / 38.93 LBS

17659.3 g / 173.2 N

|

critical level |

| 50 mm |

773 Gs

77.3 mT

|

3.89 kg / 8.59 LBS

3895.0 g / 38.2 N

|

warning |

Table 2: Shear hold (vertical surface)

MW 70x50 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

33.64 kg / 74.17 LBS

33642.0 g / 330.0 N

|

| 1 mm | Stal (~0.2) |

31.78 kg / 70.05 LBS

31776.0 g / 311.7 N

|

| 2 mm | Stal (~0.2) |

29.93 kg / 65.99 LBS

29934.0 g / 293.7 N

|

| 3 mm | Stal (~0.2) |

28.14 kg / 62.04 LBS

28142.0 g / 276.1 N

|

| 5 mm | Stal (~0.2) |

24.73 kg / 54.53 LBS

24734.0 g / 242.6 N

|

| 10 mm | Stal (~0.2) |

17.40 kg / 38.37 LBS

17404.0 g / 170.7 N

|

| 15 mm | Stal (~0.2) |

11.87 kg / 26.18 LBS

11874.0 g / 116.5 N

|

| 20 mm | Stal (~0.2) |

7.96 kg / 17.54 LBS

7956.0 g / 78.0 N

|

| 30 mm | Stal (~0.2) |

3.53 kg / 7.79 LBS

3532.0 g / 34.6 N

|

| 50 mm | Stal (~0.2) |

0.78 kg / 1.72 LBS

778.0 g / 7.6 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 70x50 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

50.46 kg / 111.25 LBS

50463.0 g / 495.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

33.64 kg / 74.17 LBS

33642.0 g / 330.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

16.82 kg / 37.08 LBS

16821.0 g / 165.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

84.11 kg / 185.42 LBS

84105.0 g / 825.1 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 70x50 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

5.61 kg / 12.36 LBS

5607.0 g / 55.0 N

|

| 1 mm |

|

14.02 kg / 30.90 LBS

14017.5 g / 137.5 N

|

| 2 mm |

|

28.03 kg / 61.81 LBS

28035.0 g / 275.0 N

|

| 3 mm |

|

42.05 kg / 92.71 LBS

42052.5 g / 412.5 N

|

| 5 mm |

|

70.09 kg / 154.52 LBS

70087.5 g / 687.6 N

|

| 10 mm |

|

140.18 kg / 309.03 LBS

140175.0 g / 1375.1 N

|

| 11 mm |

|

154.19 kg / 339.94 LBS

154192.5 g / 1512.6 N

|

| 12 mm |

|

168.21 kg / 370.84 LBS

168210.0 g / 1650.1 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 70x50 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

168.21 kg / 370.84 LBS

168210.0 g / 1650.1 N

|

OK |

| 40 °C | -2.2% |

164.51 kg / 362.68 LBS

164509.4 g / 1613.8 N

|

OK |

| 60 °C | -4.4% |

160.81 kg / 354.52 LBS

160808.8 g / 1577.5 N

|

OK |

| 80 °C | -6.6% |

157.11 kg / 346.36 LBS

157108.1 g / 1541.2 N

|

|

| 100 °C | -28.8% |

119.77 kg / 264.04 LBS

119765.5 g / 1174.9 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 70x50 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

