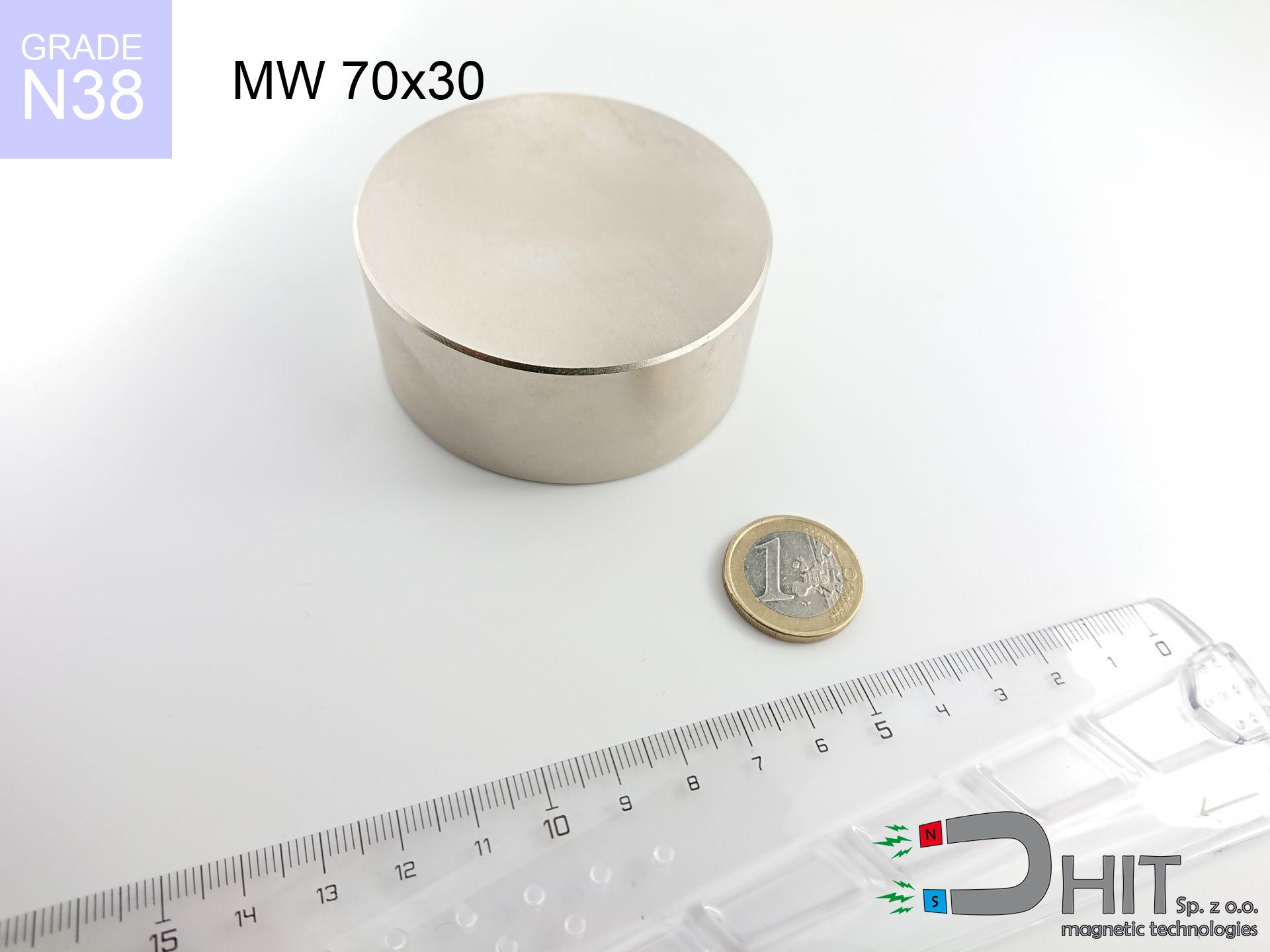

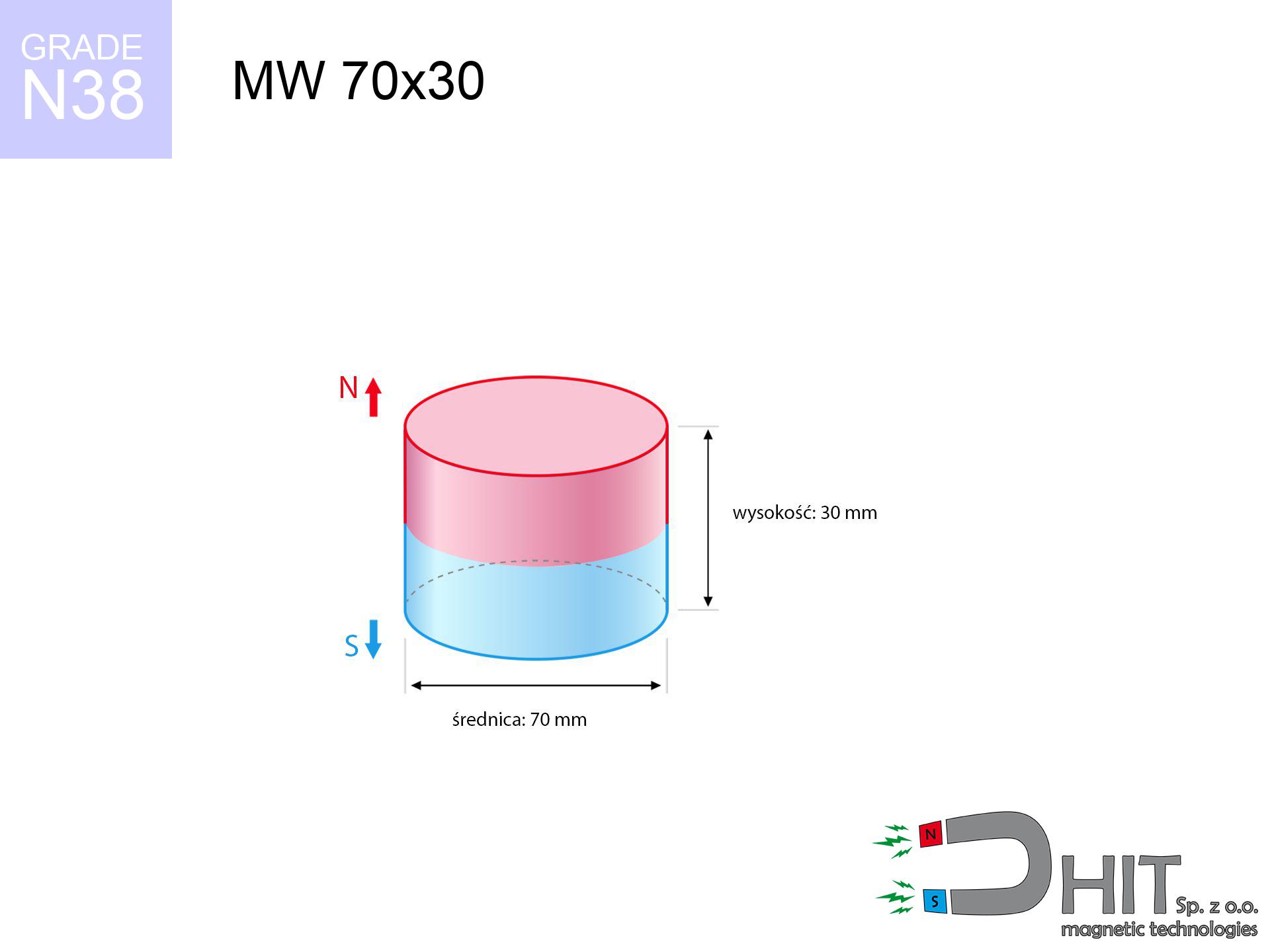

MW 70x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010096

GTIN/EAN: 5906301810957

Diameter Ø

70 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

865.9 g

Magnetization Direction

↑ axial

Load capacity

144.18 kg / 1414.37 N

Magnetic Induction

403.43 mT / 4034 Gs

Coating

[NiCuNi] Nickel

317.17 ZŁ with VAT / pcs + price for transport

257.86 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise contact us using

contact form

the contact form page.

