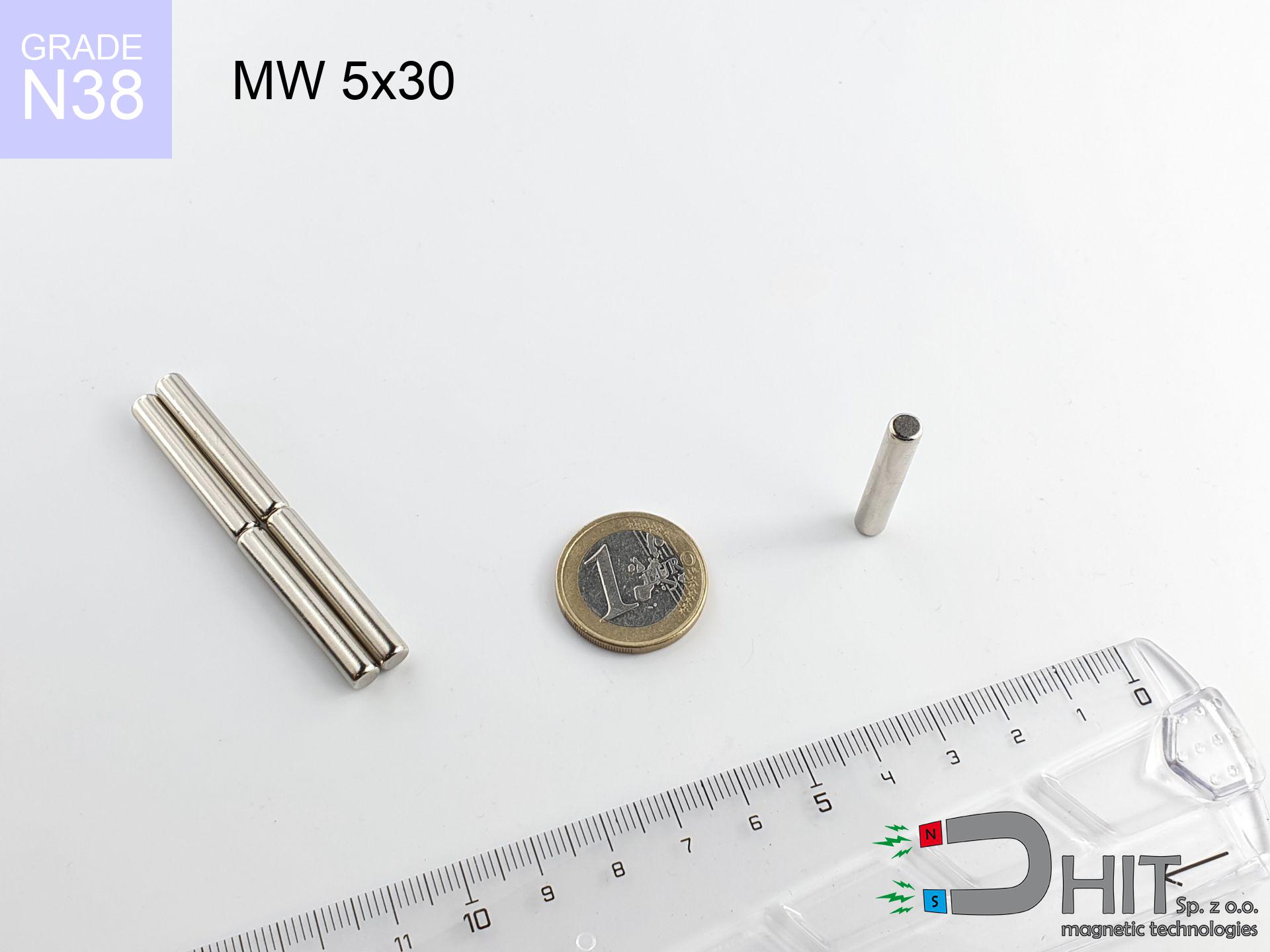

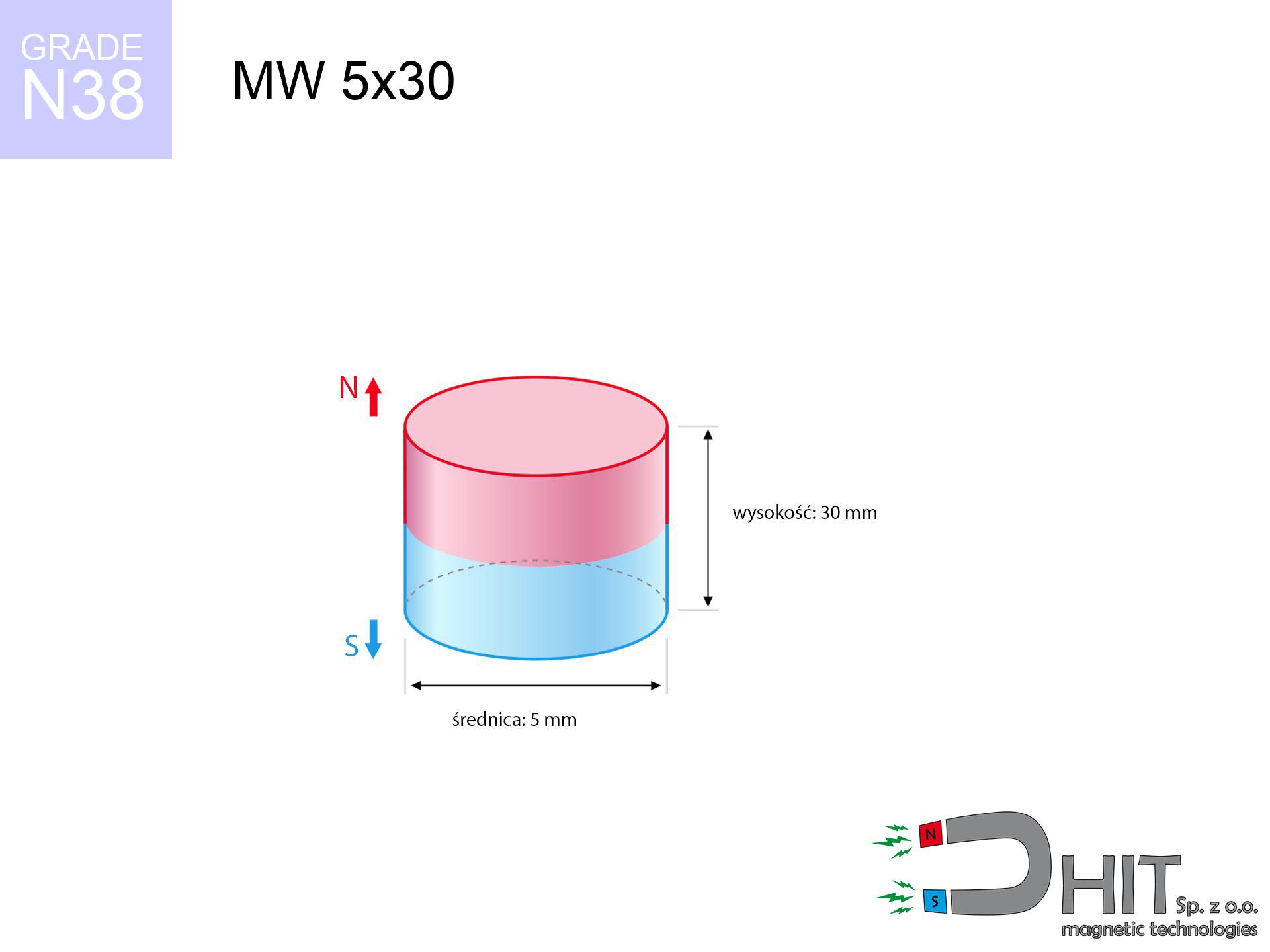

MW 5x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010088

GTIN/EAN: 5906301810872

Diameter Ø

5 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

4.42 g

Magnetization Direction

↑ axial

Load capacity

0.45 kg / 4.40 N

Magnetic Induction

616.32 mT / 6163 Gs

Coating

[NiCuNi] Nickel

3.57 ZŁ with VAT / pcs + price for transport

2.90 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

alternatively let us know through

inquiry form

our website.

Parameters along with form of a neodymium magnet can be analyzed on our

force calculator.

Orders submitted before 14:00 will be dispatched today!

