SM 18x250 [2xM5] / N42 - magnetic separator

magnetic separator

Catalog no 130275

GTIN/EAN: 5906301812777

Diameter Ø

18 mm [±1 mm]

Height

250 mm [±1 mm]

Weight

0.01 g

Magnetic Flux

~ 5 400 Gauss [±5%]

553.50 ZŁ with VAT / pcs + price for transport

450.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

otherwise drop us a message through

inquiry form

the contact section.

Strength along with form of a neodymium magnet can be estimated with our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical parameters of the product - SM 18x250 [2xM5] / N42 - magnetic separator

Specification / characteristics - SM 18x250 [2xM5] / N42 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130275 |

| GTIN/EAN | 5906301812777 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 18 mm [±1 mm] |

| Height | 250 mm [±1 mm] |

| Weight | 0.01 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 5 400 Gauss [±5%] |

| Size/Mount Quantity | 2xM5 |

| Polarity | circumferential - 11 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N42

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.9-13.2 | kGs |

| remenance Br [min. - max.] ? | 1290-1320 | mT |

| coercivity bHc ? | 10.8-12.0 | kOe |

| coercivity bHc ? | 860-955 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 40-42 | BH max MGOe |

| energy density [min. - max.] ? | 318-334 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

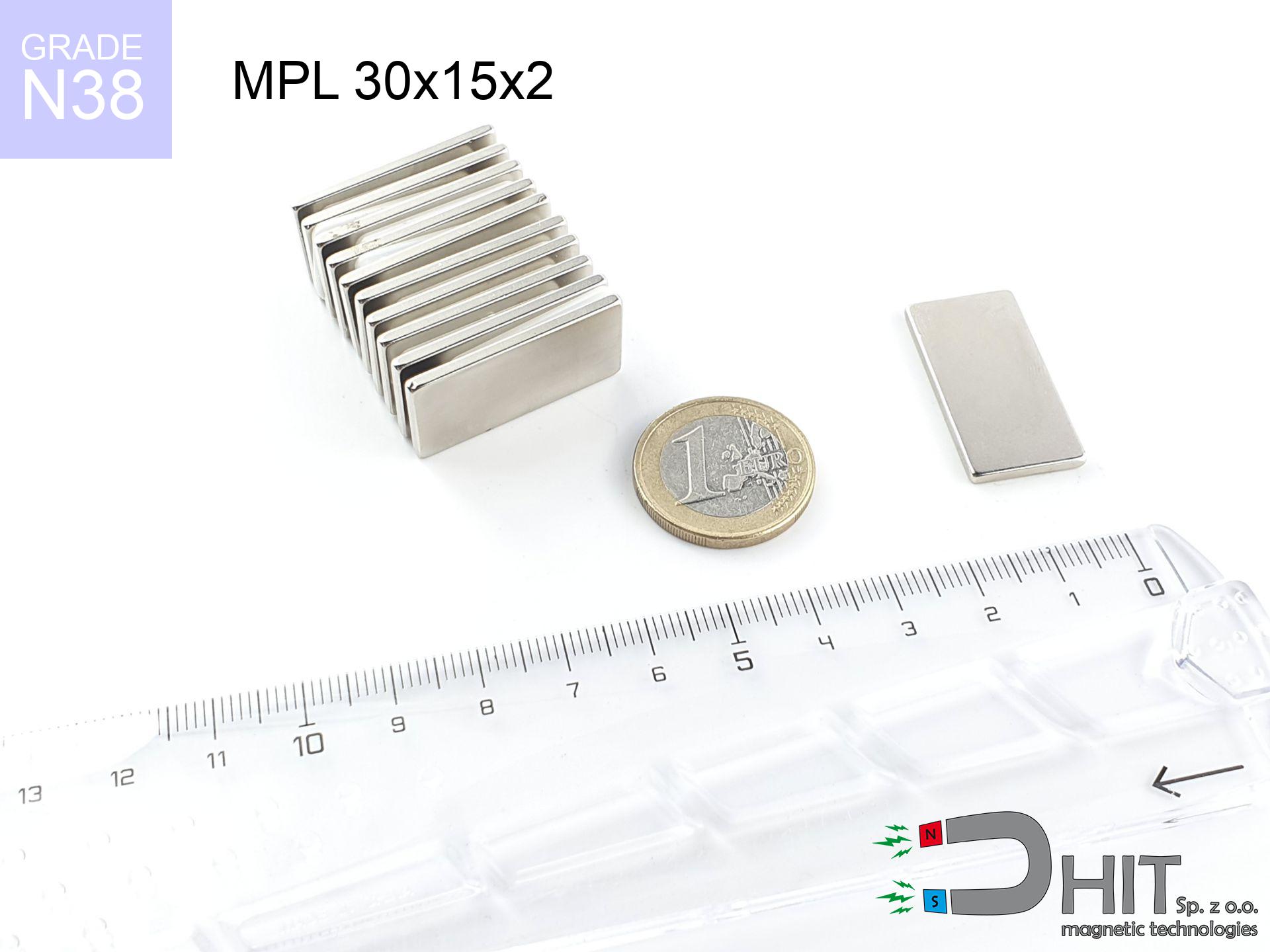

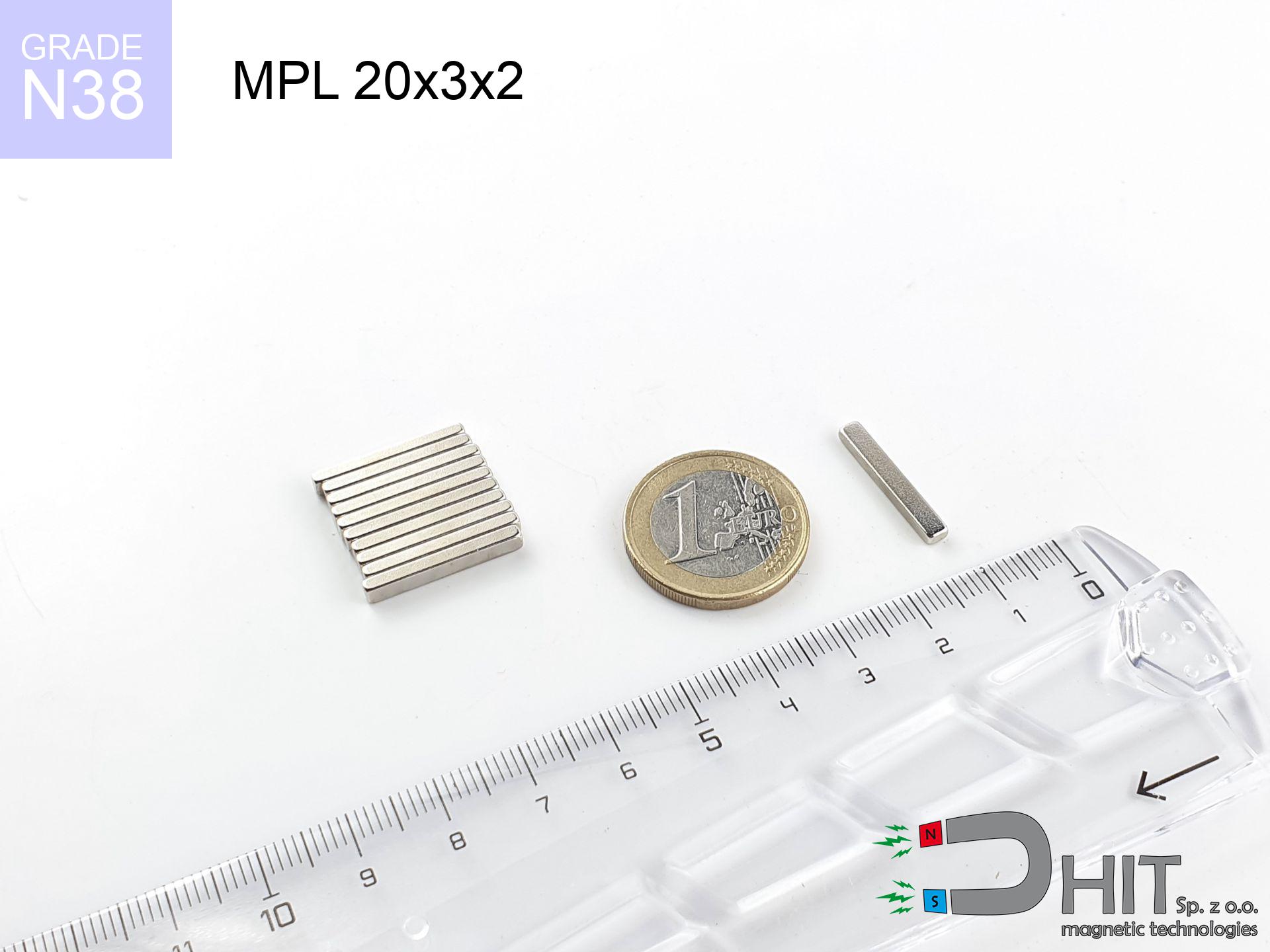

Table 1: Rod construction

SM 18x250 [2xM5] / N42

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 18 | mm |

| Total length | 250 | mm (L) |

| Active length | 214 | mm |

| Section count | 9 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~483 | g |

| Active area | 121 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 3.8 | kg (theor.) |

| Induction (surface) | ~5 400 | Gauss (Max) |

Chart 2: Field profile (9 sections)

Chart 3: Temperature performance

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros and cons of Nd2Fe14B magnets.

Pros

- They retain magnetic properties for almost 10 years – the loss is just ~1% (according to analyses),

