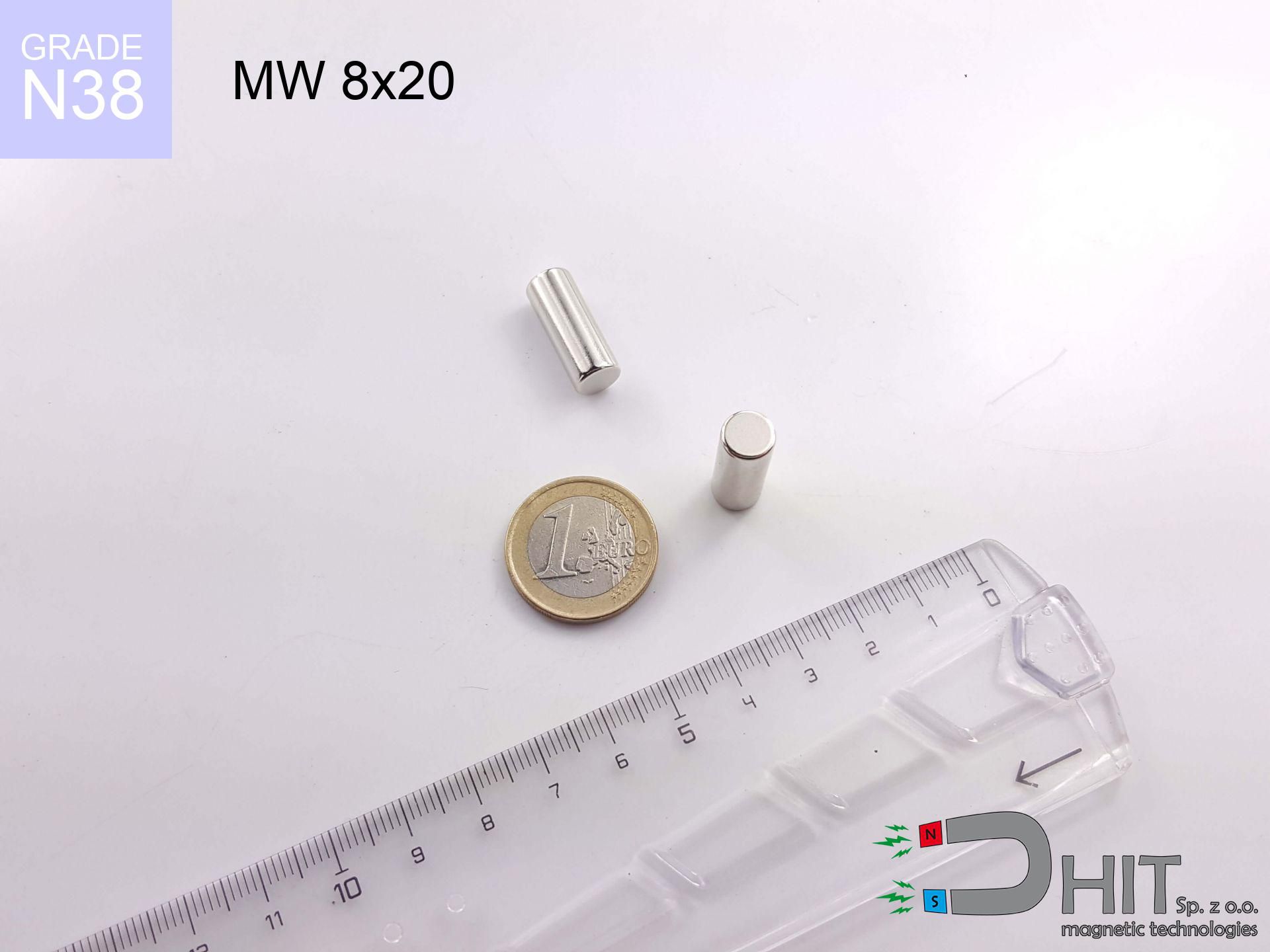

MW 8x20 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010475

GTIN/EAN: 5906301811138

Diameter Ø

8 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

7.54 g

Magnetization Direction

→ diametrical

Load capacity

1.30 kg / 12.71 N

Magnetic Induction

607.01 mT / 6070 Gs

Coating

[NiCuNi] Nickel

4.60 ZŁ with VAT / pcs + price for transport

3.74 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise drop us a message by means of

inquiry form

the contact section.

