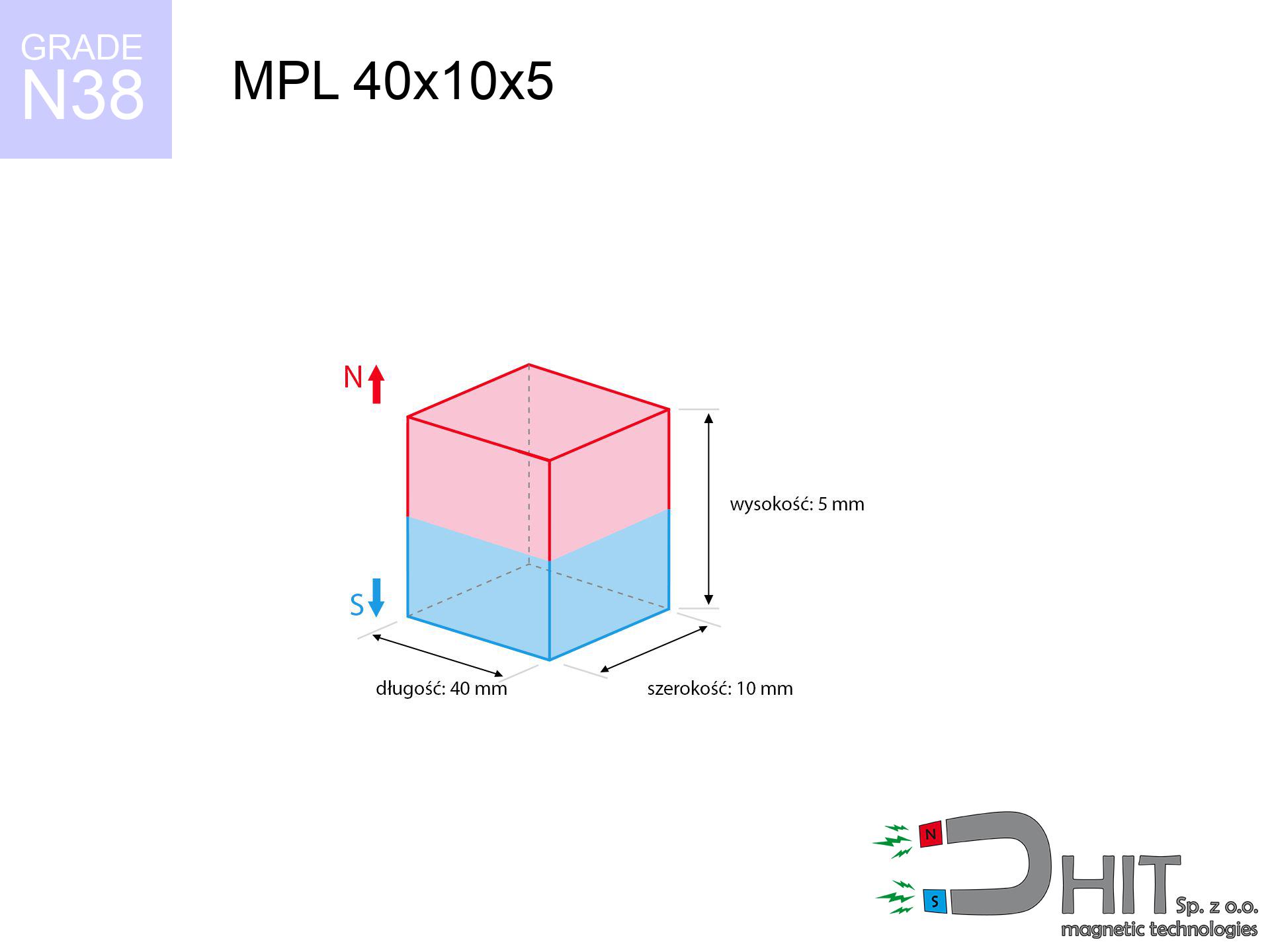

MPL 40x10x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020152

GTIN/EAN: 5906301811589

length

40 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

15 g

Magnetization Direction

↑ axial

Load capacity

11.85 kg / 116.27 N

Magnetic Induction

321.37 mT / 3214 Gs

Coating

[NiCuNi] Nickel

6.03 ZŁ with VAT / pcs + price for transport

4.90 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

otherwise get in touch through

contact form

our website.

Parameters as well as shape of neodymium magnets can be calculated with our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MPL 40x10x5 / N38 - lamellar magnet

Specification / characteristics - MPL 40x10x5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020152 |

| GTIN/EAN | 5906301811589 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 15 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 11.85 kg / 116.27 N |

| Magnetic Induction ~ ? | 321.37 mT / 3214 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the magnet - report

The following values are the outcome of a engineering analysis. Results are based on models for the class Nd2Fe14B. Actual conditions may differ. Use these calculations as a preliminary roadmap when designing systems.