Parameters along with appearance of neodymium magnets can be tested on our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical data - MW 70x30 / N38 - cylindrical magnet

Specification / characteristics - MW 70x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010096 |

| GTIN/EAN | 5906301810957 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 70 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 865.9 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 144.18 kg / 1414.37 N |

| Magnetic Induction ~ ? | 403.43 mT / 4034 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the magnet - technical parameters

The following values constitute the direct effect of a physical analysis. Results are based on models for the class Nd2Fe14B. Real-world performance may differ from theoretical values. Use these calculations as a supplementary guide when designing systems.

Table 1: Static force (force vs distance) - characteristics

MW 70x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4034 Gs

403.4 mT

|

144.18 kg / 317.86 lbs

144180.0 g / 1414.4 N

|

dangerous! |

| 1 mm |

3934 Gs

393.4 mT

|

137.11 kg / 302.27 lbs

137108.9 g / 1345.0 N

|

dangerous! |

| 2 mm |

3830 Gs

383.0 mT

|

129.96 kg / 286.52 lbs

129962.6 g / 1274.9 N

|

dangerous! |

| 3 mm |

3724 Gs

372.4 mT

|

122.86 kg / 270.87 lbs

122863.7 g / 1205.3 N

|

dangerous! |

| 5 mm |

3507 Gs

350.7 mT

|

108.99 kg / 240.28 lbs

108989.8 g / 1069.2 N

|

dangerous! |

| 10 mm |

2963 Gs

296.3 mT

|

77.77 kg / 171.46 lbs

77773.1 g / 763.0 N

|

dangerous! |

| 15 mm |

2452 Gs

245.2 mT

|

53.26 kg / 117.41 lbs

53257.6 g / 522.5 N

|

dangerous! |

| 20 mm |

2003 Gs

200.3 mT

|

35.55 kg / 78.38 lbs

35554.2 g / 348.8 N

|

dangerous! |

| 30 mm |

1321 Gs

132.1 mT

|

15.45 kg / 34.06 lbs

15450.6 g / 151.6 N

|

dangerous! |

| 50 mm |

601 Gs

60.1 mT

|

3.20 kg / 7.05 lbs

3199.7 g / 31.4 N

|

medium risk |

Table 2: Slippage hold (vertical surface)

MW 70x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

28.84 kg / 63.57 lbs

28836.0 g / 282.9 N

|

| 1 mm | Stal (~0.2) |

27.42 kg / 60.46 lbs

27422.0 g / 269.0 N

|

| 2 mm | Stal (~0.2) |

25.99 kg / 57.30 lbs

25992.0 g / 255.0 N

|

| 3 mm | Stal (~0.2) |

24.57 kg / 54.17 lbs

24572.0 g / 241.1 N

|

| 5 mm | Stal (~0.2) |

21.80 kg / 48.06 lbs

21798.0 g / 213.8 N

|

| 10 mm | Stal (~0.2) |

15.55 kg / 34.29 lbs

15554.0 g / 152.6 N

|

| 15 mm | Stal (~0.2) |

10.65 kg / 23.48 lbs

10652.0 g / 104.5 N

|

| 20 mm | Stal (~0.2) |

7.11 kg / 15.67 lbs

7110.0 g / 69.7 N

|

| 30 mm | Stal (~0.2) |

3.09 kg / 6.81 lbs

3090.0 g / 30.3 N

|

| 50 mm | Stal (~0.2) |

0.64 kg / 1.41 lbs

640.0 g / 6.3 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 70x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