Specifications and shape of magnets can be verified with our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Physical properties - MW 8x20 / N38 - cylindrical magnet

Specification / characteristics - MW 8x20 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010475 |

| GTIN/EAN | 5906301811138 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 7.54 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 1.30 kg / 12.71 N |

| Magnetic Induction ~ ? | 607.01 mT / 6070 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - data

These data represent the result of a physical analysis. Results are based on models for the class Nd2Fe14B. Real-world performance might slightly differ. Use these calculations as a supplementary guide when designing systems.

Table 1: Static force (force vs gap) - power drop

MW 8x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6064 Gs

606.4 mT

|

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

safe |

| 1 mm |

4587 Gs

458.7 mT

|

0.74 kg / 1.64 lbs

743.7 g / 7.3 N

|

safe |

| 2 mm |

3327 Gs

332.7 mT

|

0.39 kg / 0.86 lbs

391.4 g / 3.8 N

|

safe |

| 3 mm |

2388 Gs

238.8 mT

|

0.20 kg / 0.44 lbs

201.6 g / 2.0 N

|

safe |

| 5 mm |

1281 Gs

128.1 mT

|

0.06 kg / 0.13 lbs

58.0 g / 0.6 N

|

safe |

| 10 mm |

389 Gs

38.9 mT

|

0.01 kg / 0.01 lbs

5.4 g / 0.1 N

|

safe |

| 15 mm |

169 Gs

16.9 mT

|

0.00 kg / 0.00 lbs

1.0 g / 0.0 N

|

safe |

| 20 mm |

90 Gs

9.0 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

safe |

| 30 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

| 50 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Shear load (vertical surface)

MW 8x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.26 kg / 0.57 lbs

260.0 g / 2.6 N

|

| 1 mm | Stal (~0.2) |

0.15 kg / 0.33 lbs

148.0 g / 1.5 N

|

| 2 mm | Stal (~0.2) |

0.08 kg / 0.17 lbs

78.0 g / 0.8 N

|

| 3 mm | Stal (~0.2) |

0.04 kg / 0.09 lbs

40.0 g / 0.4 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

12.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 8x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.39 kg / 0.86 lbs

390.0 g / 3.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.26 kg / 0.57 lbs

260.0 g / 2.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.13 kg / 0.29 lbs

130.0 g / 1.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.65 kg / 1.43 lbs

650.0 g / 6.4 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 8x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.13 kg / 0.29 lbs