Table 1: Static force (force vs distance) - characteristics

MPL 40x10x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3212 Gs

321.2 mT

|

11.85 kg / 26.12 pounds

11850.0 g / 116.2 N

|

dangerous! |

| 1 mm |

2791 Gs

279.1 mT

|

8.95 kg / 19.73 pounds

8947.7 g / 87.8 N

|

warning |

| 2 mm |

2358 Gs

235.8 mT

|

6.38 kg / 14.08 pounds

6384.9 g / 62.6 N

|

warning |

| 3 mm |

1965 Gs

196.5 mT

|

4.43 kg / 9.77 pounds

4432.4 g / 43.5 N

|

warning |

| 5 mm |

1360 Gs

136.0 mT

|

2.12 kg / 4.68 pounds

2122.9 g / 20.8 N

|

warning |

| 10 mm |

615 Gs

61.5 mT

|

0.43 kg / 0.96 pounds

434.1 g / 4.3 N

|

weak grip |

| 15 mm |

329 Gs

32.9 mT

|

0.12 kg / 0.27 pounds

124.5 g / 1.2 N

|

weak grip |

| 20 mm |

195 Gs

19.5 mT

|

0.04 kg / 0.10 pounds

43.9 g / 0.4 N

|

weak grip |

| 30 mm |

83 Gs

8.3 mT

|

0.01 kg / 0.02 pounds

8.0 g / 0.1 N

|

weak grip |

| 50 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 pounds

0.6 g / 0.0 N

|

weak grip |

Table 2: Shear hold (vertical surface)

MPL 40x10x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.37 kg / 5.22 pounds

2370.0 g / 23.2 N

|

| 1 mm | Stal (~0.2) |

1.79 kg / 3.95 pounds

1790.0 g / 17.6 N

|

| 2 mm | Stal (~0.2) |

1.28 kg / 2.81 pounds

1276.0 g / 12.5 N

|

| 3 mm | Stal (~0.2) |

0.89 kg / 1.95 pounds

886.0 g / 8.7 N

|

| 5 mm | Stal (~0.2) |

0.42 kg / 0.93 pounds

424.0 g / 4.2 N

|

| 10 mm | Stal (~0.2) |

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.05 pounds

24.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 pounds

8.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 40x10x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

3.55 kg / 7.84 pounds

3555.0 g / 34.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.37 kg / 5.22 pounds

2370.0 g / 23.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.19 kg / 2.61 pounds

1185.0 g / 11.6 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

5.93 kg / 13.06 pounds

5925.0 g / 58.1 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 40x10x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.59 kg / 1.31 pounds