Product card - MW 5x30 / N38 - cylindrical magnet

Specification / characteristics - MW 5x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010088 |

| GTIN/EAN | 5906301810872 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 4.42 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.45 kg / 4.40 N |

| Magnetic Induction ~ ? | 616.32 mT / 6163 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - report

These information represent the direct effect of a physical analysis. Values rely on algorithms for the material Nd2Fe14B. Actual conditions may differ from theoretical values. Treat these calculations as a reference point when designing systems.

Table 1: Static pull force (pull vs distance) - power drop

MW 5x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6154 Gs

615.4 mT

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

weak grip |

| 1 mm |

3877 Gs

387.7 mT

|

0.18 kg / 0.39 LBS

178.6 g / 1.8 N

|

weak grip |

| 2 mm |

2308 Gs

230.8 mT

|

0.06 kg / 0.14 LBS

63.3 g / 0.6 N

|

weak grip |

| 3 mm |

1419 Gs

141.9 mT

|

0.02 kg / 0.05 LBS

23.9 g / 0.2 N

|

weak grip |

| 5 mm |

639 Gs

63.9 mT

|

0.00 kg / 0.01 LBS

4.8 g / 0.0 N

|

weak grip |

| 10 mm |

173 Gs

17.3 mT

|

0.00 kg / 0.00 LBS

0.4 g / 0.0 N

|

weak grip |

| 15 mm |

75 Gs

7.5 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

weak grip |

| 20 mm |

40 Gs

4.0 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

16 Gs

1.6 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding hold (wall)

MW 5x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.09 kg / 0.20 LBS

90.0 g / 0.9 N

|

| 1 mm | Stal (~0.2) |

0.04 kg / 0.08 LBS

36.0 g / 0.4 N

|

| 2 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 3 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 5x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.14 kg / 0.30 LBS

135.0 g / 1.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.09 kg / 0.20 LBS

90.0 g / 0.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.05 kg / 0.10 LBS

45.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.23 kg / 0.50 LBS

225.0 g / 2.2 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 5x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.05 kg / 0.10 LBS

45.0 g / 0.4 N

|

| 1 mm |

|

0.11 kg / 0.25 LBS

112.5 g / 1.1 N

|

| 2 mm |

|

0.23 kg / 0.50 LBS

225.0 g / 2.2 N

|

| 3 mm |

|

0.34 kg / 0.74 LBS

337.5 g / 3.3 N

|

| 5 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

| 10 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

| 11 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

| 12 mm |

|

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MW 5x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.45 kg / 0.99 LBS

450.0 g / 4.4 N

|

OK |

| 40 °C | -2.2% |

0.44 kg / 0.97 LBS

440.1 g / 4.3 N

|

OK |

| 60 °C | -4.4% |

0.43 kg / 0.95 LBS

430.2 g / 4.2 N

|

OK |

| 80 °C | -6.6% |

0.42 kg / 0.93 LBS

420.3 g / 4.1 N

|

|

| 100 °C | -28.8% |

0.32 kg / 0.71 LBS

320.4 g / 3.1 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 5x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

4.58 kg / 10.11 LBS

6 170 Gs

|

0.69 kg / 1.52 LBS

688 g / 6.7 N

|

N/A |

| 1 mm |

2.98 kg / 6.57 LBS

9 927 Gs

|

0.45 kg / 0.99 LBS

447 g / 4.4 N

|

2.68 kg / 5.92 LBS

~0 Gs

|

| 2 mm |

1.82 kg / 4.01 LBS

7 755 Gs

|

0.27 kg / 0.60 LBS

273 g / 2.7 N

|

1.64 kg / 3.61 LBS

~0 Gs

|

| 3 mm |

1.08 kg / 2.39 LBS

5 981 Gs

|

0.16 kg / 0.36 LBS

162 g / 1.6 N

|

0.97 kg / 2.15 LBS

~0 Gs

|

| 5 mm |

0.39 kg / 0.86 LBS

3 595 Gs

|

0.06 kg / 0.13 LBS

59 g / 0.6 N

|

0.35 kg / 0.78 LBS

~0 Gs

|

| 10 mm |

0.05 kg / 0.11 LBS

1 278 Gs

|

0.01 kg / 0.02 LBS

7 g / 0.1 N

|

0.04 kg / 0.10 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 LBS

346 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

49 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

32 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

22 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

9 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MW 5x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 5x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