611.75 kg / 1348.67 LBS

5 850 Gs

|

91.76 kg / 202.30 LBS

91762 g / 900.2 N

|

N/A |

| 1 mm |

594.86 kg / 1311.43 LBS

10 014 Gs

|

89.23 kg / 196.72 LBS

89229 g / 875.3 N

|

535.37 kg / 1180.29 LBS

~0 Gs

|

| 2 mm |

577.80 kg / 1273.84 LBS

9 870 Gs

|

86.67 kg / 191.08 LBS

86670 g / 850.2 N

|

520.02 kg / 1146.45 LBS

~0 Gs

|

| 3 mm |

560.95 kg / 1236.68 LBS

9 725 Gs

|

84.14 kg / 185.50 LBS

84142 g / 825.4 N

|

504.85 kg / 1113.01 LBS

~0 Gs

|

| 5 mm |

527.90 kg / 1163.81 LBS

9 434 Gs

|

79.18 kg / 174.57 LBS

79184 g / 776.8 N

|

475.11 kg / 1047.43 LBS

~0 Gs

|

| 10 mm |

449.75 kg / 991.54 LBS

8 708 Gs

|

67.46 kg / 148.73 LBS

67463 g / 661.8 N

|

404.78 kg / 892.38 LBS

~0 Gs

|

| 20 mm |

316.46 kg / 697.68 LBS

7 304 Gs

|

47.47 kg / 104.65 LBS

47469 g / 465.7 N

|

284.81 kg / 627.91 LBS

~0 Gs

|

| 50 mm |

96.30 kg / 212.30 LBS

4 029 Gs

|

14.44 kg / 31.85 LBS

14445 g / 141.7 N

|

86.67 kg / 191.07 LBS

~0 Gs

|

| 60 mm |

64.22 kg / 141.59 LBS

3 291 Gs

|

9.63 kg / 21.24 LBS

9634 g / 94.5 N

|

57.80 kg / 127.43 LBS

~0 Gs

|

| 70 mm |

43.17 kg / 95.18 LBS

2 698 Gs

|

6.48 kg / 14.28 LBS

6476 g / 63.5 N

|

38.86 kg / 85.66 LBS

~0 Gs

|

| 80 mm |

29.36 kg / 64.73 LBS

2 225 Gs

|

4.40 kg / 9.71 LBS

4404 g / 43.2 N

|

26.43 kg / 58.26 LBS

~0 Gs

|

| 90 mm |

20.25 kg / 44.63 LBS

1 847 Gs

|

3.04 kg / 6.69 LBS

3037 g / 29.8 N

|

18.22 kg / 40.17 LBS

~0 Gs

|

| 100 mm |

14.17 kg / 31.23 LBS

1 545 Gs

|

2.12 kg / 4.68 LBS

2125 g / 20.8 N

|

12.75 kg / 28.11 LBS

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 70x50 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 40.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 31.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 24.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 19.0 cm |

| Car key | 50 Gs (5.0 mT) | 17.5 cm |

| Payment card | 400 Gs (40.0 mT) | 7.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 6.0 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 70x50 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

13.97 km/h

(3.88 m/s)

|

10.87 J | |

| 30 mm |

20.06 km/h

(5.57 m/s)

|

22.40 J | |

| 50 mm |

24.70 km/h

(6.86 m/s)

|

33.96 J | |

| 100 mm |

34.46 km/h

(9.57 m/s)

|

66.12 J |

Table 9: Anti-corrosion coating durability

MW 70x50 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 70x50 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 197 145 Mx | 1971.5 µWb |

| Pc Coefficient | 0.74 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 70x50 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 168.21 kg | Standard |

| Water (riverbed) |

192.60 kg

(+24.39 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet retains only ~20% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.74

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths and weaknesses of Nd2Fe14B magnets.

Benefits

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (in laboratory conditions),

- They have excellent resistance to weakening of magnetic properties when exposed to opposing magnetic fields,

- By using a smooth coating of nickel, the element has an elegant look,

- The surface of neodymium magnets generates a maximum magnetic field – this is one of their assets,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, allowing for operation at temperatures approaching 230°C and above...

- Thanks to versatility in forming and the capacity to customize to individual projects,

- Universal use in future technologies – they are utilized in mass storage devices, electric motors, medical equipment, also industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which makes them useful in small systems

Cons

- To avoid cracks under impact, we recommend using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in realizing nuts and complex forms in magnets, we recommend using cover - magnetic mechanism.

- Potential hazard related to microscopic parts of magnets are risky, if swallowed, which gains importance in the aspect of protecting the youngest. Furthermore, small elements of these products are able to disrupt the diagnostic process medical in case of swallowing.

- Due to expensive raw materials, their price is higher than average,

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what it depends on?

- on a base made of mild steel, perfectly concentrating the magnetic field

- with a cross-section no less than 10 mm

- characterized by even structure

- without the slightest clearance between the magnet and steel

- during detachment in a direction perpendicular to the mounting surface

- at room temperature

Lifting capacity in practice – influencing factors

- Gap between surfaces – even a fraction of a millimeter of distance (caused e.g. by veneer or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – declared lifting capacity refers to detachment vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of nominal force).

- Substrate thickness – to utilize 100% power, the steel must be sufficiently thick. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Material composition – not every steel reacts the same. High carbon content worsen the attraction effect.

- Smoothness – full contact is possible only on polished steel. Rough texture reduce the real contact area, reducing force.

- Temperature influence – hot environment weakens magnetic field. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was assessed using a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the lifting capacity is smaller. In addition, even a minimal clearance between the magnet and the plate reduces the holding force.

Warnings

Heat warning

Regular neodymium magnets (N-type) lose magnetization when the temperature surpasses 80°C. The loss of strength is permanent.

Pinching danger

Mind your fingers. Two large magnets will join instantly with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

Sensitization to coating

Nickel alert: The nickel-copper-nickel coating consists of nickel. If skin irritation appears, cease handling magnets and wear gloves.

This is not a toy

NdFeB magnets are not suitable for play. Eating several magnets can lead to them pinching intestinal walls, which poses a critical condition and requires urgent medical intervention.

Do not drill into magnets

Dust produced during cutting of magnets is combustible. Do not drill into magnets unless you are an expert.

Handling guide

Before starting, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Be predictive.

GPS Danger

Navigation devices and smartphones are highly susceptible to magnetism. Direct contact with a powerful NdFeB magnet can decalibrate the sensors in your phone.

Shattering risk

Beware of splinters. Magnets can explode upon uncontrolled impact, ejecting shards into the air. Eye protection is mandatory.

Pacemakers

For implant holders: Powerful magnets disrupt electronics. Maintain at least 30 cm distance or ask another person to handle the magnets.

Cards and drives

Data protection: Strong magnets can damage payment cards and delicate electronics (heart implants, medical aids, timepieces).

![UMGW 75x33x18 [M10] GW / N38 - magnetic holder internal thread UMGW 75x33x18 [M10] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/umgw-75x33x18-m10-gw-cak.jpg)