592.5 g / 5.8 N

|

| 1 mm |

|

1.48 kg / 3.27 pounds

1481.3 g / 14.5 N

|

| 2 mm |

|

2.96 kg / 6.53 pounds

2962.5 g / 29.1 N

|

| 3 mm |

|

4.44 kg / 9.80 pounds

4443.8 g / 43.6 N

|

| 5 mm |

|

7.41 kg / 16.33 pounds

7406.3 g / 72.7 N

|

| 10 mm |

|

11.85 kg / 26.12 pounds

11850.0 g / 116.2 N

|

| 11 mm |

|

11.85 kg / 26.12 pounds

11850.0 g / 116.2 N

|

| 12 mm |

|

11.85 kg / 26.12 pounds

11850.0 g / 116.2 N

|

Table 5: Thermal resistance (material behavior) - power drop

MPL 40x10x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

11.85 kg / 26.12 pounds

11850.0 g / 116.2 N

|

OK |

| 40 °C | -2.2% |

11.59 kg / 25.55 pounds

11589.3 g / 113.7 N

|

OK |

| 60 °C | -4.4% |

11.33 kg / 24.98 pounds

11328.6 g / 111.1 N

|

|

| 80 °C | -6.6% |

11.07 kg / 24.40 pounds

11067.9 g / 108.6 N

|

|

| 100 °C | -28.8% |

8.44 kg / 18.60 pounds

8437.2 g / 82.8 N

|

Table 6: Two magnets (attraction) - field collision

MPL 40x10x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

25.44 kg / 56.10 pounds

4 569 Gs

|

3.82 kg / 8.41 pounds

3817 g / 37.4 N

|

N/A |

| 1 mm |

22.33 kg / 49.22 pounds

6 018 Gs

|

3.35 kg / 7.38 pounds

3349 g / 32.9 N

|

20.09 kg / 44.30 pounds

~0 Gs

|

| 2 mm |

19.21 kg / 42.36 pounds

5 582 Gs

|

2.88 kg / 6.35 pounds

2882 g / 28.3 N

|

17.29 kg / 38.12 pounds

~0 Gs

|

| 3 mm |

16.31 kg / 35.96 pounds

5 144 Gs

|

2.45 kg / 5.39 pounds

2447 g / 24.0 N

|

14.68 kg / 32.36 pounds

~0 Gs

|

| 5 mm |

11.45 kg / 25.23 pounds

4 309 Gs

|

1.72 kg / 3.78 pounds

1717 g / 16.8 N

|

10.30 kg / 22.71 pounds

~0 Gs

|

| 10 mm |

4.56 kg / 10.05 pounds

2 719 Gs

|

0.68 kg / 1.51 pounds

684 g / 6.7 N

|

4.10 kg / 9.04 pounds

~0 Gs

|

| 20 mm |

0.93 kg / 2.05 pounds

1 230 Gs

|

0.14 kg / 0.31 pounds

140 g / 1.4 N

|

0.84 kg / 1.85 pounds

~0 Gs

|

| 50 mm |

0.04 kg / 0.08 pounds

249 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.03 kg / 0.08 pounds

~0 Gs

|

| 60 mm |

0.02 kg / 0.04 pounds

167 Gs

|

0.00 kg / 0.01 pounds

3 g / 0.0 N

|

0.02 kg / 0.03 pounds

~0 Gs

|

| 70 mm |

0.01 kg / 0.02 pounds

116 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.01 pounds

84 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 pounds

62 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

48 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MPL 40x10x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 9.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 7.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.5 cm |

| Remote | 50 Gs (5.0 mT) | 4.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MPL 40x10x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.99 km/h

(8.05 m/s)

|

0.49 J | |

| 30 mm |

49.12 km/h

(13.64 m/s)

|

1.40 J | |

| 50 mm |

63.39 km/h

(17.61 m/s)

|

2.33 J | |

| 100 mm |

89.64 km/h

(24.90 m/s)

|

4.65 J |

Table 9: Surface protection spec

MPL 40x10x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 40x10x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 11 419 Mx | 114.2 µWb |

| Pc Coefficient | 0.31 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 40x10x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 11.85 kg | Standard |

| Water (riverbed) |

13.57 kg

(+1.72 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical wall, the magnet holds merely a fraction of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly reduces the holding force.

3. Power loss vs temp

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.31

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of rare earth magnets.

Advantages

- They have stable power, and over nearly ten years their performance decreases symbolically – ~1% (in testing),

- They maintain their magnetic properties even under external field action,

- Thanks to the smooth finish, the layer of Ni-Cu-Ni, gold-plated, or silver-plated gives an elegant appearance,

- They feature high magnetic induction at the operating surface, making them more effective,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to the ability of precise forming and customization to specialized requirements, magnetic components can be produced in a wide range of forms and dimensions, which amplifies use scope,

- Universal use in high-tech industry – they are commonly used in computer drives, electric motors, precision medical tools, also industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- To avoid cracks under impact, we suggest using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- We recommend cover - magnetic holder, due to difficulties in creating threads inside the magnet and complicated shapes.

- Possible danger related to microscopic parts of magnets are risky, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small elements of these devices are able to complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what it depends on?

- with the application of a sheet made of low-carbon steel, ensuring full magnetic saturation

- possessing a massiveness of min. 10 mm to avoid saturation

- characterized by smoothness

- under conditions of gap-free contact (surface-to-surface)

- for force applied at a right angle (pull-off, not shear)

- at ambient temperature approx. 20 degrees Celsius

Practical aspects of lifting capacity – factors

- Air gap (betwixt the magnet and the plate), as even a tiny distance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to varnish, rust or debris).

- Force direction – catalog parameter refers to pulling vertically. When slipping, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the power to be wasted into the air.

- Metal type – different alloys reacts the same. High carbon content worsen the interaction with the magnet.

- Surface condition – ground elements ensure maximum contact, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal factor – high temperature weakens magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity testing was conducted on a smooth plate of optimal thickness, under a perpendicular pulling force, in contrast under parallel forces the holding force is lower. Moreover, even a small distance between the magnet and the plate decreases the holding force.

Precautions when working with neodymium magnets

Demagnetization risk

Standard neodymium magnets (N-type) lose power when the temperature surpasses 80°C. Damage is permanent.

Warning for allergy sufferers

Studies show that nickel (standard magnet coating) is a common allergen. For allergy sufferers, prevent direct skin contact or choose versions in plastic housing.

Fire warning

Mechanical processing of NdFeB material carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Do not underestimate power

Handle with care. Rare earth magnets act from a long distance and snap with huge force, often quicker than you can react.

Warning for heart patients

People with a pacemaker must maintain an absolute distance from magnets. The magnetic field can disrupt the operation of the implant.

Keep away from electronics

Remember: neodymium magnets generate a field that confuses precision electronics. Keep a separation from your phone, device, and GPS.

Risk of cracking

Neodymium magnets are ceramic materials, which means they are prone to chipping. Clashing of two magnets leads to them breaking into small pieces.

Keep away from computers

Very strong magnetic fields can destroy records on credit cards, HDDs, and storage devices. Maintain a gap of min. 10 cm.

Finger safety

Mind your fingers. Two large magnets will join instantly with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Product not for children

Neodymium magnets are not toys. Swallowing a few magnets can lead to them pinching intestinal walls, which constitutes a critical condition and necessitates urgent medical intervention.

![UMGZ 32x18x8 [M6] GZ / N38 - magnetic holder external thread UMGZ 32x18x8 [M6] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-32x18x8-m6-gz-jix.jpg)

![SM 32x325 [2xM8] / N42 - magnetic separator SM 32x325 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-fog.jpg)