130.0 g / 1.3 N

|

| 1 mm |

|

0.33 kg / 0.72 lbs

325.0 g / 3.2 N

|

| 2 mm |

|

0.65 kg / 1.43 lbs

650.0 g / 6.4 N

|

| 3 mm |

|

0.98 kg / 2.15 lbs

975.0 g / 9.6 N

|

| 5 mm |

|

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

| 10 mm |

|

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

| 11 mm |

|

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

| 12 mm |

|

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

Table 5: Working in heat (stability) - resistance threshold

MW 8x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

OK |

| 40 °C | -2.2% |

1.27 kg / 2.80 lbs

1271.4 g / 12.5 N

|

OK |

| 60 °C | -4.4% |

1.24 kg / 2.74 lbs

1242.8 g / 12.2 N

|

OK |

| 80 °C | -6.6% |

1.21 kg / 2.68 lbs

1214.2 g / 11.9 N

|

|

| 100 °C | -28.8% |

0.93 kg / 2.04 lbs

925.6 g / 9.1 N

|

Table 6: Two magnets (attraction) - field range

MW 8x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

11.40 kg / 25.12 lbs

6 154 Gs

|

1.71 kg / 3.77 lbs

1709 g / 16.8 N

|

N/A |

| 1 mm |

8.76 kg / 19.31 lbs

10 632 Gs

|

1.31 kg / 2.90 lbs

1314 g / 12.9 N

|

7.88 kg / 17.38 lbs

~0 Gs

|

| 2 mm |

6.52 kg / 14.37 lbs

9 174 Gs

|

0.98 kg / 2.16 lbs

978 g / 9.6 N

|

5.87 kg / 12.94 lbs

~0 Gs

|

| 3 mm |

4.76 kg / 10.49 lbs

7 837 Gs

|

0.71 kg / 1.57 lbs

714 g / 7.0 N

|

4.28 kg / 9.44 lbs

~0 Gs

|

| 5 mm |

2.46 kg / 5.43 lbs

5 637 Gs

|

0.37 kg / 0.81 lbs

369 g / 3.6 N

|

2.22 kg / 4.88 lbs

~0 Gs

|

| 10 mm |

0.51 kg / 1.12 lbs

2 561 Gs

|

0.08 kg / 0.17 lbs

76 g / 0.7 N

|

0.46 kg / 1.01 lbs

~0 Gs

|

| 20 mm |

0.05 kg / 0.10 lbs

778 Gs

|

0.01 kg / 0.02 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

107 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

69 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

48 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

34 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

25 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

19 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MW 8x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 8x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

13.28 km/h

(3.69 m/s)

|

0.05 J | |

| 30 mm |

22.94 km/h

(6.37 m/s)

|

0.15 J | |

| 50 mm |

29.61 km/h

(8.23 m/s)

|

0.26 J | |

| 100 mm |

41.88 km/h

(11.63 m/s)

|

0.51 J |

Table 9: Anti-corrosion coating durability

MW 8x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 8x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 457 Mx | 34.6 µWb |

| Pc Coefficient | 1.31 | High (Stable) |

Table 11: Submerged application

MW 8x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.30 kg | Standard |

| Water (riverbed) |

1.49 kg

(+0.19 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet retains only ~20% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) severely limits the holding force.

3. Power loss vs temp

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.31

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of rare earth magnets.

Strengths

- They have constant strength, and over more than ten years their attraction force decreases symbolically – ~1% (in testing),

- Neodymium magnets are distinguished by exceptionally resistant to demagnetization caused by external magnetic fields,

- Thanks to the metallic finish, the surface of nickel, gold, or silver-plated gives an modern appearance,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a distinguishing feature,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of precise forming and optimizing to concrete needs,

- Key role in future technologies – they find application in HDD drives, electric motors, medical devices, also modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- We recommend casing - magnetic mount, due to difficulties in producing threads inside the magnet and complex forms.

- Possible danger related to microscopic parts of magnets pose a threat, in case of ingestion, which gains importance in the aspect of protecting the youngest. Furthermore, small components of these magnets are able to complicate diagnosis medical in case of swallowing.

- Due to complex production process, their price is relatively high,

Lifting parameters

Detachment force of the magnet in optimal conditions – what contributes to it?

- using a base made of high-permeability steel, acting as a magnetic yoke

- with a cross-section of at least 10 mm

- with an ground touching surface

- with total lack of distance (without coatings)

- during pulling in a direction perpendicular to the plane

- in neutral thermal conditions

What influences lifting capacity in practice

- Clearance – existence of any layer (rust, dirt, air) interrupts the magnetic circuit, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet exhibits much less (typically approx. 20-30% of nominal force).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Hardened steels may generate lower lifting capacity.

- Surface structure – the smoother and more polished the plate, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal environment – temperature increase results in weakening of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was carried out on a smooth plate of optimal thickness, under perpendicular forces, however under attempts to slide the magnet the holding force is lower. Additionally, even a slight gap between the magnet and the plate decreases the load capacity.

Safety rules for work with neodymium magnets

Immense force

Use magnets consciously. Their huge power can shock even experienced users. Be vigilant and respect their force.

Safe distance

Avoid bringing magnets near a wallet, laptop, or screen. The magnetism can destroy these devices and wipe information from cards.

Health Danger

Warning for patients: Powerful magnets disrupt electronics. Keep minimum 30 cm distance or request help to handle the magnets.

Compass and GPS

A powerful magnetic field negatively affects the functioning of compasses in smartphones and GPS navigation. Do not bring magnets near a smartphone to avoid damaging the sensors.

Swallowing risk

Strictly store magnets out of reach of children. Risk of swallowing is high, and the effects of magnets clamping inside the body are tragic.

Pinching danger

Watch your fingers. Two powerful magnets will snap together immediately with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!

Flammability

Machining of NdFeB material poses a fire hazard. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Operating temperature

Avoid heat. NdFeB magnets are susceptible to temperature. If you need resistance above 80°C, look for HT versions (H, SH, UH).

Material brittleness

Watch out for shards. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. We recommend safety glasses.

Allergy Warning

Nickel alert: The nickel-copper-nickel coating contains nickel. If redness happens, cease handling magnets and wear gloves.