- Neodymium magnets prove to be remarkably resistant to demagnetization caused by external magnetic fields,

- The use of an refined layer of noble metals (nickel, gold, silver) causes the element to look better,

- Magnetic induction on the working layer of the magnet turns out to be impressive,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Thanks to versatility in shaping and the ability to modify to complex applications,

- Versatile presence in modern industrial fields – they are utilized in hard drives, motor assemblies, precision medical tools, also complex engineering applications.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Disadvantages

- To avoid cracks under impact, we recommend using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in creating threads and complex forms in magnets, we propose using a housing - magnetic holder.

- Potential hazard to health – tiny shards of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. Additionally, small elements of these devices can be problematic in diagnostics medical after entering the body.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what affects it?

- with the contact of a sheet made of low-carbon steel, guaranteeing full magnetic saturation

- whose thickness equals approx. 10 mm

- characterized by lack of roughness

- with zero gap (no impurities)

- during detachment in a direction perpendicular to the mounting surface

- at room temperature

What influences lifting capacity in practice

- Distance (between the magnet and the plate), because even a microscopic clearance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Loading method – declared lifting capacity refers to detachment vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of maximum force).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material composition – not every steel reacts the same. Alloy additives weaken the interaction with the magnet.

- Base smoothness – the smoother and more polished the surface, the larger the contact zone and higher the lifting capacity. Unevenness acts like micro-gaps.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Holding force was checked on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under parallel forces the lifting capacity is smaller. Moreover, even a slight gap between the magnet’s surface and the plate decreases the holding force.