43.25 kg / 95.36 lbs

43254.0 g / 424.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

28.84 kg / 63.57 lbs

28836.0 g / 282.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

14.42 kg / 31.79 lbs

14418.0 g / 141.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

72.09 kg / 158.93 lbs

72090.0 g / 707.2 N

|

Table 4: Steel thickness (saturation) - power losses

MW 70x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

4.81 kg / 10.60 lbs

4806.0 g / 47.1 N

|

| 1 mm |

|

12.01 kg / 26.49 lbs

12015.0 g / 117.9 N

|

| 2 mm |

|

24.03 kg / 52.98 lbs

24030.0 g / 235.7 N

|

| 3 mm |

|

36.05 kg / 79.47 lbs

36045.0 g / 353.6 N

|

| 5 mm |

|

60.08 kg / 132.44 lbs

60075.0 g / 589.3 N

|

| 10 mm |

|

120.15 kg / 264.89 lbs

120150.0 g / 1178.7 N

|

| 11 mm |

|

132.17 kg / 291.37 lbs

132165.0 g / 1296.5 N

|

| 12 mm |

|

144.18 kg / 317.86 lbs

144180.0 g / 1414.4 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MW 70x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

144.18 kg / 317.86 lbs

144180.0 g / 1414.4 N

|

OK |

| 40 °C | -2.2% |

141.01 kg / 310.87 lbs

141008.0 g / 1383.3 N

|

OK |

| 60 °C | -4.4% |

137.84 kg / 303.88 lbs

137836.1 g / 1352.2 N

|

|

| 80 °C | -6.6% |

134.66 kg / 296.88 lbs

134664.1 g / 1321.1 N

|

|

| 100 °C | -28.8% |

102.66 kg / 226.32 lbs

102656.2 g / 1007.1 N

|

Table 6: Two magnets (attraction) - forces in the system

MW 70x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

386.08 kg / 851.15 lbs

5 354 Gs

|

57.91 kg / 127.67 lbs

57911 g / 568.1 N

|

N/A |

| 1 mm |

376.71 kg / 830.51 lbs

7 969 Gs

|

56.51 kg / 124.58 lbs

56507 g / 554.3 N

|

339.04 kg / 747.46 lbs

~0 Gs

|

| 2 mm |

367.14 kg / 809.41 lbs

7 867 Gs

|

55.07 kg / 121.41 lbs

55071 g / 540.2 N

|

330.43 kg / 728.47 lbs

~0 Gs

|

| 3 mm |

357.57 kg / 788.30 lbs

7 764 Gs

|

53.63 kg / 118.24 lbs

53635 g / 526.2 N

|

321.81 kg / 709.47 lbs

~0 Gs

|

| 5 mm |

338.48 kg / 746.21 lbs

7 554 Gs

|

50.77 kg / 111.93 lbs

50772 g / 498.1 N

|

304.63 kg / 671.59 lbs

~0 Gs

|

| 10 mm |

291.85 kg / 643.41 lbs

7 014 Gs

|

43.78 kg / 96.51 lbs

43777 g / 429.5 N

|

262.66 kg / 579.07 lbs

~0 Gs

|

| 20 mm |

208.26 kg / 459.13 lbs

5 925 Gs

|

31.24 kg / 68.87 lbs

31238 g / 306.4 N

|

187.43 kg / 413.21 lbs

~0 Gs

|

| 50 mm |

62.81 kg / 138.47 lbs

3 254 Gs

|

9.42 kg / 20.77 lbs

9421 g / 92.4 N

|

56.53 kg / 124.62 lbs

~0 Gs

|

| 60 mm |

41.37 kg / 91.21 lbs

2 641 Gs

|

6.21 kg / 13.68 lbs

6206 g / 60.9 N

|

37.24 kg / 82.09 lbs

~0 Gs

|

| 70 mm |

27.41 kg / 60.43 lbs

2 150 Gs

|

4.11 kg / 9.06 lbs

4112 g / 40.3 N

|

24.67 kg / 54.39 lbs

~0 Gs

|

| 80 mm |

18.35 kg / 40.46 lbs

1 759 Gs

|

2.75 kg / 6.07 lbs

2753 g / 27.0 N

|

16.52 kg / 36.41 lbs

~0 Gs

|

| 90 mm |

12.45 kg / 27.44 lbs

1 449 Gs

|

1.87 kg / 4.12 lbs

1867 g / 18.3 N

|

11.20 kg / 24.70 lbs

~0 Gs

|

| 100 mm |

8.57 kg / 18.89 lbs

1 202 Gs

|

1.29 kg / 2.83 lbs

1285 g / 12.6 N

|

7.71 kg / 17.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 70x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 34.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 27.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 21.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 16.5 cm |

| Remote | 50 Gs (5.0 mT) | 15.0 cm |

| Payment card | 400 Gs (40.0 mT) | 6.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 5.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 70x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.84 km/h