10.18 km/h

(2.83 m/s)

|

0.02 J | |

| 30 mm |

17.63 km/h

(4.90 m/s)

|

0.05 J | |

| 50 mm |

22.75 km/h

(6.32 m/s)

|

0.09 J | |

| 100 mm |

32.18 km/h

(8.94 m/s)

|

0.18 J |

Table 9: Corrosion resistance

MW 5x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 5x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 468 Mx | 14.7 µWb |

| Pc Coefficient | 1.59 | High (Stable) |

Table 11: Submerged application

MW 5x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.45 kg | Standard |

| Water (riverbed) |

0.52 kg

(+0.07 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical wall, the magnet retains just a fraction of its nominal pull.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) severely limits the holding force.

3. Thermal stability

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.59

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Pros and cons of Nd2Fe14B magnets.

Benefits

- They retain magnetic properties for nearly 10 years – the loss is just ~1% (according to analyses),

- Magnets very well defend themselves against demagnetization caused by ambient magnetic noise,

- By applying a reflective coating of nickel, the element acquires an professional look,

- Magnetic induction on the surface of the magnet is exceptional,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, enabling functioning at temperatures reaching 230°C and above...

- Due to the possibility of free shaping and adaptation to unique requirements, NdFeB magnets can be produced in a variety of shapes and sizes, which makes them more universal,

- Huge importance in future technologies – they are used in hard drives, drive modules, medical devices, as well as other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- At strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of producing threads in the magnet and complex shapes - preferred is cover - mounting mechanism.

- Health risk to health – tiny shards of magnets pose a threat, in case of ingestion, which becomes key in the context of child health protection. Additionally, tiny parts of these magnets can disrupt the diagnostic process medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting force for a neodymium magnet – what it depends on?

- on a block made of structural steel, optimally conducting the magnetic field

- possessing a massiveness of minimum 10 mm to avoid saturation

- characterized by smoothness

- without any air gap between the magnet and steel

- under perpendicular force direction (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in practice – influencing factors

- Distance – the presence of any layer (rust, dirt, gap) acts as an insulator, which lowers power rapidly (even by 50% at 0.5 mm).

- Pull-off angle – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of generating force.

- Material composition – not every steel attracts identically. High carbon content worsen the interaction with the magnet.

- Plate texture – smooth surfaces ensure maximum contact, which increases force. Uneven metal reduce efficiency.

- Heat – NdFeB sinters have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures gain strength (up to a certain limit).

Lifting capacity testing was performed on plates with a smooth surface of optimal thickness, under perpendicular forces, whereas under shearing force the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet and the plate decreases the lifting capacity.

Precautions when working with NdFeB magnets

Do not give to children

Only for adults. Small elements can be swallowed, causing serious injuries. Keep away from kids and pets.

Crushing risk

Mind your fingers. Two powerful magnets will join immediately with a force of massive weight, crushing everything in their path. Be careful!

Eye protection

Despite the nickel coating, the material is delicate and cannot withstand shocks. Do not hit, as the magnet may shatter into hazardous fragments.

Demagnetization risk

Monitor thermal conditions. Heating the magnet above 80 degrees Celsius will permanently weaken its properties and strength.

Compass and GPS

Navigation devices and mobile phones are highly susceptible to magnetism. Close proximity with a strong magnet can decalibrate the sensors in your phone.

Do not underestimate power

Exercise caution. Rare earth magnets act from a long distance and snap with huge force, often faster than you can move away.

Medical interference

Medical warning: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Protect data

Avoid bringing magnets near a wallet, computer, or TV. The magnetic field can permanently damage these devices and wipe information from cards.

Skin irritation risks

Nickel alert: The nickel-copper-nickel coating consists of nickel. If skin irritation happens, immediately stop working with magnets and wear gloves.

Fire warning

Mechanical processing of neodymium magnets poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

![SM 18x100 [2xM5] / N42 - magnetic separator SM 18x100 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x100-2xm5-pem.jpg)

![SM 32x250 [2xM8] / N52 - magnetic separator SM 32x250 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-guf.jpg)