Warnings

Magnet fragility

Neodymium magnets are ceramic materials, which means they are fragile like glass. Collision of two magnets leads to them breaking into small pieces.

Bone fractures

Protect your hands. Two powerful magnets will snap together instantly with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

Danger to the youngest

Always keep magnets away from children. Risk of swallowing is significant, and the effects of magnets clamping inside the body are fatal.

Phone sensors

A strong magnetic field interferes with the operation of compasses in phones and GPS navigation. Maintain magnets close to a smartphone to prevent breaking the sensors.

Skin irritation risks

It is widely known that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, refrain from direct skin contact or select encased magnets.

Operating temperature

Keep cool. NdFeB magnets are sensitive to heat. If you require operation above 80°C, inquire about HT versions (H, SH, UH).

Handling guide

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or injure your hand. Be predictive.

Mechanical processing

Powder generated during machining of magnets is combustible. Do not drill into magnets without proper cooling and knowledge.

Electronic devices

Very strong magnetic fields can destroy records on payment cards, HDDs, and other magnetic media. Maintain a gap of at least 10 cm.

Pacemakers

Health Alert: Strong magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

![Separation magnetic rod SM 18x250 [2xM5] / N42 Separation magnetic rod SM 18x250 [2xM5] / N42](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 18x250 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x250-2xm5-raz.jpg)

![SM 25x200 [2xM8] / N42 - magnetic separator SM 25x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x200-2xm8-dos.jpg)

![UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 29x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-29x8-m4-gw-duf.jpg)