(4.68 m/s)

|

9.47 J | |

| 30 mm |

24.00 km/h

(6.67 m/s)

|

19.25 J | |

| 50 mm |

29.50 km/h

(8.19 m/s)

|

29.07 J | |

| 100 mm |

41.18 km/h

(11.44 m/s)

|

56.66 J |

Table 9: Corrosion resistance

MW 70x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 70x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 159 225 Mx | 1592.3 µWb |

| Pc Coefficient | 0.53 | Low (Flat) |

Table 11: Physics of underwater searching

MW 70x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 144.18 kg | Standard |

| Water (riverbed) |

165.09 kg

(+20.91 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds merely ~20% of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.53

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Advantages

- They do not lose strength, even after nearly 10 years – the drop in power is only ~1% (according to tests),

- They feature excellent resistance to weakening of magnetic properties due to opposing magnetic fields,

- By covering with a lustrous layer of gold, the element acquires an elegant look,

- Magnets possess impressive magnetic induction on the active area,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to modularity in shaping and the ability to adapt to complex applications,

- Wide application in advanced technology sectors – they are utilized in hard drives, brushless drives, medical devices, and other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a strong case, which not only secures them against impacts but also increases their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- Due to limitations in creating threads and complicated forms in magnets, we propose using cover - magnetic mount.

- Possible danger related to microscopic parts of magnets are risky, when accidentally swallowed, which becomes key in the context of child health protection. Furthermore, small elements of these magnets are able to complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Lifting parameters

Maximum magnetic pulling force – what it depends on?

- using a sheet made of low-carbon steel, functioning as a circuit closing element

- possessing a massiveness of min. 10 mm to ensure full flux closure

- with a plane perfectly flat

- with zero gap (without impurities)

- for force applied at a right angle (in the magnet axis)

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in real conditions – factors

- Distance – existence of any layer (rust, tape, gap) acts as an insulator, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Angle of force application – highest force is obtained only during pulling at a 90° angle. The force required to slide of the magnet along the plate is standardly many times smaller (approx. 1/5 of the lifting capacity).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Chemical composition of the base – mild steel gives the best results. Alloy admixtures lower magnetic properties and holding force.

- Surface quality – the smoother and more polished the plate, the better the adhesion and stronger the hold. Roughness creates an air distance.

- Operating temperature – NdFeB sinters have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was determined with the use of a polished steel plate of suitable thickness (min. 20 mm), under vertically applied force, in contrast under shearing force the load capacity is reduced by as much as fivefold. In addition, even a small distance between the magnet’s surface and the plate reduces the holding force.

Safety rules for work with neodymium magnets

Danger to the youngest

Always keep magnets away from children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are life-threatening.

Crushing force

Large magnets can smash fingers in a fraction of a second. Never place your hand between two strong magnets.

Health Danger

Health Alert: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have medical devices.

Cards and drives

Device Safety: Neodymium magnets can damage data carriers and sensitive devices (pacemakers, medical aids, timepieces).

Shattering risk

Despite metallic appearance, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Sensitization to coating

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction appears, immediately stop working with magnets and use protective gear.

Fire risk

Dust created during cutting of magnets is flammable. Do not drill into magnets unless you are an expert.

Magnetic interference

Navigation devices and smartphones are extremely sensitive to magnetism. Close proximity with a strong magnet can permanently damage the internal compass in your phone.

Immense force

Before use, read the rules. Uncontrolled attraction can destroy the magnet or hurt your hand. Think ahead.

Permanent damage

Do not overheat. Neodymium magnets are susceptible to temperature. If you require operation above 80°C, ask us about HT versions (H, SH, UH).

![AM szekla [M10] - magnetic accessories AM szekla [M10] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-szekla-m10-zeh.jpg)